Miller Weldmaster stands as the global expert in fabric welding equipment, providing innovative solutions that revolutionize how thermoplastic materials are joined. Our industrial fabric welding machines enable unmatched precision, durability, and efficiency across diverse industries—from automotive to medical and beyond. This comprehensive guide serves as your authoritative resource for understanding how fabric welding technology can transform your production capabilities with stronger, more reliable seams than traditional methods could ever deliver.

What Are Fabric Welding Machines and Fabric Welding Equipment?

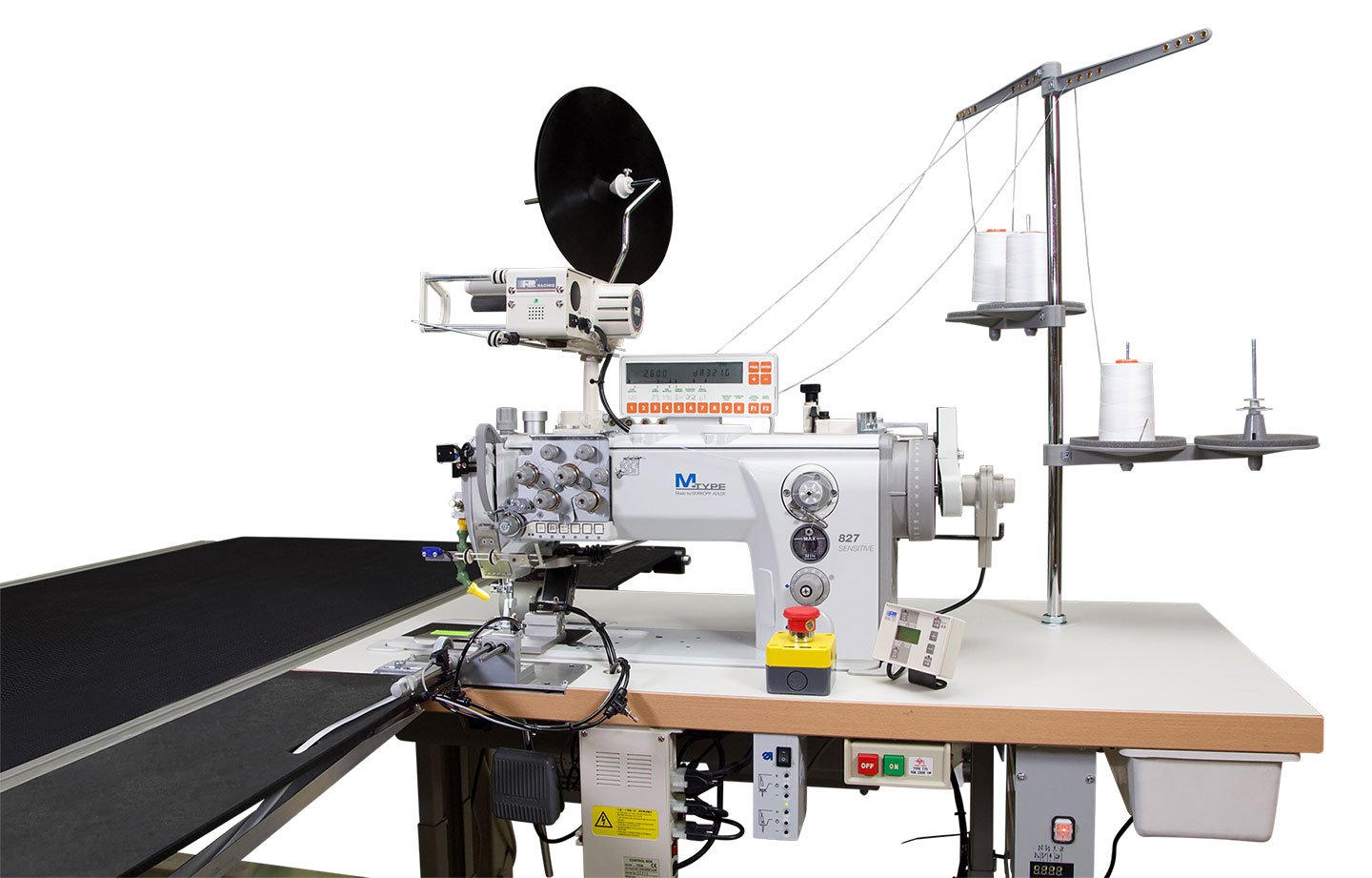

Fabric welding machines are specialized industrial equipment that use heat and pressure to permanently bond thermoplastic materials without traditional stitching. Unlike conventional sewing, fabric welding equipment creates waterproof, airtight seams that are often stronger than the base material itself. This innovative joining technology has revolutionized production across numerous industries requiring durable, consistent, and high-performance textile connections.

