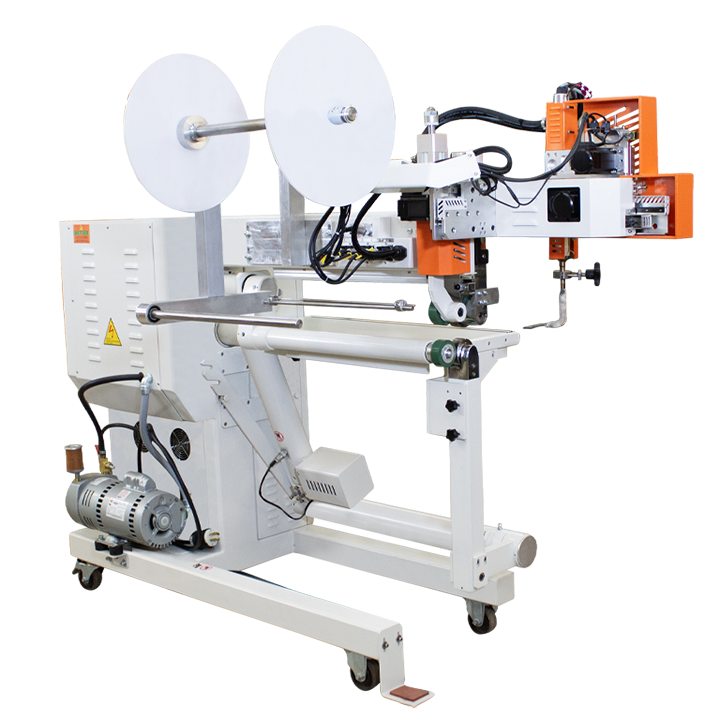

How the T300 Curve Ensures Accurate Welds on Curved and Complex Surfaces

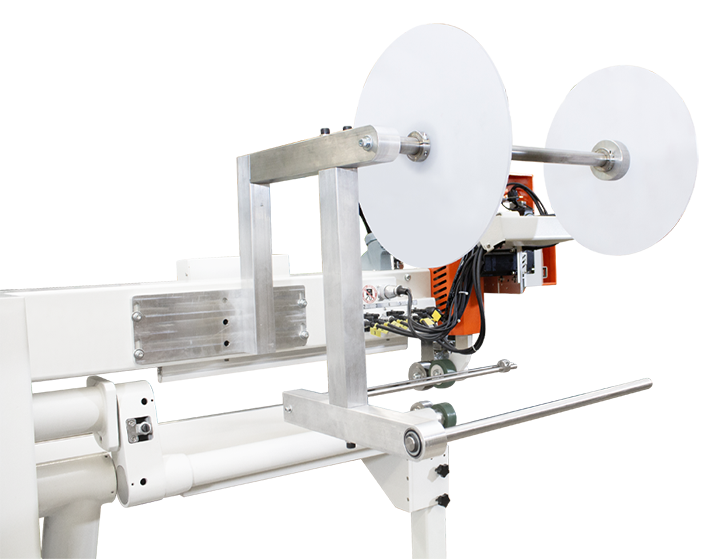

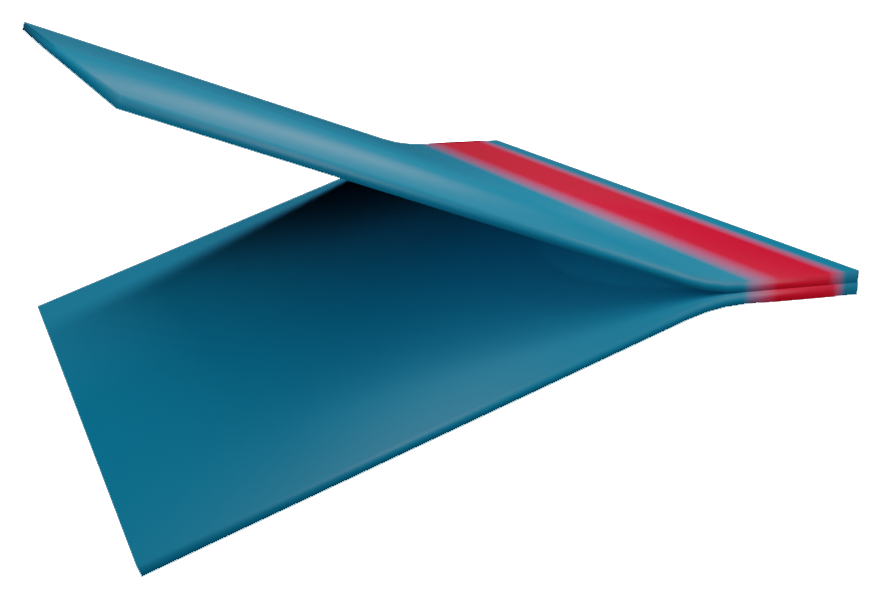

The T300 Curve is specifically engineered to handle the curved and contoured surfaces of double-wall inflatables that traditional welders often struggle with. Its uniquely designed welding head and precision heat and pressure controls, including advanced hot wedge and wedge welding machine capabilities, allow it to follow complex geometries without sacrificing seam integrity. This results in consistently accurate welds even on multi-dimensional surfaces.

Advanced welding technology ensures uniform weld penetration and edge alignment across curves and irregular shapes, making the T300 ideal for producing airtight, high-strength seams in double-wall materials.

Benefits of Seam Accuracy for Inflatable Air Structures and Products

Accurate seams are critical in inflatable products to maintain structural integrity, prevent air leaks, and extend product lifespan. The T300 delivers tight, reliable welds that contribute to:

-

Greater durability under continuous stress

-

Increased safety in marine or high-pressure environments

-

Long-term cost savings through reduced repair or failure rates

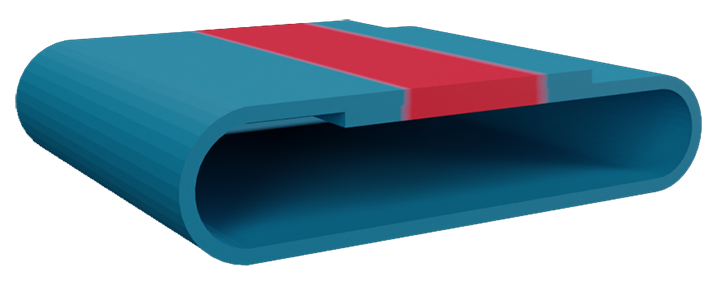

The T300 Curve and T300 Extreme Curve machines are specifically designed to create seams that are airtight and waterproof, essential for crafting durable 2D and 3D inflatables.

Use Case Examples:

-

Inflatable boats where airtight compartments are essential for flotation

-

Air mattresses that must hold air overnight without sagging or leaking

-

Inflatable shelters used in emergency response or military applications

Advanced Features of the T300 Curve Double Wall Inflatable Seam Welder

Digital Controls for Seam Welding Consistency

The T300 features an intuitive touchscreen interface with programmable settings to simplify operation and improve repeatability. Operators can store and recall specific recipes for different materials and products, ensuring consistent performance across production runs.

