This instruction manual is intended to be a guide when operating the T2 Extreme Seam welder. To ensure optimal performance from your welder, please follow the recommendations and specifications precisely.

Table of Contents

- Chapter 1: Intended Use

- Chapter 2: Explanation of Warnings

- Chapter 3: Electrical Requirements

- Chapter 4: Principles of Heat Sealing

- Chapter 5: Definition of Controls

- Chapter 6: Operation

- Chapter 7: Adjustment

- Chapter 8: Welding Tips

- Chapter 9: Guides

- Chapter 10: Maintenance

- Chapter 11: Recommended Replacement Parts

- Chapter 12: Transportation and Storage

- Chapter 13: Additional Machine Documents

For more technical information regarding this machine call our Resolution Center at 1-855-888-WELD or email service@weldmaster.com.

1.0 Intended Use

The T2 is a rotary hot wedge welding machine intended to heat-seal weldable thermal plastics such as:

- Vinyl (PVC) laminated and coated fabrics

- Vinyl (PVC) and Polyurethane (PU) films

- Polyurethane (PU) and Polypropylene (PP) coated fabric

- Polyethylene (PE)

- Thermoplastic rubber (TPR) film and fabrics

- Non-woven Polyester and Polypropylene

- Various Fusing Tapes

- Weldable Webbing

- Rigid Extruded Products

The manufacturer does not approve of:

- Any other uses for these machines.

- The removal of any safety guards while in operation.

- Unauthorized modification of the machines.

- Using replacement parts that are not manufacturer-approved.

Only a properly-trained technician may operate and/or perform any routine maintenance orrepairs to the machines.

Only a properly-trained technician may operate and/or perform any routine maintenance orrepairs to the machines.

NOTE: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

2.0 Explanation of Warnings

There are several different warning symbols placed on the Miller Weldmaster T3. The symbols are to alert the operator of potentially hazardous areas on the machine. Familiarize yourself with their placement and meaning.

Caution: Unplug Machine

The “Caution: Unplug Machine” sticker is placed near the opening of the cabinet and all access panels. To prevent electrocution, the machine should always have the power disconnected before the cabinet door is open.

Caution: Electricity

The “Caution: Electricity” sticker is placed near areas that contain electrical.

Caution: Read Document

Read accompanying documentation before use.

3.0 Electrical and Air Requirements

Warning! Only a qualified electrician may connect the electrical power.

Electrical Supply

Due to the number of different style outlets available, the cord will not include a plug. It is recommended that your electrician install a plug that is compatible to your style power outlet. You may choose to have your power cord hard-wired into your power supply. It

is recommended that your electrician use a junction box with an ON/OFF switch with short circuit protection as required by local electrical code to be suitable for the primary disconnect. The Miller Weldmaster T-3 requires the following power supply.

•15 Amperes - Single phase - 110/220 Volts

4.0 Principals of Heat Sealing

Heat

Hot Air Heating System

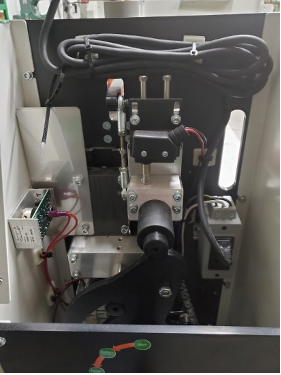

The Heat required for the welding operation is created electrically by one heating element located inside the Heat Element Housing. The Internal Air Compressor pumps air over the heat element and carries the heat through the Hot Air Nozzle, applying the heat to the material to be welded. The hot air temperature ranges from 25 to 600 Degrees Celsius (100 to 1,200 Degrees Fahrenheit).

Speed

The Speed of the Weld Rollers determines the amount of time the heat is applied to the material being welded. The slower the speed setting, the more the material will be heated. The faster the speed setting, the less the material will be heated. To achieve the best weld, a minimal amount of heat should be applied to the material while still achieving a full weld. Too much heat will cause distortion of the material; while not enough heat will prevent the material from welding.

Pressure

The pressure of the weld roller is the final step when creating a weld. The pressure of the weld roller compresses the heated material together completing the welding process.