Miller Weldmaster’s industrial fabric welding equipment is specifically designed to handle materials like PVC-coated fabrics, polyethylene, polypropylene, and technical textiles with production speeds ranging from 1-20 meters per minute depending on material thickness and application requirements.

Understanding the Technology Behind Fabric Welding Machines

The science behind fabric welding technology involves several sophisticated methods. Radio frequency/high frequency welding generates electromagnetic energy to heat materials from within, creating molecular bonds. Hot air welding systems direct precisely controlled heated air (400-600°C) to soften thermoplastic layers before pressure is applied. Hot wedge welding employs a heated metal element to create continuous, consistent seams ideal for straight-line applications.

Each fabric welding method offers distinct advantages for specific material types and production requirements, with Miller Weldmaster providing optimized solutions for each approach. The process fundamentally changes how fabrics bond at the molecular level, where thermoplastic materials melt and fuse together under controlled heat and pressure conditions.

Why Choose Fabric Welding Equipment over Traditional Sewing?

Fabric welding machines deliver substantial advantages over conventional sewing methods. The precision of welded seams creates join points that are consistently waterproof and airtight—a critical requirement for many industrial applications. Welded seams offer superior strength characteristics, often exceeding the durability of the base material itself by 10-25%.

From a cost-effectiveness perspective, industrial fabric welding equipment eliminates the need for consumables like thread or adhesives, reducing ongoing operational expenses while increasing production speeds by 3-5 times compared to traditional stitching methods. For businesses focused on quality and scalability, Miller Weldmaster’s solutions provide the ideal long-term investment that delivers continuous operation capabilities with minimal downtime.

Recent Innovations and Advances in Fabric Welding Machines and Equipment

The fabric welding industry has witnessed remarkable technological evolution, making these systems more accessible, precise, and automated than ever before. Today’s advanced fabric welding machines incorporate digital controls, IoT connectivity, and precision tooling that deliver unprecedented levels of control and consistency.

Miller Weldmaster continues to lead innovation with fabric welding equipment that features cutting-edge capabilities designed for the modern manufacturing environment. These machines now integrate smart sensors that maintain welding parameters within ±5°C for optimal performance across extended production runs.

New Features Driving Precision and Efficiency in Fabric Welding Machines

Modern fabric welding technology now incorporates smart sensors and automated controls that maintain weld parameters with exceptional precision. Digital temperature controls ensure stability within ±5°C for consistent quality across production runs, while automated feeding systems efficiently manage large material rolls without manual intervention.