These controls help reduce operator error, minimize training time, and speed up machine setup for each job—ideal for shops looking to streamline operations.

Adjustable Weld Arm for Enhanced Maneuverability

One of the standout features is the adjustable welding head and arm, which enhances access to tight and intricate weld zones. Whether you're working inside small inflatable tubes or on the seam of a complex structure, the adjustable components make positioning effortless.

This adjustability increases comfort for operators while improving the precision and efficiency of each weld—especially on custom-shaped or hard-to-reach areas.

Applications for Industrial-Grade Inflatable Product Manufacturing

Best Seam Welding Machine for Inflatable SUPs, Rafts, and Kayaks

For outdoor and marine product manufacturers, the T300 Curve offers unmatched seam strength and flexibility. Whether you’re creating stand-up paddleboards, inflatable kayaks, or commercial rafts, this machine ensures air- and water-tight seams that perform under pressure.

Precise welding ensures every product meets performance and safety expectations, especially in challenging environments like open water or rugged terrain.

Perfect for Custom Inflatable Structures and Architectural Airforms

The T300 is also widely used in manufacturing custom inflatables such as event domes, inflatable buildings, and military shelters. Its adaptable welding components and material handling capabilities allow you to execute complex designs with ease. Additionally, the T300 excels in producing airtight and waterproof seams for uniquely shaped inflatables, making it ideal for both 2D and 3D designs.

Customizations are supported through programmable welding settings and accessory options, allowing users to tailor the machine to unique builds and specs. The machine also features multiple seam configurations, enabling operators to quickly change guides for different seam types, thus improving efficiency and adaptability in various welding applications.

