This instruction manual is intended to be a guide when operating the RFlex Extreme. To ensure opti- mal performance from your welder, please follow the recommendations and specifications precisely.

Table of Contents

- Chapter 1: Intended Use

- Chapter 2: Safety Signs and Pictographs

- Chapter 3: Technical Data

- Chapter 4: Technical Description

- Chapter 5: Assembly and Installation

- Chapter 6: Operation

- Chapter 7: Selection Of Weld Parameters

- Chapter 8: Maintenance

- Chapter 9:

Occupational Health & Safety

- Chapter 10: Electrical Documentation

- Chapter 11: Pneumatic Documentation

- Chapter 12: General Instructions

- Chapter 13: Appendices

- Chapter 14: Additional Machine Documents

For more technical information regarding this machine call our Resolution Center at 1-855-888-WELD or email service@weldmaster.com.

1.0 Machine Overview/Intended Use

The RFlex RF welder is the machine designed for welding the large structural surfaces such as membranes, canvas covers, tents, stretched structures, billboards and other technical fabrics made of PVC/PU. What is more, the machine is equipped with the advanced technology due to which the production efficiency and quality can be improved.

Furthermore, the use of the RF generator (27.12MHz) enables the operator to adjust the power flow smoothly, it ensures also the parameters’ stabilization and the proper welding efficiency (linear welds up to the length of 1200 mm). Due to the placement of the control panel on the movable extension arm the operators’ work becomes easier. All the machines are safe for the operators and they were constructed according to the strict requirements of the applicable EC directives.

In addition, two or more layers of the artificial dielectric loss materials can be welded in the machine and in particular such as the ones made from polyvinyl chloride (PVC, PA, PU) or of polyurethane, polyamide and polyester, let alone the ones made from mixtures of the above mentioned ingredients.

Finally, the implementation of the technical solution based on the pneumatic pressing against the welded materials allows the layers to be permanently bonded when they cool down, though, the shape of the weld depends on the chosen electrode.

THE MOST IMPORTANT MACHINE FEATURES:

- the machine routine maintenance is very simple;

- the pressing can be precisely adjusted;

- the manufacturer installed the emergency button on the control panel;

- the machine is equipped with the signal light column so as to enhance the operator’s safety when the machine is on;

- the operator can programme and control the machine’s duty cycle due to the HMI touch-sensitive panel;

- the programming tool enables the operator to enter in the system such parameters as: the weld time and power along with the cooling time;

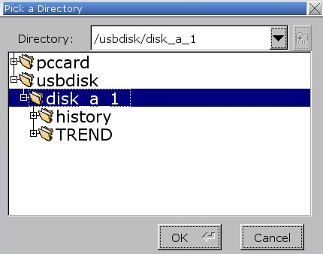

- using the HMI panel installed on the machine the operator can save many weld programmes for different kinds of materials, let alone the ones used for work with different types of electrodes;

- for the operator’s convenience the machine is equipped with the electrode holder especially designed for a quick change of the welding electrode;

- the machine is fitted out with the additional grounding electrode so as to protect the user against the increased level of HF non-ionizing radiation emitted by the machine;

- ZTG HF AutoTuning System™ - the machine is equipped with the automatic output power control system in order to increase the operator’s safety;

- ZTG SafeDOWN™ - the machine is furnished with the system which should effectively protect the operator against the electrode when it is being lowered;

- ZTG Flash™ - another machine’s system which is supposed to protect the electrode and the raw material being welded from the possible damage caused by an arc-over;

- All machines have received the CE Certificates of Conformity

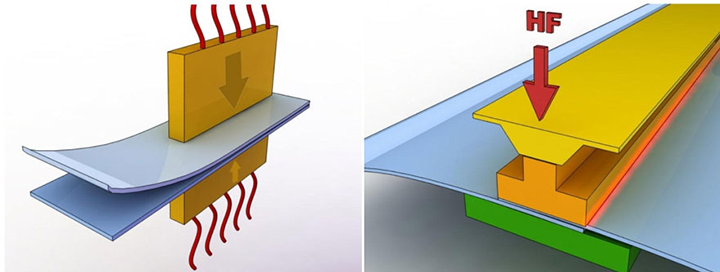

HIGH FREQUENCY TECHNOLOGY:

High Frequency Welding, known as Radio Frequency (RF) or Dielectric welding, is the process of fusing materials together by applying radio frequency energy to the area to be joined. The resulting weld can be as strong as the original materials.

HF Welding relies on certain properties of the material being welded to cause the generation of heat in a rapidly alternating electric field. This means that only certain materials can be welded using this technique. The process involves subjecting the parts to be joined to a high frequency (most often 27.12MHz) electromagnetic field, which is normally applied between two metal bars. These bars also act as pressure applicators during heating and cooling. The dynamic electric field causes the molecules in polar thermoplastics to oscillate. Depending on their geometry and dipole moment, these molecules may translate some of this oscillatory motion into thermal energy and cause heating of the material. A measure of this interaction is the loss factor, which is temperature and frequency dependent.

Polyvinylchloride (PVC) and polyurethanes are the most common thermoplastics to be welded by the RF process. It is possible to RF weld other polymers including nylon, PET, PET-G, A-PET, EVA and some ABS resins, but special conditions are required, for example nylon and PET are weldable if preheated welding bars are used in addition to the RF power.

HF welding is generally not suitable for PTFE, polycarbonate, polystyrene, polyethylene or polypropylene. However, due to the impending restrictions in the use of PVC, a special grade of polyolefin has been developed which does have the capability to be RF welded.

The primary function of HF welding is to form a joint in two or more thicknesses of sheet material. A number of optional features exist. The welding tool can be engraved or profiled to give the entire welded area a decorative appearance or it can incorporate an embossing technique to place lettering, logos or decorative effects on the welded items. By incorporating a cutting edge adjacent to the welding surface, the process can simultaneously weld and cut a material. The cutting edge compresses the hot plastic sufficiently to allow the excess scrap material to be torn off, hence this process is often referred to as tear-seal welding.

ATTENTION: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

ATTENTION: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

ATTENTION: In order to use the machine an optimum and safe way, please read carefully and follow all the instructions included in this Operation & Maintenance Manual.

ATTENTION: In order to use the machine an optimum and safe way, please read carefully and follow all the instructions included in this Operation & Maintenance Manual.

ATTENTION: All operatives, trained in operational safety, operating procedures and welding machine risk, as well as those qualified to operate the welding machine, are requested, by the Contractor, to sign, with their legible signature, the attached form.

ATTENTION: All operatives, trained in operational safety, operating procedures and welding machine risk, as well as those qualified to operate the welding machine, are requested, by the Contractor, to sign, with their legible signature, the attached form.

ATTENTION: The high frequency welding machine was designed and produced in a version which is unsuitable for persons with disabilities. Where the machine is to be operated by disabled persons, the machine should be properly adapted after consultation with the manufacturer.

ATTENTION: The high frequency welding machine was designed and produced in a version which is unsuitable for persons with disabilities. Where the machine is to be operated by disabled persons, the machine should be properly adapted after consultation with the manufacturer.

2.0 Safety Signs and Pictographs

2.1 General Information

In order to use the welder in an optimum and safe way, please read carefully and follow all the instructions included in this Operation & Maintenance Manual, also particularly all warning, prohibition, restriction and order information and signs.

On the basis of the information included in this Operation & Maintenance Manual, the Client must elaborate Workstation Manuals for employees.

The Client is fully, legally and materially liable for any and all events resulting from insufficient knowledge of this Operation & Maintenance Manual or failure to conform to the principles of the Occupational Health & Safety.

WARNINGS PUT ON THE DEVICES AND/OR DESCRIBED IN SUBSEQUENT Operation and Maintenance Manual BEING ACQUAINTED WITH THEM IS STRICTLY OBLIGATORY.

WARNINGS PUT ON THE DEVICES AND/OR DESCRIBED IN SUBSEQUENT Operation and Maintenance Manual BEING ACQUAINTED WITH THEM IS STRICTLY OBLIGATORY.  ATTENTION: Before getting into any work of any person operating HF welding machine it is obligatory to become acquainted with the subsequent Operation and Maintenance Manual.