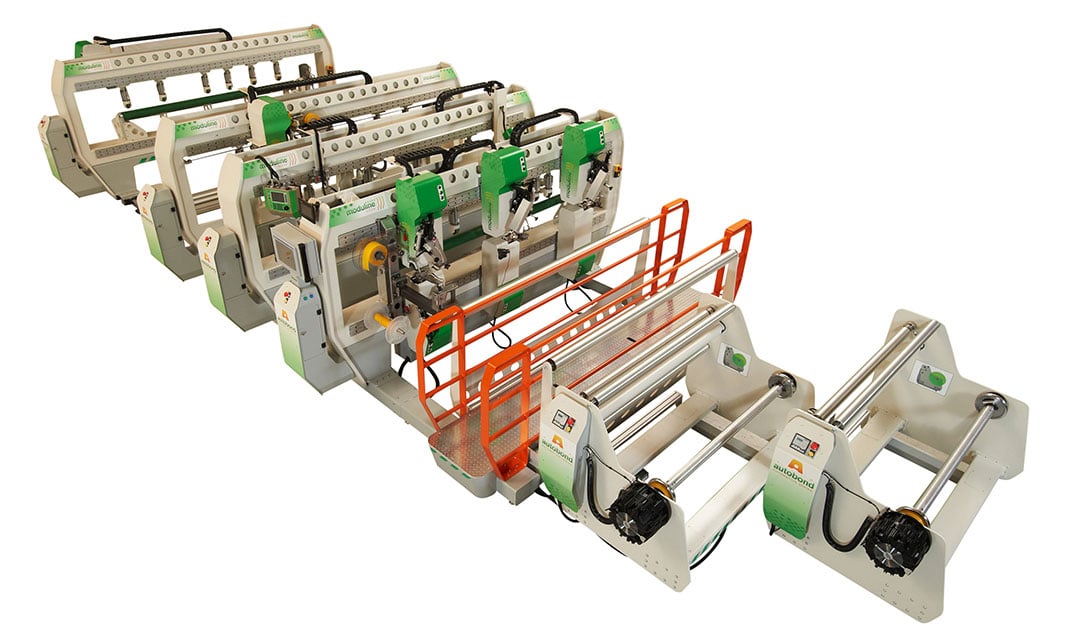

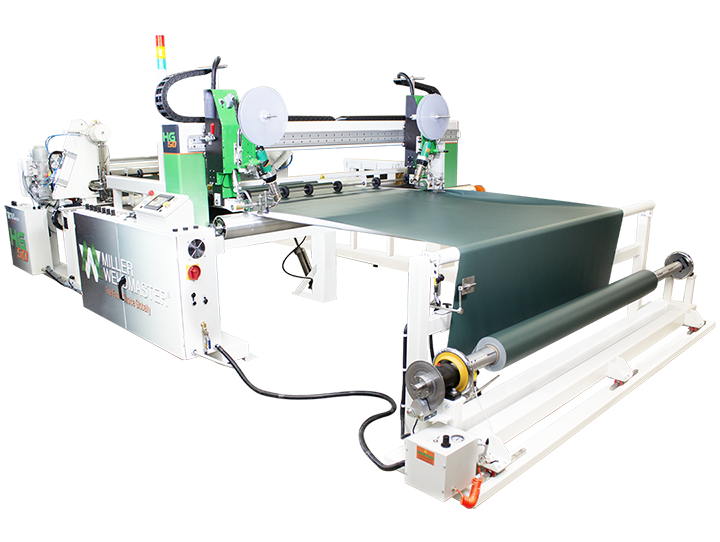

The latest industrial fabric welding machines feature modular designs allowing for easy reconfiguration between different production requirements. Quality monitoring systems detect and prevent defective welds in real-time, dramatically reducing waste and rework compared to traditional joining methods. These welding machines can process everything from lightweight technical textiles to heavy-duty truck tarpaulins with the same level of precision and reliability.

Sustainability and Cost-Saving Innovations in Fabric Welding Equipment

Today’s fabric welding equipment delivers significant sustainability benefits through reduced waste and lower energy consumption. By eliminating the need for additional consumables like thread or adhesives, these systems create cleaner production processes with smaller environmental footprints. Advanced machines reduce power consumption by up to 30% compared to legacy technologies.

For industries increasingly focused on sustainability and ESG (Environmental, Social, and Governance) metrics, investing in Miller Weldmaster’s efficient fabric welding machines represents a strategic decision that aligns operational excellence with environmental responsibility. The ability to process recyclable thermoplastics further enhances the environmental benefits of this technology.

Benefits of Investing in Fabric Welding Machines and Equipment

Businesses that bring fabric welding capabilities in-house experience transformative benefits across their operations. From automotive manufacturers to medical device producers, companies leveraging industrial fabric welding equipment gain significant competitive advantages through improved quality, reduced costs, and enhanced production flexibility.

The range of applications spans from delicate medical textiles requiring ultrasonic welding to heavy duty applications demanding robust hot wedge solutions. This versatility makes fabric welding machines suitable for diverse production environments and material types.

Cost and Operational Efficiency Compared to Outsourced Services

In-house fabric welding machines eliminate dependencies on external vendors, reducing lead times and providing complete quality control over critical joining processes. The continuous operation capability of modern equipment maximizes productivity with minimal downtime for maintenance, delivering superior efficiency compared to outsourced solutions.

Miller Weldmaster’s fabric welding solutions deliver scalability benefits that accommodate varying production volumes—from small batch specialty production to high-volume manufacturing runs at speeds up to 30 meters per minute for certain applications. This flexibility allows businesses to meet fluctuating demand without compromising quality or delivery schedules.

