Modern packaging demands have evolved far beyond one-size-fits-all solutions. The packaging industry faces unprecedented pressure to deliver precise, cost-effective packaging that adapts to diverse product requirements while maintaining efficiency and sustainability. Traditional pre made boxes simply cannot meet the flexibility requirements of today’s dynamic manufacturing environment.

Customized packaging box making machines represent a revolutionary approach to addressing these challenges. These advanced automated systems combine cutting, creasing, folding, and gluing processes in a single unit, eliminating the need for extensive pre-made box inventory while delivering precisely-sized packaging on demand.

This comprehensive guide explores everything you need to know about customized packaging solutions, from understanding the underlying technology to evaluating investment considerations and comparing different production methods. Whether you’re an e-commerce operation seeking flexible packaging solutions or a manufacturing business looking to reduce costs and improve efficiency, this guide will help you make informed decisions about automated box making equipment.

What Are Customized Packaging Box Making Machines and How Do They Work?

Customized packaging box making machines are advanced automated systems that combine cutting, creasing, folding, and gluing processes in a single unit. These sophisticated machines eliminate pre-made box inventory by creating right-sized packaging instantly, supporting businesses with diverse needs across multiple industries.

The core advantage of these systems lies in their ability to produce custom sized boxes according to specific dimensions without requiring extensive setup time or tooling changes. This flexibility makes them particularly valuable for operations handling varied product catalogs or frequently changing packaging requirements.

Understanding the Technology Behind Automated Box Making Equipment

Box making machines utilize servo motor controls for precise cutting and folding with minimal material waste. These advanced control systems ensure consistent quality across production runs while adapting to different corrugated board thicknesses and specifications.

Horizontal cutting systems use thin blades for clean, precise edges while vertical creasing employs rubber-wrapped wheels to prevent cardboard bursting. This combination ensures that each box maintains structural integrity while meeting exact specifications for reliable packaging performance.

Vacuum feeding systems maintain accurate corrugated cardboard positioning throughout the production process. These systems prevent misfeeds and ensure proper material alignment, which is critical for maintaining consistent quality in high speed production environments.

The integration of programmable logic controllers (PLCs) enables seamless production line integration and rapid changeovers between different box styles. This automation capability allows operators to switch between various packaging configurations in seconds rather than hours.

Key Industries Benefiting from In-House Box Making Machines

E-commerce operations requiring flexible, on-demand box production for varied product sizes represent one of the largest market segments for these machines. The ability to create boxes that perfectly fit products reduces shipping costs and improves customer experience while minimizing packaging waste.

Food and beverage industry operations utilize top-loading boxes with ventilation features that maintain product freshness and safety. These specialized configurations often include vent holes and temperature-resistant materials that support specific storage and transportation requirements.

Retail and logistics operations demanding high speed production capabilities benefit from machines that can produce hundreds of boxes per hour while maintaining consistent quality. The ability to handle short run and long production cycles makes these systems suitable for diverse operational needs.

Small to medium packaging businesses seeking cost-effective automation solutions find these machines particularly valuable for competing with larger operations while maintaining flexibility. The modular design of many systems allows businesses to start with basic configurations and expand capabilities as demand grows.

Latest Advancements and Trends in Customized Packaging Box Making Machines

New Features and Technologies in Automated Box Making Machines

Programmable logic controllers (PLCs) enabling high speed automation and production line integration represent a significant advancement in box making technology. These systems facilitate reliable automated operation while providing the flexibility to adapt to changing packaging requirements without extensive reprogramming.

Touchscreen interfaces providing quick switching between box styles in 1-6 seconds have revolutionized operational efficiency. Operators can easily manage different box configurations without manual recalibration, making it practical to handle diverse product lines within the same production shift.

Integrated error detection systems monitoring production quality in real-time ensure each box meets specified standards while reducing material waste. These systems use advanced sensors and cameras to identify potential issues before they affect the final product quality.