ATTENTION: Before getting into any work of any person operating HF welding machine it is obligatory to become acquainted with the subsequent Operation and Maintenance Manual.

ATTENTION: Any receiver or person authorized by the receiver on the basis of the hereby Operation and Maintenance Manual and proper characteristic of production-technology is obligatory due to issue WORKSTAND MANUAL for operators.

ATTENTION: Any receiver or person authorized by the receiver on the basis of the hereby Operation and Maintenance Manual and proper characteristic of production-technology is obligatory due to issue WORKSTAND MANUAL for operators.

ATTENTION: High frequency welding machine can be operated ONLY by workers that have been trained in servicing the device and INDUSTRIAL SAFETY with the special consideration of possible risk coming from the machine.

ATTENTION: High frequency welding machine can be operated ONLY by workers that have been trained in servicing the device and INDUSTRIAL SAFETY with the special consideration of possible risk coming from the machine.

ATTENTION: During the whole working life of the machine, the device Manufacturer suggests to the Purchaser using the trained service personnel provided by the Manufacturer or any service teams authorized by the Manufacturer.

ATTENTION: During the whole working life of the machine, the device Manufacturer suggests to the Purchaser using the trained service personnel provided by the Manufacturer or any service teams authorized by the Manufacturer.

ATTENTION: Manufacturer strongly recommends to install the welding machine only in industrial environment.

ATTENTION: Manufacturer strongly recommends to install the welding machine only in industrial environment.

ATTENTION: The machine must be properly levelled and must have fixed place of a operation.

ATTENTION: The machine must be properly levelled and must have fixed place of a operation.

ATTENTION: Careless handling of the machine during transportation (moving) may result in serious injuries or accidents.

ATTENTION: Careless handling of the machine during transportation (moving) may result in serious injuries or accidents.

ATTENTION: The generator is powered by the dangerous for life voltage of power grid 3 x480 VAC; 50 Hz. The device has the high voltage up to 8000 VDC. All service or prevention activities can be executed only by the trained personnel with the authority required by the law.

ATTENTION: The generator is powered by the dangerous for life voltage of power grid 3 x480 VAC; 50 Hz. The device has the high voltage up to 8000 VDC. All service or prevention activities can be executed only by the trained personnel with the authority required by the law.

ATTENTION: Purchaser should necessary take care of proper execution and regular prevention control of anti-electric shock protection installation for each device that is in use. All responsibility in this matter is on the Purchaser 's side.

ATTENTION: Purchaser should necessary take care of proper execution and regular prevention control of anti-electric shock protection installation for each device that is in use. All responsibility in this matter is on the Purchaser 's side.

ATTENTION: The lamp voltage must be the same as specified in the datasheet of the product – it is possible to adjust it using branches on the primary side of the incandescent transformer.

ATTENTION: The lamp voltage must be the same as specified in the datasheet of the product – it is possible to adjust it using branches on the primary side of the incandescent transformer.

ATTENTION: The lamp must be preheated for about an hour after the installation.

ATTENTION: The lamp must be preheated for about an hour after the installation.

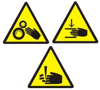

ATTENTION: Any work in within the zone of active pressing unit of the press, ie. device replacement can be executed with special precaution measurements only by trained service team.

ATTENTION: Any work in within the zone of active pressing unit of the press, ie. device replacement can be executed with special precaution measurements only by trained service team.

ATTENTION: Emergency stop of the machine is possible at any moment by pressing the EMERGENCY STOP button (the red button on yellow background).

ATTENTION: Emergency stop of the machine is possible at any moment by pressing the EMERGENCY STOP button (the red button on yellow background).

ATTENTION: The working environment of the machine, the floor and the manual holders and grips must be always clean and free of any contamination, grease or mud, in order to reduce the risk of slipping or falling to the minimum possible level.

ATTENTION: The working environment of the machine, the floor and the manual holders and grips must be always clean and free of any contamination, grease or mud, in order to reduce the risk of slipping or falling to the minimum possible level.

CAUTION: Unplug machine before removing any access panels or opening doors. All guards and access panels must be in place before operating this machine.

CAUTION: Unplug machine before removing any access panels or opening doors. All guards and access panels must be in place before operating this machine.

ATTENTION: The temperature of the electrode is up to 100 °C. Therefore, when touched one can be burnt.

ATTENTION: The temperature of the electrode is up to 100 °C. Therefore, when touched one can be burnt.

ATTENTION: The lamp contains rare-earth metals and rare-earth metal oxides that are highly toxic. In the event of breaking, the lamp must be disposed with utmost care and with the help of specialized services.

ATTENTION: The lamp contains rare-earth metals and rare-earth metal oxides that are highly toxic. In the event of breaking, the lamp must be disposed with utmost care and with the help of specialized services.

ATTENTION: High frequency welding machine is the source of non–ionic electromagnetic radiation. After installation of machine at buyer's place, non-ionic radiation measurement must be done. The radiation measurements should be done by authorized company.

ATTENTION: High frequency welding machine is the source of non–ionic electromagnetic radiation. After installation of machine at buyer's place, non-ionic radiation measurement must be done. The radiation measurements should be done by authorized company.

ATTENTION: High frequency welding machine must work in a firm working place as transposition requires new measurement of non-ionic radiation intensity.

ATTENTION: High frequency welding machine must work in a firm working place as transposition requires new measurement of non-ionic radiation intensity.

ATTENTION: It is forbidden for people with implanted pacemaker to stay in the zone of active radiation.

ATTENTION: It is forbidden for people with implanted pacemaker to stay in the zone of active radiation.

ATTENTION: Manufacturer suggest not to employ any pregnant or nursing woman in the zone of active non-ionic radiation.

ATTENTION: Manufacturer suggest not to employ any pregnant or nursing woman in the zone of active non-ionic radiation.

ATTENTION: Clear air filter in pneumatic installation at least once a month.

ATTENTION: Clear air filter in pneumatic installation at least once a month.

IT IS FORBIDDEN to execute any work at the welder by people without being previously trained in high frequency machine service and Industrial Safety regulations with the special consideration of possible risk coming from the machine.

IT IS FORBIDDEN to execute any work at the welder by people without being previously trained in high frequency machine service and Industrial Safety regulations with the special consideration of possible risk coming from the machine.  IT IS FORBIDDEN to turn on the machine by workers without being previously trained in service and Industrial Safety regulations.

IT IS FORBIDDEN to turn on the machine by workers without being previously trained in service and Industrial Safety regulations.  IT IS FORBIDDEN to turn on the machine by workers without being previously trained in service and Industrial Safety regulations.

IT IS FORBIDDEN to turn on the machine by workers without being previously trained in service and Industrial Safety regulations.  IT IS STRICTLY FORBIDDEN to execute any service or prevention work without previously disconnecting the generator and machine from power supply.

IT IS STRICTLY FORBIDDEN to execute any service or prevention work without previously disconnecting the generator and machine from power supply. IT IS STRICTLY FORBIDDEN to take up any attempts to touch electrodes or elements of pressing unit in press. Touching them while welding or may cause burns by high frequency current or high temperature ~ 100 oC.

IT IS STRICTLY FORBIDDEN to take up any attempts to touch electrodes or elements of pressing unit in press. Touching them while welding or may cause burns by high frequency current or high temperature ~ 100 oC.  IT IS STRICTLY FORBIDDEN to take up any actions that can decrease safety status of the machine, ie. working with open protection cover, blocking key buttons, etc.

IT IS STRICTLY FORBIDDEN to take up any actions that can decrease safety status of the machine, ie. working with open protection cover, blocking key buttons, etc. IT IS FORBIDDEN for pregnant or nursing woman to stay in the zone of active non-ionic radiation.

IT IS FORBIDDEN for pregnant or nursing woman to stay in the zone of active non-ionic radiation. IT IS STRICTLY FORBIDDEN for people with implanted pacemaker to stay in the zone of active non-ionic radiation.

IT IS STRICTLY FORBIDDEN for people with implanted pacemaker to stay in the zone of active non-ionic radiation. IT IS FORBIDDEN for people with metal-orthopedic implant to stay in the zone of active non-ionic radiation.

IT IS FORBIDDEN for people with metal-orthopedic implant to stay in the zone of active non-ionic radiation. IT IS FORBIDDEN to bring in the zone of active non-ionic radiation metal tools.

