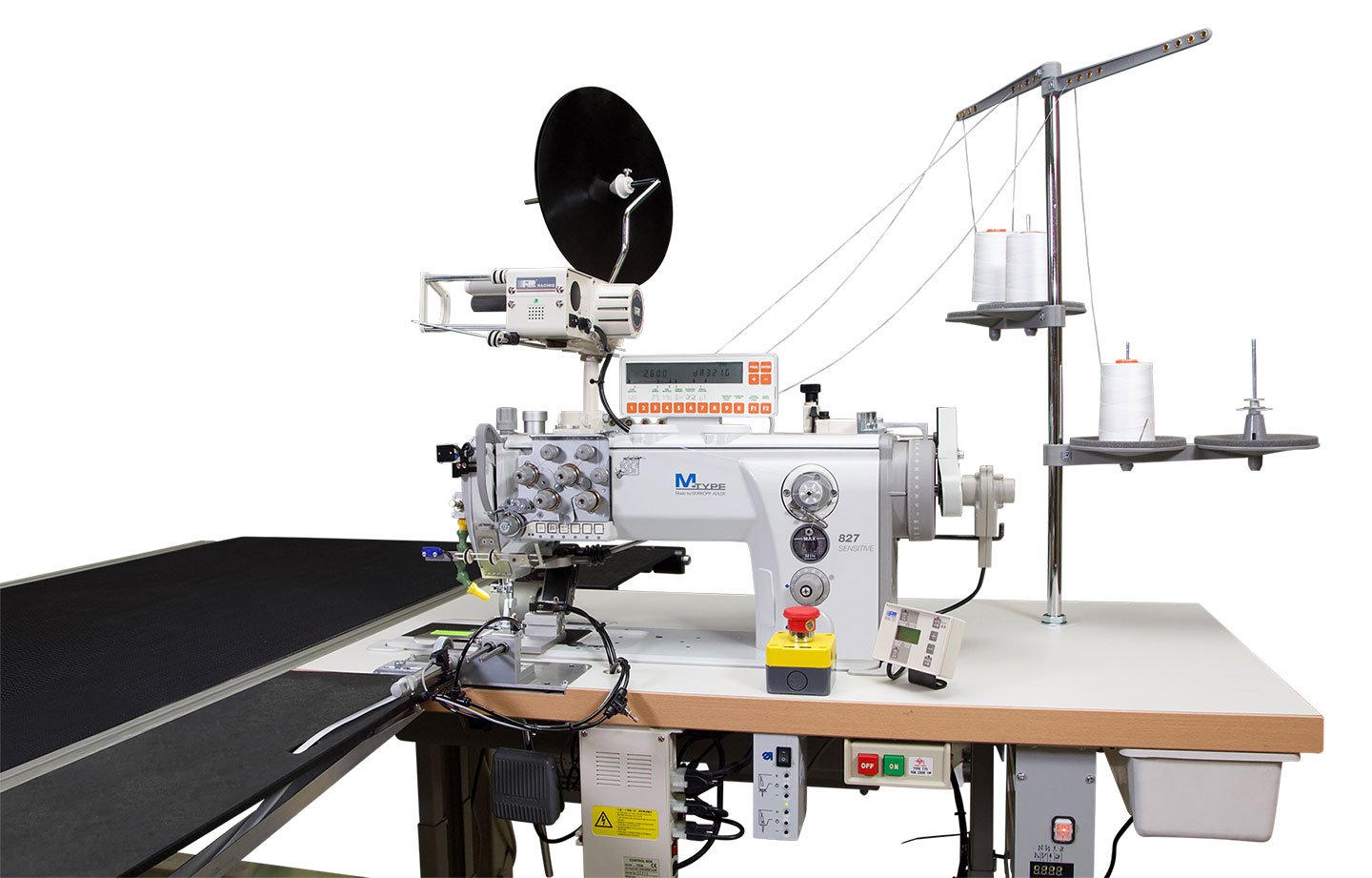

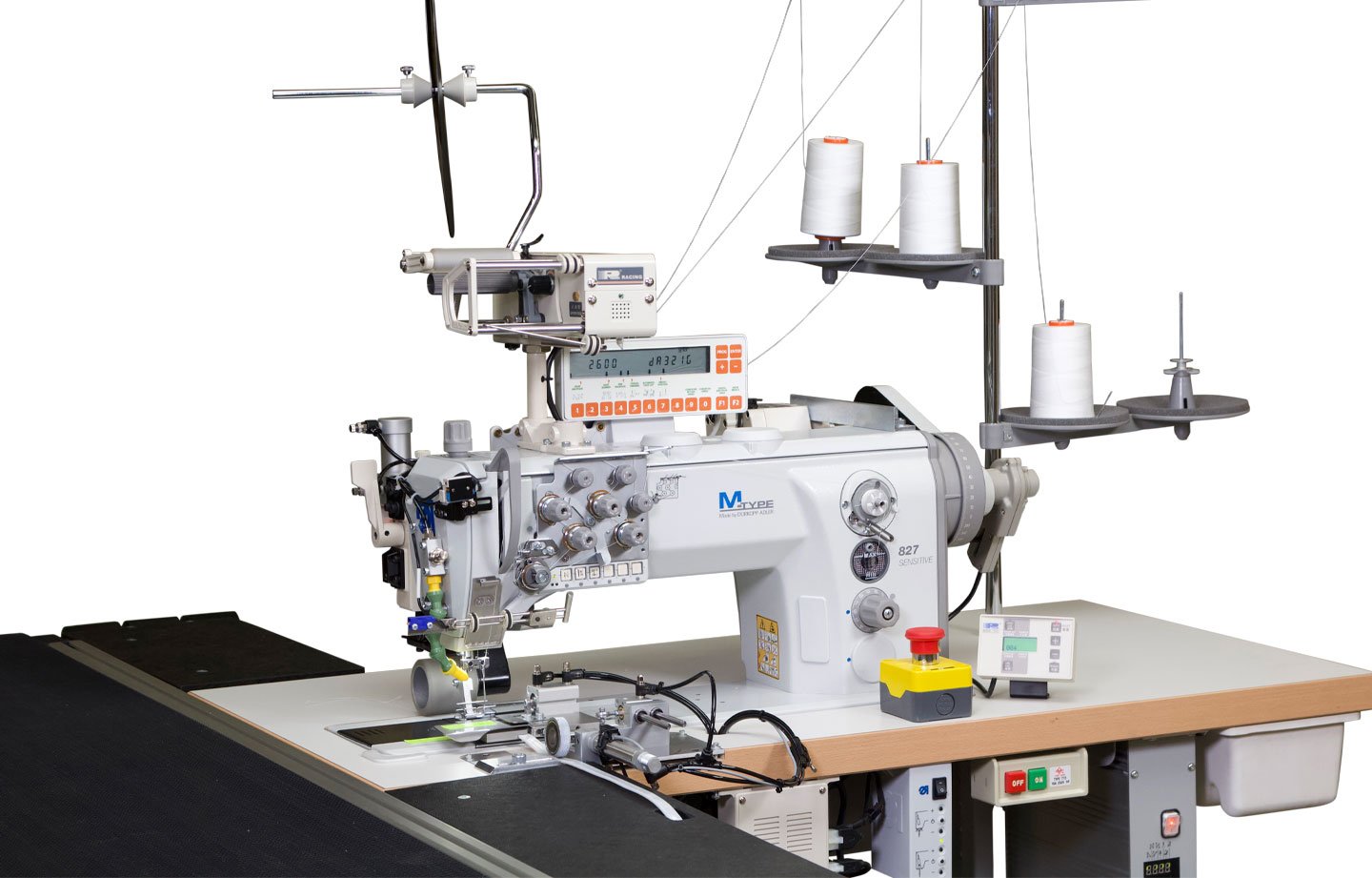

The Digitran Automated Sewing Machine is a state-of-the-art solution engineered for sewing silicone edge graphics (SEG) and a wide variety of digital textiles. Designed to meet the demands of high-output environments in the sign, display, textile printing, and clothing industries, the Digitran utilizes advanced sewing robots to deliver unmatched precision and professional-grade finishes. By automating the most time-consuming sewing processes, it empowers production teams to achieve faster throughput, greater consistency, and higher overall efficiency—whether working on small custom jobs or large-scale orders. This machine helps businesses save money and is suitable for industrial sewing applications.