Motor-driven tungsten steel slitting knives providing burr-free cutting performance enhance the precision and quality of finished boxes. This technology ensures clean edges that improve the professional appearance of packaging while maintaining structural integrity.

Importance of Sustainability in Box Making Equipment and Materials

Reduced corrugated material consumption supporting eco-friendly packaging initiatives has become a primary driver for equipment investment. Companies are increasingly focused on minimizing their environmental footprint while maintaining packaging effectiveness and cost efficiency.

Material waste reduction of 20-30% through custom sizing and precise cutting technology directly impacts both environmental goals and operational costs. This reduction is achieved through optimized cutting patterns and the elimination of oversized packaging that requires additional filler materials.

Optimized shipping loads decreasing overall transportation carbon footprint provide additional sustainability benefits. When boxes are precisely sized to products, more packages can fit in each shipment, reducing the number of trips required and associated emissions.

Support for recycled and specialty coated materials enhancing sustainability goals allows companies to use environmentally preferred materials without compromising packaging performance. Modern machines can handle various corrugated board types while maintaining consistent quality output.

Advantages of Investing in Customized Packaging Box Making Machines

Cost Savings and Operational Efficiency of In-House Box Making Solutions

Warehouse space reduction of 60-80% by eliminating pre-made box storage requirements provides immediate operational benefits and cost savings. Companies no longer need to maintain extensive inventory of various box sizes, freeing up valuable floor space for other operations or revenue-generating activities.

Shipping cost optimization of 15-25% through better load efficiency and right-sized packaging significantly impacts bottom-line profitability. When packages are precisely sized to their contents, shipping companies can optimize loads more effectively, resulting in lower per-unit transportation costs.

Labor cost reductions through automation and minimized manual box assembly processes improve operational efficiency while reducing dependency on manual labor. Automated systems can operate continuously with minimal supervision, allowing staff to focus on higher-value activities.

Production capacity doubling with 2-Up Production systems manufacturing two boxes per sheet maximizes equipment utilization and throughput. This technology allows businesses to meet increased demand without proportional increases in equipment investment or floor space requirements.

Benefits of Custom Box Making Compared to Pre-Made Packaging

Adjustable box dimensions enabling rapid adaptation to changing product specifications provide unmatched flexibility for businesses with evolving product lines. This capability eliminates the need to maintain extensive inventory of different box sizes while ensuring optimal packaging for each product.

Special design capabilities including rounded corners, hand holes, and vent holes offer packaging solutions that enhance both functionality and customer experience. These features are difficult or expensive to achieve with pre-made boxes but can be easily incorporated into custom box production.

Inline printing delivering high quality products branding and product information during production eliminates additional processing steps while ensuring consistent brand presentation. This capability allows companies to maintain brand standards while reducing overall packaging costs.

Reduced damage rates and enhanced customer experience through perfectly-sized packaging minimize product movement during shipping while creating a professional unboxing experience that reinforces brand quality and attention to detail.

Challenges and Considerations When Investing in Custom Box Making Machines

Limitations and Maintenance Needs for Automated Box Making Machines

Initial investment considerations for equipment acquisition and installation require careful financial planning and ROI analysis. While the long-term benefits are substantial, the upfront costs can be significant, particularly for smaller operations or businesses with limited capital resources.

Professional turnkey installation covering foundation work, utilities, and commissioning ensures proper equipment setup but adds to initial costs and timeline considerations. Proper installation is critical for optimal performance and requires coordination with facility management and production schedules.

Comprehensive operator training on safety, maintenance, and troubleshooting procedures is essential for maximizing equipment performance and longevity. Training requirements include both initial certification and ongoing education as technology evolves and new features are added.

Energy consumption and operating costs over machine lifecycle analysis helps ensure that total cost of ownership aligns with business objectives. While these machines are generally efficient, their power requirements and maintenance needs must be factored into long-term operational planning.

When to Choose Outsourced Box Making vs In-House Box Making Equipment

Production volume assessment ranging from 50 boxes per hour to over 2,000 units helps determine the economic viability of in-house equipment versus outsourced solutions. Higher volumes generally favor in-house production, while lower volumes may be more cost-effective when outsourced.

