Scrap Discharge

Plug and Play Module

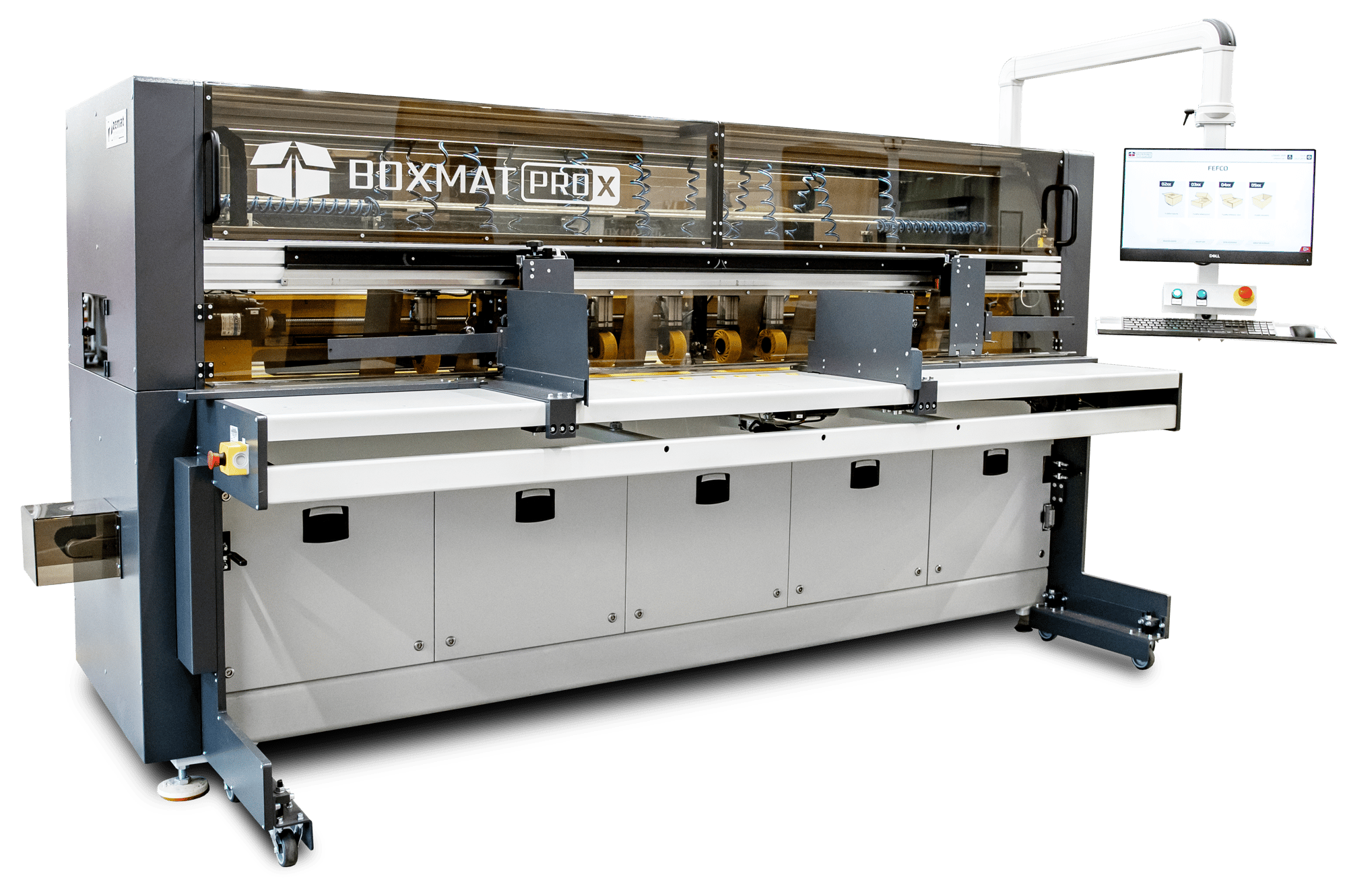

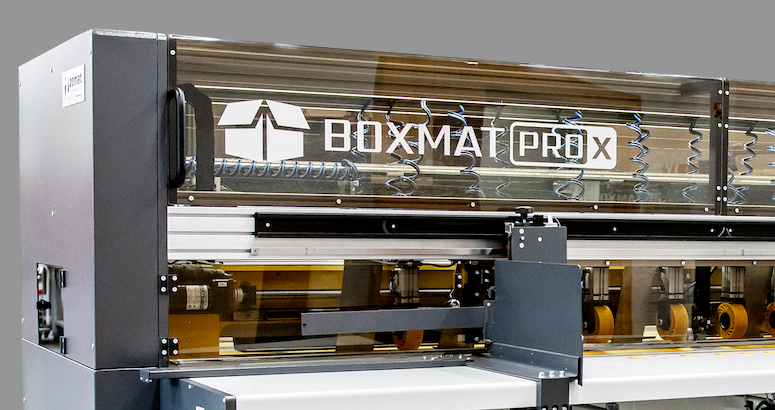

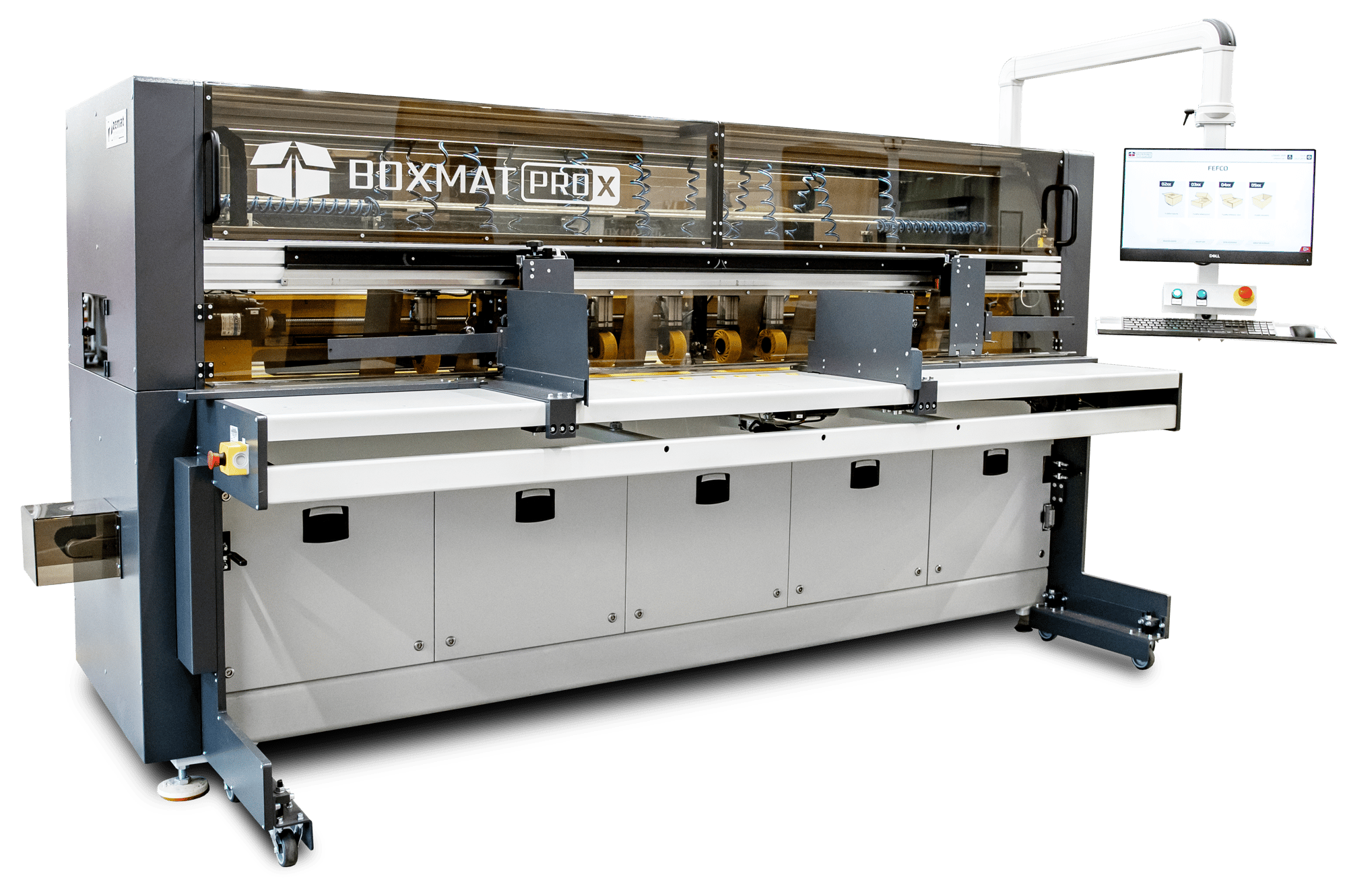

Our cutting-edge Boxmat ProX is designed to adapt to your production needs, offering flexible feeding options that handle a range of materials and box styles with ease. Whether you're running short batches or medium-sized production runs, our versatile feeders allow seamless transitions between different box sizes and designs, reducing downtime and maximizing efficiency. With the ability to switch between various types of feeds, including sheet, vaccum, fanfold, and automated feeding, you can customize your setup to suit specific projects, save on materials, and streamline your workflow. Experience faster setups, improved productivity, and greater flexibility with our innovative boxmaking solution.

The Vacuum feeder ensures precise and smooth feeding of corrugated sheets, minimizing jams and maintaining consistent production flow.

Effortlessly handles continuous fanfold corrugated sheets, ideal for producing longer box runs without constant reloading

The Lightweight feeder is designed for efficiently handling thinner, lighter corrugated materials, ensuring smooth and reliable box production.

The Heavyweight feeder is built to manage thicker, more rigid corrugated sheets, providing robust support for heavier box designs

The Boxmat Pro X is designed to produce a wide variety of box styles, including standard RSC, FPF, HSC, trays, and custom designs. Its versatility allows you to switch quickly between different box configurations, making it perfect for short and medium production runs.

The Boxmat Pro X features multiple feeding options, including sheet, roll, and manual feeds. This flexibility enables you to use various corrugated materials and switch between them easily, reducing setup time and ensuring smooth transitions between jobs.

Yes, the Boxmat Pro X is ideal for short runs. Its quick setup time and adaptable feeding system make it easy to change box sizes and styles, helping businesses produce small batches without sacrificing efficiency or increasing costs.