Key Features of the Digitran Sewing System

One of the most important features of the Digitran is its synchronized transport system, which guarantees accurate thread handling as fabric moves through the sewing process. This precision eliminates common alignment issues and ensures straight, even seams every time. The machine utilizes advanced technology, including AI and computer vision, to enhance its performance and reliability. The machine also includes a hands-free SEG feeding and cutting mechanism, enabling automatic material advancement and trimming to reduce operator involvement. With programmable stitch cut and backstitch configurations, users can customize operations to fit specific production requirements, resulting in a high level of precision and efficiency with minimal manual input. Additionally, the Digitran incorporates safety features that make it a secure and innovative choice for modern manufacturing processes.

Technical Specifications Overview

The Digitran runs on 220V single-phase power and requires only 1 cfm at 90 psi of compressed air, making it energy-efficient and suitable for most production environments. It can handle thick materials, making it versatile for various sewing tasks. It has a compact footprint measuring 168 inches long, 44 inches wide, and 63 inches tall, with a total weight of 1,500 pounds. The standard conveyor length is 122 inches, and the machine is capable of sewing at speeds of up to 8,500 stitches per minute. It supports a range of seam widths and multiple seam configurations, including lockstitch and custom setups tailored to each user’s application, ensuring high sewing speed and consistent results.

Enhancing Production Efficiency with the Digitran

The Digitran is designed to elevate manufacturing operations by reducing labor time and improving overall productivity. It also reduces costs and waste by increasing production efficiency and minimizing errors. By streamlining repetitive sewing tasks and maintaining precision across various material types, the machine contributes to a more consistent workflow. It can easily scale with changing production volumes, making it an ideal fit for both growing shops and established businesses. Its design also allows for quick implementation into existing production lines, helping operators increase output without a steep learning curve. The machine's versatility in handling different types of sewing projects further enhances its value in diverse manufacturing environments.