IT IS FORBIDDEN to bring in the zone of active non-ionic radiation metal tools. IT IS STRICTLY FORBIDDEN to fight any fire at the generator and machine using water or other liquid.

IT IS STRICTLY FORBIDDEN to fight any fire at the generator and machine using water or other liquid. IT IS STRICTLY FORBIDDEN to remove protection covers while the machine is operating.

IT IS STRICTLY FORBIDDEN to remove protection covers while the machine is operating. IT IS STRICTLY FORBIDDEN to hose down the machine during operate or go down the system.

IT IS STRICTLY FORBIDDEN to hose down the machine during operate or go down the system. IT IS FORBIDDEN to pour away oils, solvents or other toxic liquiud waste in the surroundings of operating machine.

IT IS FORBIDDEN to pour away oils, solvents or other toxic liquiud waste in the surroundings of operating machine. IT IS FORBIDDEN to use the cellphone in the surroundings of operating machine.

IT IS FORBIDDEN to use the cellphone in the surroundings of operating machine. IT IS FORBIDDEN to use fire in the surroundings of operating machine.

IT IS FORBIDDEN to use fire in the surroundings of operating machine. IT IS FORBIDDEN to smoke in the surroundings of operating machine.

IT IS FORBIDDEN to smoke in the surroundings of operating machine. IT IS FORBIDDEN to drink the alcohol in the surroundings of operating machine and operate all the devices by drunk workers.

IT IS FORBIDDEN to drink the alcohol in the surroundings of operating machine and operate all the devices by drunk workers. IT IS FORBIDDEN to consume in the surroundings of operating machine.

IT IS FORBIDDEN to consume in the surroundings of operating machine. IT IS OBLIGED to train each person that is to execute any work at the generator and press in machine service and Industrial Safety regulations with the special consideration of possible risk coming from the machine.

IT IS OBLIGED to train each person that is to execute any work at the generator and press in machine service and Industrial Safety regulations with the special consideration of possible risk coming from the machine. IT IS STRICTLY OBLIGED to use ALL designed protection covers and blocking key buttons.

IT IS STRICTLY OBLIGED to use ALL designed protection covers and blocking key buttons. IT IS OBLIGED to inform the supervisor and / or traffic personnel about any and all cases of incorrect operation of the machine.

IT IS OBLIGED to inform the supervisor and / or traffic personnel about any and all cases of incorrect operation of the machine. IT IS OBLIGED to use work clothes with minimal parts that can be caught or dragged by the press from high frequency machine.

IT IS OBLIGED to use work clothes with minimal parts that can be caught or dragged by the press from high frequency machine. IT IS OBLIGED to execute any work on welder elements (electrode, pressing unit) using special protection gloves.

IT IS OBLIGED to execute any work on welder elements (electrode, pressing unit) using special protection gloves. IT IS OBLIGED to use anti slide work shoes by workers.

IT IS OBLIGED to use anti slide work shoes by workers. IT IS OBLIGED to use headgear by workers.

IT IS OBLIGED to use headgear by workers. IT IS OBLIGED to keep the floor clean in the surroundings of operating machine.

IT IS OBLIGED to keep the floor clean in the surroundings of operating machine. IT IS STRICTLY OBLIGED to operate the welding machine by workers trained in high frequency machines service and Industrial Safety regulations.

IT IS STRICTLY OBLIGED to operate the welding machine by workers trained in high frequency machines service and Industrial Safety regulations. IT IS OBLIGED to immediately turn off the machine cases of incorrect operation using EMERGENCY STOP button.

IT IS OBLIGED to immediately turn off the machine cases of incorrect operation using EMERGENCY STOP button. IT IS STRICTLY OBLIGED to disconnect the generator and machine from any supply media before taking up any service or prevention work.

IT IS STRICTLY OBLIGED to disconnect the generator and machine from any supply media before taking up any service or prevention work. IT IS STRICTLY OBLIGED to discharge ceramic capacitors in high frequency generator. Even after being disconnected, they can maintain charge at voltage of several thousand Volt which can cause danger to life.

IT IS STRICTLY OBLIGED to discharge ceramic capacitors in high frequency generator. Even after being disconnected, they can maintain charge at voltage of several thousand Volt which can cause danger to life. The lamp must be always transported or moved in the original manufacturer’s packaging, in vertical position, with anode directed to the top or bottom, without any hitting or shaking the lamp.

The lamp must be always transported or moved in the original manufacturer’s packaging, in vertical position, with anode directed to the top or bottom, without any hitting or shaking the lamp.3.0 Technical Data

|

Machine type |

ZDW-15-K |

|

Welding materials |

PVC, PVC coated fabrics |

|

Power supply |

3 x 480 V; 50Hz |

|

PLC driver |

Delta |

|

Control voltage |

24 VDC |

|

Installed capacity |

22 kVA |

|

HF Power Output |

15 kW |

|

Output capacity adjustment |

manual/autotuner |

|

Main cut-out |

40 A; delayed |

|

Operating frequency |

27,12 MHz |

|

Frequency stability |

+/- 0,6 % |

|

Antiflash system, ZEMAT TG |

ultra-fast sensitive ARC sensor |

|

Compressed air consumption |

70 nl/cycle |

|

Compressed air pressure |

0,4-0,8 MPa |

|

Max. electrode length |

1200 mm |

|

Work table size |

1620 x 820 mm |

|

Pressure plate size |

1200 x 50 mm |

|

Actuator stroke |

~ 150mm |

|

Pressing electrode drive |

pneumatic |

|

Ground electrode drive |

pneumatic |

|

Pressure force (max) |

1200 kG |

|

Generator lamp |

ITL 12-1 |

|

Coolant |

air |

|

Machine weight |

~ 1100 kg |

|

Dimensions |

SEE APPENDICES |

4.0 Technical Description

The main element of the ZDW-15-K High Frequency Welder is the load-bearing structure made from the welded steel sheets and sections. All the other machine parts are mounted on the said structure. The load-bearing structure can be divided into two basic parts:

- The rear one where the high frequency generator along with the anode transformer and the switchbox are located. This part is encased in the removable shields protected by the limit switch-key.

The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

-

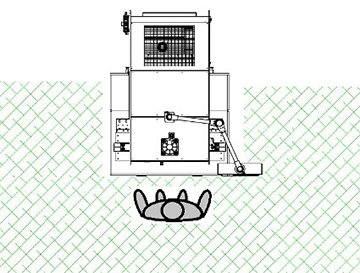

The fore one - the so called welding zone where the work table on which the operator positions the material during the welding procedure is supposed to be found. The weld is performed by the electrode which is pressed against the work table lined with the insulating pad (the divider in the form of the aluminum plate lined with the insulating pad can be also put into use in order to prevent any damage to the work table). The electrode is fixed into the automatic holder that is fastened to the actuator piston rod. The upper part of the electrode holder is attached to the machine’s construction with the help of thin brass sheets (mass). The welding electrode holder is equipped with the automatic clamp which is controlled with the help of the HMI touch-sensitive panel. Due to the automatic clamp the operator can change the electrode without using tools. The electrode is attached to the high frequency generator’s output with the help of the sheet (as wave-guide). The welding zone is protected from non-ionizing radiation by the movable grounding electrode which is pressed against the table during the weld procedure and as a result a kind of capacitor which is supposed to limit the non-ionizing radiation is created.

The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

The machine makes full use of the following systems:

- THE CONTROL ONE consisting of the PLC with the HMI touch-sensitive panel, controls and indicators placed on the main control panel attached to the extension arm and other electric and electronic apparatus installed on this machine; and

- THE COMPRESSED AIR ONE consisting mainly of the compressed air preparation set including: distribution valves and the pneumatic actuators; and

- THE GENERATING ONE consisting of high frequency self-excited generator of disintegration constants which consists mainly of the LC circuit of high Q factor set on 27.30MHz. The system consists also of the travelling-wave tube, the anode transformer, the filament transformer and the tube cooling system;

The welding electrode holder is equipped with an automatic grip system controlled from the HMI touch-panel. It allows for the tool free replacement of electrodes.

