This instruction manual is intended to be a guide when operating the SeamRover. To ensure optimal performance from your welder, please follow the recommendations and specifications precisely.

Table of Contents

- Chapter 1: Intended Use

- Chapter 2: Explanation of Warnings

- Chapter 3: Electrical and Air Requirements

- Chapter 4: Principles of Heat Sealing

- Chapter 5: Definition of Controls

- Chapter 6: Recommended Replacement Parts

- Chapter 7: Machine Specifications

- Chapter 8: Maintenance

- Chapter 9: Transportation Specs and Storage

- Chapter 10: Technical Requirements

For more technical information regarding this machine call our Resolution Center at 1-855-888-WELD or email service@weldmaster.com.

1.0 Intended Use

The Seamrover DD is a rotary hot air welding machine intended to heat-seal weldable thermal plastics such as fabric or membrane. Includes PVC, TPO and other weldable material. Always test weld first.

The manufacturer does not approve of:

- Any other uses for these machines.

- The removal of any safety guards while in operation.

- Unauthorized modification of the machines.

- Using replacement parts that are not manufacturer-approved.

Only a properly-trained technician may operate and/or perform any routine maintenance orrepairs to the machines.

Only a properly-trained technician may operate and/or perform any routine maintenance orrepairs to the machines.

NOTE: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

2.0 Explanation of Warnings

There are several different warning symbols placed on the Miller Weldmaster 112. The symbols are to alert the operator of potentially hazardous areas on the machine. Familiarize yourself with their placement and meaning.

Caution: Hot

The “Caution: Hot” symbol is placed on a guard near hot surfaces.

Caution: Unplug Machine

The “Caution: Unplug Machine” sticker is placed near the opening of the cabinet and all access panels. To prevent electrocution, the machine should always have the power disconnected before the cabinet door is open.

Warning: Keep Hands Clear

The“Warning: Keep Hands Clear” sticker is placed on the Heater Assembly. To prevent any pinching or burns, be aware of the location of your hands at all times.

Warning: High Temperature Air

The “Warning: High Temperature Air” sticker is placed on the Heater Assembly.

Caution: Electricity

The “Caution: Electricity” sticker is placed near areas that contain electrical.

3.0 Electrical and Air Requirements

Warning! Only a qualified electrician may connect the electrical power.

Preparation - World Power

1. Make sure the Power Supply is at 230v, 25amp.

2. Make sure the voltage and current is dedicated to the machine and to the above

specification.

3. Before operation of the machine be sure the surrounding area of the machine is free of flammable debris. Only authorized persons should be in the area of the machine while in use.

Electrical Supply

The Miller Weldmaster Seamrover DD requires the following electrical requirements:

- 25 Amp - Single phase - 230 Volts

- Recommend a 10k+ generator

4.0 Principals of Heat Sealing

Hot Air

The heat required for the welding operation is created electrically by two heating element located inside the heat element housing. The hot air temperature ranges from 100 to 1350 Degrees Fahrenheit or 25 to 730 Degrees Celsius.

Speed

The Speed of the Weld Rollers determines the amount of time the heat is applied to the material being welded. The slower the speed setting, the more the material will be heated. The faster the speed setting, the less the material will be heated. To achieve the best weld, a minimal amount of heat should be applied to the material while still achieving a full weld. Too much heat will cause distortion of the material; while not enough heat will prevent the material from welding.

Pressure

The pressure of the weld roller is the final step when creating a weld. The pressure of the weld roller compresses the heated material together completing the welding process.

Summary

When heat sealing, the correct combination of heat, speed, and pressure will allow you to achieve a properly welded seam.

5.0 Definition of Controls

Main Screen - HMI Operation

Home Screen

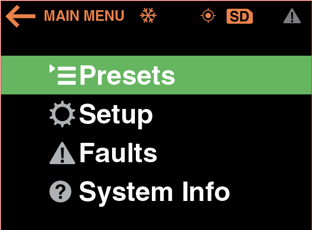

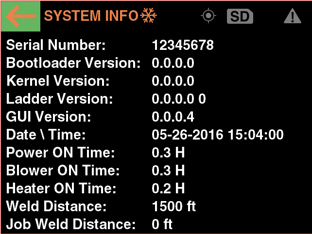

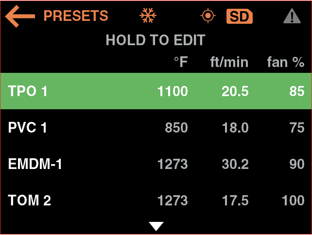

Presets: This is a particular combination of the parameters of heat and speed used to weld different types of fabric. This shows which recipe you’re currently using on the machine. 0 - 15 Available recipe settings.