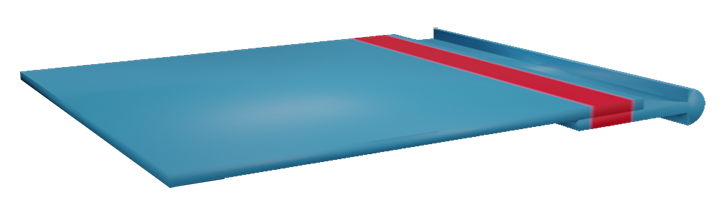

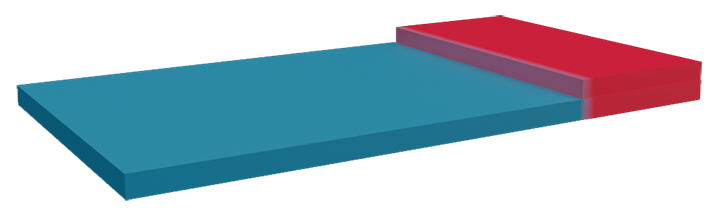

Seam Versatility for Diverse Applications

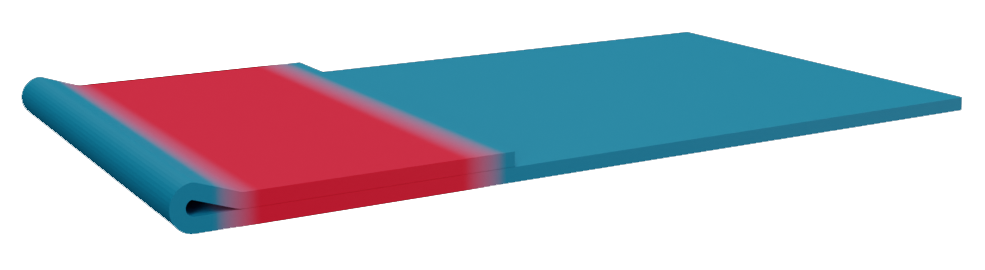

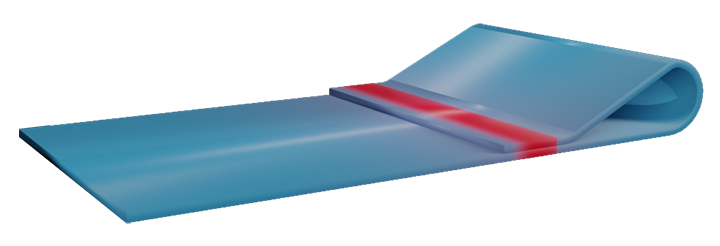

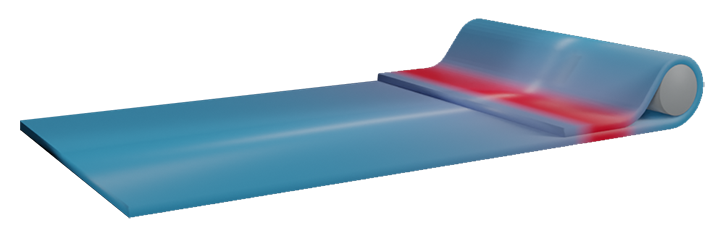

Built to support a wide range of textile applications, the Digitran can produce several common seam types including butt seams, hems with pockets, and reinforced seams with webbing. It can also sew cuffs and other details with exceptional precision. Butt seams are ideal for joining fabric edge-to-edge, commonly seen in SEG applications. Hem with pocket seams are used in banners that require pole pockets or weighted edges. Webbing seams add reinforcement and are especially useful for high-tension displays and large-format textiles. This seam flexibility, along with the ability to handle various stitching patterns, ensures the Digitran can meet the needs of applications such as signage, curtains, backdrops, and display graphics.

User-Friendly Controls and Maintenance

Ease of use is a hallmark of the Digitran. It comes equipped with a simple interface that makes it easy for operators to navigate controls, adjust settings, and monitor progress. Maintenance has also been simplified—routine servicing involves accessible components, and Miller Weldmaster provides comprehensive documentation, training videos, and expert support. Our experts are always available to assist you with any questions or specialized projects.

Whether you’re training a new team or optimizing an existing one, the Digitran is designed to be approachable and reliable. We are always willing to help customers with their needs. If you are interested in learning more, please reach out to us to establish a long-term partnership.

Integration with Miller Weldmaster's Welding Solutions

For customers seeking an all-in-one production line, the Digitran pairs seamlessly with Miller Weldmaster’s T3 Extreme or T300 Extreme Edge welding machines. This integration offers the ability to switch between sewing and hot air welding functions within the same workflow, maximizing both versatility and space efficiency. The machine's ability to handle complex pattern assembly further enhances its utility, delivering high-quality outputs with speed and accuracy. It’s an ideal setup for manufacturers handling a mix of products that require both seam sealing and sewn edges. Integrating the Digitran with other automatic sewing machines can significantly boost productivity, allowing continuous operation on heavy materials like thick leather and upholstery while offering programmability and design flexibility.

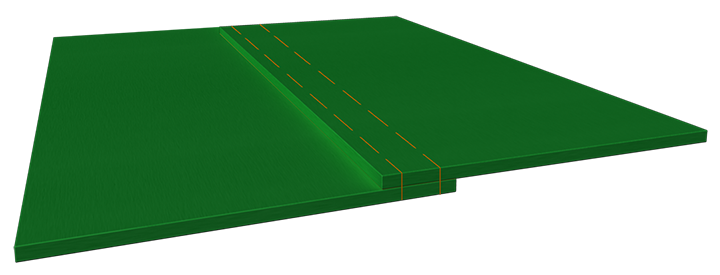

Transitioning Between Sewing and Welding Operations

Transitioning from sewing to welding mode is straightforward. Operators can easily roll the Digitran out and replace it with a compatible welding machine, or reposition the welding station as needed. The efficient way to transition between operations is further enhanced by optional accessories and alignment tools that streamline the switchover process and ensure precise material placement. This flexibility allows businesses to adapt quickly to changing production demands. Additionally, setting up an account for easy ordering of sewing supplies can further improve operational efficiency and customer satisfaction.