![]() The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

The machine has built in system (ZTG AntyCRUSH) designed to protect the operators' hands against crushing. When a hand or any object with a height different from the height of the welded material is placed under the welding electrode, the electrode is automatically pulled up during the pressing phase.

The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

The applied shields along with the switch-keys are supposed to minimize the emission of non-ionizing radiation. Operating the welder without the shields on is strictly FORBIDDEN!!!

Additionally, there is laser indicators installed on the machine’s chassis to provide easy positioning of the welded material on the work table.

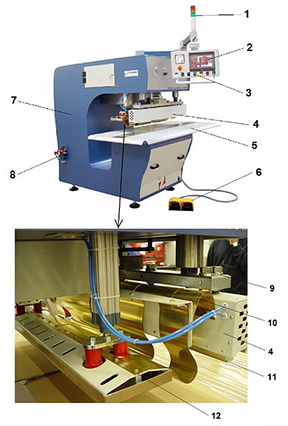

The basic parts of the machine:

- The signal light column;

- The HMI touch-sensitive paneI;

- The controls and indicators placed on the main control panel;

- The electrode clamp;

- The work table;

- The foot switch-keys;

- The load-bearing structure;

- The compressed air preparation set;

- The adjusting screw with the help of which the electrode should be adjusted parallely to the work table;

- Thin brass sheets (mass) with the help of which the upper part of the electrode is attached to the machine's construction;

- Welding electrode;

- Grounding electrode.

5.0 Assembly and Installation

5.1 Information and Signs of Restrictions and Imperatives

The Manufacturer provides appropriate packaging of the machine for the time of transportation. Packaging type and durability are adapted to the distance and the means of transport, and consequently to the potential risk of damages during transportation. The Manufacturer suggests that every Client uses the means of transport and technical service personnel of the Manufacturer.

Storage of the machine does not involve any particular requirements, apart from appropriate storage environment.

The storage room must ensure sufficient protection against weather factors, it should be as dry as possible and have an acceptable level of humidity (below 70%). It is also necessary to ensure appropriate protection against corrosion, particularly regarding metal components that are not painted for technical reasons.

If the machine is supplied in a box and is wrapped in plastic generating anti-corrosion atmosphere, the machine should stay wrapped and packed for the entire storage period.

For the purposes of protection against humidity, it is recommended that the machine is not stored directly on the floor of the storage room, but rather on pallets.

A component that requires special attention and handling at every stage – including storage – is the generator lamp (triode). The lamp must be stored in its original packaging, in vertical position, with anode directed to the top or bottom, in a dry room. The lamp is a high-vacuum, metal and ceramic component, which is extremely fragile and cannot be hit or dropped even from low height.

Hitting, dropping, shaking or tilting the lamp for a longer time may and usually do result in permanent and irreversible damaging of the lamp. In particular, the filament of the lamp - cathode can be broken, which in most extreme cases can lead to internal short circuits or lamp breaking.

ATTENTION: Manufacturer suggest not to employ any pregnant or nursing woman in the zone of active non-ionic radiation.

ATTENTION: Manufacturer suggest not to employ any pregnant or nursing woman in the zone of active non-ionic radiation.

The above provisions are meant to instruct and warn all persons and services that may have contact with this unit concerning its high vulnerability to all impulses and strokes. At the same time, no claims connected with permanent damages described above will be accepted in the course of the complaint procedure.

It should also be emphasized that the generator lamp is a very expensive component.

In the case of any doubts, it is recommended to consult the specialized staff of the Manufacturer.

5.2 Transportation of the machine

The party responsible for the transportation and installation of the machine in the Site of the Ordering Party should be determined at the stage of signing the contract and not later than after the final acceptance test of the machine in the Site of the Manufacturer, before the device is handed over to the Ordering Party.

ATTENTION: Careless handling of the device during transportation / moving may result in serious injuries or accidents.

ATTENTION: Careless handling of the device during transportation / moving may result in serious injuries or accidents.

IT IS FORBIDDEN to assembly, dismantle or transport the machine by personnel without proper qualifications or without being acquainted with safety requirements described in hereby Operation and Maintenance Manual. Such actions may cause accidents or material damage.

IT IS FORBIDDEN to assembly, dismantle or transport the machine by personnel without proper qualifications or without being acquainted with safety requirements described in hereby Operation and Maintenance Manual. Such actions may cause accidents or material damage.

Taking into account the specific character of the device, the Manufacturer suggests that every Ordering Party uses the means of transport and technical service personnel of the Manufacturer.

The power tube must be disassembled before any transportation or moving actions.

The lamp must be always transported or moved in the original manufacturer’s packaging, in vertical position, with anode directed to the top or bottom, without any hitting or shaking the lamp.

The lamp must be always transported or moved in the original manufacturer’s packaging, in vertical position, with anode directed to the top or bottom, without any hitting or shaking the lamp.

ATTENTION: The machine should be transported in vertical position.

ATTENTION: The machine should be transported in vertical position.

Due to its size and structure, the machine requires disassembly and disconnection of some components and units for the time of transportation or moving. It is necessary to disassemble fragile and expensive components and tools (which should be transported in a separate case). It is absolutely necessary to dismount the generator lamp.

The machine should be moved using lifting devices – cranes, fork-lift trucks, pallet trucks – with sufficient lifting capacity enabling safe transportation of the generator, whereas the people operating such lifting devices should have all valid licenses and qualifications required by law.

All components of the machine that might be damaged during transportation (if a packaging box of high durability is not used) or by lifting or moving devices should be appropriately secured (provided that they are disassembled and packed separately).

In order to ensure stable position of the device, it is very important to ensure appropriate protection of the machine for the time of long transportation (safety belts, anchor bolts), as well as protection and assistance during in-site transportation.

If the machine is not equipped with appropriate fittings, it is possible to use any other available holes or elements of sufficient durability can be used to ensure that the generator and other parts of the machine are properly balanced and stabilized.

Weight of the machine (about 1100 kg) must be definitely taken into account while planning the transportation.

5.3 Installation In The Place of Operation

Depending on the degree of complexity of the machine, the installation in the place of operation should be performed by the personnel of the Ordering Party, having read this Operation & Maintenance Manual or technical service staff of the Manufacturer, in cooperation with the personnel of the Ordering Party.

Please remember that appropriate positioning and installation of the welding machine is vital for ensuring its optimum functioning, as well as the comfort and safety of the operator in the device’s environment.

The Ordering Party is responsible for preparing the place for the installation of the device, availability and preparation of electrical connections and realization of the particular requirements of the technical design and technical acceptance tests approving the entire generator for use.

The Manufacturer will provide the Ordering Party with all the required instructions and information in this respect.

ATTENTION: Make sure that the floor / surface / foundations on which the machine is to placed have sufficient durability, taking into account the weight, surface and distribution of the machine weight to its points of support (usually legs).

ATTENTION: Make sure that the floor / surface / foundations on which the machine is to placed have sufficient durability, taking into account the weight, surface and distribution of the machine weight to its points of support (usually legs).

ATTENTION: The device must be properly leveled and must have fixed place of a operation.

ATTENTION: The device must be properly leveled and must have fixed place of a operation.

Optimum place of operation of the HF welding machine is the concrete surface not covered or covered with a very thin layer of non-conducting material.

The surface should be made in accordance with the particular design following construction and safety standards, as well as following the requirements concerning parallel, perpendicular and flat positions.

ATTENTION: The Ordering Party is solely responsible for the realization of the aforementioned conditions.

ATTENTION: The Ordering Party is solely responsible for the realization of the aforementioned conditions.

After the location of the welding machine in the selected place, it is necessary to level the machine, check its technical condition and remove any and all defects that might have occurred during transportation. Next, unpack, position, level and fix the generator. The high-frequency generator lamp should be mounted in the very end of the installation process. This task must be done with particular attention, both when mounting the lamp in the socket/base and when connecting the lamp’s electrical contacts. Connect the connectors of the control console to appropriately marked sockets on the press. It is recommended that the installation of the machine after transportation is performed under direct supervision of a representative of the manufacturer.

ATTENTION: If the aforementioned tasks are performed by a representative of the Client, they should be performed strictly in accordance with the description contained in this Operation & Maintenance Manual and / or instructions provided by the manufacturer during the technical acceptance test.

