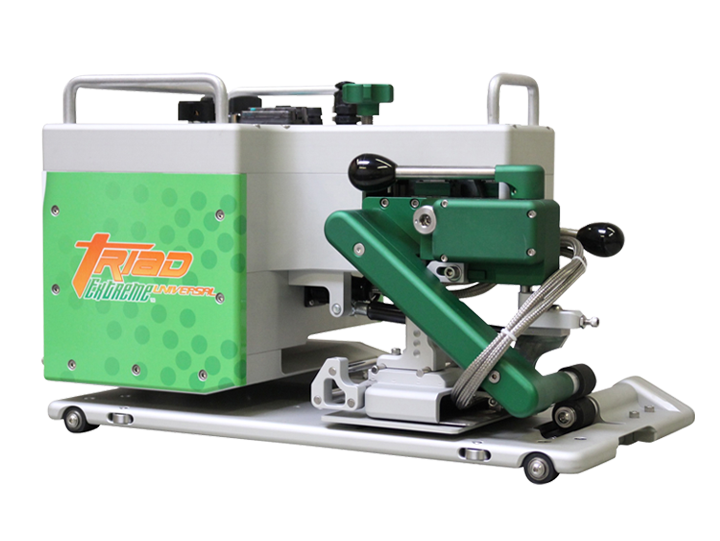

The Triad Extreme Universal Hot Wedge Welder has revolutionized fabric welding across various industries with its versatile and efficient capabilities. This machine is a game-changer for businesses in the production of tents, where it delivers seamless joins, enhancing both aesthetic appeal and durability. In the awning industry, it is pivotal for creating weather-resistant seams that stand up to environmental factors. The machine's precision is critical in the geosynthetics sector as well, used in lining and covering projects where impermeable seams are crucial. This broad applicability makes the Triad Extreme Universal a vital tool in numerous fields, driving demand for this innovative technology.

Triad Extreme Universal vs. Other Portable Hot Wedge Welders: A Comparison

When comparing the Triad Extreme Universal to other portable hot wedge welders, its superior design and functionality stand out. The Triad Extreme offers enhanced control systems and customizable welding parameters that are not typically available in other models, making it the preferred choice for professionals seeking precision and adaptability. It features a robust construction that ensures longevity and consistent performance under various environmental conditions. Competing machines often fall short in areas like speed adjustment, pressure control, and ease of use, making the Triad Extreme Universal the best portable wedge welding machine on the market today.

How to Set Up and Operate the Triad Extreme Universal Seam Welder

Setting up and operating the Triad Extreme Universal Seam Welder is straightforward, ensuring that users can achieve high-quality welds from their first use. Begin by assembling the machine according to the manual. Ensure all components are securely fastened before connecting the machine to a power source. Calibration involves adjusting the welding speed, temperature, and pressure to match the material specifications. For first-time operation, load your fabric and perform a test weld to check seam integrity. Regular practice and adherence to the operational guide will help users master the process, leading to optimal welding results.

Troubleshooting & Maintaining Your Triad Extreme Universal for Optimal Performance

Maintaining the Triad Extreme Universal involves regular checks and routine maintenance to ensure it operates at peak efficiency. Common issues like a misaligned wedge or uneven welds typically stem from calibration drift or material feed inconsistencies and can be resolved by referring to the troubleshooting section in the user manual. Keep the machine clean, especially around the welding head and feed rollers to prevent debris build-up. Scheduled maintenance, such as checking electrical connections and replacing worn parts, is crucial for longevity and reliable operation.

How the Triad Extreme Universal Saves You Time & Money in Industrial Fabric Welding

The Triad Extreme Universal offers significant time and cost savings in industrial fabric welding through its efficiency and precision. Users experience a decrease in material waste due to the machine's accurate alignment and control, which also reduces the need for reworks and repairs. The speed of the Triad Extreme allows for faster project completion, which can significantly lower labor costs. An ROI analysis would typically show that the investment in a Triad Extreme Universal pays off quickly as production capacity increases without sacrificing quality.