The ability to process a wide variety of materials—from thin films for medical applications to thick tarpaulins for industrial use—means one machine can often replace multiple traditional sewing stations, significantly improving floor space utilization and workflow efficiency.

Benefits of Fabric Welding Compared to Traditional Sewing

Fabric welding equipment creates joins that are 100% waterproof and airtight—critical performance characteristics impossible to achieve consistently with conventional stitching. These stronger, more reliable seams maintain their integrity even under extreme conditions and repeated stress, making them ideal for demanding applications like awnings, tents, and protective covers.

The versatility of industrial fabric welding machines enables work with a significantly wider range of thermoplastics, including materials that cannot be effectively joined through traditional sewing methods. This expanded material compatibility opens new product development possibilities and market opportunities for forward-thinking manufacturers.

Seam sealing capabilities are built into the welding process, eliminating secondary operations required with sewn seams. This integrated approach reduces production time and labor costs while ensuring consistent seam quality across all products.

Key Challenges and Important Considerations in Selecting Fabric Welding Machines

While the benefits of fabric welding technology are substantial, making informed equipment decisions requires careful consideration of several factors. Initial investment costs for quality systems range from $3,300 for basic units to $150,000+ for comprehensive automated production lines designed for heavy duty applications.

Miller Weldmaster serves as your expert guide through the purchasing process, ensuring you select the fabric welding equipment that precisely matches your production requirements and business objectives. Our team understands that each application has unique demands, from processing hem pockets in awnings to creating complex seams in automotive covers.

Understanding Material Compatibility and Limitations

Different fabric welding machines excel with specific material types. PVC, TPU, and coated fabrics up to 2mm thick work exceptionally well with hot air systems, while ultrasonic welding is ideal for thin non-woven fabrics and medical textiles. Hot wedge welders excel at processing heavy materials like truck tarpaulins and pool covers where straight-line seams are predominant.

It’s important to recognize scenarios where traditional sewing might still be preferred, particularly for natural fibers or non-thermoplastic materials that cannot be heat-welded. Miller Weldmaster’s expertise helps you navigate these material considerations for optimal performance, ensuring you choose the right method for your specific fabrics and application requirements.

Understanding the process limitations helps in making informed decisions. While fabric welding excels in many areas, certain complex three-dimensional shapes may require specialized tooling or hybrid approaches combining multiple technologies.

Training and Maintenance Needs for Fabric Welding Equipment

Successful implementation of industrial fabric welding machines requires proper operator training to maximize equipment capabilities. Understanding temperature management, speed control, and material handling techniques ensures consistent, high-quality production while minimizing material waste and preventing damage to expensive textiles.

Regular maintenance practices preserve the long-term reliability of your fabric welding equipment investment. Miller Weldmaster’s comprehensive training programs and preventative maintenance protocols minimize downtime while extending equipment lifespan. Our team provides ongoing support to assist customers in maintaining peak performance throughout the equipment lifecycle.

Proper training also covers safety protocols specific to high-temperature welding operations, ensuring operators understand how to work safely with heated components and maintain proper ventilation in production areas.

Fabric Welding Machines vs Alternative Welding Techniques

Understanding the distinctions between various welding technologies helps identify the optimal approach for specific production requirements. Miller Weldmaster offers expertise across the spectrum of joining techniques, guiding customers to the ideal solution for their unique applications, whether processing medical textiles or heavy industrial fabrics.

Each welding method offers distinct advantages, and selecting the appropriate technology depends on factors including material type, seam configuration, production volume, and quality requirements.