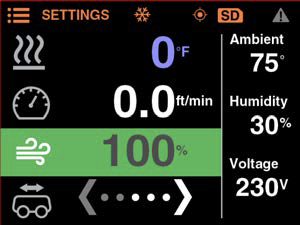

Machine Speed: This is the speed of the Weld Roller. The speed can be adjusted by spinning the control knob. Each detent of the knob increases or decreases the speed by .1ft/min.

Actual Temperature: This is how hot the machine is currently.

Temperature Set Point: This is how hot you want the machine to be for the purpose of welding your thermal plastics.

Set Blower

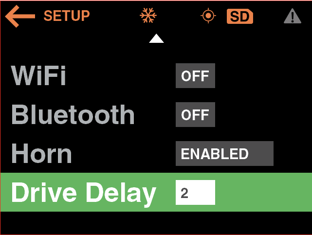

Delay Settings: These are used to eliminate voids in seam. Remember to test various drive delay settings to ensure quality welds. If the drive delay is too long the material may be burnt.

Drive Start Delay Time: Once the nozzle swings into position, the Drive Start Delay Time will delay the weld rollers from turning until the set point is reached. The Drive Start Delay Time will be adjusted by the operator to the desired setting.

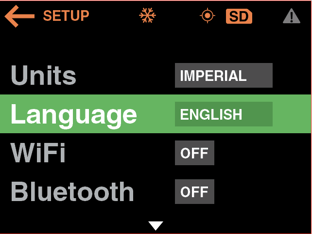

Language: Select the language according to demand.

MAX Output: 1350˚F 32ft/min 50-100% blower.

Hour Meter: The hour meter will count total time of which the heating system is on.

Presets: When changing parameters, pressing the SAVE button will save the adjusted settings to the selected recipe.

6.0 Recommended Replacement Parts

Miller Weldmaster recommends keeping the following spare parts in stock:

![]() NOTE: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

NOTE: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

Principles of Operation

The Seamrover DD is a heat sealing machine which welds thermal plastic fabrics or films by Hot Air, through applying pressure, consistent speed, and accurate temperature for perfectly sealing thermal plastic materials.

Technical Specifications

- Amp Rating - 25amp at 230volt

- Rated Power - 4600 W

- Rated Voltage - 230v AC, 50/60hz

- Maximum Temperature - 1350°F (730°C)

- Machine Speed - 1-32 ft/min

- Overall Dimensions - 27” x 14” x 13”

- Seam Width - up to 2”

- Net Weight - 88lbs

Operator Controls Section

- Control Panel: The HMI (Human Machine Interface)

- Digital Screen allows you to set system controls.

- Power On/Off Switch: Power switch turns the machine on and off.

Other

- Power Supply Outboard Fuses: Used for the protective control of the General Power Supply of the complete machine.

- Start/Stop Switch: Controls the starting and stopping of the seaming operation. (Nozzle Swing)

![]() Warning! The operator must disconnect the power from the machine before proceeding.

Warning! The operator must disconnect the power from the machine before proceeding.

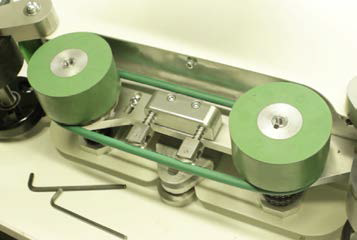

Weld Roller: To replace weld roller remove the fasteners on the drive shaft. Slide the weld roller off the drive shaft and remove key from key-way. Installation is reverse of removal.

Fig. 1 Fig. 2

Nozzle Position (Horizontal): To adjust horizontal nozzle position loosen the four flat head bolts located on the nozzle mounting bracket. When all four bolts are slightly loose, slide the nozzle into place while applying downward pressure on the nozzle mounting bracket. Once the nozzle placement is satisfactory, tighten the bolts in a crisscross pattern starting with one of the bolts closest to the element housing (Fig. 2).