Box size range evaluation from 220mm to 1,150mm in flow direction determines whether standard equipment configurations can meet operational requirements or whether specialized machines are necessary. Understanding size requirements helps select appropriate equipment specifications.

Changeover time requirements supporting high-mix, low-volume production demands are critical for operations that frequently switch between different packaging configurations. Quick set capabilities become essential when producing multiple box types within single shifts.

Floor space availability and integration with existing production lines affects equipment selection and installation planning. Compact machines may be necessary for space-constrained facilities, while larger operations can accommodate more comprehensive systems with enhanced capabilities.

Comparing Box Making Techniques: Automated vs Manual vs Outsourced

Automated Box Making Machines vs Manual Box Making Methods

Automated box making achieves slotting accuracy within 0.5 millimeters compared to manual variability that can exceed several millimeters. This precision is critical for ensuring proper box assembly and maintaining consistent packaging quality across production runs.

Production speeds up to 400 blanks per minute versus limited manual output demonstrate the efficiency advantages of automation. While manual methods may be suitable for very small volumes, they cannot compete with automated systems for any significant production requirements.

Consistent quality control through integrated error detection systems ensures reliable output that is not possible with manual methods. Automated systems continuously monitor production parameters and make real-time adjustments to maintain specifications.

In-House Box Making vs Pre-Made or Outsourced Packaging Solutions

On-demand production eliminating lead times associated with pre-made box ordering provides immediate responsiveness to changing business needs. Companies can produce boxes as needed without waiting for supplier deliveries or maintaining extensive inventory.

Right-sized packaging reducing material costs compared to standard pre-made sizes results in both cost savings and improved sustainability. Custom sizing eliminates waste associated with oversized boxes and reduces filler material requirements.

Customization flexibility supporting varied product lines and changing requirements enables businesses to adapt quickly to market demands without being constrained by supplier limitations or minimum order quantities.

Specialized Solutions for Corrugated Box Making Machines and Corrugated Cardboard Boxes

What Are Corrugated Box Making Machines and How Do They Operate?

Corrugated box making machines include vertical form fill seal machines for top-loading boxes that are particularly suitable for food and beverage applications requiring specific ventilation and loading characteristics. These machines are equipped with specialized features for handling the structural requirements of corrugated materials.

Horizontal packaging systems handle flow-wrap and side-loading applications that are common in retail and e-commerce environments. These systems are designed to accommodate the directional strength characteristics of corrugated board while maintaining production efficiency.

Rotary cutting machines offer high speed continuous corrugated cardboard processing for high-volume operations requiring maximum throughput. The rotary design enables continuous operation without the stop-start cycles associated with other cutting methods.

Multi-blade cutting systems enable simultaneous production of multiple box sizes, maximizing equipment utilization and production flexibility. This technology is particularly valuable for operations producing various box types within the same production run.

Advantages of Making Corrugated Cardboard Boxes In-House

Direct control over corrugated cardboard box quality and specifications ensures that packaging meets exact requirements without relying on external suppliers who may have different quality standards or priorities.

Immediate adaptability to changing product requirements without supplier delays enables rapid response to market demands or product modifications. This flexibility is particularly valuable in fast-moving industries where time-to-market is critical.

Elimination of minimum order quantities required by external suppliers provides cost advantages for operations with variable demand or seasonal fluctuations. Companies can produce exactly the quantities needed without excess inventory.

Just-in-time production capabilities reducing inventory carrying costs improve cash flow and reduce storage requirements while ensuring fresh packaging materials for each production run.

Key Features to Look for in Corrugated Box Making Machines

Single facer units with temperature control optimizing board formation across thickness levels ensure consistent material quality regardless of corrugated board specifications. Temperature control is critical for proper adhesive activation and board lamination.

Pneumatic brakes and hydraulic mill roll stands ensuring precise material handling are essential for maintaining corrugated board integrity during processing. These systems prevent crushing or deformation that could compromise box strength.

