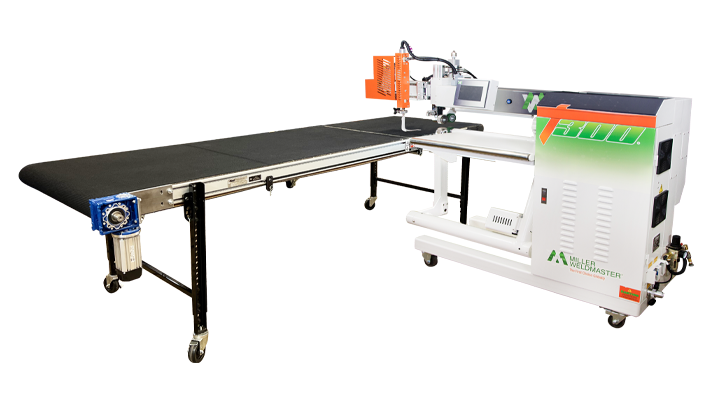

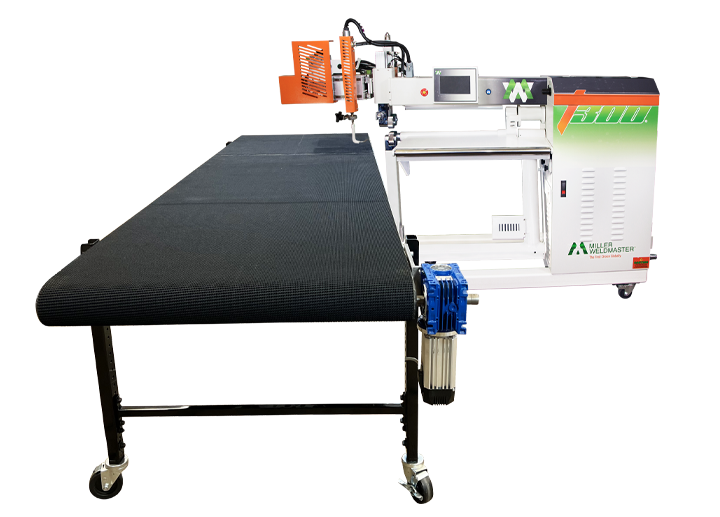

Industry-Leading Technology for Precision Seam Welding

The T300 Flex stands out in the hot air and hot wedge welding market with its advanced technology that ensures precision and efficiency. This machine boasts cutting-edge features such as a precision welding head, various table positions, adjustable heating head, and easy operator capabilities that make it superior to competitors. Its precision in seam alignment and consistent heat distribution ensures high-quality welds, making it an indispensable tool for fabricators who value precision and reliability.

Built for Durability and High-Volume Production

Designed with industrial applications in mind, the T300 Flex is engineered for durability and high-volume production. It features a rugged construction that withstands harsh manufacturing environments and continuous use without compromising performance. The machine’s design emphasizes minimal maintenance, ensuring that it remains reliable over years of service. This durability translates into a lower total cost of ownership and fewer production interruptions. Additionally, we offer comprehensive maintenance services, including operator training and the availability of genuine spare parts, to ensure optimal performance over time.

Trusted by Industry Leaders Across Multiple Markets

The T300 Extreme Flex is highly regarded across multiple industries, from awnings to inflatables, and is particularly popular in the production of tents, banners, and geotextiles. Its versatility and performance are confirmed by numerous positive testimonials and case studies from market leaders who rely on its consistent results to maintain competitive advantages in their respective fields.

How the T300 Flex Enhances Your Production Workflow

Faster Weld Times Without Sacrificing Quality

The T300 Flex is designed to optimize welding speeds while maintaining the integrity of strong, airtight seams. It significantly outperforms other industry solutions by combining high-speed production capabilities with precise temperature and speed controls, along with repeatable head adjustments, ensuring that each weld is both fast and flawless. This balance of speed and quality is essential for businesses looking to increase throughput without compromising product standards.

Intuitive Controls for Effortless Operation

Featuring an easy operation touch screen, the T300 Flex allows operators to easily adjust welding parameters to suit different materials and applications. This intuitive control system reduces training time and enables quick changes on the fly, enhancing overall production efficiency and flexibility.