Summary

When heat sealing, the correct combination of heat, speed, and pressure will allow you to achieve a properly welded seam.

Start Position: With the Lever in the start position the heat nozzle will be swung out and in a paused state.

Start Position: With the Lever in the start position the heat nozzle will be swung out and in a paused state.

Rollers Open/Close: With the Lever in Rollers Open/Close position, closes the upper weld roller clamping the material into place.

Rollers Open/Close: With the Lever in Rollers Open/Close position, closes the upper weld roller clamping the material into place.

Nozzle Swing In/Out: Moving the Lever into Nozzle Swing In/Out will initiate the nozzle to swing into place and weld rollers to begin rotating.

Nozzle Swing In/Out: Moving the Lever into Nozzle Swing In/Out will initiate the nozzle to swing into place and weld rollers to begin rotating.

Air On/Off: On and off toggle switch.

Air On/Off: On and off toggle switch.

Temperature Knob: Spinning the knob clockwise increases temperature. Spinning the knob counterclockwise decrease temperature.

6.0 Operation

NOTE: Before starting up the machine, please check it carefully and guarantee that there are no foreign objects under the welding area. Be sure the surrounding area of the machine is free of flammable debris. Only authorized persons are permitted to use machine.

Start Up

1. (Ensure machine start control lever is in "Start" position.) Connect the power cord to the appropriate power supply.

2. Check Nozzle, Weld Roller and Guide Alignment

3. Turn the hot air power switch to ON (-).

4. Spin temperature knob to desired set temperature and allow heat to rise to the desired set temp.

5. Check Nozzle alignment after heat system is at desired temp.

6. Input material into weld rollers and begin welding.

Shut Down:

1. Turn the temperature knob tot he lowest temp setting (0). Allow air temp. coming out of the nozzle to reach an ambient temperature.

2. Switch the hot air power switch to OFF (0).

3. Unplug machines power cord and/or main breaker is turned off.

Hot Air Nozzle Adjustment

Hot Air Nozzle placement is an important component with Hot Air welding. When the Hot Air system swings in, it is imperative that the point of the nozzle is blowing hot air directly into the pinch point of the weld rollers. Before adjusting the hot air nozzle be sure the material guide is removed to allow it to swing into place and to allow you to make adjustments freely.

Hot Air Nozzle Adjustment

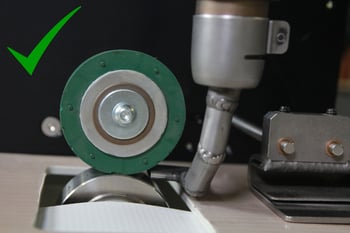

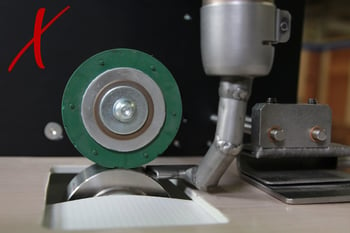

Before checking the Hot air nozzle alignment, set the speed control to a low setting, and close the weld rollers.

- Swing the hot air nozzle into place by rotating the control lever into the Nozzle Swing In/Out position. Once the hot air nozzle swing has reached the weld position, view the placement of the hot air nozzle with respect to the weld rollers then rotate the control lever back to the start position.

- Ensure nozzle is square with the weld rollers and blowing directly and straight into the pinch point of the rollers.

- If the height of the hot air nozzle is high or low of the pinch point an adjustment will be required.

- To adjust the Nozzle alignment the wedge must first be in the home position.

- Loosen the single Phillips head screw holding the nozzle to the hot air system and proceed with making adjustments. (Ensure the Heat system is cool, not checking this can result in injury.)

- Proceed with making adjustments and begin welding.

Bad Weld

This is not a good weld. Although the fabric is somewhat welded, it is not what could be considered 100%. One of two things must happen for this weld to become accepted. Either the speed must be decreased or the heat must be increased.

Good Weld

This is a good weld. The fabric is welded 100%. You can see the fabric is delaminating over the entire width of the seam.