Fabric Welding vs Hot Air Welding

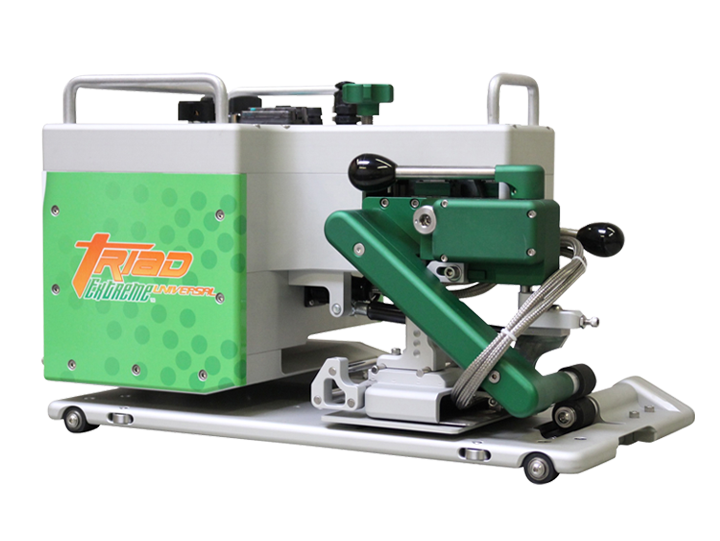

Hot air welding excels in applications requiring flexibility and versatility, particularly with portable units for field repairs or when working with complex three-dimensional shapes. This method provides excellent control when welding temperature-sensitive materials and offers the ability to adjust parameters on-the-fly for varying material conditions.

Industrial fabric welding equipment from Miller Weldmaster delivers superior results for high-volume production environments where consistency, speed, and minimal operator intervention are paramount considerations. The precision control available with advanced systems ensures optimal performance across extended production runs without quality degradation.

Hot air systems are particularly suitable for applications requiring curved seams or when working with materials of varying thickness within a single product, such as banners with reinforced hem areas.

Fabric Welding vs Hot Wedge Welding

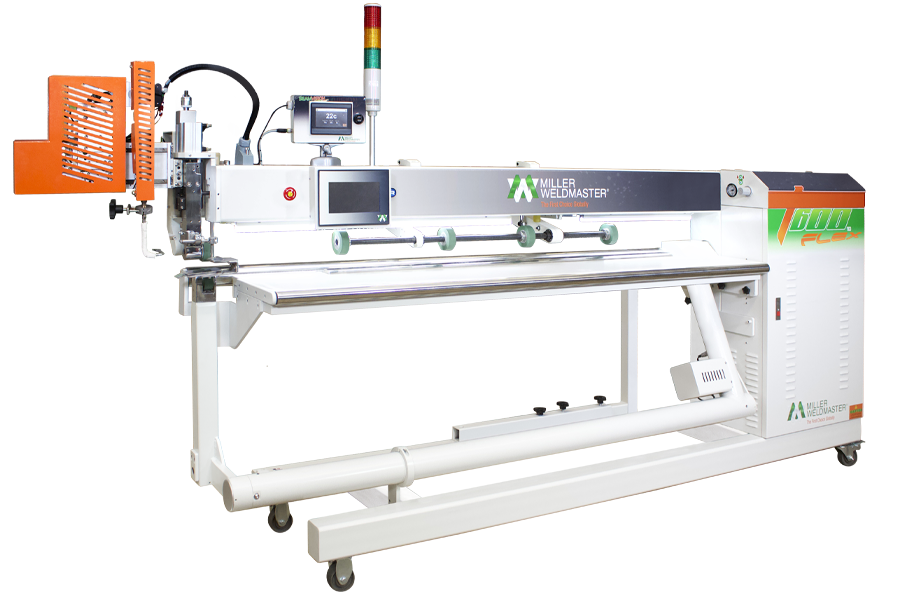

Hot wedge welding offers distinct advantages for straight-line seams with welding widths from 20mm to 100mm, achieving exceptional speed and efficiency for specific applications like truck tarps and pool liners. The continuous contact method provides consistent heat distribution along the seam length.

Miller Weldmaster’s fabric welding machines provide greater precision and versatility when working with complex seam geometries or when frequently changing between different material types and thicknesses. Advanced systems can accommodate both straight and curved seams with equal efficiency.

Hot wedge systems excel in field applications where portability is essential, making them ideal for on-site repairs of large structures like tents, awnings, and architectural membranes where bringing materials to a factory setting is impractical.

Fabric Welding vs Impulse Welding

Impulse welding provides cost advantages for simpler applications but cannot match the speed capabilities of continuous fabric welding equipment for high-volume production environments. The intermittent nature of impulse welding limits throughput in demanding manufacturing settings.

For applications demanding superior quality, consistency, and production efficiency, Miller Weldmaster’s advanced fabric welding machines deliver significantly better long-term value despite higher initial investment. The continuous operation capability and precise parameter control justify the additional cost through improved productivity and reduced per-unit costs.

Impulse welding may be suitable for prototype development or low-volume specialty applications, but lacks the scalability required for commercial production of products like automotive covers or medical devices.