Reduce Waste and Increase Material Efficiency

The precision controls of the T300 Flex minimize errors and material waste, translating directly into cost savings. By reducing the occurrence of defects and reworks, businesses can achieve more efficient use of materials and lower production costs, enhancing profitability.

What Can You Weld with the T300 Flex?

Compatible Materials for Hot Air & Hot Wedge Welding

The T300 Flex is compatible with a wide range of materials, including PVC, vinyl, acrylic, polyurethane, and technical textiles, making it extremely versatile. It excels in applications requiring either hot air or hot wedge technologies, with specific settings optimized for each material type to ensure the best possible weld quality.

Common Products Manufactured with the T300 Flex

The T300 Flex is instrumental in manufacturing products such as tents, banners, inflatables, awnings, and ducting. Its capability to handle diverse materials and complex shapes makes it ideal for producing high-quality, durable products across various industries. Additionally, the T300 Flex allows for rapid adjustments with quick setting recalls, making it efficient for both straight and curved seams quick.

Maximize Your ROI with the T300 Flex

Cost Savings from Efficient, High-Quality Welding

The T300 Flex reduces labor costs and enhances throughput with its efficient welding processes. By incorporating precision welding, which allows for quick, repeatable head adjustments and synchronized controls, it speeds up production and reduces the need for skilled labor, offering significant long-term cost benefits compared to manual welding or outsourcing.

How the T300 Flex Pays for Itself Over Time

The machine's efficiency not only meets but often exceeds investment costs through direct savings in materials and labor. ROI calculations and customer success stories illustrate how the T300 Flex can rapidly recoup its investment, demonstrating its value in reducing the cost per product through enhanced efficiency.

T300 Flex Compared to Other Welding Machines

T300 Flex vs Traditional Welding Methods

Compared to traditional methods like sewing, gluing, or RF welding, the T300 Flex offers stronger seams, faster production speeds, and reduced material waste. These advantages make hot air and hot wedge welding with the T300 Flex a more effective solution for industrial fabric welding.

T300 Flex vs Other Industrial Welding Machines

When compared to other welding machines, both from Miller Weldmaster and competitors, the T300 Flex stands out for its advanced features and performance. A side-by-side comparison highlights its superior efficiency, ease of use, and adaptability, making it a preferred choice for businesses looking to upgrade their fabric welding capabilities.