ATTENTION: If the aforementioned tasks are performed by a representative of the Client, they should be performed strictly in accordance with the description contained in this Operation & Maintenance Manual and / or instructions provided by the manufacturer during the technical acceptance test.

Due to the generated magnetic field, large metal items should not be placed near the machine. The machine can affect the operation of electronic devices (radio, TV sets, computers) located near the machine, as a result of high input sensitivity of the aforementioned devices. Optimum place of operation of the machine is the concrete surface not covered or covered with a very thin layer of non-conducting material.

5.4 Installation In The Place of Operation

5.4.1 Installation In The Place of Operation

ATTENTION: The Manufacturer strongly recommends to install the machine only in industrial environment.

ATTENTION: The Manufacturer strongly recommends to install the machine only in industrial environment.

The machine being the subject of this Operation & Maintenance Manual has been designed and manufactured for the purposes of work in the industrial environment for processing conveyor belts.

Specific conditions of operation of the devices, i.e. high air humidity, high temperature, steam and dust, have been taken into account by the designers of the machine and do not affect its operation, but determine more stringent requirements concerning the performance of preventive programmes.

The machine cannot be used in potentially explosive atmosphere, highly dusted atmosphere, environment with high humidity and / or high temperature and the presence of aggressive fumes (acidic, basic, organic or inorganic, having potentially or factually corrosive impact).

The temperature of the work environment should range between +10º C and +40º C and the relative humidity: between 30% and 90%. Condensation of atmospheric moisture or any aggressive substances on the surface of the machine (or any of its components) is not allowable.

It is required that the long-term temperature amplitude during the day in the generator operation room do not exceed 10º C and in the case of relative humidity: 10%.

The clause above does not apply to the media or substances used for greasing, preservation or non-aggressive substances used in the course of production / operation of the device.

ATTENTION: If there is large difference between the outside temperature and the temperature in the room where the machine is installed, the device should be started after 24 hours from its assembly in the room.

ATTENTION: If there is large difference between the outside temperature and the temperature in the room where the machine is installed, the device should be started after 24 hours from its assembly in the room.

5.4.2 Lighting

The requirements for the minimum luminous intensity state that on the horizontal operating area, illuminance that can be accepted in rooms where people stay for a longer time, regardless of whether there are any visual activities performed should be 300 lx.

In the case of visual activities whose difficulty level is higher than average and when highly comfortable seeing is required, as well as when the majority of operators are over 40 years old, the required luminous intensity should be higher the minimum, i.e. at least 500 lx.

5.4.3 Noise

The machine does not generate noise of the level that would require using any means or devices of personnel protection.

However, it must be remembered that all work environments have its own noise emissions, which might have impact on the level of noise emitted by the machine during its operation.

5.5 Connection Parameters

5.5.1 Electrical Enegry

Connection: 3 x 480V; 50Hz (3P+N+PE), overcurrent protection with delayed properties. The installation of the Client must ensure electric shock protection measures conforming to EN 60204-1:2001.

ATTENTION: Always check the filament voltage after installation the tube – see tube technical data.

ATTENTION: Always check the filament voltage after installation the tube – see tube technical data.

5.5.2 Compressed Air

Pressure: 0.4 – 0.8 MPa, demanded cleanness class according ISO8573-1 4-4-4, consumption: 70 nl per one cycle.

ATTENTION: If the pressure in the End User’s system is higher than 0.8 MPa, it must be reduced to about 0.6 MPa with a reducing valve mounted on the welding machine connection.

ATTENTION: If the pressure in the End User’s system is higher than 0.8 MPa, it must be reduced to about 0.6 MPa with a reducing valve mounted on the welding machine connection.

5.6 Connection Parameters

Depending on the complexity of the system and the qualifications and licenses of employees, the connection of the welding machine in the place of its operation is performed by people selected by the Ordering Party or technical service workers of the Manufacturer, in cooperation with the personnel of the Ordering Party, for an additional price or free of charge, which is always arranged before the machine is handed over to the Ordering Party from the site of the Manufacturer.

It is always necessary to check whether all connections have been performed in accordance with the documentation of the device.

It must be stated that the aforementioned tasks require appropriate qualifications of the personnel, including applicable licenses issued by the appropriate bodies.

It applies both to specialised qualifications, as well as completed and valid training courses in Occupational Health & Safety, including particularly the risks involved in those tasks.

6.0 Operation

6.1 Preparation of the Machine for Operation - First Start Up

ATTENTION: In order to use the machine in an optimum and safe way, please read carefully and follow all the instructions included in this Operation & Maintenance Manual.

ATTENTION: In order to use the machine in an optimum and safe way, please read carefully and follow all the instructions included in this Operation & Maintenance Manual.

IT IS FORBIDDEN to execute any work at the welding machine by people without being previously trained in high frequency machines service and Industrial Safety regulations with the special consideration of possible risk coming from the machine.

IT IS FORBIDDEN to execute any work at the welding machine by people without being previously trained in high frequency machines service and Industrial Safety regulations with the special consideration of possible risk coming from the machine.

Provided that all the installation requirements have been met and the tasks described in Item 5 have been performed, we are ready to start the welding machine for the first time in the production environment of the site of the Ordering Party.

ATTENTION: The first start-up of the machine should be performed in the presence and under supervision of the representatives of the Manufacturer.

ATTENTION: The first start-up of the machine should be performed in the presence and under supervision of the representatives of the Manufacturer.

6.2 Operating Requirements - General Instructions and Guidelines

All adjustments and calibration required for the correct device operation parameters have been done by the Manufacturer during the assembly and internal test procedures. General conformity with contractual technical requirements and correct operation of the machine are confirmed during the technical acceptance taking place in the site of the Manufacturer, in the presence of a representative of the Ordering Party and using original raw materials delivered by the Ordering Party for the testing purposes.

ATTENTION: Due to the specific properties of the devices that emit high-frequency energy, it is necessary to carry out certain measurements in the place of the device’s operation in the site of the Ordering Party. For the same reason, it is very important that the machine has a fixed place of operation.

ATTENTION: Due to the specific properties of the devices that emit high-frequency energy, it is necessary to carry out certain measurements in the place of the device’s operation in the site of the Ordering Party. For the same reason, it is very important that the machine has a fixed place of operation.

BEFORE OPERATION IS ABSOLUTELY NECESSARY TO CONTROL:

- Effectiveness of electric shock protection measures;

- Power supply voltage – value and correctness of phases connection;

- Direction of engine rotation (if applicable);

- Incandescent filament lamp voltage;

ATTENTION: The lamp voltage must be the same as specified in the datasheet of the product – it is possible to adjust it using branches on the primary side of the incandescent transformer.

ATTENTION: The lamp voltage must be the same as specified in the datasheet of the product – it is possible to adjust it using branches on the primary side of the incandescent transformer.

ATTENTION: Due to the specific character of the device, it is always necessary to warn and inform the personnel about high power supply voltage of the lamp’s anode and the potential risk of fatal electric shock by electric current of the voltage of up to 8000 VDC.

ATTENTION: Due to the specific character of the device, it is always necessary to warn and inform the personnel about high power supply voltage of the lamp’s anode and the potential risk of fatal electric shock by electric current of the voltage of up to 8000 VDC.

ATTENTION: The lamp must be preheated for about an hour after the installation.

ATTENTION: The lamp must be preheated for about an hour after the installation.

- Position of the holder to the base of the working table;

- Emission of electromagnetic field – after the adjustment of welding parameters, during the welding process;

ATTENTION: High frequency welding machine is the source of non–ionic electromagnetic radiation. After installation of machine at buyer's place, non-ionic radiation measurement must be done. The radiation measurements should be done by authorized company.

ATTENTION: High frequency welding machine is the source of non–ionic electromagnetic radiation. After installation of machine at buyer's place, non-ionic radiation measurement must be done. The radiation measurements should be done by authorized company.

ATTENTION: Machine must work in a firm working place as transposition requires new measurement of non-ionic radiation intensity.

ATTENTION: Machine must work in a firm working place as transposition requires new measurement of non-ionic radiation intensity.

ATTENTION: It is forbidden for people with implanted pacemaker to stay in the zone of active non-ionic radiation.

