Investing in a new technology for any aspect of your business takes time and resources. But while a technology investment requires upfront resources and manpower, consider the long-term advantages of a more modern production floor—most manufacturers enjoy faster production, more output, less human error and more efficient operations.

This is especially true for industrial fabric welders. Fabric and material welders offer benefits traditional seam sewing and production simply can’t compete with. Manufacturers typically spend less on materials and labor costs, while improving customer satisfaction, and product quality and lifespan.To reduce some of the research time and frustration, we’ve identified the top three questions to consider before starting your search for the right fabric welder. Ask yourself the following questions to help identify your unique welding needs.

1. What kind of materials does my company work with?

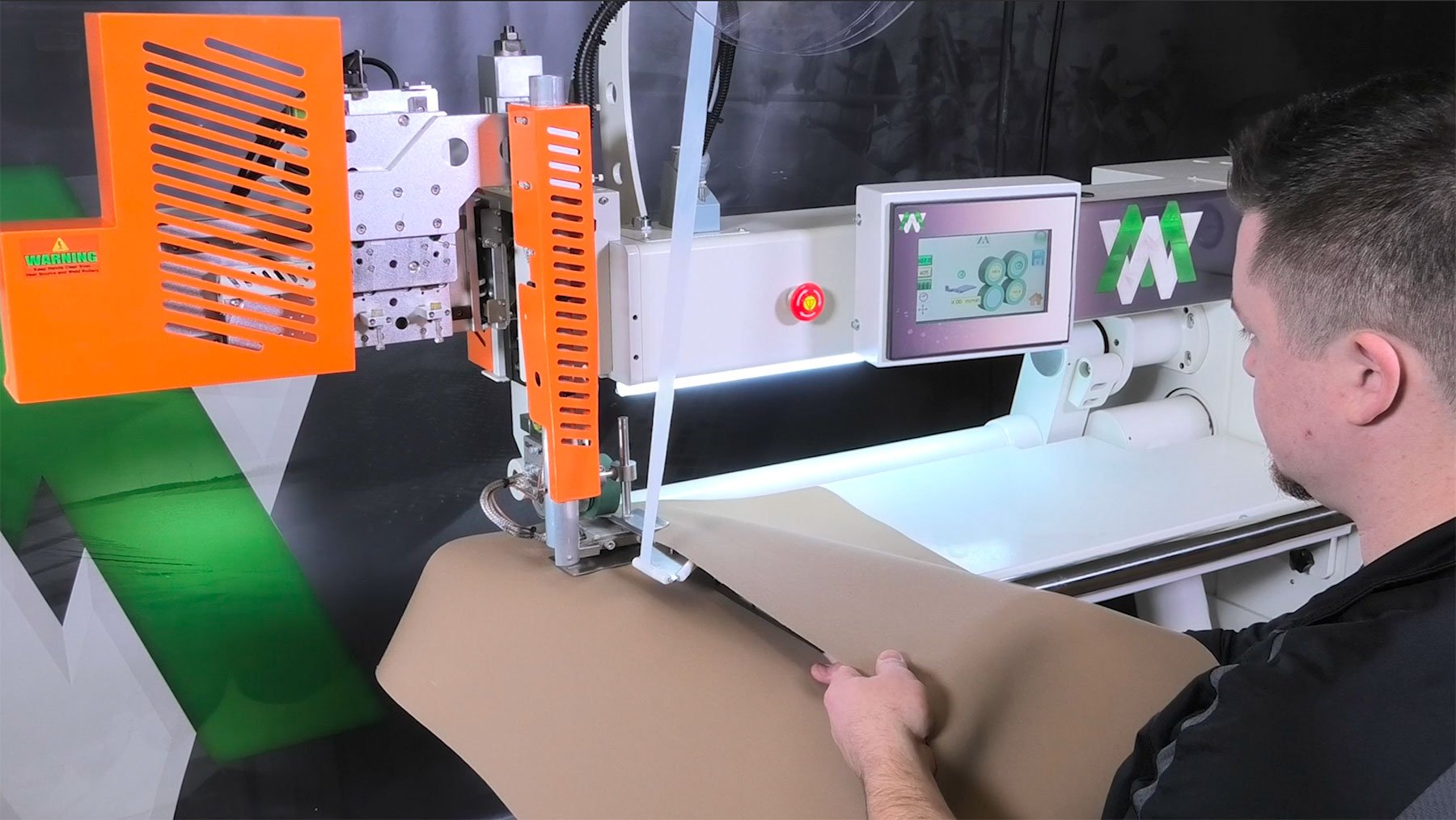

Certain fabric welders work best with certain applications. Industrial fabrics are unique because they’re designed to withstand harsh elements. But as durable as industrial fabrics are, a proper welding machine is needed in order to create virtually indestructible seams.

Miller Weldmaster’s machines are capable of handling many kinds of industrial fabrics, including the following:

- Vinyl (PVC) Laminated Fabrics

- Vinyl (PVC) Coated Fabrics

- Vinyl Films

- Polypropylene

- Polyurethane

- Polyethylene (PE)

Industrial fabric welders can tremendously increase production. One Miller Weldmaster customer reported their welder saved them three days’ worth of work. Different machines offer different welding cycles, with some of the fastest welding up to an impressive 20 meters per minute.

Consider these questions while researching your new technology:

- Do I need a large capacity machine? How much increase in production do I expect from this investment?

- Will I need to create multiple products that are made of multiple materials? Is this machine capable of that?

- Where are slowdowns occurring on the production floor? Will this technology fix these issues?

- How will this new machine change our production floor set up? Will this change operator roles, schedules, skill sets?

Did you know that welding machines can complete tasks other than just create welds? With the right industrial fabric welder, your team can easily improve efficiency with certain machines that automatically manage and complete multiple tasks. Certain machines offer additional capabilities that automatically weld, cut, grommet and fold materials, which can further shorten your production time and reduce the need to invest in multiple technologies.

Some fabric welding machines can also swiftly complete other jobs such as:

- Applying keder for awnings.

- Adding grommets to edges.

- Finishing edges on multiple panels and screens.

- Folding completed products.

Interested in Learning More About Your Welding Options?

With so many options on the market, it can be difficult to select the best industrial welding machine for your needs. Browse the Miller Weldmaster lineup of machines to learn more about each machine’s welding cycles and capabilities.

The best way to ensure success for your company is to speak with a fabric welding expert. Contact a Miller Weldmaster team member today to discuss your options.