Nozzle Position (Vertical): To adjust vertical nozzle position locate the socket head cap screw and jam nut underneath the nozzle float assembly. Break the jam nut loose and drive the socket head cap screw in or out to adjust the resting position of the nozzle. Once the nozzle placement is satisfactory, tighten the jam nut. Fine tune the vertical nozzle position such that the nozzle can easily swing into the seam to be welded.

Thermocouple: Replace the thermocouple by removing the four socket head cap screws on the side of the element housing. This allows removal of the thermocouple guard. Break the thermocouple free using a wrench. Cut and remove the protective heat shrink from the thermocouple plug and unplug the thermocouple. Installation is reverse of removal.

Step 1 Step 2 Step 3

Step 1 Step 2 Step 3

Step 4 Step 5

Step 4 Step 5

Element: To replace the element loosen and remove the four socket head cap screws from the top of the element housing cap. Slowly pull the cap directly out of the element housing. Remove the element insulating tube and the element housing cap gasket and set aside. Now, the element can be unplugged from the element housing cap. Installation is reverse of removal.

Electrical Circuits

1. When replacing parts and components, you must use the part or components of the same type as the original or equivalent to the original type. Original equipment replacement parts should be purchased through Miller Weldmaster and or a Miller Weldmaster authorize distributor.

2. To avoid damaging the control module, Display and Operating Panel, never plug or unplug the cables connecting the PLC, Display and Operating Panel while the power is on.

3. If there is any fault that cannot be removed, please immediately contact the service department at Industrial Heat Sources (IHS) at +1 (330) 970-9353.

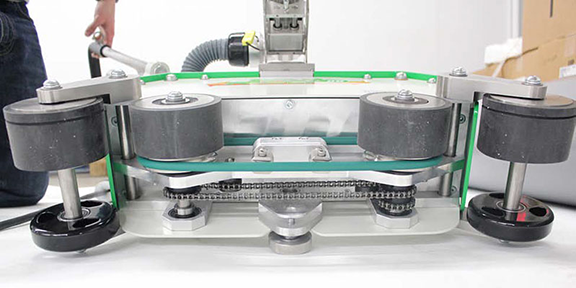

Drive System

1. Check if the Driving Sprockets are dislocated or loosened.

2. Check if the chains are too loose. Tighten as needed.

NOTICE: By not properly maintaining the machine, the performance may be effected. Please contact Miller Weldmaster with any questions.

Tightening/Oiling Chains

The Miller Weldmaster Seamrover DD has two chains that are used to drive weld rollers. Although not a high maintenance item, chains should be inspected once a year to ensure there is not excessive corrosion, rust, or dirt. Also inspect for any looseness or slack. If needed, lubricate chains once a year with 80w – 90w gear oil.

1. Turn the circuit breaker to the off position.

2. Disconnect the power cord from the power supply.

3. Tilt the machine on it’s side and inspect the chains. Perform any maintenance to the chains as needed.

Hot Air Heat System Adjustments

Begin by turning your hot air on and setting to the desired temperature.

1. Depth of your nozzle should be at approximately 1 of an inch from the pinch point of your weld rollers. If the nozzle is aligned, perform a test weld. If not replace the nozzle or have machine serviced.

9.0 Transportation Specs and Storage

Storage

The manufacturer recommends that any time the machine is not in use, it must be protected from excess dust and moisture. The operator should familiarize themselves with the warning symbols on the machine to be alert to the potentially hazardous areas on the machine.

NOTE: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

10.0 Technical RequirementsTechnical Requirements

1. When the Weld Rollers are aligned properly, the edges of the two rollers should be parallel and aligned.

2. Heat System Swing: The swing in/out of the heat system should be smooth and natural at moderate speed.

3. Air lines and air fittings should be free of leaks.

NOTE: Changes in factors such as thickness of materials, qualifications of the operators and different environment and weather may directly affect the product. The operator should be able to understand the following adjustable factors particularly:

1. Heating Temperature

2. The pressure of the Weld Rollers

3. Air volume

4. Placement of heating system