Typical Uses or Fabric Welding Machines and Fabric Welding Equipment

Fabric welding technology has become essential across numerous industries requiring durable, waterproof, and precisely manufactured products. Miller Weldmaster’s versatile equipment solutions serve this diverse range of applications with specialized features optimized for each sector’s unique requirements.

The technology spans applications from delicate medical textiles requiring contamination-free joins to heavy duty applications like architectural membranes and industrial tarps that must withstand extreme environmental conditions.

Medical Devices and Fabric Welding Equipment

The medical industry relies on industrial fabric welding machines for critical applications including medical mattresses, IV bags, sterile packaging, and filtration products. These applications demand hermetic seals without introducing foreign materials or chemicals—requirements perfectly met by precision welding technology that creates contamination-free joints.

Miller Weldmaster’s fabric welding equipment delivers the exacting standards required for medical device manufacturing, with ultrasonic welding creating clean, contamination-free joins at speeds up to 30 meters per minute. The precision and repeatability of automated systems ensure compliance with stringent medical device regulations while maintaining high productivity.

Medical textiles often require specialized sealing capabilities that prevent fluid penetration while maintaining breathability in non-sealed areas. Our advanced systems can accommodate these complex requirements through precise control of weld parameters and selective sealing patterns.

Automotive and Industrial Uses for Fabric Welding Machines

Automotive manufacturers utilize fabric welding technology for producing seat covers, door panels, and convertible tops with superior durability and aesthetic finish. Industrial applications include welded tarps, architectural membranes, and technical textiles for roofing materials that must withstand extreme weather conditions.

The heavy-duty capabilities of Miller Weldmaster’s industrial fabric welding equipment provide the strength and consistency required for these demanding applications where failure is not an option. Automotive applications particularly benefit from the smooth, aesthetically pleasing seams that welding produces compared to visible stitching.

Industrial applications often involve large-format materials requiring specialized handling systems and wide welding capabilities. Our machines can process materials several meters wide, accommodating the scale demands of architectural and infrastructure projects.

Inflatables, Leisure Products, and Specialized Applications

Fabric welding machines are essential for manufacturing inflatable watercraft, air mattresses, and specialty inflatable structures where airtight integrity is critical. Swimming pool liners benefit from continuous seam welding for leak-proof installation, while advertising companies depend on welded PVC banners and displays for outdoor durability.

Miller Weldmaster’s specialized fabric welding equipment provides the precision and reliability these applications demand, ensuring products that perform flawlessly under challenging conditions. The ability to create truly airtight seams is essential for inflatable products where even microscopic leaks can cause failure.

Leisure applications often require aesthetically pleasing seams in addition to functional performance. Welded seams provide the clean appearance demanded by consumer products while delivering the durability required for outdoor use and repeated inflation/deflation cycles.

Specialized applications extend to tunnels, protective enclosures, and temporary structures where rapid deployment and reliable performance are essential. The versatility of modern welding equipment allows for custom solutions tailored to unique application requirements.

Reasons to Choose Miller Weldmaster for Your Fabric Welding Machines and Fabric Welding Equipment

As the authoritative manufacturer of premium fabric welding solutions, Miller Weldmaster combines engineering excellence with comprehensive customer support. Our decades of experience inform every aspect of our equipment design, ensuring you receive systems precisely calibrated to your production challenges.

Our company has built its reputation on delivering innovative solutions that meet the most demanding application requirements across diverse industries worldwide. From medical device manufacturers requiring ultra-clean welds to industrial companies processing heavy tarpaulins, we provide equipment built to excel in any production environment.

