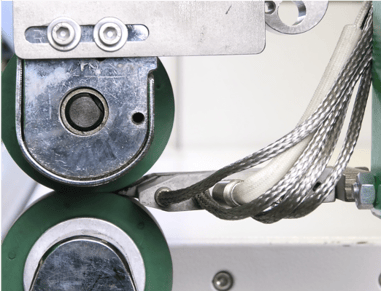

Industrial hot wedge welding uses a heated wedge that is precisely positioned at a weld point fuse and welds together thermoplastic materials. Using dual pressure rollers, the material or film is then pulled across the heated wedge to create a long-lasting seam.

uses a heated wedge that is precisely positioned at a weld point fuse and welds together thermoplastic materials. Using dual pressure rollers, the material or film is then pulled across the heated wedge to create a long-lasting seam.

Often paired with industrial hot air welding technology, hot wedge welding reduces costs, improves efficiency and increases overall product quality. Both mend together thermoplastic materials to create airtight and watertight seams, as well as curved and straight seams, to create strong, durable products.

While industrial hot wedge welding provides manufacturers with undeniable benefits, one application may work better than the other. To help you decide whether it’s time to invest in a hot wedge welding solution, we’ve outlined key benefits, applications and more below.

Top Benefits of Hot Wedge Welding

Industrial hot wedge welding technology offers specific benefits, dependent on each application. However, this technology is designed to increase production speed, enhance quality and improve overall consistency of products, specifically those that require a long, straight seam.

Consider the following benefits of an industrial hot wedge welding solution

- Increase the lifespan of products. Produce airtight and watertight straight seams to increase longevity of products and materials welded together.

- Construct a product made of very thick fabric. Create sturdy products by welding together multiple layers of materials.

- Enable a quieter work environment. Eliminate noise created during the manufacturing process when equipment is in use.

- Higher speed. Weld your products at speeds of up to 90 feet per minute.

Top Hot Wedge Welding Technology Applications

Industrial hot wedge technology is often used to create a product made of films, coated materials, laminated materials and/or in need of a long, straight seam. Products that benefit from hot wedge technology range in size and thickness, but all have the same goal in mind: sturdy and long-lasting materials.

Products that often benefit the most from using hot wedge welding technology are:

Which Materials Are Weldable Using Hot Wedge Technology?

When evaluating your welding needs, it’s also crucial to determine if your materials are weldable using hot wedge welding technology. Industrial thermoplastic fabrics and films are typically ideal for hot wedge welding, including:

- Polyurethane (PU)

- Polypropylene (PP)

- Polyvinylchloride (PVC)

- Polyethylene (PE)

How to Determine Which Hot Wedge Technology Is Right for Your Processes, Product or Application

Finding the right industrial hot wedge solution will depend on a variety of factors, such as materials, existing processes and current equipment. When vetting your available technology options, work closely with an experienced industrial welding expert to meet your goals and customize your solution.

Consider the following technology options during your vetting process:

- T3 Extreme. This welder produces all the seams required for a banner and sign maker and is designed with the smaller business in mind.

- T300 Extreme Flex. As a universal welder, this technology uses hot air and hot wedge technologies with an array of seam types.

- T300 Extreme Shade. With this welder’s straightforward design, it controls consistent and easy product construction.

- T600 Extreme Flex. This technology uses hot air or hot wedge welding solutions with an array of seam types and extended fabric handling support for consistent, easy product construction with efficient and straightforward design and controls.

When evaluating technology options, also ask yourself and your manufacturing partner the following questions:

- What types of thermoplastic materials are weldable using hot wedge welding?

- Will a hot wedge welding solution work with my existing equipment? Or does it require a complete overhaul?

- Are my products in need of a long, straight seam?

- What is my product output goal?

- Do my products contain film?

- Am I looking to reduce noise created during the manufacturing process?

- Do I need to combine multiple technologies to amplify my manufacturing process (automation, hot air, hot wedge)?

Ready to Learn More About Industrial Hot Wedge Technology?

Interested in learning more about hot wedge welding solutions? Speak with a Miller Weldmaster expert for more information about the best system for your application.