Boosting Production Efficiency with the T300 Curve

Faster Weld Times Without Compromising Quality

Thanks to its efficient heat system and automated controls, the T300 achieves fast weld speeds while maintaining high-quality results. Real-world users report reduced lead times on high-volume orders without sacrificing seam quality or structural performance.

This makes the T300 an ideal choice for manufacturers seeking to scale production without adding unnecessary labor or time.

Reducing Labor Costs Through Automation and Ease of Use

The T300 is designed for ease of operation, reducing the learning curve for new operators. Its digital interface, automatic material feeding, and guided weld path ensure operators can produce quality seams quickly—even with minimal experience.

Repeatable results and low training demands make it a smart investment for growing manufacturers looking to reduce labor costs while maximizing ROI.

Why Choose Weldmaster for Inflatable Seam Welding Solutions

Decades of Industry Expertise and Global Trust

With over 50 years of experience, Miller Weldmaster has become a trusted name in heat welding solutions worldwide. Our customers span a wide range of industries—from marine and recreation to military and emergency response—making us uniquely equipped to support your business needs.

We offer not just machines, but complete solutions with expert guidance at every step.

Ongoing Support, Service, and Training for Seam Welding Success

Our commitment doesn’t stop at the sale. We provide ongoing support through remote diagnostics, on-site training, service plans, and a global network of technicians.

We emphasize the importance of proper installation and comprehensive training on welding equipment to ensure your staff can operate and maintain various welding machines effectively. This post-sale partnership ensures you get the most from your T300 machine for years to come, whether you’re ramping up production or troubleshooting complex builds.

