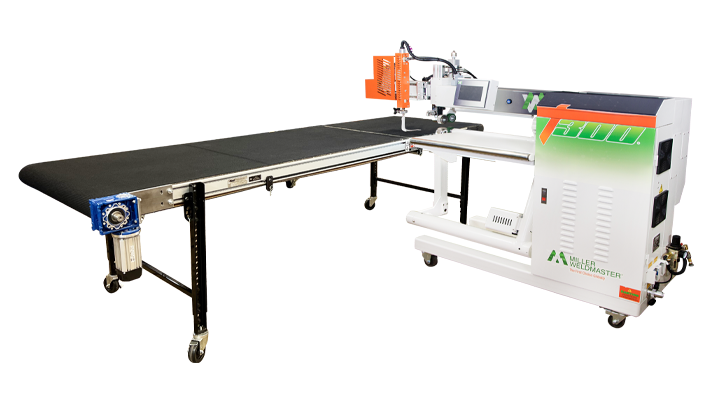

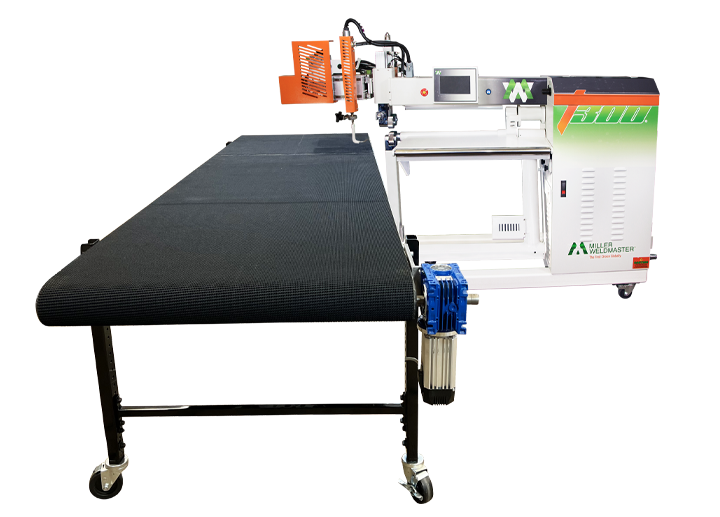

The T300 Edge stands out with its exceptional versatility, efficiency, and precision in fabric welding, making it an ideal choice among banner welders and banner welding machines. Engineered for multiple industries, this machine excels in creating seamless, high-strength welds on diverse materials, making it perfect for applications in industrial fabrics, tarps, awnings, and more. Its ability to handle various material types ensures top-notch performance and adaptability across different sectors.

T300 Edge: A Powerful Solution for Sign Finishing

The T300 Edge employs hot air welding technologies, offering unmatched precision in heat control and customizable settings. Banner welding is crucial for creating seamless hems in vinyl banners, ensuring durability and high-quality seams. This design is tailored for high-speed production without sacrificing weld integrity or quality.

How Hot Air & Hot Wedge Welding Enhance Fabric Bonding

Hot Air Welding: Utilizes a stream of hot air to melt the material along the seam. It's ideal for thicker, more rugged materials where high energy and deeper penetration are needed. Hot Wedge Welding: Features a heated metal wedge placed between two fabric layers for consistent heating. Best for thinner or heat-sensitive materials due to its gentle processing. Comparison: Choose hot air welding for robust, thick materials needing strong bonds. Opt for hot wedge for precision on lighter or delicate fabrics.

Features That Set the T300 Edge Apart

This model rises above competitors with its user-friendly controls and automation features, making operation straightforward. Precision adjustments contribute to the machine's versatility and efficiency, allowing it to quickly finish banners. It offers customizable settings for different material thicknesses and an energy-efficient design, significantly lowering operating costs.

Precision Heat & Speed Controls for Any Fabric Type

Adjust temperature settings cater to a variety of materials, ensuring precise heat application and reducing waste. Speed adjustments enhance production flexibility and efficiency.

Seam Strength & Durability for Industrial Applications

The T300 is engineered to produce long-lasting, durable welds, ideal for high-stress environments like outdoor applications, including tarps, inflatables, and shelters. The seam width is crucial in determining the machine's performance and versatility, as it varies depending on the application and type of material used. Rigorous testing and quality assurance are standard, ensuring reliable performance.

