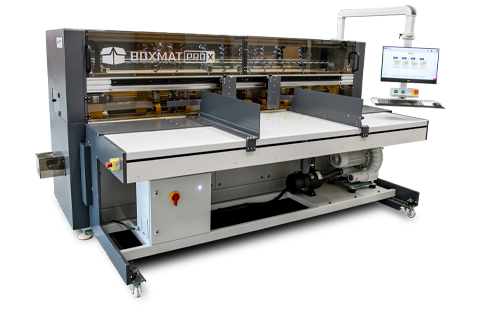

When it comes to boxmaking, selecting the right feeder is critical for maximizing productivity, material efficiency, and overall machine performance. Different feeder types are designed to handle various corrugated materials, from lightweight single-wall sheets to heavy-duty double-wall or fanfold stock.

This guide breaks down the most common feeder options available for boxmaking machines, including:

Fanfold Feeders – Ideal for continuous production with minimal reloads, perfect for variable box sizes and on-demand manufacturing.

Vacuum Feeders – Designed for high-speed precision, these feeders use suction technology to handle thin, warped, or uneven sheets without jamming.

Sheet Feeders – A simple yet versatile solution for feeding pre-cut corrugated sheets, ideal for repeat jobs and custom box designs.

Lightweight Feeders – Engineered for thin, delicate board types, offering gentle handling and higher speeds for small-format boxes.

Heavyweight Feeders – Built for strength, these feeders manage thick and heavy materials used in industrial or oversized packaging.

Whether you're producing high volumes of e-commerce boxes or specialty packaging for industrial goods, choosing the right feeder can significantly enhance your machine’s efficiency, reduce material waste, and streamline your production process.