With the rise of e-commerce and the push for streamlined supply chains, the demand for a universal box making machine has never been higher. Fulfillment centers, warehouses, and packaging operations are looking for smarter, leaner solutions to respond to fluctuating order volumes. The Boxmat Pro is built to support these modern needs by enabling just-in-time production and eliminating the need for large inventories of pre-made boxes.

Benefits of On-Demand Box Making for E-Commerce and Fulfillment Centers

The Boxmat Pro empowers packaging operations to produce boxes in real-time based on current orders. This flexibility eliminates the need to stockpile a wide range of box sizes, reducing warehouse storage requirements and ensuring faster order fulfillment. Whether handling high-volume order days or last-minute shipments, Boxmat Pro adapts seamlessly. Additionally, the Boxmat Pro is ideal for both short and medium runs, enhancing its flexibility for various production needs.

How the Boxmat Pro Streamlines Custom Corrugated Packaging

The Boxmat Pro is a fully automated solution that reduces manual labor and packaging complexity. Its intuitive touchscreen interface and built-in design software allow operators to quickly input box dimensions, which are then set automatically, and produce right-sized packaging with minimal training. For example, one fulfillment center used Boxmat Pro to switch from 12 pre-stocked sizes to on-demand production, cutting packaging time by 35%.

The Boxmat Pro's user-friendly touch screen panel further streamlines the production process, eliminating the need for manual adjustments and allowing for quick selection of box styles and dimensions.

Reduce Packaging Waste and Save on Shipping Costs

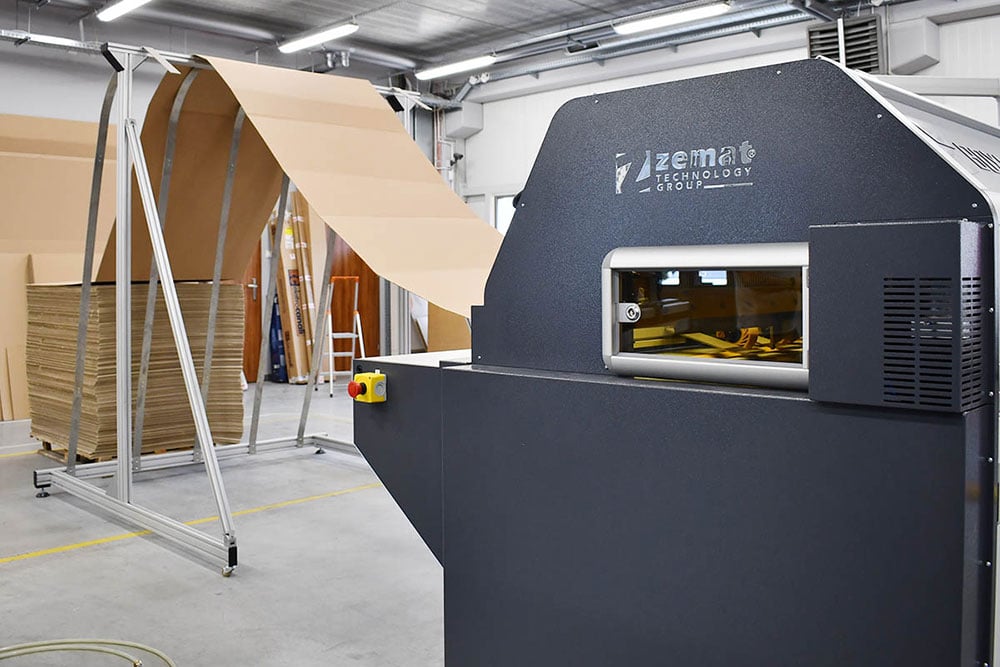

By creating custom-fit boxes, the Boxmat Pro reduces void fill and minimizes wasted space. The precision board feed control, featuring servo-drives, soft grip rollers, and double encoders, ensures accurate positioning and prevents skewing of the corrugated cardboard. This helps lower DIM weight charges from carriers, ultimately saving on shipping. Customers have reported up to 30% reductions in packaging waste and 20% lower shipping costs, all while supporting sustainability initiatives.

Fully Automatic Box Making Machine with Digital Controls

Compared to legacy systems, the Boxmat Pro offers a next-generation servo driven automated packaging solution. It enhances digital transformation across operations with programmable logic, real-time diagnostics, and touchscreen functionality. Additionally, the Boxmat Pro features an automatic feeder, enhancing efficiency by eliminating the need for manual feeding of materials.

Automated Setup and Job Changeover with Boxmat Pro

With automated changeover capabilities, the Boxmat Pro switches box styles and sizes with ease. Operators can save frequently used jobs, reducing downtime and supporting multi-SKU environments. Changeovers take just minutes, with all necessary tool setups performed automatically in less than a minute, allowing teams to adapt quickly to new packaging needs.

Touchscreen Controls and Real-Time Monitoring Features

The intuitive touch screen panel offers guided navigation, job previews, and system alerts. Built-in diagnostics and memory settings streamline troubleshooting and operator training. Designed with usability in mind, it empowers teams to run consistent, error-free packaging. All settings for box production can be managed through the touch screen panel.

Precision Scoring and Cutting for Consistent Box Quality

Accurate scoring and cutting mechanisms, including the automatic setup of cutting knives and slotting knives, ensure high-quality box construction. This consistency supports product protection, easy stacking, and a professional appearance. Boxmat Pro maintains tight tolerances for repeatable results, even in large batch runs.

