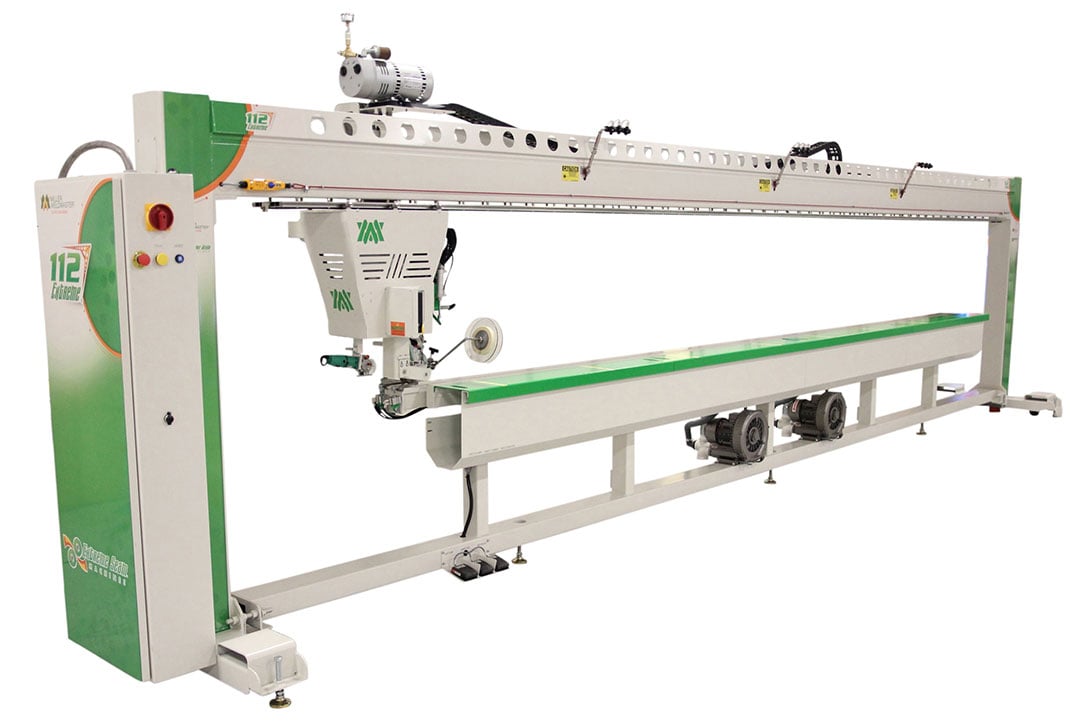

High-Performance Welder in Action: Precision, Power, and Durability!

Sign, & Billboard Fabric Welding Machine for Vinyl, PVC & More!

Welding High Production Signs & Banners

Welding High Quality Tarps & Tents

The Complete Solar Shade Solution

Watch the Miller 112 Extreme in Action!

Fastest Fabric Welder for Thermoplastic, Acrylic & More!