Dual Slotter Units with 6 knives achieving high-precision slotting for 2-Up Production systems enable simultaneous processing of multiple boxes while maintaining accuracy. This technology doubles production capacity without proportional increases in equipment size.

Slotting width adjustable from 7-21mm supporting carton heights from 50mm to 2500mm provides flexibility for diverse packaging requirements. This adjustability eliminates the need for multiple machines or extensive tooling changes.

Common Applications for Corrugated Box Making Machines

E-commerce fulfillment requiring variable box sizes for diverse product catalogs benefits from the flexibility and quick changeover capabilities of modern corrugated box making machines. The ability to produce right-sized packaging improves shipping efficiency and customer satisfaction.

Food and beverage packaging with special ventilation and strength requirements utilizes specialized features like vent holes and moisture-resistant treatments. These applications often require specific material grades and structural configurations.

Electronics packaging demanding precise dimensions and protective features relies on the accuracy and consistency of automated production. Electronics packaging often requires anti-static treatments and precise dimensional control for proper product fit.

Retail displays and shipping containers with brand-forward printing capabilities benefit from inline printing and finishing options that create professional packaging that reinforces brand identity throughout the supply chain.

Challenges Specific to Making Corrugated Cardboard Boxes In-House

Material storage considerations for varying corrugated board thicknesses and widths require proper environmental controls and handling systems. Corrugated materials must be stored in controlled humidity conditions to maintain performance characteristics.

Operator training for handling different corrugated cardboard grades and thicknesses is essential for maintaining quality and preventing material waste. Different grades require specific handling techniques and machine settings.

Maintenance requirements for specialized corrugated processing components are more complex than standard box making equipment. Corrugated processing requires specific tooling and maintenance procedures to ensure optimal performance.

Quality control processes specific to corrugated material integrity and performance must be implemented to ensure that finished boxes meet strength and durability requirements for their intended applications.

Why Choose Professional Equipment for Customized and Corrugated Box Making Solutions

Tailored Box Making Machines for Specific Production Needs

Compact all-in-one machines like BM2506, BM3000, and FF2800 series for medium-volume production offer complete solutions in space-efficient designs suitable for operations with limited floor space or moderate production requirements.

Modular systems supporting flexible production from small batch to high-volume manufacturing enable businesses to start with basic configurations and expand capabilities as demand grows. This scalability protects initial investment while providing growth flexibility.

Specialized equipment configurations for unique industry requirements and applications ensure that machines are optimized for specific operational needs rather than generic packaging requirements. Custom configurations can address unique material handling, printing, or finishing requirements.

Advanced 2-Up Production systems doubling manufacturing capacity for growing operations provide a path for expansion without complete equipment replacement. These systems offer the ultimate solution for businesses experiencing rapid growth.

Training, Service, and Support for Long-Term Box Making and Corrugated Box Production

24/7 technical support with remote diagnostics for rapid issue resolution minimizes downtime and ensures continuous production capability. Remote diagnostic capabilities enable service technicians to identify and often resolve issues without on-site visits.

One-year warranty coverage with extended maintenance program options provides peace of mind and predictable service costs. Extended programs often include preventive maintenance and spare parts to ensure optimal performance.

Overseas installation services and OEM customization for global markets ensure that equipment is properly configured and installed regardless of location. Professional installation services include all necessary utilities and commissioning.

Continuous software updates and performance optimization services ensure that machines remain current with technology advances and maintain peak efficiency throughout their operational life.

Get Started with Customized Box Making Machines and Corrugated Box Making Solutions

Evaluate your production needs with industry specialists to select the optimal box making machine for your specific requirements. Professional consultation ensures that equipment selection aligns with operational goals and provides the best ROI.

Request demonstrations of customized packaging box making machines to verify performance and suitability for your applications. Hands-on demonstrations provide valuable insights into equipment operation and capabilities that cannot be gained from specifications alone.