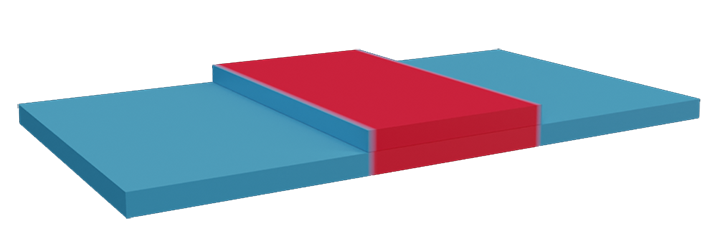

Butt Seam

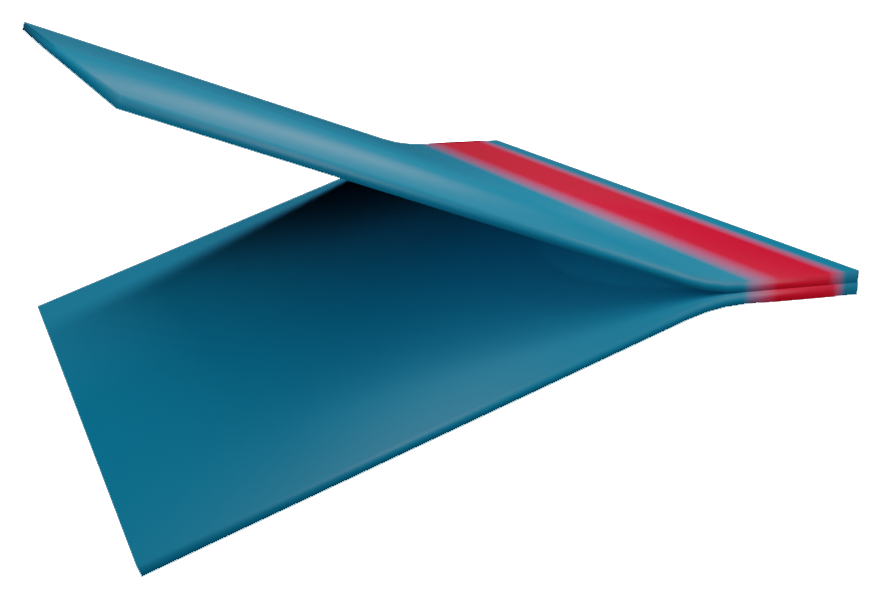

Butt Seam  Fin Prayer Seam

Fin Prayer Seam  Fold Overlap

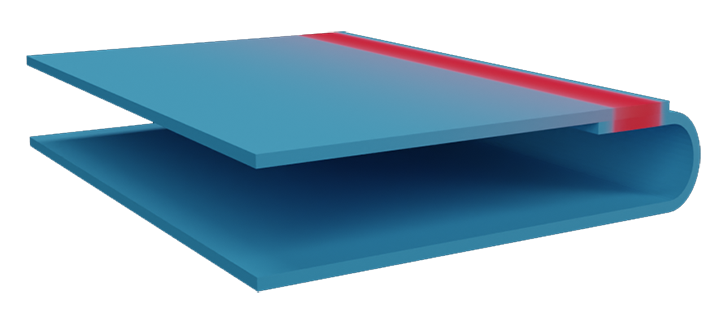

Fold Overlap  Hem

Hem  Hem with Pocket

Hem with Pocket  Hem with Rope

Hem with Rope  Sewn Seam

Sewn Seam  Extrusion Beading

Extrusion Beading  Webbing - SEG

Webbing - SEG