In the world of industrial fabric manufacturing, achieving durable and efficient fabric joining is critical for both product quality and operational success. Among the many techniques available, hot wedge welding technology has emerged as a superior method for bonding industrial fabrics. This comprehensive guide will explore the mechanics, benefits, and applications of hot wedge welding, and how it outperforms other methods.

What Makes Hot Wedge Welding Unique?

Hot wedge welding is a specialized fabric bonding technique that uses a heated wedge to fuse materials together. The process involves precise temperature control, pressure application, and material alignment to create strong and seamless bonds. Unlike traditional methods like sewing or adhesives, hot wedge welding eliminates the need for perforations or chemical curing, making it cleaner, faster, and more durable.

Understanding the Hot Wedge Process

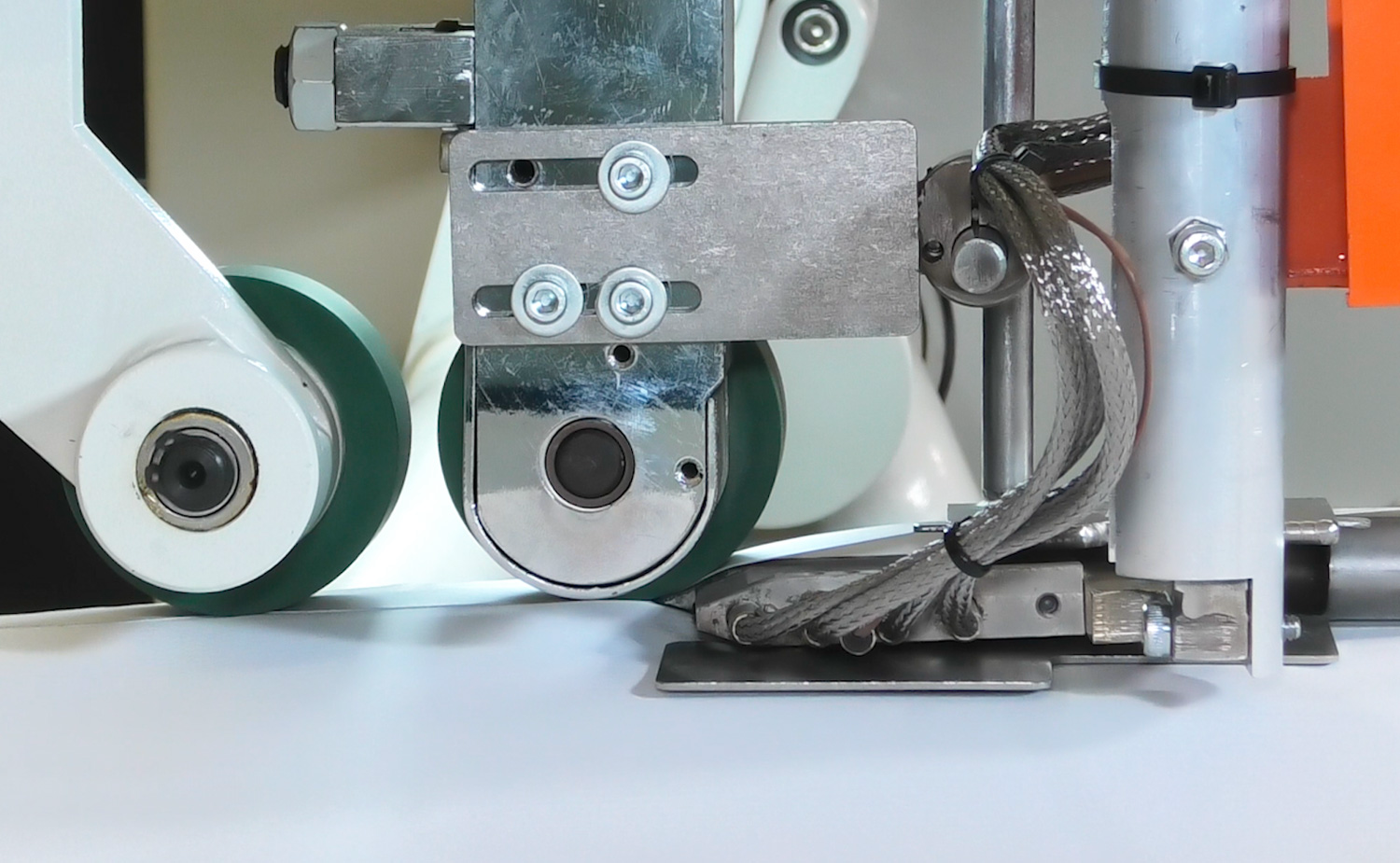

- Heating: The wedge heats the fabric layers to a precise temperature, softening the material edges.

- Bonding: As the materials pass through, rollers apply pressure to fuse the layers together seamlessly.

