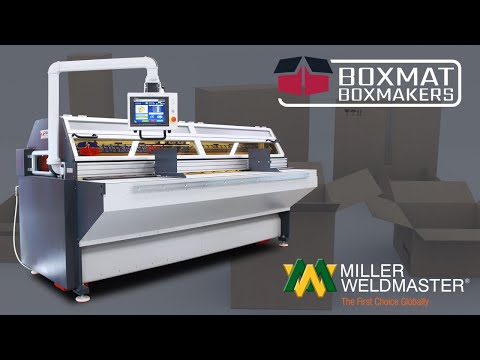

INTELIGO HMI System

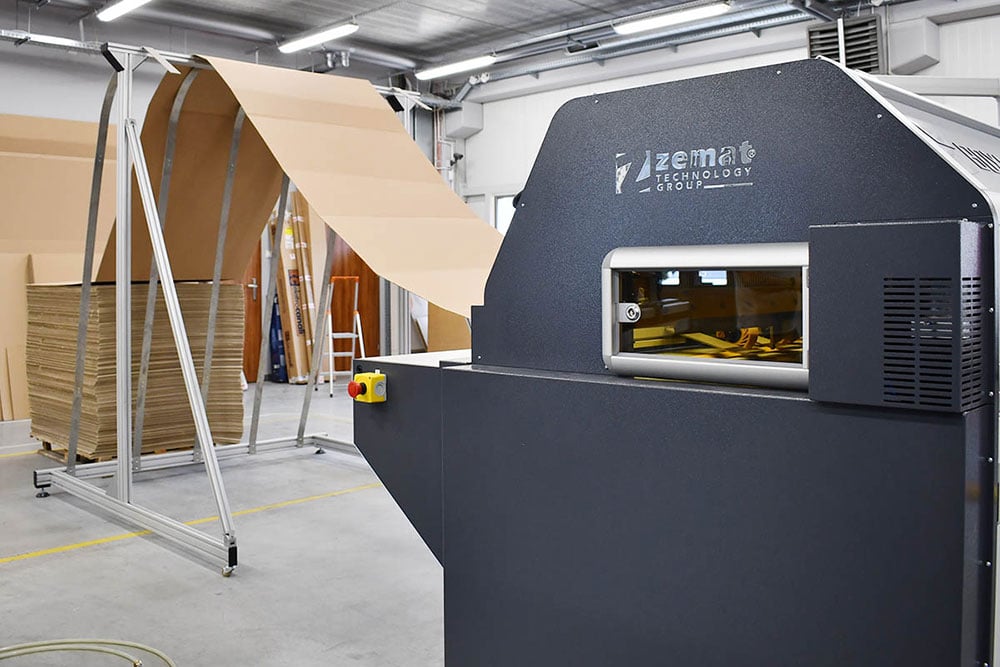

- Finish Single Corrugated Sheets or Fanfold Option

- User-friendly 19" touch screen interface for the Boxmat series of machines

- Box Design WIZARD allows to create any box intuitively right on the screen

- Barcode Scanner integration allows for efficient production data input into the work flow scheduling process

- 3D product scanning can scan dimension and weight capabilities

- Job Queue System for scheduling will synchronize with near every system

Gluing System

- Double nozzle cold glue applicator integrated with a cross-cutting knife, saving time and streamlining the box production cycle

- The gluing system uses single or double nozzles for dotted, dashed or continuous glue line application

Flexomat

- Corrugated cardboard flexographic printer

- Ability to print images on full size boxes up to 2400mm (94") wide

- Includes one fully programmable 800mm (31") wide printing drum/cylinder

- Add a second drum/cylinder to double the print area or for an additional color