ATTENTION: It is forbidden for people with implanted pacemaker to stay in the zone of active non-ionic radiation.

ATTENTION: The Manufacturer suggest not to employ any pregnant or nursing woman in the zone of active non-ionic radiation.

ATTENTION: The Manufacturer suggest not to employ any pregnant or nursing woman in the zone of active non-ionic radiation.

IMPORTANT: If the high-voltage circuits have been accidentally connected when the anode is disconnected or the generator lamp is defective, the high-voltage filter condensers must be discharged by short-circuiting them with the casing for a very short time.

IMPORTANT: If the high-voltage circuits have been accidentally connected when the anode is disconnected or the generator lamp is defective, the high-voltage filter condensers must be discharged by short-circuiting them with the casing for a very short time.

ATTENTION: All activities during the start-up and measurements, when the safety level is lower (open protection screens, blocked key switches), must take as little time as possible, and the full machine operation safety level must be ensured as quickly as possible.

ATTENTION: All activities during the start-up and measurements, when the safety level is lower (open protection screens, blocked key switches), must take as little time as possible, and the full machine operation safety level must be ensured as quickly as possible.

ATTENTION: All control & measurement activities must be performed after checking whether the switches for anodic voltage adjustment are in 0 – OFF position (it does not apply to measurement of the emission of electromagnetic field).

ATTENTION: All control & measurement activities must be performed after checking whether the switches for anodic voltage adjustment are in 0 – OFF position (it does not apply to measurement of the emission of electromagnetic field).

ATTENTION: All control & measurement activities must be performed exclusively by authorised personnel.

ATTENTION: All control & measurement activities must be performed exclusively by authorised personnel.

IT IS ALWAYS PROHIBITED to start the welding process, i.e. turn on the high voltage of the lamp, which initiates the high-frequency voltage on the insulated holder of the electrode, when the safety level of the device operation is reduced.

IT IS ALWAYS PROHIBITED to start the welding process, i.e. turn on the high voltage of the lamp, which initiates the high-frequency voltage on the insulated holder of the electrode, when the safety level of the device operation is reduced.

The machine is adapted to work in the automatic cycle. Automatic mode is the standard mode of operation of the device during the production process.

The high frequency welding machine enables the operation in the manual mode for adjustment purposes.

Machine operators should always wear standard work clothes and anti-slip footwear.

The working environment of the device, the floor and the manual holders and grips must be always clean and free of any contamination, grease or mud, in order to reduce the risk of slipping or falling to the minimum possible level.

Never use the machine of operation without the fixed or mobile protection elements. Check regularly whether all protection screens and all other protection elements are properly mounted and function properly.

Only authorized persons, who are properly trained in the machine operation and Occupational Health & Safety, can have direct contact with the machine.

Each operator of the device must be instructed on the functions of the protection elements of the machine and their proper use.

In the area surrounding the device (about 1.5 m around the generator and press), there can be no items that might interfere with the operation of the device. This area must be kept clean and have proper lighting.

Never use the machine’s manipulators or flexible pipes as holders. Please remember that any accidental moving of the device’s manipulator can accidentally start the welding process, change parameters or even cause the failure of the machine or damage its tools.

IT IS OBLIGED to inform the supervisor and / or traffic personnel about any and all cases of incorrect operation of the device.

IT IS OBLIGED to inform the supervisor and / or traffic personnel about any and all cases of incorrect operation of the device.

6.3 Controls and Indicators Available For Operator

All welder’s controls and indicators can be easily found either on its construction or on its control desk. Before getting down to work, the machine operator should acquaint themselves with the arrangement of the controls and indicators on the machine as long as with the functions they control.

The complete list of the above mentioned controls and indicators available for the operator is attached below:

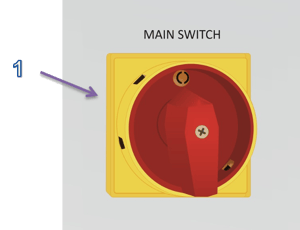

- MAIN SWITCH - a switch (Fig.3) designed for switching on or off the electricity supplies. 1-ON position means that the switch is switched on whereas the 0-OFF position means that the switch is switched off.

- HMI PANEL – the touch-sensitive panel (Fig.5) should be used for changing the machine’s setting parameters and it is supposed to become a reliable source of information about the current state of the welding machine. See chapter 5. for more information about performing the servicing procedure applying to the touch-sensitive panel.

- POWER – an indicator, which flashes white when the machine is connected to the power supply (Fig.5).

- RESTART – the blue push-button (Fig.5) which should be used to restart the machine control and protection system whenever the alarm message is displayed on the HMI panel.

- HF OFF/ON – a switch with the help of which the HF current can be released or put on hold (when it is in OFF position it means that the HF weld cannot be performed)

As long as the standard welding procedure is concerned the HF OFF/ON switch should be in ON position.When the HF OFF/ON switch is turned to OFF position it means that the duty cycle can be performed without releasing the HF current.

As long as the standard welding procedure is concerned the HF OFF/ON switch should be in ON position.When the HF OFF/ON switch is turned to OFF position it means that the duty cycle can be performed without releasing the HF current. - ELECTRODE UP/DOWN – a joystick with the help of which the electrode can be either lifted up or lowered (Fig.5).

- HF - when the indicator flashes yellow it means that the HF welding process is on (Fig.5).

- STOP HF – the red push-button (Fig.5) is designed for switching off the process of high frequency welding.

- START HF – the red push-button (Fig.5) is used for switching on the process of high frequency welding.

- EMERGENCY STOP - the red mushroom-headed push-button (Fig.5) it is a button that should be pressed only when the functions of the machine need to be halted immediately or when anything regarding the machine’s functions or the operator’s surroundings pose a threat to the production or safety.

The EMERGENCY STOP button should not be overused, it is supposed to be used only in case of emergency.

The EMERGENCY STOP button should not be overused, it is supposed to be used only in case of emergency. - ANODE CURRENT - the panel ammeter (Fig.5) is supposed to indicate the value of current intensity in La anode circuit and should enable the operator to conduct the vision inspection of the welding process (The Generator Full-load Characteristics).

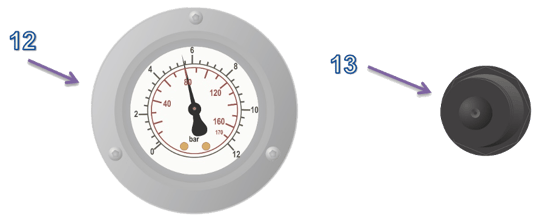

- PRESSURE – manometer (Fig. 6) is supposed to indicate the level of pressure of the compressed air in the pneumatic system with the help of which the electrode is pressed against the table.

- PRESSURE SETTING – a hand-setting knob of a pressure reducing valve (Fig. 6) is a knob used for setting the level of pressure in the pneumatic system with the help of which the electrode is pressed against the table. (Pull the knob and: a turn to the right – the level of pressure should rise, and a turn to the left – the level of pressure should drop);

![]() The level of pressure in the pneumatic system with the help of which the electrode is pressed against the table never exceeds the level of pressure propelling the machine.

The level of pressure in the pneumatic system with the help of which the electrode is pressed against the table never exceeds the level of pressure propelling the machine.

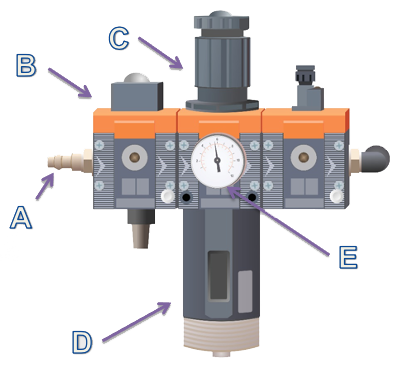

14. COMPRESSED AIR PREPARATION SYSTEM – consists of:

- The compressed air terminal into which the compressed air hose should be connected. The hose is supposed to provide the system with the compressed air ranging from 0.4 to 0.8 MPa;

- The manually operated compressed air shut-off valve (in order to open the valve - turn it to the left and set to ON position; a turn to the right - the OFF position - the valve is closed);

- The manually operated pressure reducing valve is a valve used for a pressure setting in the machine’s pneumatic system (pull the valve up and turn: a turn to the right - higher pressure, a turn to the left - lower pressure), the rated operating pressure of the machine totals to 0.6 MPa;

The level of pressure in the pneumatic system never exceeds the level of pressure propelling the machine.

