As manufacturing continues to evolve, high-frequency welding technologies are transforming how thermoplastics are joined with precision, strength, and energy efficiency. In 2025, both traditional RF welders and solid-state RF systems play vital roles in industrial applications—from large-format geomembranes to delicate medical devices. The typical frequency range for dielectric heating in HF welding is 10-100 MHz, commonly conducted at 27 MHz, ensuring effective and efficient bonding.

Compared to other welding methods, such as hot air welding, high-frequency welding generates heat internally within the material, resulting in stronger, more airtight, and more efficient bonds—especially for plastics and fabrics. Hot air is sometimes used as an alternative process, but it is generally less effective for joining thermoplastics like PVC. Adequate pressure is crucial during HF welding to ensure proper contact between the materials, facilitating efficient energy transfer.

To understand the differences and advantages of each, it’s important to first explore the fundamentals of radio frequency welding technology.

What You’ll Learn in This Article

-

The key differences between solid-state and traditional RF welders

-

Which technology delivers better efficiency and precision

-

Maintenance and cost-of-ownership considerations

-

Which industries benefit most from each

What Are High-Frequency Welding Technologies?

High-frequency (HF) welding uses electromagnetic energy—typically around 27.12 MHz—to bond thermoplastic materials through molecular vibration. This process creates clean, uniform seams without adhesives or open flames, making it ideal for precision industrial manufacturing. HF welding employs radio waves and pressure to create strong, high-quality welds.

The HF welding process works by applying a high frequency electromagnetic field—generated by high frequency electromagnetic waves or radio waves—across the welding area where the material layers are positioned in intimate contact. The electric field interacts with the polar molecular structure of polar thermoplastics, such as PVC, which contain dipole molecules and polar molecules. When exposed to the high frequency field, these dipole molecules undergo dipole polarization, causing them to rotate rapidly and align with the alternating electrical current. This molecular motion results in intermolecular friction and molecular friction, generating heat internally within the plastic materials. The heat generated is highly localized, allowing the material to be heated and welded precisely without damaging the surrounding material or surrounding materials. The efficiency of heat generation depends on the frequency and strength of the high frequency electromagnetic energy, with optimal power loss and decreased power loss at specific frequencies. The welding procedure in HF welding includes loading, applying pressure, applying the electric field, and cooling the joint. This mechanism enables the joining of thermoplastic materials by melting and fusing them together, resulting in strong, seamless joints and high quality welds.

HF welding is especially effective for joining multiple layers of polar thermoplastics, including thin sheets and thick plastic films. The process is widely used for welding multiple layers, sealing thin sheets, and producing durable weld seams in a variety of plastic materials. The ability to weld complex material layers and achieve consistent results makes HF welding the preferred process and often the best method for applications requiring airtight, watertight, or long lasting welds. HF welding results in airtight and waterproof bonds, making it ideal for applications requiring barrier properties.

During the welding process, precise control over welding time, pressure, and cooling time ensures repeatable outcomes and consistent weld quality. As the material cools under pressure, the welded joint achieves its final properties, such as weld strength, toughness, and dimensional stability. Controlling the welding time is critical to ensuring sufficient heating and bonding of the materials during the welding process. The result is a strong bond and durable weld that can be as robust as or stronger than the original materials, with weld seams that are smooth and reliable. HF welds are known for their high quality, seamless joint formation, and ability to withstand stress and environmental factors, making them suitable for demanding industrial applications.

High frequency welding machines and automated machines are commonly used in industrial production to ensure efficient, high-volume manufacturing with precise, repeatable, and high quality welds. HF welding is ideal for high-volume production due to its high speed and efficiency.

Common Thermoplastics Used in HF Welding:

-

PVC (polyvinyl chloride)

-

PU (polyurethane)

-

PET (polyester)

-

EVA (ethylene-vinyl acetate)

PVC and polyurethane are among the most common thermoplastics used in high frequency welding.

HF welding is widely used across packaging, automotive, textiles, and medical industries—often integrated into industrial high-frequency welders for automated production lines. High-frequency welding is commonly used in the medical industry for sealing and assembling medical items such as blood bags and IV bags.

Traditional RF Welders: Proven but Maintenance-Heavy

Traditional RF welders have been industry workhorses for decades, relying on vacuum tube oscillators to generate high-frequency energy. They are powerful and reliable for large-scale welding but come with ongoing maintenance requirements. Traditional RF welders are known for producing strong hf welds and durable weld seams, ensuring the integrity and longevity of the welded materials.

| Pros | Cons |

|---|---|

| High power for large parts | Frequent tube replacement |

| Proven reliability | Longer warm-up times |

| Lower upfront cost | Higher energy use and downtime |

Traditional RF systems excel in durability but require consistent upkeep and skilled technicians to maintain performance. The materials are welded to create reliable products. Learn more about how radio frequency welding works.