Weld, Cut and Grommet in 6 easy Steps on the 112 Extreme

112 Extreme Hot Air Welder with Ultrasonic Cutter

Mt. Lebanon Awning Success Story

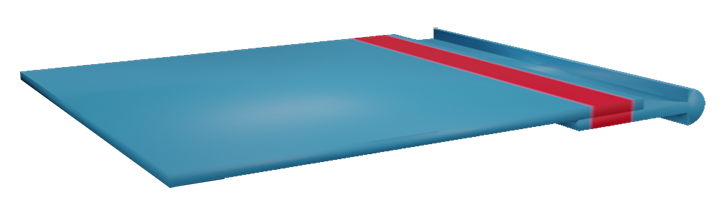

Custom Striped Awning Case Study

How to make a Tarp or Cover with Hot Air Welding

How to make a High Speed Roll Up Door

How To Weld High Speed Insulated Freezer Doors

Dual Heat System Doing Increase Productivity

Welding Acrylic and Clear PVC Awnings and Shades

Add On Adhesive Glue System To Your 112 Extreme

How To Check & Replace Heating Elements

How To Shut Down The Machine

Proper Operation Of Weld & Clutch Pressure

Adjusting The Air Pressure Nozzle

How To Clean your Air Filters on the Compressors

How to Adjust your Heat Nozzle

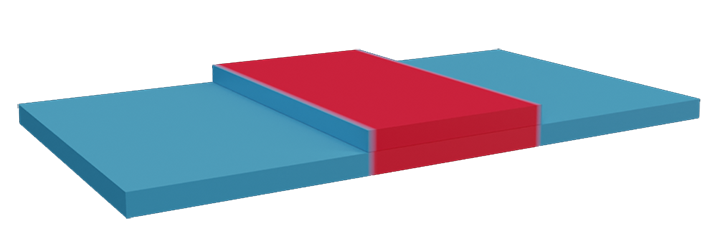

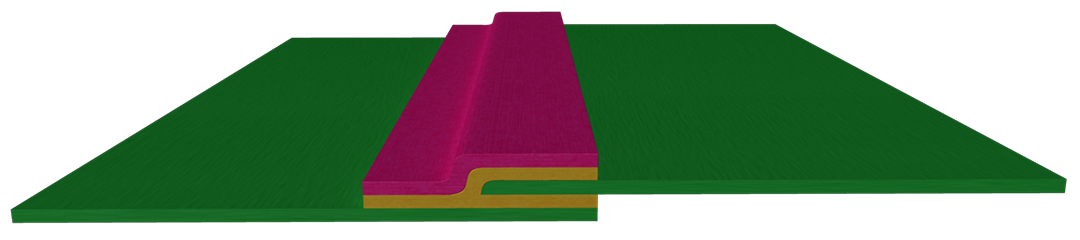

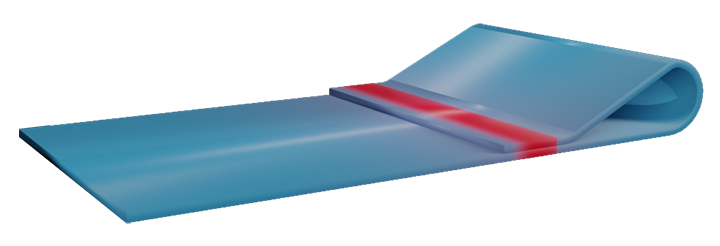

Butt Seam

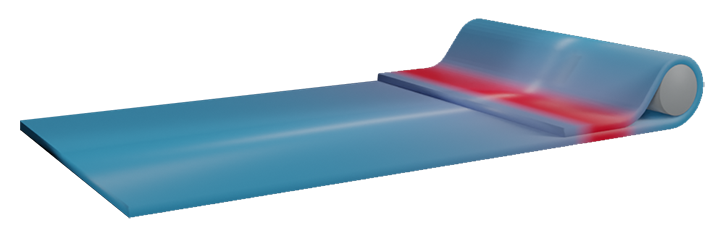

Butt Seam  Channel Seam