Applications of the T300 Edge in Various Industries

This machine serves multiple industries, proving essential in the production of tents, tarps, awnings, geomembranes, agricultural covers, signage, banners, and inflatables.

Industrial Textile Welding for Tents, Tarps & Awnings

It delivers strong, weather-resistant seams, crucial for products exposed to the elements. The reliability of the T300 benefits tent manufacturers, awning fabricators, and tarp producers by enhancing product longevity and performance.

Efficient Production for Geomembranes & Agricultural Covers

Ensures leak-proof, reinforced seams, vital for applications like pond liners and greenhouse covers, providing enhanced protection and durability.

Custom Welding Solutions for Signage, Banners & Inflatables

The precise welding capabilities are key for visual materials, improving both production speed and quality in these visually focused industries. Banner welding machines play a crucial role in creating high-quality seams in vinyl signage and banners, enhancing durability and precision.

Why Choose the T300 Edge for Your Business?

Rely on the proven reliability of Miller Weldmaster, with options tailored to various production needs and comprehensive customer support and training.

Backed by Miller Weldmaster’s Decades of Expertise

With a long history of innovation in welding technology, Miller Weldmaster supports its customers through extensive training and reliable service.

Flexible Configurations to Meet Your Production Needs

The T300 offers customizable settings and a range of attachments and accessories, enhancing its versatility and functionality in different applications.

Get a Quote or Schedule a Demo for the T300 Edge

Encouraging businesses to reach out, this section should have a strong CTA, offering options to request a quote, schedule a demo, or speak with an expert to discuss specific needs.