- Cooling: The seam cools quickly, solidifying into a strong, airtight, and watertight bond.

Versatility Across Materials

Hot wedge welding is compatible with a wide range of industrial fabrics, including:

- PVC (Polyvinyl Chloride): Commonly used in tarpaulins, billboards, and inflatables.

- PE (Polyethylene): Used in geotextiles, liners, and agricultural products.

- PU (Polyurethane): Ideal for lightweight and flexible applications like banners and tents.

Applications of Hot Wedge Welding

- Outdoor Products: Tents, awnings, and covers require durable, weather-resistant seams.

- Industrial Uses: Conveyor belts, inflatable structures, and protective gear benefit from the high-strength bonds.

- Geotextiles: Liners for ponds, landfills, and agricultural fields rely on leak-proof seams.

Comparing Hot Wedge Welding with Other Methods

To understand why hot wedge welding is a preferred choice, let’s compare it with other fabric joining techniques:

Sewing

Advantages: Familiar and low upfront cost.

Drawbacks: Creates perforations in the fabric, leading to weak points and potential leaks.

Adhesive Bonding

Advantages: Can work with complex shapes.

Drawbacks: Time-intensive and dependent on curing processes, which can delay production.

RF (Radio Frequency) Welding

Advantages: Provides excellent bond strength for certain materials.

Drawbacks: Limited material compatibility and higher equipment costs.

Hot Wedge Welding

Advantages: Combines speed, versatility, and durability. Ideal for large-scale industrial applications.

Drawbacks: Requires investment in specialized equipment, but this is quickly offset by efficiency gains.

Benefits of Hot Wedge Welding for Fabric Joining

Hot wedge welding delivers a range of benefits that make it an essential tool for fabric manufacturers:

Enhanced Efficiency and Productivity

- Speed: The automated process significantly reduces production time compared to manual methods like sewing or adhesive bonding.

- Streamlined Workflow: Modern hot wedge welding machines can handle large-scale production with minimal operator intervention.

- Automation: Features like programmable settings allow for consistent results across multiple fabric types.

Durability and Quality of Seam Bonds

- Strength: Hot wedge welding produces high-quality bonds that can withstand tension, abrasion, and environmental stresses.

- Airtight and Watertight Seams: Essential for products like inflatable structures and geotextiles.

- Aesthetic Finish: Seamless bonds improve the appearance of finished products.

Cost Savings with Hot Wedge Welding

- Material Efficiency: Precise bonding reduces waste, saving on raw material costs.

- Labor Reduction: The process is less labor-intensive, allowing manufacturers to allocate resources more effectively.

- Long-Term ROI: The initial investment in equipment pays off through reduced production costs and increased product durability.

Tips for Optimizing Hot Wedge Welding

To maximize the benefits of hot wedge welding, it’s important to fine-tune your processes:

Preparing Materials for Welding

- Cleaning: Ensure materials are free of dirt, dust, or oil that could interfere with bonding.

- Alignment: Properly align fabric layers to prevent uneven seams.

- Trial Runs: Conduct test welds to identify the best temperature and speed settings.

Fine-Tuning the Welding Process

- Adjust for Thickness: Thicker materials require slower speeds and higher temperatures.

- Monitor Consistency: Regularly check the bond quality during production to avoid defects.

- Optimize Roller Pressure: Ensure even pressure is applied for a uniform seam.

Avoiding Common Welding Mistakes

- Temperature Control: Overheating can damage materials, while underheating results in weak bonds.

- Equipment Maintenance: Regularly inspect and clean the welding machine to ensure optimal performance.

- Training: Provide thorough training for operators to reduce human error.

Miller Weldmaster’s Expertise in Hot Wedge Welding

Miller Weldmaster has been a leader in fabric welding technology for decades, offering innovative solutions tailored to meet the diverse needs of manufacturers worldwide.

Innovative Hot Wedge Welding Solutions

- Versatile Machines: From small-scale operations to large industrial setups, Miller Weldmaster provides a range of hot wedge welding machines to suit any application.

- Advanced Features: Their machines are equipped with user-friendly interfaces, programmable settings, and robust construction for long-term reliability.

Partnering with Miller Weldmaster

- Customer Support: Miller Weldmaster works closely with clients to understand their needs and provide personalized support.

- Ongoing Training: The company offers training programs to help clients maximize the efficiency of their welding equipment.

- Commitment to Innovation: Miller Weldmaster continues to push the boundaries of what hot wedge welding technology can achieve.

Hot wedge welding technology has revolutionized fabric joining by providing a fast, efficient, and durable solution for industrial applications. Whether you’re manufacturing outdoor products, geotextiles, or protective gear, the benefits of hot wedge welding are clear: enhanced productivity, superior bond strength, and long-term cost savings.

Ready to transform your fabric welding processes? Contact Miller Weldmaster today to explore their range of innovative hot wedge welding machines.