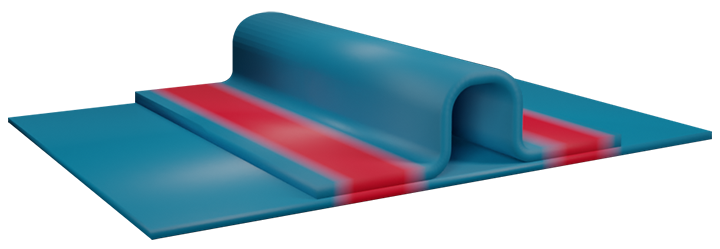

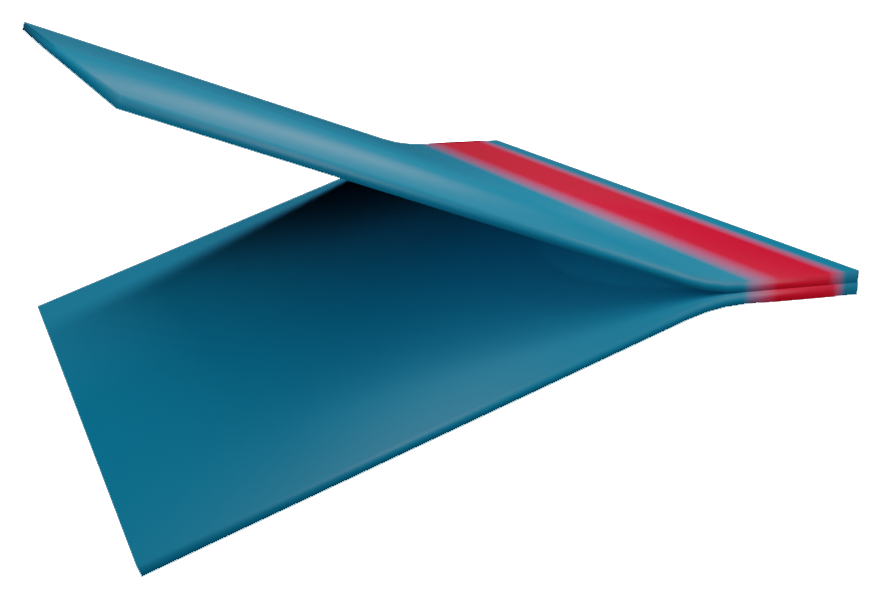

Channel Seam  Coverstrip

Coverstrip  Fin Prayer Seam

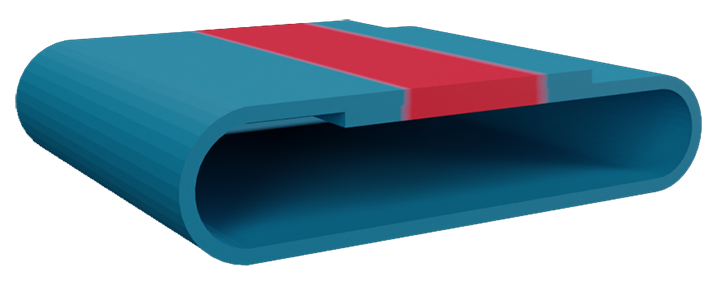

Fin Prayer Seam  Flat Seam Tube

Flat Seam Tube  Hem

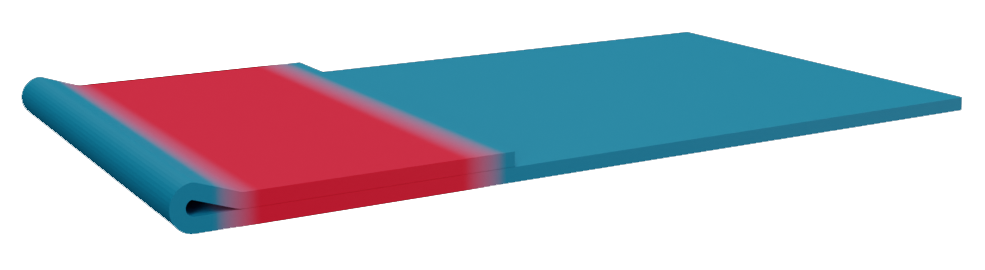

Hem  Hem with Pocket

Hem with Pocket  Hem with Rope

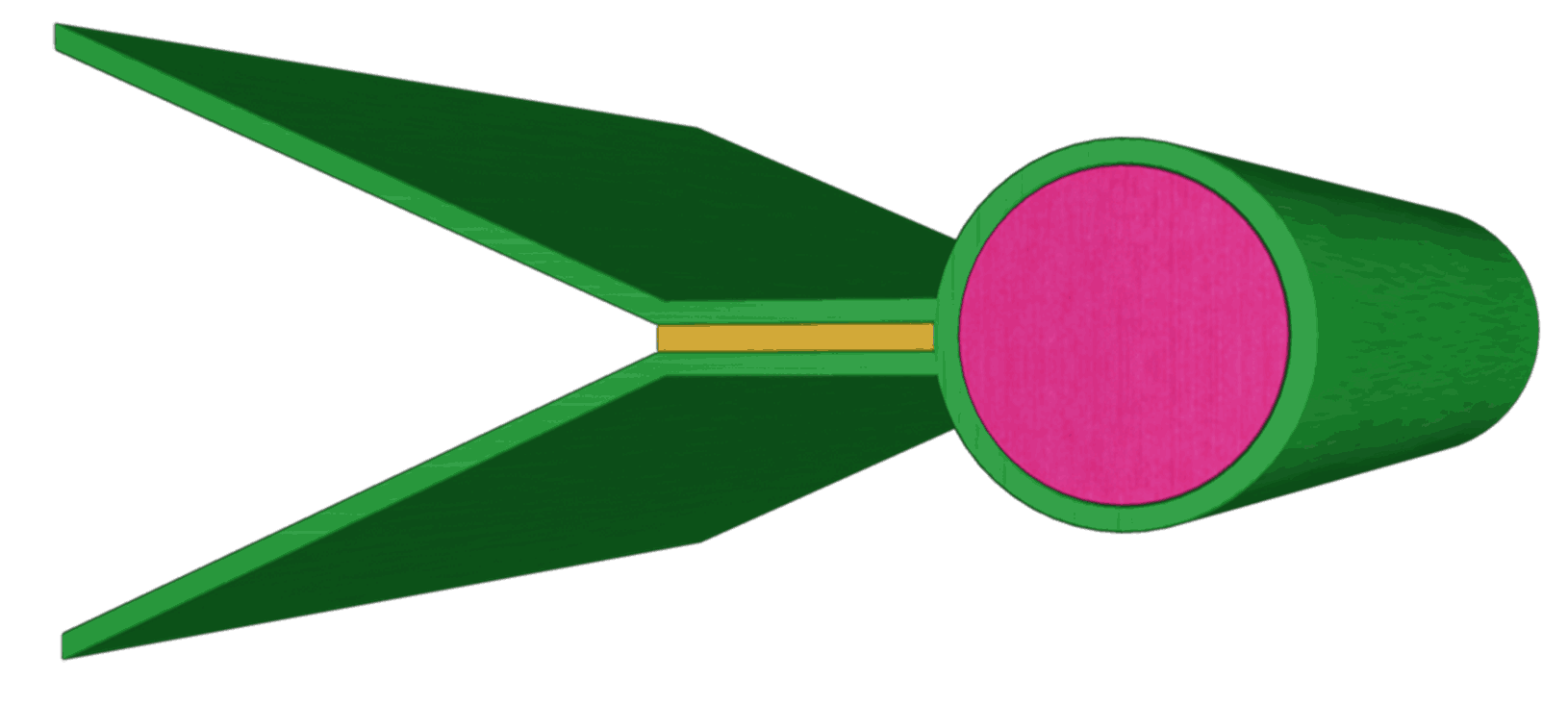

Hem with Rope  Keder

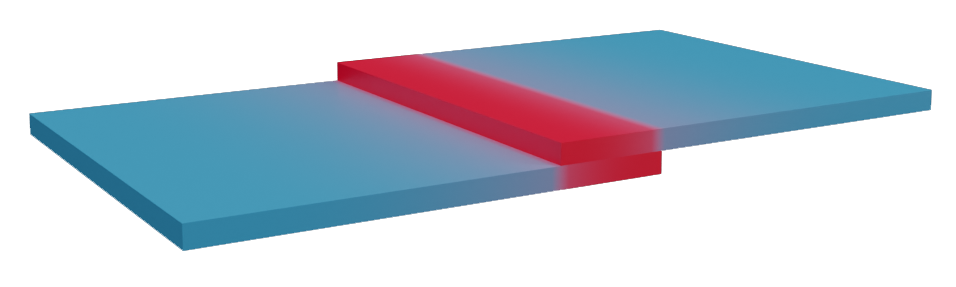

Keder  Overlap

Overlap  Extrusion Beading

Extrusion Beading