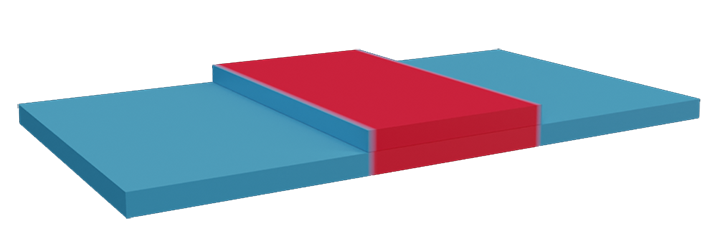

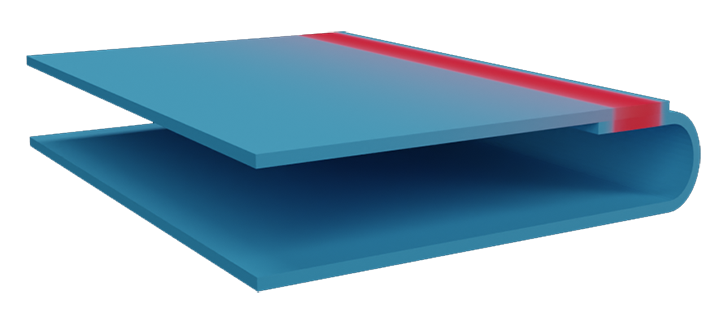

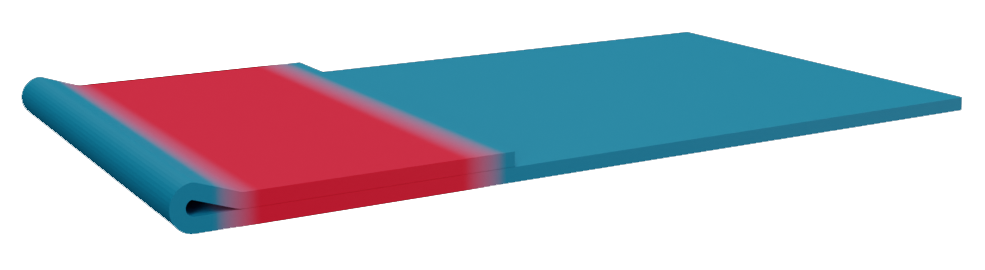

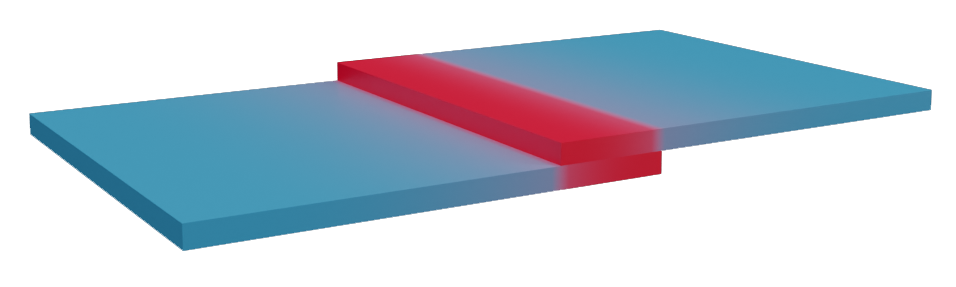

Butt Seam

Butt Seam  Coverstrip

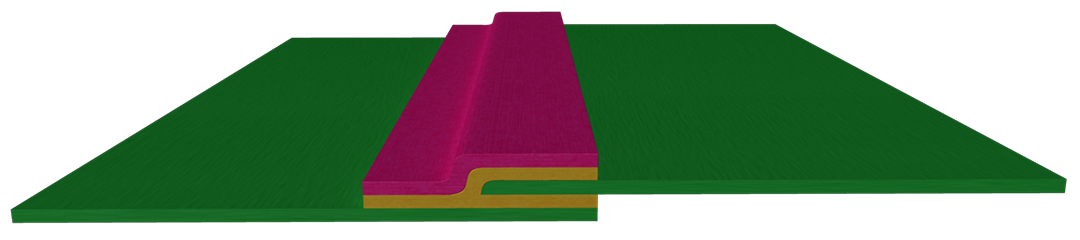

Coverstrip  Drop Stitch

Drop Stitch  Fin Prayer Seam

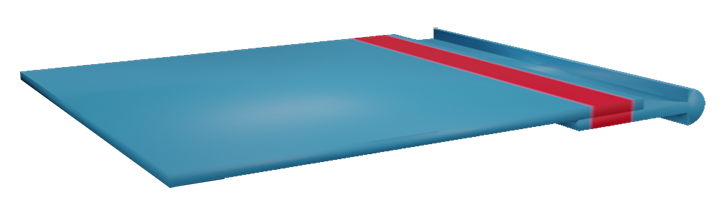

Fin Prayer Seam  Flat Seam Tube

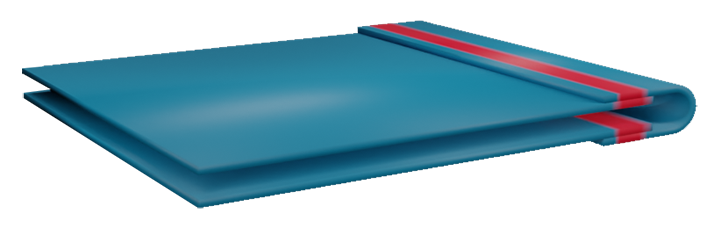

Flat Seam Tube  Fold Overlap

Fold Overlap  Hem

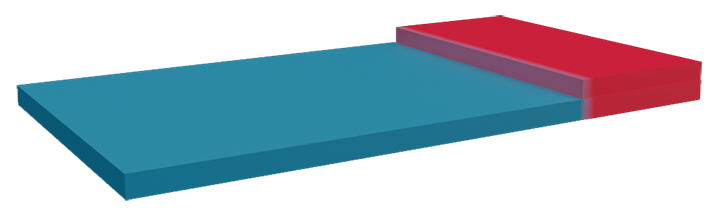

Hem  Overlap

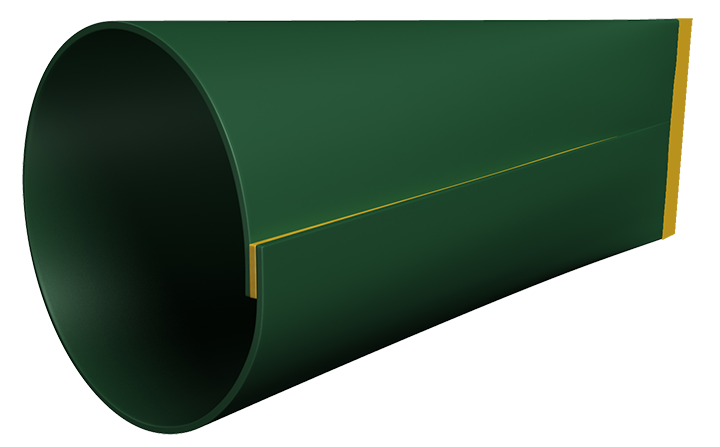

Overlap  Tube

Tube  Extrusion Beading

Extrusion Beading  Webbing - SEG

Webbing - SEG