The level of pressure in the pneumatic system never exceeds the level of pressure propelling the machine. - The compressed air filter along with the condensation water release mechanism;

- The manometer indicating the level of pressure in the machine’s compressed air system;

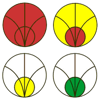

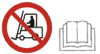

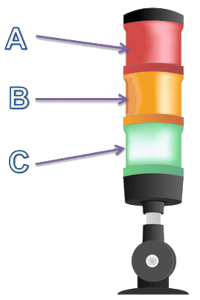

- Red color indicates failure and at the same time the alarm message should be displayed on the HMI touch-sensitive panel.

The alarm massages are deleted and the red light on the signal light column stops flashing when the RESTART button is pressed. In case the efforts were put in vain and the alarm message has not been deleted when the RESTART button had been pushed so it might mean that the cause of failure occurrence had not been removed yet. See chapter 0. for further information applying to the alarm massages.

The alarm massages are deleted and the red light on the signal light column stops flashing when the RESTART button is pressed. In case the efforts were put in vain and the alarm message has not been deleted when the RESTART button had been pushed so it might mean that the cause of failure occurrence had not been removed yet. See chapter 0. for further information applying to the alarm massages. - Orange color indicates that the high frequency welder starts operating.

- Green color indicates that the machine is ready for work.

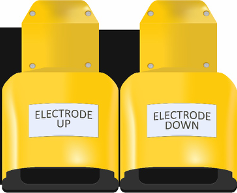

Fig.9. The foot switch-keys:,

Fig.9. The foot switch-keys:,

17. ELECTRODE DOWN – a foot switch-key is a tool used for lowering the electrode.

As the aforesaid system needs to work flawlessly it is strongly recommended to perform the adjustment of the height limiter in such a way that it should indicate the lower position of the electrode. Inappropriate setting of the height control slide of the limit switch may result in both a self-triggered emergency lifting of the electrode and the appearance of the following alarm message on the HMI display: EMERGENCY ELECTRODE UP.

As the aforesaid system needs to work flawlessly it is strongly recommended to perform the adjustment of the height limiter in such a way that it should indicate the lower position of the electrode. Inappropriate setting of the height control slide of the limit switch may result in both a self-triggered emergency lifting of the electrode and the appearance of the following alarm message on the HMI display: EMERGENCY ELECTRODE UP.The procedure of appropriate adjustment of height control system:

- Put the chosen electrode in the holder and close the HMI holder → Options → electrode → closed,

- Position the material on the work table – as for welding,

- Lower the holder with the electrode upon the material (in such a way that the electrode should only touch the material without adding any pressing force) and leave it,

- Loosen two clamping screws that clamp the limit switch and when they are loose, move the limit switch in such a way that its roll should be on the electrode’s height indicator (Fig.9), then unscrew the clamping screws that clamped the switch.

- Lift the electrode’s holder to its upper position,

- Lower the electrode’s holder, press it against the material and check if the switch roll stops on the electrode’s height indicator. If the protection system against squeezing is put into practice and as a result the electrode is being lifted up to its upper position it means that the lower position of the limit switch needs to be readjusted.

ATTENTION! Manipulation with the limit switch indicating the lower position of the electrode excluding the one quoted above is strictly forbidden. Disregarding the manufacturer’s warning may lead to the severe machine failure and as a result to serious body injuries.

ATTENTION! Manipulation with the limit switch indicating the lower position of the electrode excluding the one quoted above is strictly forbidden. Disregarding the manufacturer’s warning may lead to the severe machine failure and as a result to serious body injuries.

Fig.10. Limit switch indicating the lower position of the electrode.

Fig.10. Limit switch indicating the lower position of the electrode.

6.5 Programming and Operating the HMI Touch-Sensitive Panel

ATTENTION! Each value of the parameter depicted on the graphics of this manual is taken at random and should be disregarded by the machine’s operator. The values of the parameters should derive from user’s practical experience as they may vary profoundly according to the type of welded material or implemented instrumentation.

ATTENTION! Each value of the parameter depicted on the graphics of this manual is taken at random and should be disregarded by the machine’s operator. The values of the parameters should derive from user’s practical experience as they may vary profoundly according to the type of welded material or implemented instrumentation.

![]() In the HMI panel all editable values of the parameters are displayed on a white colour background. In order to display a parameter the user needs to press its value and as a result the on-screen keyboard should be opened. Data can be saved by pressing Enter key.

In the HMI panel all editable values of the parameters are displayed on a white colour background. In order to display a parameter the user needs to press its value and as a result the on-screen keyboard should be opened. Data can be saved by pressing Enter key.

6.5.1 Connection to Power Source

Shortly after the machine is connected to a power source on the HMI display an alarm window appears along with the following message:

EMERGENCY STOP

According to this situation, the machine needs to be restarted so the blue RESTART key should be pressed. Then we need to wait for 30 seconds till the machine is ready for work and enters a stand-by mode which we know due to the following facts: a light indicator in the light signal column flashes green and the progress bar displayed in the HMI main window flashes green. In case the alarm massage does not disappear from the HMI display see chapter 0.

6.5.2 Alarm Messages

When a machine failure occurs or when one of the protection systems is switched on or when some other abnormalities in machine’s functioning are detected then one of the alarm messages is going to be displayed on the HMI touch-sensitive panel. All alarm messages are deleted with the help of the RESTART key.The types of alarm massages:

EMERGENCY STOP – this kind of message is displayed when:

- the machine is switched on - the machine’s safety circuit must be always checked when the RESTART key is pressed,

- the red mushroom-headed EMERGENCY STOP push-button was pressed and has been jammed. It needs to be unstuck by turning its head to the right.

- one of the shields was taken off - the shields are equipped with the key- switches that turn themselves on only if the shields are appropriately placed and tightened,

CHECK RESET CIRCUIT IN SAFETY RELAY – means that the safety circuit of the machine has probably been damaged. The manufacturer’s service should be contacted in such a case.

SAFETY VALVE DAMAGE – means that an irregularity has occurred in the action of the valve which raises the electrode into its upper position as in the case of a break-down. The manufacturer’s service should be contacted in such a case.

LOW AIR PRESSURE IN SUPPORTING CYLINDERS – means that air pressure in the servomotors supporting the electrode is too low which can result in a rapid lowering of the electrode and it hitting the bench. Adjustment of the compressed air pressure in the circuit of these servomotors should be carried out.

WELDING PARAMETERS NOT REACHED – the machine's control software includes an algorithm which checks whether each partial weld has been properly carried out. If, during the welding, the parameters set out have not been achieved or if welding has been stopped before the task has been completed, the above message will be displayed. The quality of the weld will then be checked and if unsatisfactory, the task must be repeated.

ELECTRODE TEMPERATURE – this message signals that the maximum permissible electrode temperature (80oC) has been exceeded – the machine will be disabled into emergency mode. You should wait until the electrode cools and then check whether the temperature setting on the temperature controller is too high. Another possible option is that the electrode's warm up circuit has broken down. The manufacturer’s service should be contacted in such a case.

TUBE TEMPERATURE – this type of massage means that either the travelling-wave tube cooling does not exist or that the cooling system failure occurs and it is displayed when:

- the fuses that are supposed to protect the power supply circuit of the fan which should cool down the travelling-wave tube are disconnected;

- the contactor that is supposed to trigger the fan that should cool down the tube is either turned off or damaged;

- the tube thermal protection system is put into operation which means that the travelling-wave tube got heated up to too high temperature and as a result the tube band cotter pin that had been connected to the limit switch by a cord got unsoldered.

Fig.11. The tube thermal protection system.

Fig.11. The tube thermal protection system. - A cotter pin is soldered to a tube band with the help of a solder of melting point much lower than the one at which the tube got overheated (got damaged). If the lamp temperature rises too much the cotter pin will fall out of the band and as a result the limit switch will be triggered, simultaneously the alarm message will be displayed and the power supply for a glow in the tube will be cut off. Then the cause of overheating should be removed.

