Automatic industrial sewing machines are advanced manufacturing systems that integrate computer control, servo motors, and automated material handling to execute sewing operations with minimal human intervention. These sophisticated machines represent a fundamental shift from traditional manual operations toward fully automated production environments where precision, speed, and consistency define competitive advantage.

Manufacturing efficiency demands across the textile industry have accelerated adoption of industrial sewing machine technologies. From automotive seating assemblies to technical filtration applications, modern production lines require equipment capable of handling diverse materials while maintaining exacting quality standards. This comprehensive guide examines the technology fundamentals, operational benefits, and strategic considerations for integrating automatic industrial sewing machines into manufacturing operations.

Whether you’re evaluating automation solutions for high-volume apparel production or specialized technical textile applications, understanding these advanced industrial sewing machine technologies helps inform critical equipment decisions that impact productivity, quality control, and long-term operational costs.

What Are Automatic Industrial Sewing Machines?

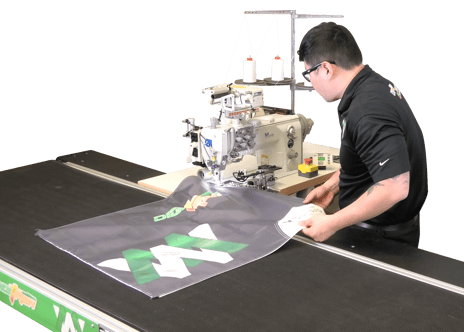

Automatic industrial sewing machines are computer-controlled manufacturing systems that combine precision mechanics with programmable software to execute complex stitching patterns autonomously. Unlike traditional sewing machines that require continuous operator intervention, these advanced systems automate fabric feeding, positioning, and material handling while maintaining consistent stitch quality across production runs.

The core distinction lies in operational control and intervention requirements:

- Manual machines: Operator-controlled speed, positioning, and pattern execution requiring high skill levels

- Semi-automatic machines: Partial automation with operator intervention required for material handling and pattern changes

- Automatic machines: Full computer control with minimal human oversight, featuring programmable stitch patterns and automated quality monitoring

Modern automatic systems integrate several critical industrial sewing machine technologies that enable autonomous operation. Servo motor control provides precise speed and positioning accuracy while computer numerical control (CNC) integration allows machines to follow digitized stitch paths with repeatable precision. Programmable sewing machines can store multiple pattern configurations, enabling rapid changeover between production runs without extensive manual setup.

These machines excel in applications requiring high-volume production with consistent quality standards. Industries ranging from automotive manufacturing to technical textiles rely on automated fabric sewing systems to meet demanding production schedules while maintaining strict quality control requirements.

How Industrial Sewing Machine Technology Works

Industrial sewing automation follows a systematic workflow that minimizes manual intervention while maximizing production consistency. The process begins with material positioning using servo-driven feeders or robotic arms that precisely locate fabric components according to programmed specifications.

Pattern programming occurs through intuitive touchscreen interfaces or computer connections where operators select stored stitch sequences or upload new patterns. Advanced programmable sewing machines can store hundreds of patterns, each with customized parameters for stitch length, width, and tension settings specific to different material types.

Core Technology Components

Servo motor control systems provide the foundation for precise automation. These motors offer real-time speed and position adjustment with energy-efficient operation, allowing machines to accelerate and decelerate smoothly while maintaining consistent stitch formation across varying material thicknesses.

Computer numerical control (CNC) integration enables machines to follow complex digitized patterns with micron-level accuracy. This technology supports advanced applications like embroidery, decorative stitching, and multi-directional seam creation that would be impossible to achieve consistently with manual operation.

Automatic material feeding systems use synchronized conveyor mechanisms, programmable clamps, and vacuum positioning to advance textiles through the sewing process. These systems eliminate alignment errors and ensure consistent material presentation to the needle assembly.

Built-in quality control sensors provide real-time performance monitoring through vision systems, thread break detectors, and material presence sensors. When irregularities are detected, machines can automatically stop operation and alert operators, preventing defective products from continuing through the production line.