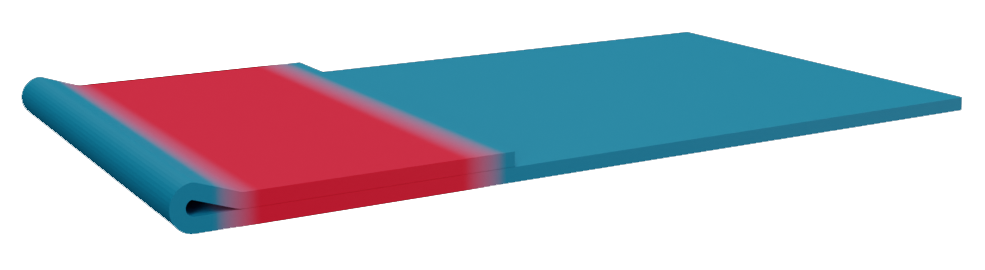

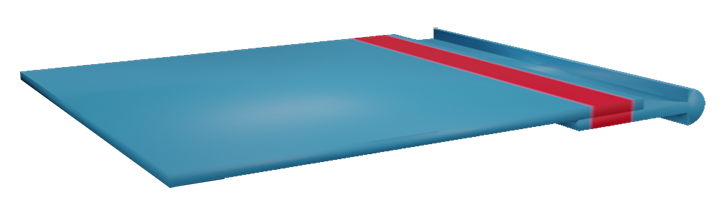

Hem

Hem  Hem with Pocket

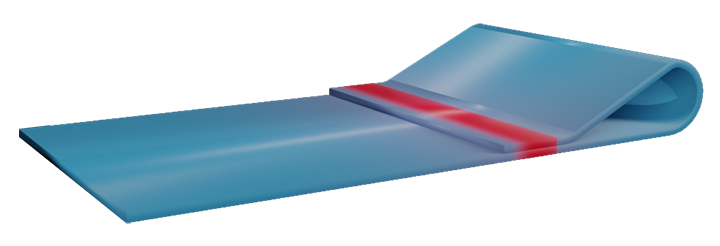

Hem with Pocket  Hem with Rope

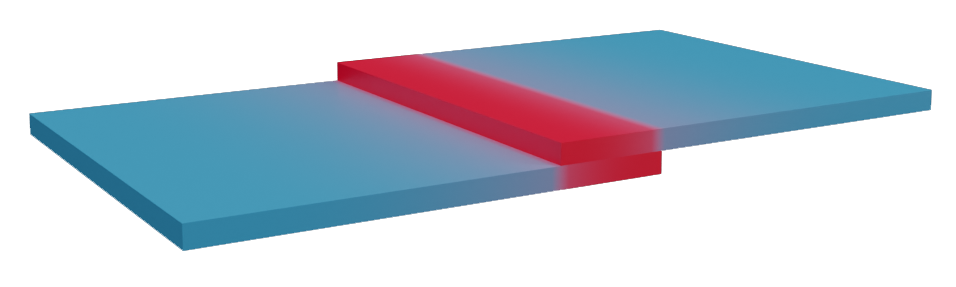

Hem with Rope  Overlap

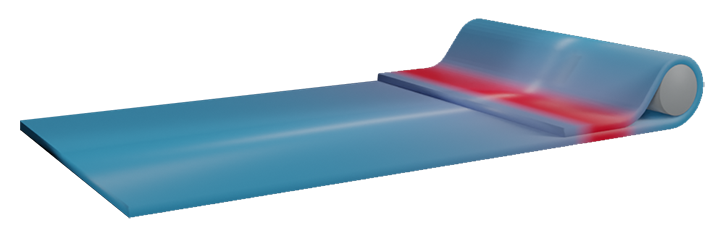

Overlap  Extrusion Beading

Extrusion Beading