Solid-State RF Welding: Precision and Energy Efficiency

Solid-state RF welding replaces tubes with semiconductor amplifiers, resulting in faster response times, tighter frequency control, and significantly improved energy efficiency. These systems deliver consistent results and repeatable outcomes in industrial applications, ensuring high-quality, reliable welds.

Performance Benefits:

-

Enhanced Precision: Stable frequency output ensures uniform welds every time.

-

Energy Efficiency: Uses up to 50% less power than tube-based systems.

-

Reduced Arcing: Better control minimizes sparks and material damage.

-

Fast Tuning: No need for manual frequency adjustments.

While initial costs can be higher, these machines offer lower operating expenses and consistent performance. For maintenance guidance, visit our RF welding service and support page.

Performance and Precision Compared

When comparing solid-state vs. traditional RF welding, the key difference lies in frequency stability and weld consistency. Solid-state welders also deliver superior weld quality and weld strength due to their precise control over process parameters, ensuring strong, reliable, and consistent welds across various applications.

| Feature | Solid-State RF | Traditional RF |

|---|---|---|

| Frequency Stability | Excellent | Moderate |

| Weld Consistency | High | Variable |

| Downtime | Minimal | Higher (tube replacement) |

| Maintenance Needs | Low | High |

Solid-state welders maintain precise control over the entire weld cycle, while traditional systems may drift or require re-tuning as tubes age.

Maintenance and Longevity: Tubes vs. Semiconductors

Maintenance is one of the most significant factors in choosing between these two technologies. Proper maintenance ensures that the equipment delivers optimal cooling time after welding, which is essential for achieving the desired final properties of the weld, such as strength and dimensional stability.

Tube-Based Maintenance:

-

Requires periodic tube replacement

-

Susceptible to heat degradation

-

Demands manual tuning and calibration

Solid-State Maintenance:

-

Minimal consumables or wear parts

-

Stable power output over time

-

Lower downtime and total cost of ownership

For long-term ROI, solid-state systems deliver superior reliability and uptime, especially for operations running multiple shifts or precision-critical products.

Use Cases: When to Choose Solid-State vs. Traditional RF

The right technology depends on your material, production scale, and precision needs. High-frequency welding is widely regarded as the best method and preferred process for many industrial applications that require precision, durability, and strong, airtight bonds.

Choose Solid-State RF Welding for:

-

Medical device RF welding requiring tight validation and clean seams.

-

Energy-conscious manufacturers aiming to cut power consumption.

-

High-volume production lines focused on uptime and consistency.

Choose Traditional RF Welding for:

-

Large-format industrial applications like tents, tarps, and geomembranes.

-

Established operations already equipped with tube-based infrastructure.

-

Heavy-duty materials that demand maximum power output.

Read more about specific radio frequency welding applications.