The automated stitching phase executes stored patterns while continuously monitoring thread tension, needle position, and material advancement. Advanced systems can dynamically adjust parameters based on real-time feedback, compensating for material variations or environmental factors that might affect stitch quality.

Types of Industrial Sewing Machines

Industrial sewing machines come in various types, each designed to meet specific sewing needs and applications. Understanding the different types helps manufacturers select the perfect machine to optimize production efficiency and quality.

- Servo Motor Machines: Equipped with energy-efficient servo motors, these machines provide precise speed control, reduced noise, and lower heat generation. Servo motor technology enhances productivity by allowing smooth acceleration and deceleration, making them ideal for continuous and heavy-duty sewing operations.

- Needle Feed Machines: These machines use a needle feed mechanism to move the fabric in sync with the needle’s motion, ensuring precise material handling. Needle feed machines are especially effective for sewing thick or multi-layered materials, providing consistent stitch quality and preventing fabric slippage.

- Drop Feed Machines: Featuring a drop feed mechanism, these machines utilize feed dogs that move fabric forward during stitching. Drop feed machines are versatile and commonly used for general sewing tasks, offering reliable performance on a wide range of fabric types.

- Chain Stitch Machines: Chain stitch machines produce a looped stitch that is strong and flexible, often used for seams requiring stretchability. These machines are widely employed in garment manufacturing and applications where seam elasticity is important.

- Flat Bed Machines: Flat bed machines have a flat sewing surface, making them suitable for sewing flat pieces of fabric and materials. They are commonly used in apparel production and general sewing tasks where fabric can be easily maneuvered on a stable platform.

Key Benefits of Automatic Industrial Sewing Machines

Automatic industrial sewing machines deliver measurable improvements across multiple operational metrics that directly impact manufacturing competitiveness and profitability.

Production Efficiency Gains

- Increased production speed with consistent cycle times eliminates operator fatigue variables

- Enhanced throughput capacity often doubles or triples compared to manual operations

- Reduced setup time between production runs through programmable pattern storage

- Continuous operation capability supporting extended production schedules

- Optimized material utilization through precise positioning and automated cutting integration

Quality and Consistency Improvements

- Enhanced stitch quality with programmable tension control and consistent needle positioning

- Repeatable precision across thousands of production cycles without degradation

- Reduced rework requirements through real-time quality monitoring and error detection

- Uniform seam appearance meeting strict aesthetic standards for visible applications

- Consistent material handling eliminating operator-dependent variations

Cost and Safety Benefits

- Reduced labor costs through decreased dependency on highly skilled operators

- Improved workplace safety by automating material handling and reducing repetitive strain injuries

- Lower training requirements as machine operation becomes more standardized

- Decreased material waste through precise cutting and positioning accuracy

- Enhanced ergonomics reducing operator fatigue and improving work environment quality

The versatility of automatic systems enables manufacturers to handle diverse fabric types ranging from lightweight synthetics to heavy leather and technical textiles. This flexibility supports product diversification without requiring separate specialized equipment for each material type.

Innovations in Industrial Sewing Machine Technology

Recent technological advancements have transformed automatic industrial sewing machines into intelligent manufacturing systems capable of adaptive operation and predictive maintenance.

Advanced Control Systems

Multi-needle automation enables simultaneous pattern execution across multiple sewing heads, dramatically increasing throughput for complex assemblies. These systems can coordinate different stitch types and thread colors within a single production cycle.

Enhanced servo motor systems provide improved energy efficiency with up to 40% power reduction compared to traditional clutch motors. Advanced motors offer precise speed control across wider operating ranges while generating less heat and noise.

Connectivity and Monitoring

User-friendly programmable interfaces feature intuitive touchscreen controls with visual pattern editing capabilities. Cloud-based software platforms enable pattern sharing across multiple production facilities and remote technical support for troubleshooting and optimization.

Applications of Automatic Industrial Sewing Machines

Automatic industrial sewing machines have proven essential across diverse manufacturing sectors where precision, speed, and consistency determine product quality and production efficiency.

