Simple Beginnings to a Global Presence Like No Other

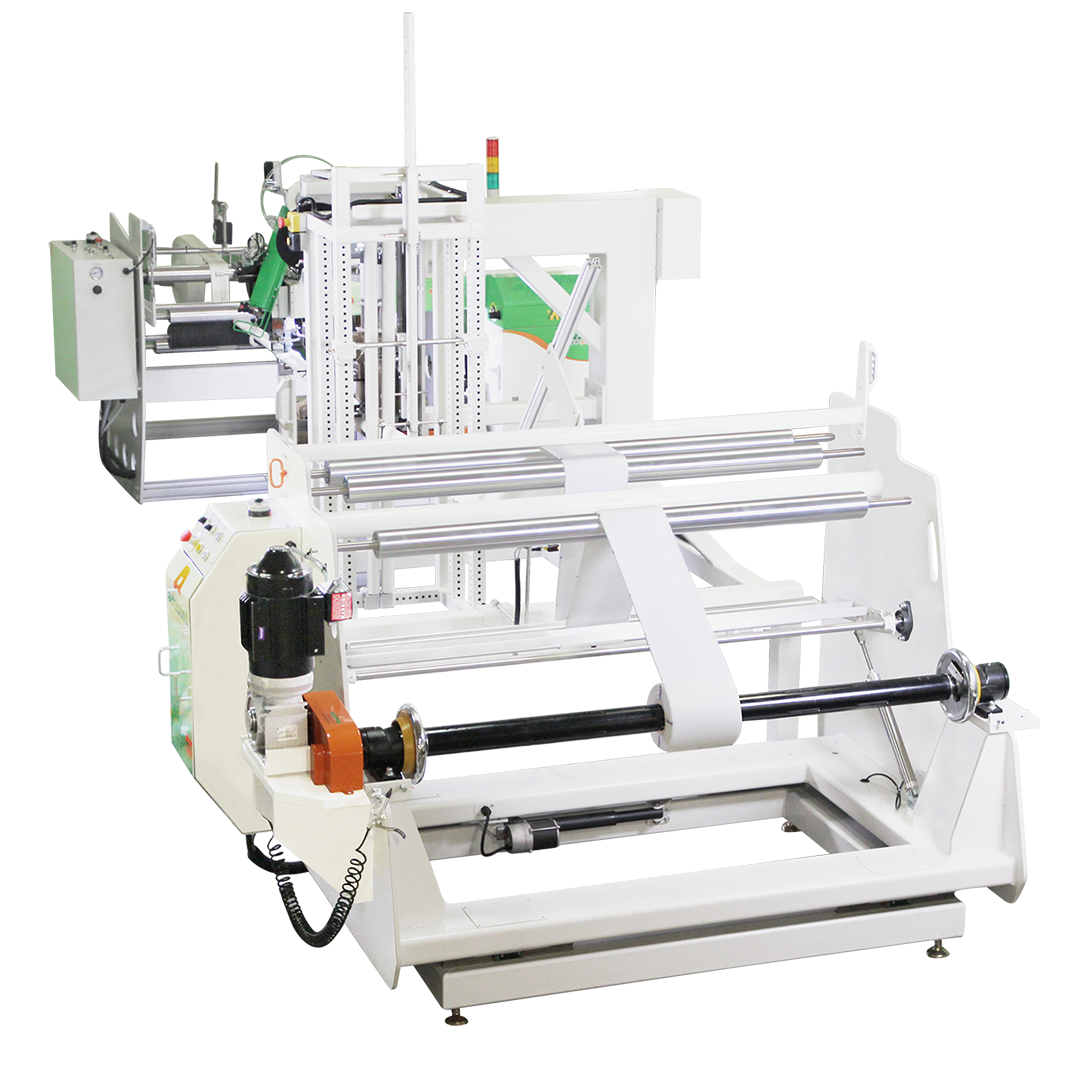

An innovative device. A simple garage. Almost 50 years ago our first machine was developed in a garage in rural Ohio. Today Miller Weldmaster is a truly global company, with operations and distributors in over 100 countries. We partner with our customers throughout the world to pioneer new industrial fabric welding solutions, including handling research, pioneering design, and building equipment to meet their exact specifications. Our standard and automated heat-seaming equipment is used to create white water rafts, truck tarpaulins, flexible air ducting, awnings, and more.

Our Vision - A Commitment to Place People First

Every day, we build lasting relationships with our customers and with each other while continuing to build a legacy of global innovation. Our customers are the reason for our existence. Our people are the reason for our success.

Internationally Recognized Leader in Global Business with 29 International Distributor Partners

From Japan to India, from Asia to Europe, from the USA to South America, Miller Weldmaster is focused on the success of each customer while building global relationships

EXPERT SERVICE, TRAINING, & SUPPORT

With over 15 Trained Field Service Technicians and a full-time support center, we are dedicated to keeping your machines running at their optimal performance. Our service team stands out from the rest by providing thorough machine installations, a library of training videos, virtual service calls, and more.