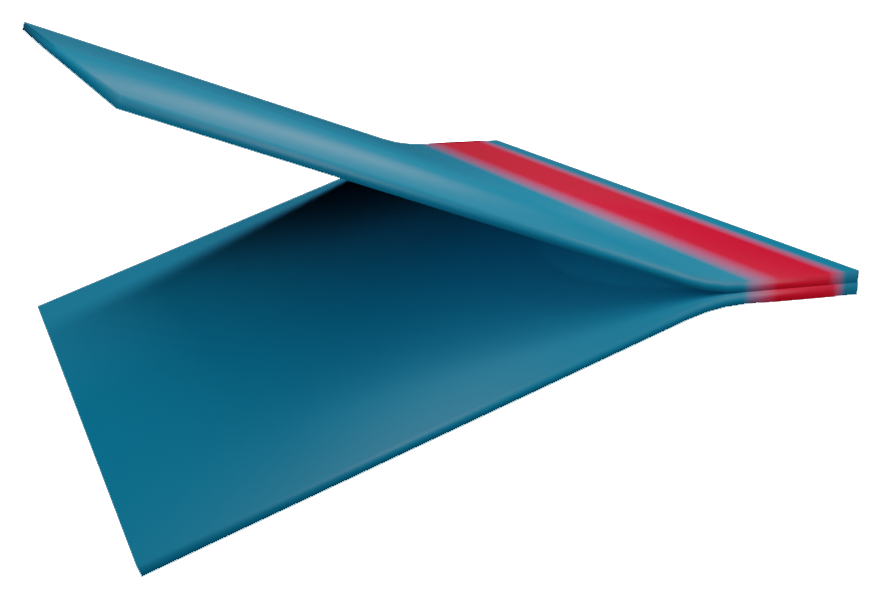

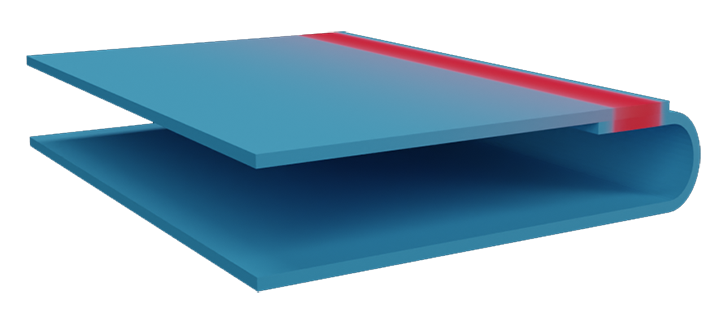

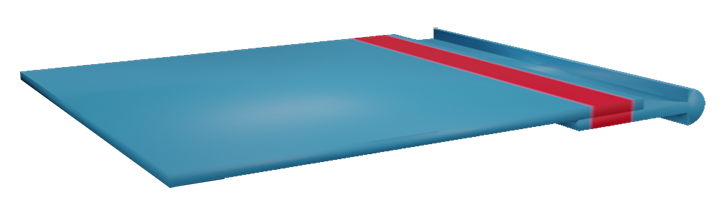

Fin Prayer Seam

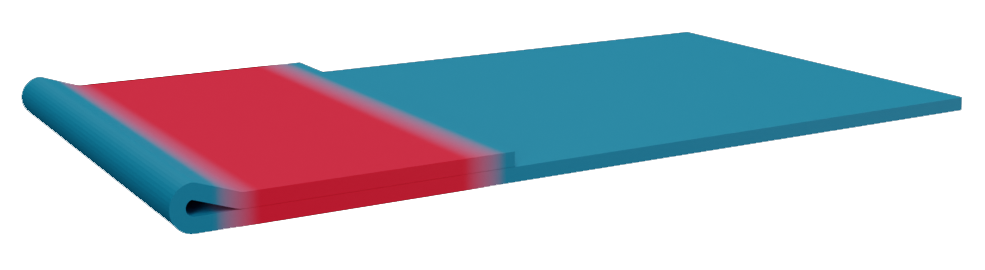

Fin Prayer Seam  Fold Overlap

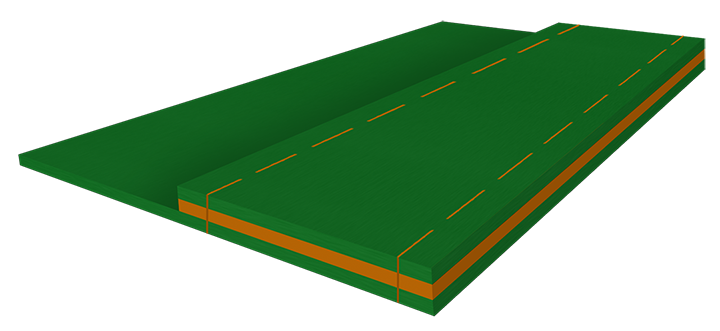

Fold Overlap  Hem

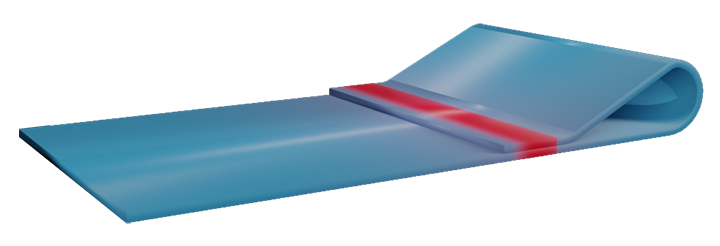

Hem  Hem with Pocket

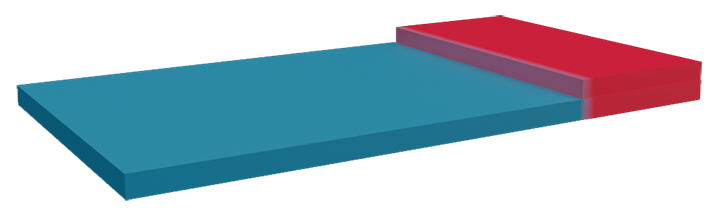

Hem with Pocket  Hem with Rope

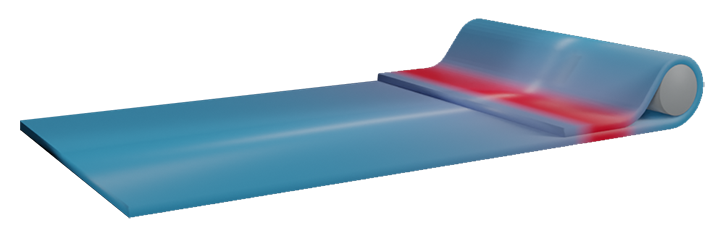

Hem with Rope  Extrusion Beading

Extrusion Beading  Velcro Webbing

Velcro Webbing  Webbing - SEG

Webbing - SEG