- Automatic tensioning of fabrics

- Automatic thread trimmer

- PLC-based control systems

- Synced conveyor belts

- Touch screen

- Quick change accessories

- High speed operation

- Photo eye guiding

- Driven puller systems

- Precision-controlled fabric-cutting operations

- Integration of a new or existing line

Technical and Industrial Applications

Industrial filtration manufacturing demands precise seam construction for filter bags and technical textiles where seam integrity directly affects product performance. Automatic systems provide the consistency required for critical applications in marine, aerospace, and industrial environments.

Outdoor gear production for tents, backpacks, and safety equipment requires automated bartacking machines for reinforcing stress points. These applications often involve heavy-duty materials and specialized stitching patterns that benefit from programmable automation.

Conveyor belt manufacturing and flexible composite fabrication require precise stitching for industrial belting applications where seam strength and alignment are critical for operational safety and performance.

Choosing the Right Automatic Industrial Sewing Machine

Selecting appropriate automatic industrial sewing machines requires careful evaluation of production requirements, material specifications, and integration considerations that affect long-term operational success.

Production Assessment Criteria

Production volume requirements determine the level of automation needed and acceptable cycle times. High-volume operations justify fully automated systems with material feeding and quality monitoring, while medium-volume production may benefit from semi-automatic solutions with operator assistance.

Material compatibility evaluation must consider fabric types, thickness ranges, and special handling requirements. Heavy duty industrial sewing machines designed for thick materials like leather require reinforced needle assemblies and powerful servo motors, while delicate textiles need precise tension control and gentle material handling.

Technical Specifications

Available workspace and machine footprint considerations affect equipment selection and production line layout. Some automatic systems require significant floor space for material feeding mechanisms and automated stacking systems.

Integration compatibility with existing production equipment determines implementation complexity and costs. Machines must interface properly with upstream cutting systems and downstream finishing equipment to maintain production flow.

Financial Considerations

Budget constraints and return on investment calculations should factor in productivity gains, labor cost reductions, and quality improvements. While automatic systems require higher initial investment, operational savings often justify costs within 12-24 months for high-volume applications.

Service support availability and spare parts access affect long-term operational costs. Established manufacturers like Miller Weldmaster provide comprehensive service networks and training programs that support successful implementation and ongoing operation.

Automatic Sewing Machine Types Comparison

Understanding the differences between automation levels helps manufacturers select the most appropriate technology for their specific production requirements and budget constraints.

| Aspect | Manual Machines | Semi-Automatic | Fully Automated |

| Operator Skill | High requirement | Moderate | Minimal |

| Production Speed | Variable | Consistent | Optimized |

| Quality Control | Operator-dependent | Partially automated | Sensor-monitored |

| Material Handling | Manual positioning | Assisted feeding | Automatic feeding |

| Pattern Changes | Manual adjustment | Programmable selection | Digital storage |

| Best For | Custom work | Medium volumes | High-volume production |

| Initial Investment | Low | Moderate | High |

| Operating Costs | High labor | Moderate labor | Low labor |

This comparison illustrates how automation level affects operational characteristics and suitability for different production environments. Manufacturers should match automation capabilities to their specific volume requirements and quality standards.

Leading Technologies in Industrial Sewing Automation

The industrial sewing machine industry has evolved through decades of technological advancement, with leading manufacturers developing specialized solutions for diverse applications and production requirements.

Technology Leadership

Over 50 years of industrial automation development has established proven methodologies for integrating servo motor control and CNC systems into reliable production equipment. Companies like Miller Weldmaster have built comprehensive expertise in programmable automation technologies that consistently deliver results across challenging manufacturing environments.

Advanced material handling systems accommodate everything from lightweight synthetics to heavy leather and technical textiles. Modern machines can automatically adjust parameters based on material sensors, ensuring optimal performance across diverse fabric types without manual intervention.

Support and Training

Comprehensive operator training programs help manufacturers successfully implement automatic systems while developing internal expertise for ongoing operation and basic maintenance. Training typically covers programming, troubleshooting, and preventive maintenance procedures that maximize equipment uptime.

Technical support networks provide remote diagnostics, software updates, and expert assistance for complex applications or integration challenges. This support structure ensures manufacturers can fully utilize their equipment capabilities while minimizing production disruptions.