Consider starting with smaller semi-automatic box maker models before scaling to fully automatic box maker systems. This approach allows businesses to gain experience with the technology while minimizing initial investment and risk.

Analyze your current packaging costs to calculate ROI for in-house corrugated box machines. Comprehensive cost analysis should include current packaging expenses, labor costs, storage costs, and shipping inefficiencies to provide accurate ROI projections.

The transition to automated box making represents a significant opportunity for businesses seeking to improve efficiency, reduce costs, and enhance packaging quality. By carefully evaluating your requirements and working with experienced equipment providers, you can select solutions that deliver immediate benefits while providing long-term flexibility for growth.

Discover the Ultimate Solution for Customized Packaging Box Making Machines

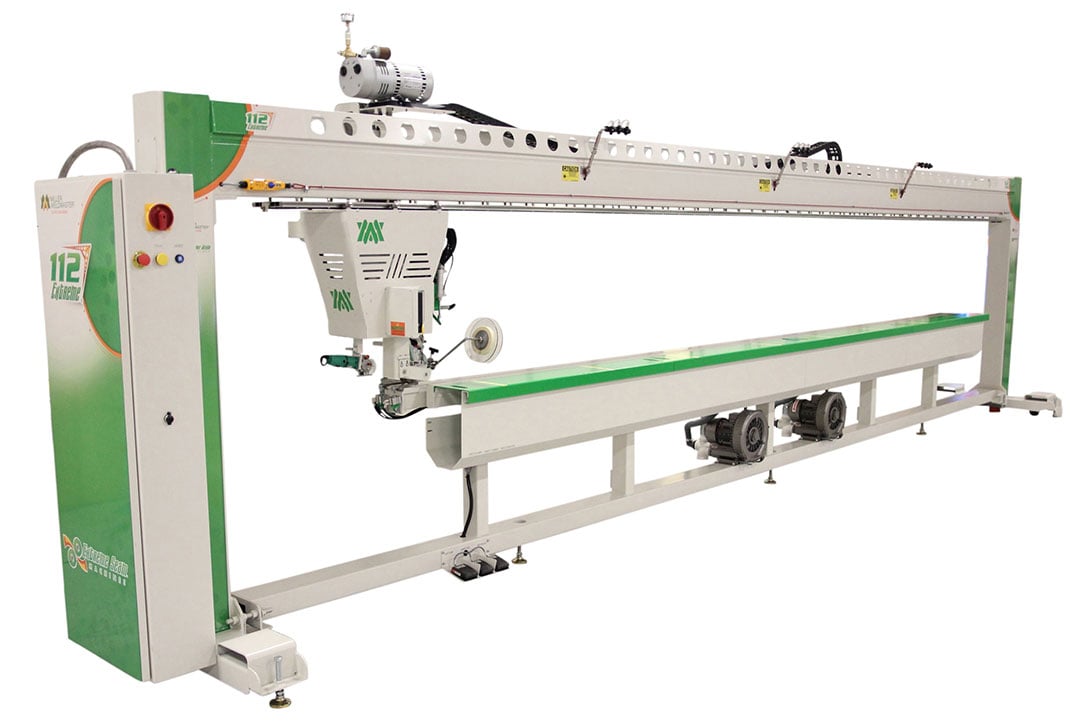

Miller Weldmaster offers industry-leading customized packaging box making machines designed to boost your production efficiency, reduce costs, and deliver high-quality, custom-sized boxes on demand. Whether you’re a growing e-commerce business or an established manufacturer, our innovative technology provides the flexibility and reliability you need to stay competitive.

Why Choose Miller Weldmaster?

-

Advanced automation for maximum production speed and precision

-

Flexible configurations tailored to your specific packaging needs

-

Comprehensive support including installation, training, and maintenance

-

Sustainable solutions that reduce material waste and optimize shipping

Take the Next Step Today

Contact Miller Weldmaster to schedule a personalized consultation or request a demonstration. Let our experts help you find the perfect customized packaging solution that fits your business goals and operational requirements.