Package Includes:

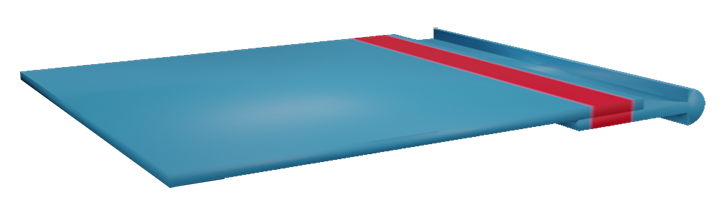

- Triad Extreme High Speed

- Overlap Guide

- 1 Full Day Of Training & Installation

Hem

Hem  Hem with Pocket

Hem with Pocket  Hem with Rope

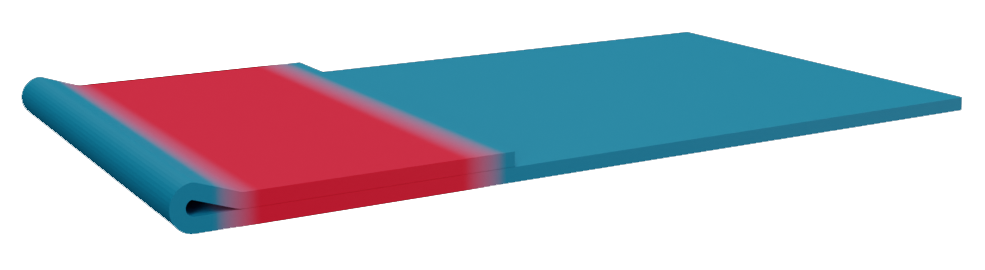

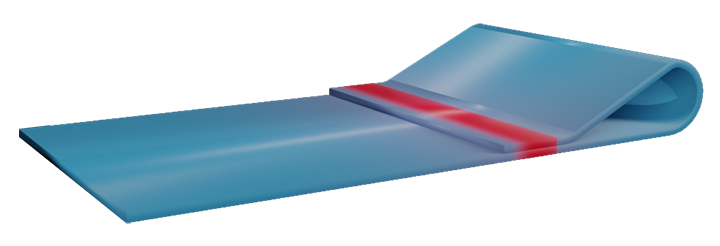

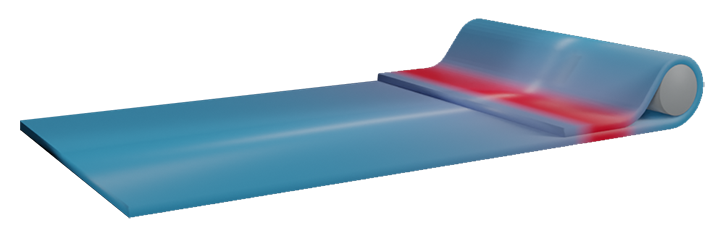

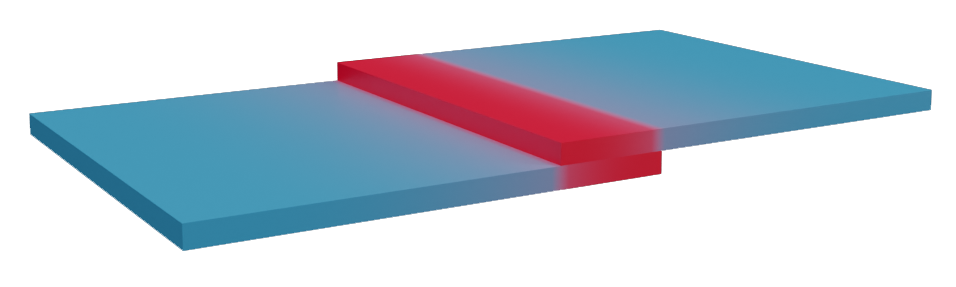

Hem with Rope  Overlap

Overlap  Extrusion Beading

Extrusion Beading

4220 Alabama Ave.

Navarre, OH 44662 USA

P: (330) 833-6739

Boekweitstraat 24

2153 GL Nieuw-Vennep

The Netherlands

P: +31 (0) 252-347032