FlexScreen is the world's first and only flexible window screen. After spending years in the window industry, Joe Alteri learned the challenges customers were facing with their screens. Difficult to replace, difficult to remove, low visibility, and traditional screens break easily. Having to face these problems himself on a daily basis, Joe knew there had to be an easier way.

Joe’s simple, problem-solving design, is changing the window industry. FlexScreen has won numerous awards and Joe continues to receive recognition for his invention. As FlexScreen continues to grow, they need a partner that will help them along the way. Working with Miller Weldmaster has increased product manufacturing for FlexScreen by expanding production and producing the high-quality products for which they are known.

FlexScreen’s Background

Throughout his years in the window industry, Joe found the challenge and issue with traditional window screens. Instead of ignoring the issue and moving along with his work, Joe worked to find a solution to the problem. So, in Joe’s home garage in Pittsburgh PA, FlexScreen was born. The first and only flexible window screen. Since then, FlexScreen has grown to a 5-location business across the US and Canada and focused on producing the highest-quality window screens.

After being featured on Shark Tank, FlexScreen expanded from simply an idea in a garage to being a full-blown manufacturing company. They have grown to producing various sizes and screen materials to fit customers’ demands. FlexScreen strives to be the go-to home window screen across the county and someday, the world.

Challenge: Increase Product Manufacturing

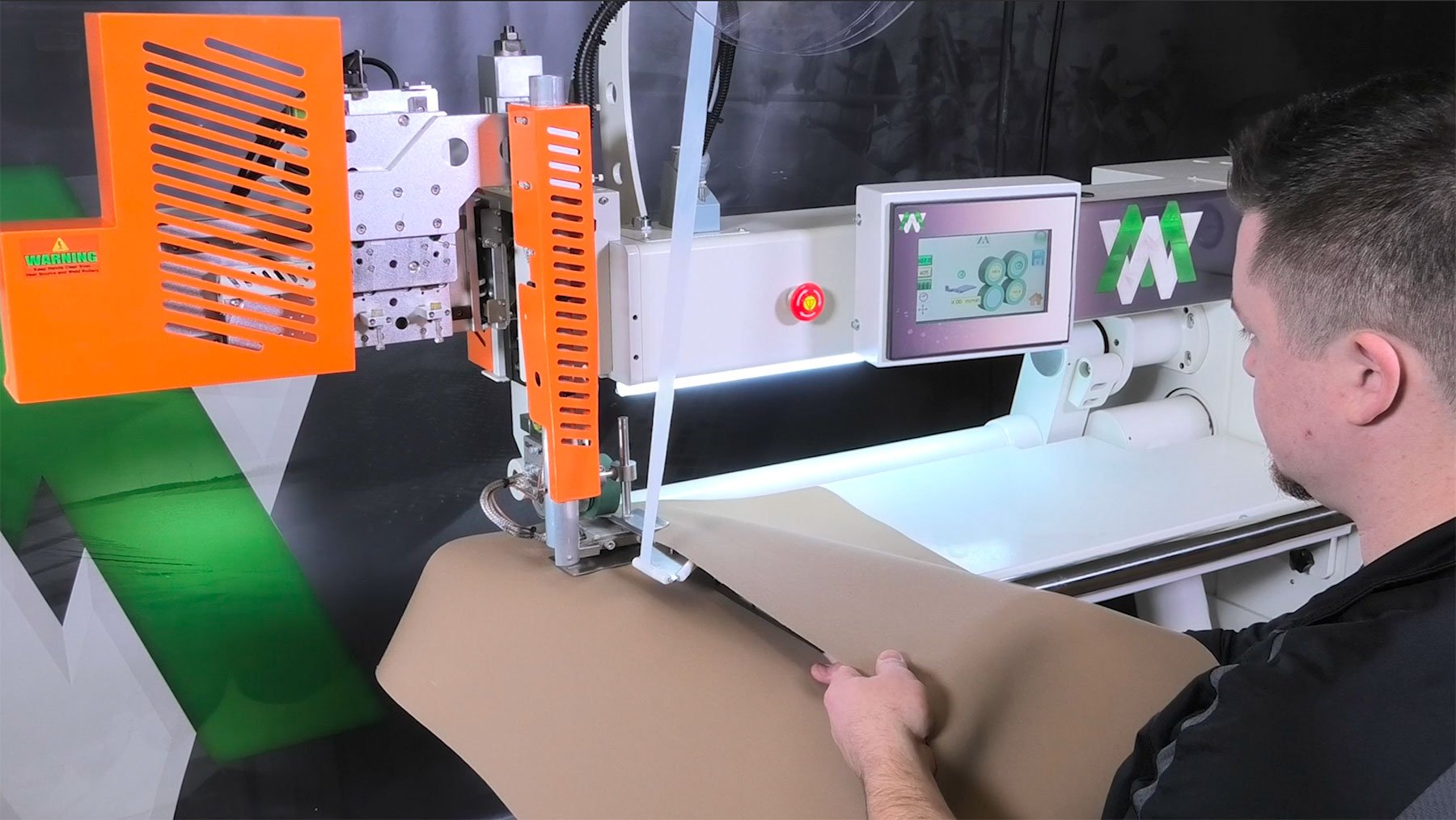

Due to their unique design and build, FlexScreen met challenges with their production. Since the mesh and frame are flexible, they needed machines and accessories that would hold the frame secure while they are moving them through the welder. Also, due to the increase in demand, they required machines that were easy to use and reliable to keep up with production needs.

Miller Weldmaster’s High Quality Production Solution

Dedicated to creating high quality products, FlexScreen searched for the best solutions to help their company grow. FlexScreen was extremely impressed by Miller Weldmaster’s ability to meet their needs. Supplying both standard machines as well as building custom tables and automation machines to accommodate the various stages of producing FlexScreen. Miller Weldmaster strives to ensure their customers’ needs are truly met throughout the entire production processes. Across their business, FlexScreen has 18 standard T300s as well as 4 custom machines to allow for more automation. From installation to servicing the machines, Miller Weldmaster keeps in close contact to ensure FlexScreen has what they need to stay up and running.

Craig Neal, Chief Operation Officer at FlexScreen, proclaims that “Miller Weldmaster is the only vendor that we started out with that we still have.” FlexScreen is proud of the partnership they have built with Miller Weldmaster and they look forward to continue their work together.

Product Manufacturing Results

Increased production: FlexScreen had to build their manufacturing from the ground up. As they gained momentum, they needed Miller Weldmaster to keep up with their machine and production needs.

Ease of manufacturing: Miller Weldmaster built a custom table to hold the frames tight while the screens are being secured. This allows the operator to easily maneuver the screen through the welder as well as produce a more consistent, high-quality, product.

Contact Miller Weldmaster today to learn more about out Standard or Automation Machines, or click here to find your ideal welder.

Want to learn more about Miller Weldmaster or their customers' success? Connect with Miller Weldmaster and FlexScreen on Facebook.