Custom Box Manufacturing for Small to Large Runs

From short-run prototyping to larger batch jobs, the Boxmat Pro is a box making machine revolutionizing scalability. It eliminates the cost and delay of die-cut tooling, making it ideal for businesses of all sizes. The Boxmat Pro supports run and serial production efficiently.

Make Single or Batch Boxes with No Die Required

The Boxmat Pro enables rapid design changes and fast prototyping without tooling. This eliminates lead times and costs associated with custom dies. It’s perfect for last-minute orders and product testing. Additionally, the Boxmat Pro eliminates the need for manual setup and can produce one box or batch boxes efficiently.

Flexible Box Styles from RSC to Die-Cut Alternatives

Operators can create a wide variety of box styles, including RSC, HSC, FEFCO formats, flap boxes, and more. Optional modules expand capabilities, offering handle cuts, perforations, and gluing for fully assembled boxes. Operators can select a preprogrammed box style from the touch screen panel, eliminating the need for manual setup and allowing for quick and efficient production.

Ideal for Short-Run, Just-in-Time Packaging Needs

Short-run and serial production supports seasonal or niche product packaging without overstocking. It’s especially beneficial for contract packagers, 3PLs, and custom manufacturers.

Boxmat Pro Specifications and Material Compatibility

Designed to meet industrial standards, the Boxmat Pro is compatible with various board types and sizes. Additionally, the Boxmat Pro can be equipped with special shape scoring wheels for enhanced box design capabilities.

Compatible Corrugated Flute Types and Board Sizes

Supports B, C, E, and double-wall flutes. Handles board widths up to 102” and lengths up to 120”. Compatible with materials ranging from lightweight single-wall to heavy-duty double-wall corrugated board, showcasing the versatility and efficiency of the machine.

Dimensions, Power Requirements, and Production Speed

Machine footprint: approx. 16’ x 5’. Power: 230V, 3-phase. Air: 90 PSI. Production speed: 400–600 boxes per hour depending on box style and size.

The Boxmat Pro streamlines the production process of corrugated cardboard boxes, allowing for efficient production of various box styles with minimal manual setup.

Optional Add-Ons: Creasing, Gluing, Printing Modules

Add-ons include inline gluing for assembly-ready boxes, digital printing for branding, and advanced creasing for reinforced edges. These modules, including optional features like perforation knives, enhance efficiency and product presentation. Additionally, the optional receiving stacker allows for efficient stacking of produced boxes, further streamlining the box-making process.

Compare Boxmat Pro to Other Box Making Machines

Make informed decisions by comparing modern automation benefits over manual methods and traditional systems.

The Boxmat Pro is an advanced and universal box making machine, featuring an intuitive touch screen panel for easy settings adjustment, the capability to create a wide variety of box styles quickly, and an all-in-one functionality that streamlines the production process.

Boxmat Pro vs. Manual Box Cutters and Die-Cutters

Manual systems require more labor and time, and are prone to error. Die-cutters need expensive tooling and time-consuming setup. The Boxmat Pro improves safety, speeds up production, and lowers cost-per-box over time by integrating multiple processes that would typically require a separate machine.

How Boxmat Pro Stands Out from Other Automated Systems

With robust engineering, easy-to-use software, and responsive U.S.-based support, the Boxmat Pro is a standout solution. Customers also value our fast service response, thorough training programs, and long-term reliability. The Boxmat Pro features an innovative system that enhances its functionality and versatility, including automatic adjustments and multi-function capabilities managed through a user-friendly touch screen interface.

Which Industries Benefit Most from the Boxmat Pro

Ideal for e-commerce, furniture, appliance, 3PL, and manufacturing industries. Supports packaging of custom shapes, large products, and low-volume SKUs. Businesses can also produce their own boxes on demand with the Boxmat Pro.

Boxmat Pro Applications and Use Cases

Built to solve real-world packaging problems across diverse industries.

The Boxmat Pro is part of the boxmat series machines known for their versatility and efficiency, capable of working inline with the FLEXOMAT printing unit or as standalone printers.

Custom Box Production for Industrial Manufacturers

Produce packaging for oversized components or irregular shapes. Reduce shipping damage and cost with right-sized boxes tailored to product specs. The Boxmat Pro also allows for creating your own design of boxes using FreeStyle settings.

Packaging Solutions for Furniture, Appliances, and Auto Parts

Supports heavy, fragile, or bulky items with robust double-wall cardboard boxes. Easy setup for unique sizes with quick job changeovers.

Boxmat Pro in Third-Party Logistics (3PL) Operations

3PLs benefit from the machine’s versatility to serve multiple clients without maintaining large inventories of box sizes. Easily switch jobs and streamline workflows. The BOXMAT PRO's external control feature allows for precise adjustments and management of box dimensions, enhancing the machine's versatility and efficiency.

Why Choose Miller Weldmaster’s Boxmat Pro

Choose a partner that backs performance with service and experience.

The Boxmat Pro can also function as a stand alone printer, offering versatile printing configurations to meet various operational needs.

Backed by Industry-Leading Service and Support

From onboarding to long-term service, Miller Weldmaster supports your success. We offer hands-on training, remote diagnostics, and expert troubleshooting when you need it most.

Additionally, the Boxmat Pro features servo drives optional, which enhances its functionality by allowing flexible configurations and advanced control for box production.

Integration Options with Existing Packaging Lines

Easily integrate with tapers, labelers, conveyors, or ERP systems. Modular connectivity and flexible software make the Boxmat Pro a smart addition to any packaging line. The machine's soft grip rollers ensure precise board feed control, preventing skewing and enhancing the efficiency and accuracy in handling corrugated cardboard.