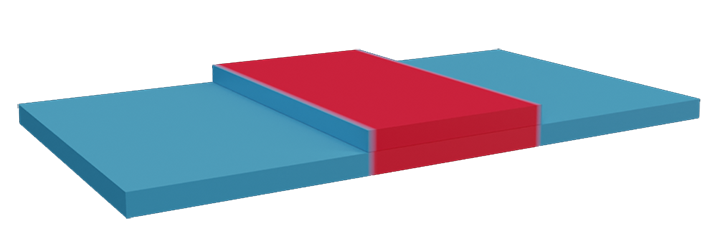

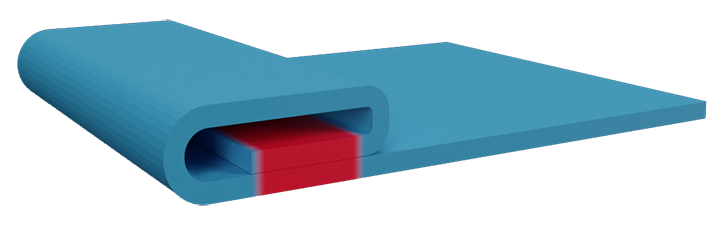

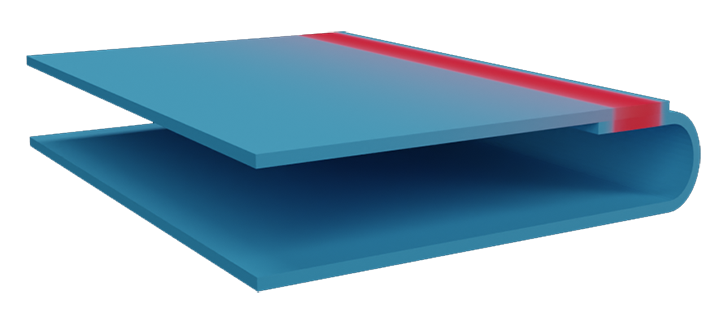

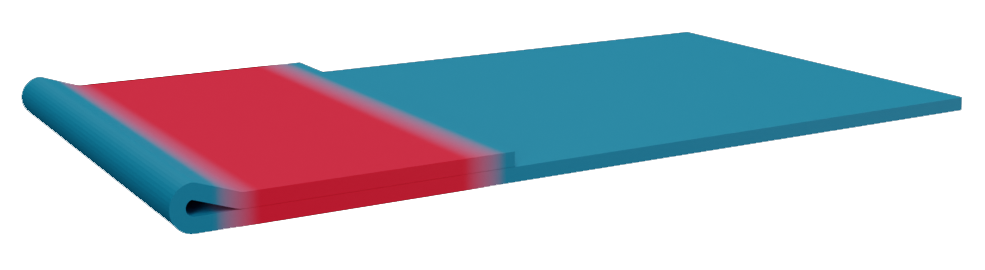

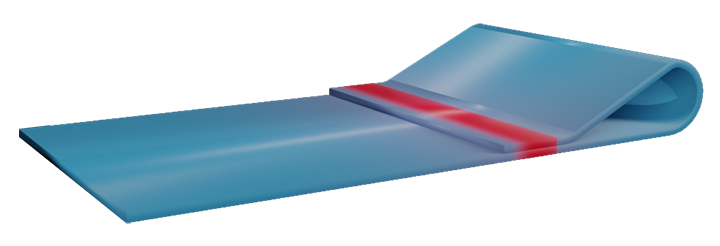