Uneven Fabric Tension

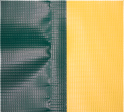

This is an example of too much tension held on the top fabric panel. It is important for the operator to hold even (equal) tension on both the top and bottom fabric panels as the machine is welding. As illustrated the green panel goes through the left side (top) of the welder and the yellow panel goes through the right side (bottom ) of the welder. When more tension is held on the top panel, the bottom panel will show wrinkling next to the weld. Adjust the tension held to give a smoother finish.

Uneven Fabric Tension

This is an example of too much tension held on the bottom fabric panel. It is important for the operator to hold even (equal) tension on both the top and bottom fabric panels as the machine is welding. As illustrated the green panel goes through the left side (top) of the welder and the yellow panel goes through the right side (bottom ) of the welder. When more tension is held on the bottom panel, the top panel will show wrinkling next to the weld. Adjust the tension held to give a smoother finish.

Perfect Seam

This is an example of a perfect seam. There is no waviness, wrinkles, or puckers. The heat, speed, and pressure, combined with the operators tension applied are perfect.

.png?width=318&name=1%E2%80%9D%20Hem%20(25mm).png)

.png?width=318&name=1.5%E2%80%9D%20Hem%20(38mm).png)

10.0 Maintenance

The Miller Weldmaster T2 has certain items that need maintained to keep the machine running as effective as possible. The T2 has one chain which is used to drive the weld rollers and travel roller on the machine. Although not high maintenance items, chains should be inspected every 3 months to ensure there is not excessive corrosion, rust, or dirt. Also inspect for any looseness in the chain, sprockets, or gears. If needed, lubricate chains and gears once every 3 months with 80-90w gear oil.

1. Before starting inspections or maintenance of any kind the power disconnect must be turned to the off position or disconnected.

2. Remove the back cover of the machine and inspect the chains, sprockets, gears, and all other mechanical parts. During the inspection, look for wearing surfaces, dark dust under the sprockets and gears, dry chains, or any other signs of wear.

3. Oil chains, sprockets, and gears as needed. Replace worn out parts as needed.

4. Once the mechanical system has been inspected and maintained then inspect the electrical system. Begin the inspection by first lightly blowing out the inside of the machine with a compressed air blow gun (be sure compressed air is completely dry and clean). Inspect electrical components, wire, and wire terminals for dark/discolored areas.

7. Once inspection and maintenance is complete, replace the back cover and tighten all mounting bolts.

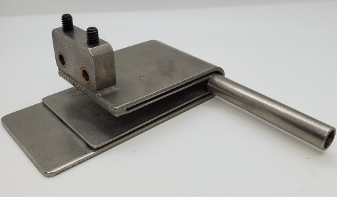

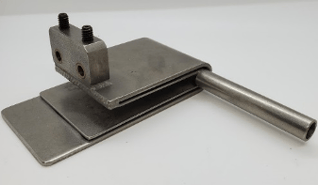

11.0 Recommended Replacement

Miller Weldmaster recommends keeping the following spare parts in stock:

NOTE: The manufacturer will not be held liable for any damage or injuries occurring from any inappropriate use of this machine.

- Heat Element

- Weld Rollers

- Nozzles ( 1”, 1.5”, 2” )

12.0 Transportation and Storage

Transportation Within a Production Facility

Due to the weight of the Miller Weldmaster machine, the manufacturer requires two persons in order to move the machine. When lifting the machine grab hold of the base and not any insecure parts, also be sure to lift slowly and carefully to eliminate potential injury. Secure all components before lifting.

Transportation Outside a Production Facility

The manufacturer requires the Miller Weldmaster machine to be placed on a pallet and loaded into a truck using a forklift or tow motor. The forks are to be inserted below the bottom frame along the center of gravity. Before lifting the machine be sure to secure all components. Lift slowly to ensure proper placement of the forks. Secure the machine to the pallet or trailer and protect the various controls and features by crating the machine.

Storage

The manufacturer recommends that any time the machine is not in use, it must be protected from excess dust and moisture. The operator should familiarize themselves with the warning symbols on the machine to be alert to the potentially hazardous areas on the machine.

13.0 Additional Machine Documents