ATTENTION! The cord should not be fastened to any other parts of the machine but the cotter pin of the band which had been screwed to the tube. Disregarding the quoted warning can result in a limit switch blockage which may lead to the travelling-wave tube overheating and in consequence of such proceeding to its damage.

ATTENTION! The cord should not be fastened to any other parts of the machine but the cotter pin of the band which had been screwed to the tube. Disregarding the quoted warning can result in a limit switch blockage which may lead to the travelling-wave tube overheating and in consequence of such proceeding to its damage.

![]() If the cotter pin gets separated from the band than the band should be taken off from the tube, the pin should be soldered to the band with the standard solder used in electronic engineering (Melting point < 190oC) so as to the repaired part could be reattached to the tube.

If the cotter pin gets separated from the band than the band should be taken off from the tube, the pin should be soldered to the band with the standard solder used in electronic engineering (Melting point < 190oC) so as to the repaired part could be reattached to the tube.

The tube overheating can be caused by:

- the dirt found either in the generator or in the tube radiator;

- the failure of the tube cooling fan or the failure of the fan power supply system;

- the blockage of the machine’s ventilating holes or by the excessive amount of soil collected by the filters installed in the ventilating holes;

- the excessive ambient temperature.

ANTIFLASH – this type of massage means that the protection system against an arc-over while welding was triggered - due to this message make sure neither the insulating pad, welded material nor the welding electrode had not been damaged.

ANODE OVERLOAD – this message means that the anode-rise limit was exceeded so the parameters applying to the power released in weld need to be adjusted.

GRID OVERLOAD – this message means that the grid-rise limit was exceeded so the parameters applying to the power released in weld need to be adjusted.

LOW AIR PRESSURE – this message means that there is lack of air pressure or the level of air pressure is too low in the pneumatic system. Make sure the hose providing the compressed air is connected to the machine or the level of compressed air is appropriate and then with the help of pressure reducing valve regulator which can be found in the compressed air preparation system adjust the pressure in the machine to the adequate level.START CAPACITOR POSITION NOT ACHIVED – the message will be displayed if the capacitors do not reach the preset position within 30 seconds. Check the capacitor drive.

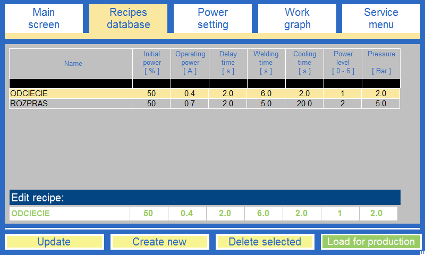

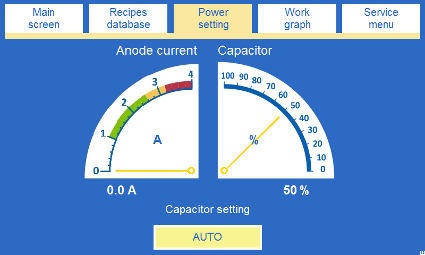

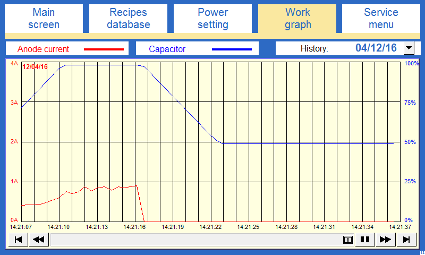

THE ELECTRODE IS NOT IN THE LOWER POSITION - an alarm message will be displayed if the START button is pressed and the electrode is not in the lower position. Lower the electrode.Menu can be found in the upper part of the HMI touch-sensitive display panel with the help of which the User can choose one out of five main virtual windows such as:

- Main screen

- Recipes database

- Power setting

- Work graph

- Service menu

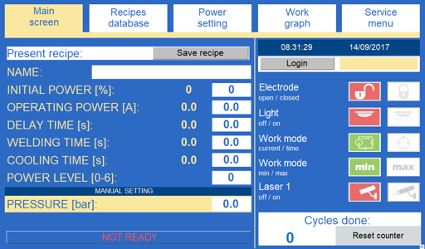

6.5.4 Main Screen

Fig.12. Main screen.

Fig.12. Main screen.

Recipe - under this name a group of parameters applying to the duty cycle can be found. Once the welding parameters for the particular kind of product deriving from practical experience (the parameters’ values strongly depend on the size of weld, the size of welded material and the electrode’s shape) are established they should be entered in the system and saved under the recipe’s name.

![]() Additionally, two values next to each parameter’s name can be also found on the HMI display. The first one (on the blue background) is the value of present operating parameter displayed in the actual time, the second one (on the white background) is the set value coming from the production recipe or the operator’s data.

Additionally, two values next to each parameter’s name can be also found on the HMI display. The first one (on the blue background) is the value of present operating parameter displayed in the actual time, the second one (on the white background) is the set value coming from the production recipe or the operator’s data.

![]() Should the need arise, the operator can always press the digit on the white background and change its value. The value of present operating parameter will be updated at once, though, the change does not affect the executed recipe.

Should the need arise, the operator can always press the digit on the white background and change its value. The value of present operating parameter will be updated at once, though, the change does not affect the executed recipe.

![]() In order to save those changes to a recipe which were made using the Main screen, press the SAVE RECIPE button to copy the parameters from the main screen to the Edit recipe bar in the Recipe database window. The parameters copied may be saved as a new recipe using the Create new button or they can be used to update an existing recipe using the Update button.

In order to save those changes to a recipe which were made using the Main screen, press the SAVE RECIPE button to copy the parameters from the main screen to the Edit recipe bar in the Recipe database window. The parameters copied may be saved as a new recipe using the Create new button or they can be used to update an existing recipe using the Update button.

Name: - the recipe’s name executed for production purposes.

Initial power – this parameter indicates the position (capacity) of the output capacitor found in the generator; the anode current intensity in the initial phase of high frequency weld strongly depends on the value of this parameter. (Parameter expressed in percentage values, where 0% indicates the lowest level of capacity - the lowest level of anode current intensity and 100% indicates the highest level of capacity - the highest level of anode current intensity.)

![]() The parameter’s value of Initial power and the value of anode current (power released in material) are not linearly dependent as a result the appropriate precautionary measures should be taken when adjusting values of this parameter.

The parameter’s value of Initial power and the value of anode current (power released in material) are not linearly dependent as a result the appropriate precautionary measures should be taken when adjusting values of this parameter.

![]() The current value of Initial power parameter and the value of set parameter are equal to each other only in the initial phase of the welding procedure. When the procedure is initiated, the output capacitor’s position is automatically adjusted in order to achieve Operating power.

The current value of Initial power parameter and the value of set parameter are equal to each other only in the initial phase of the welding procedure. When the procedure is initiated, the output capacitor’s position is automatically adjusted in order to achieve Operating power.

Operating power – this parameter indicates Ia anode current used for welding. (Parameter expressed in ampere values ranging from 0 to 4 A.)

![]() Values in green colour on the Anode current meter’s scale indicate the acceptable values of the Ia anode current.

Values in green colour on the Anode current meter’s scale indicate the acceptable values of the Ia anode current.

![]() When the welding procedure is initiated the output capacitor (Initial power) is automatically adjusted so as to achieve the Operating power.

When the welding procedure is initiated the output capacitor (Initial power) is automatically adjusted so as to achieve the Operating power.

Delay time – this parameter indicates time during which the electrode had adhered to the welded material before the weld was initiated. (Parameter expressed in second values ranging from 0 to 99 s .)

Welding time – this parameter means time the machine takes to process the high frequency weld. (Parameter expressed in second values ranging from 0 to 99 s .)

Cooling time – this parameter indicates time in which the electrode was being pressed against the welded material after the weld had come to an end - material cools down being pressed against the table. (Parameter expressed in second values ranging from 0 to 99 s .).

Power level – is the main setting of the machine's power; adjustment is carried out by changing the anode voltage Ua in the range from 1 to 6 where 1 is low power and 6 is maximum power:

0 - the anode transformer is disconnected;

1 – Ua = 3,4kV;

2 – Ua = 3,95kV;

3 – Ua = 4,75kV;

4 – Ua = 5,87kV;

5 – Ua = 6,85kV;

6 – Ua = 8,2kV;