Tailored Fabric Welding Solutions for Specific Production Needs

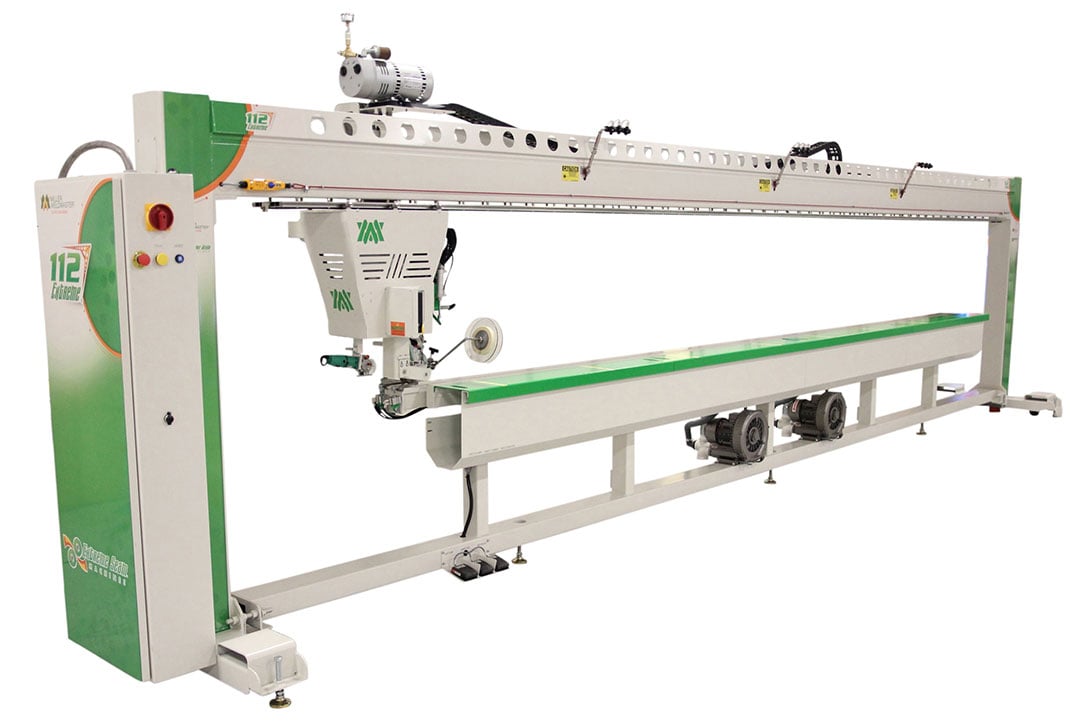

Miller Weldmaster’s custom engineering services address unique production requirements that off-the-shelf solutions cannot satisfy. Our industrial fabric welding machines offer working width specifications from 500mm portable units to 3000mm automated systems, accommodating virtually any production scale and material size requirements.

Our scalable approach allows businesses to grow from prototype development to large-scale manufacturing with equipment that evolves alongside your production needs. We understand that different applications require different capabilities, and our team works closely with customers to select the ideal combination of features and options.

Custom solutions extend beyond machine configuration to include specialized tooling for unique seam geometries, automated material handling systems for large-format textiles, and integration with existing production lines. Our engineering team can cater to virtually any application requirement through innovative machine design and process optimization.

Training, Service, and Support for Long-Term Success

Miller Weldmaster’s commitment extends beyond equipment delivery with comprehensive operator training that ensures your team maximizes the capabilities of your fabric welding machines. Our training programs cover everything from basic operation to advanced troubleshooting, enabling your operators to achieve optimal performance from day one.

Our responsive after-sales service minimizes downtime and maintains peak operational efficiency throughout the equipment lifecycle. We understand that production schedules cannot accommodate extended equipment outages, so our service team is designed to provide rapid response when issues arise.

Technical support extends beyond reactive maintenance to include proactive optimization services. Our team regularly reviews customer operations to identify opportunities for efficiency improvements, process enhancements, and productivity gains through better utilization of equipment capabilities.

The relationship with Miller Weldmaster continues long after installation, with ongoing support that adapts to changing production requirements and evolving technology. As new materials and applications emerge, we assist customers in adapting their equipment to meet these evolving demands.

Get Started with Fabric Welding Machines and Fabric Welding Equipment from Miller Weldmaster

Ready to transform your production capabilities with industry-leading fabric welding technology? Contact Miller Weldmaster today for detailed quotes, equipment specifications, or expert consultation on the ideal solution for your specific application requirements.

Our team will guide you through every step of the selection process, ensuring you invest in the fabric welding machines that deliver optimal performance for your unique production environment. Whether you need to process delicate medical textiles or heavy industrial materials, we have the expertise and equipment to meet your needs.

From initial consultation through equipment delivery and beyond, Miller Weldmaster provides the comprehensive support necessary for successful implementation of fabric welding technology in your facility. Our proven track record across diverse industries demonstrates our ability to deliver solutions that exceed customer expectations.

If you have more questions about implementing fabric welding technology in your operation, our team stands ready to assist with detailed technical information and application-specific guidance. Contact us to discuss your specific needs and discover how our solutions can transform your production capabilities.