Miller Weldmaster’s Perspective on RF Welding in 2025

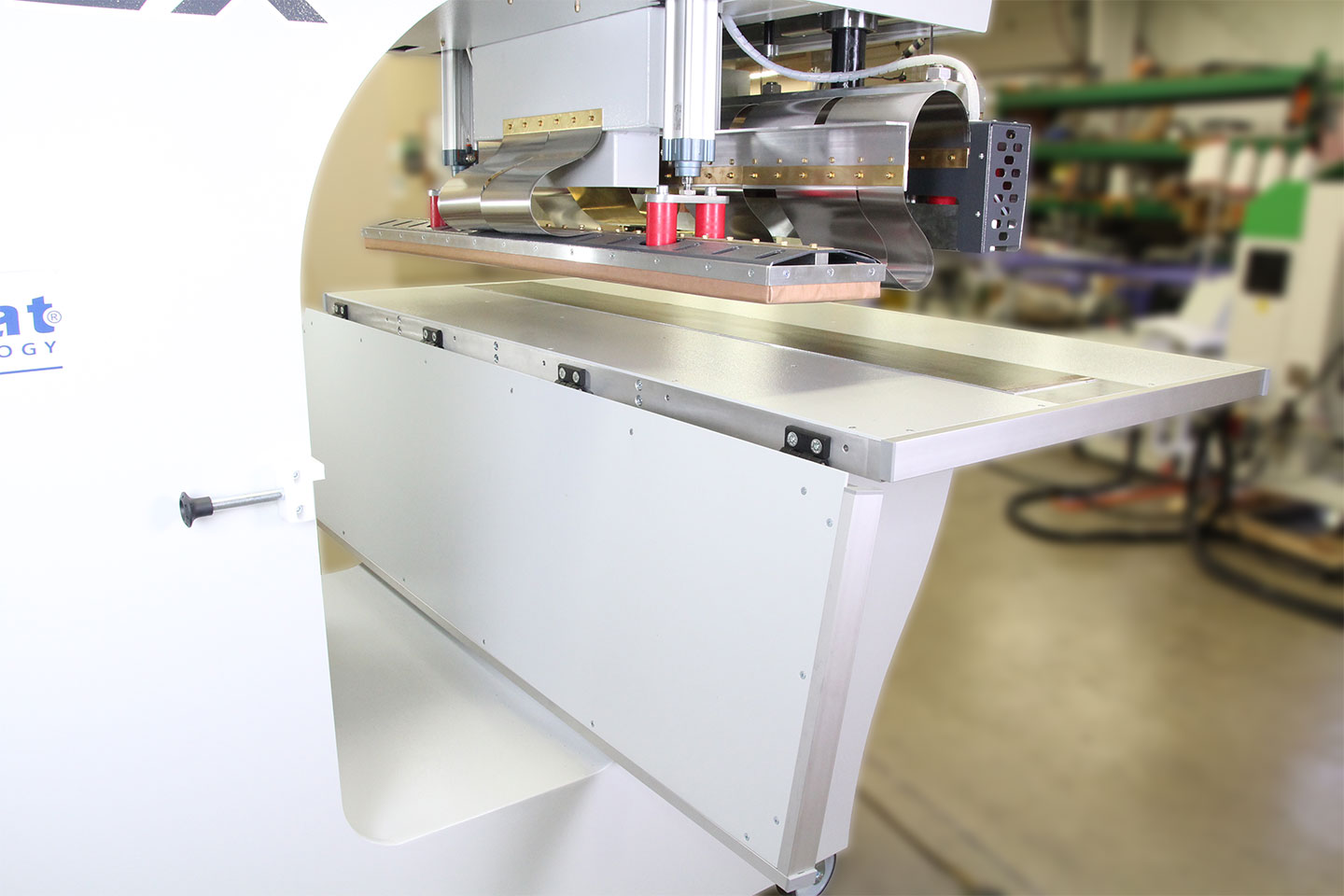

At Miller Weldmaster, our RFlex line is designed to support both traditional and solid-state high-frequency welding technologies. Our systems are designed for reliability, precision, and ease of use—featuring innovations like arc suppression, stable output, and digital control interfaces. We offer high frequency welding machines and automated machines specifically designed for processing plastic materials, ensuring strong, precise welds for a variety of applications.

Whether you’re seeking standard RF welding machines or a custom-built solution, Miller Weldmaster’s experts will guide you toward the right choice for your materials and production goals.

Explore our standard RF welding machines.

Conclusion: The Future of High-Frequency Welding Technologies

The transition from tube-based to solid-state RF welders marks a major advancement in energy-efficient RF welding. While both have their place, solid-state systems are shaping the future with improved precision, reduced maintenance, and consistent output.

Key Takeaways:

-

Solid-state RF welders use semiconductor technology for enhanced efficiency.

-

Traditional RF welders remain valuable for heavy-duty and large-scale work.

-

Maintenance and energy savings make solid-state ideal for long-term ROI.

-

Both systems contribute to evolving high-frequency welding technologies.

-

Miller Weldmaster offers solutions for every application and scale.

Frequently Asked Questions About Solid-State vs. Traditional RF Welding

What are high-frequency welding technologies?

They use electromagnetic energy to bond thermoplastic materials at molecular levels—creating strong, clean seams without adhesives or open heat sources.

What is the difference between solid-state and traditional RF welding?

Traditional RF uses vacuum tubes to generate power, while solid-state systems rely on semiconductors for faster, more precise control and lower maintenance.

Why is solid-state RF welding more energy-efficient?

Semiconductor amplifiers deliver power only when needed, reducing waste and eliminating the inefficiencies of continuous tube heating.

Which industries benefit most from solid-state RF welding?

Medical, electronics, and precision textile manufacturers benefit most due to the need for accuracy, repeatability, and low energy consumption.

Do traditional RF welders still have advantages in 2025?

Yes. They remain excellent for high-power, large-format projects where brute strength and proven reliability are essential.

.png)