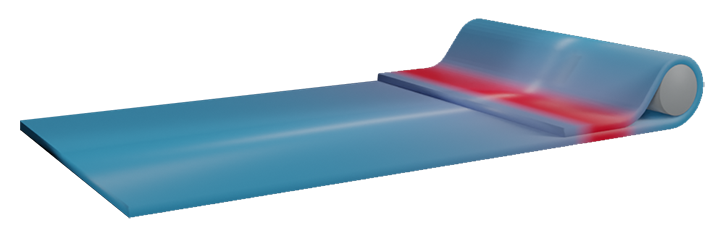

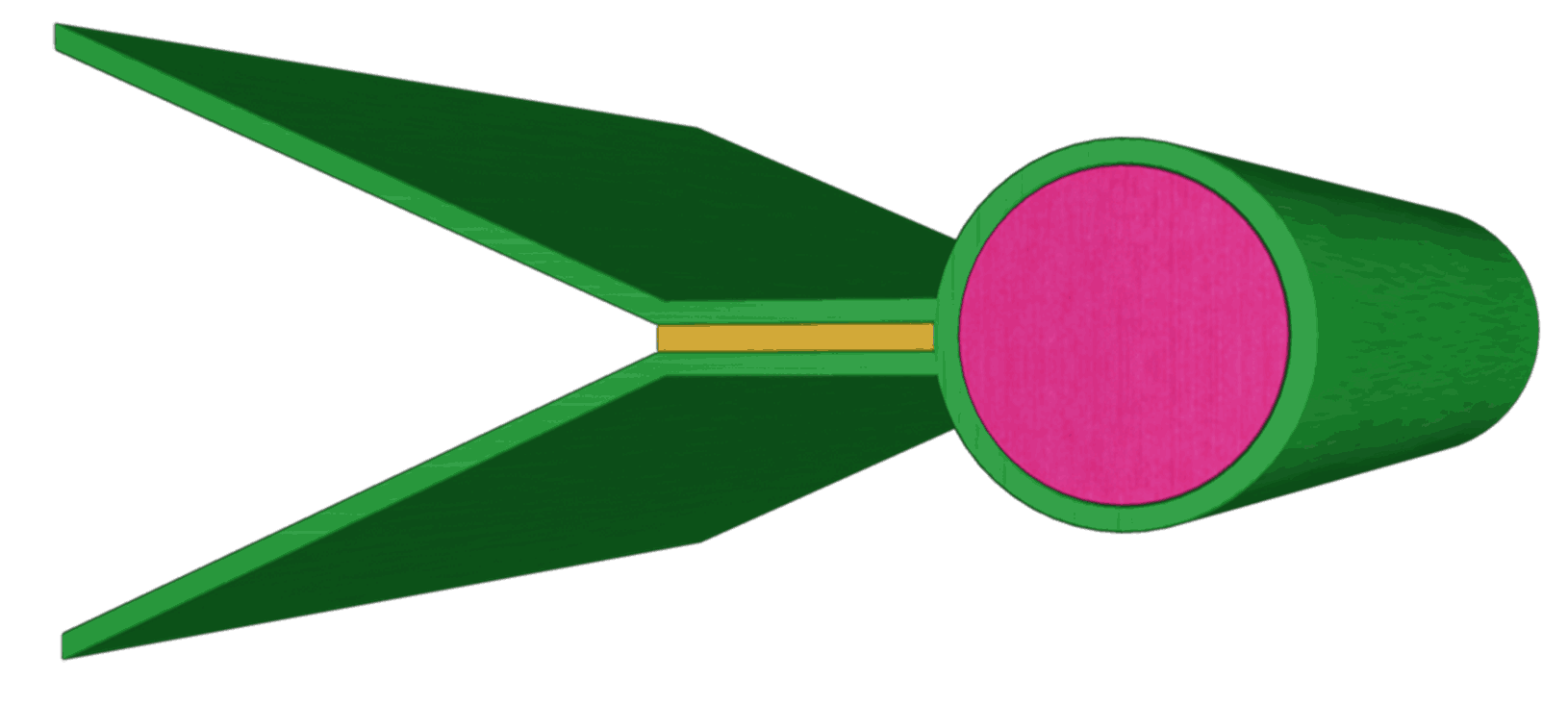

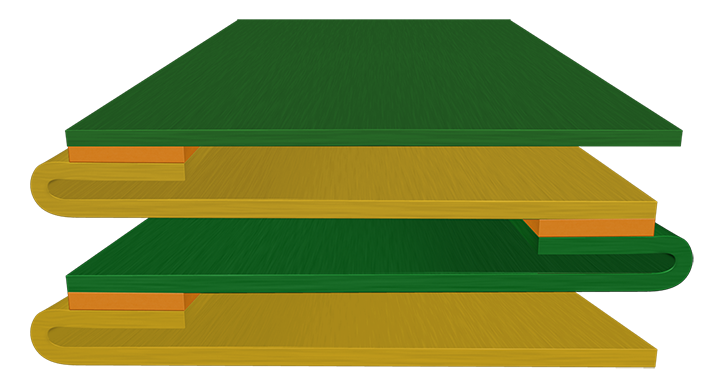

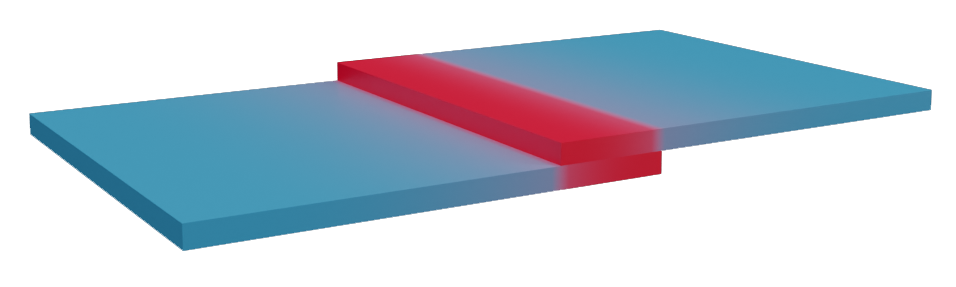

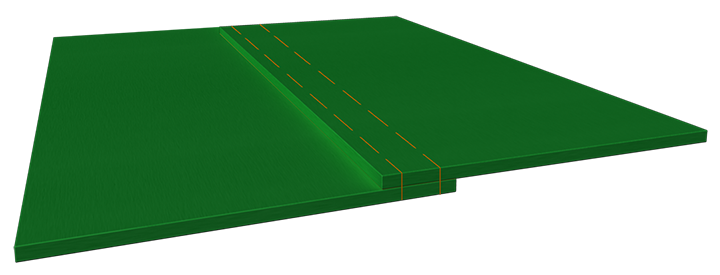

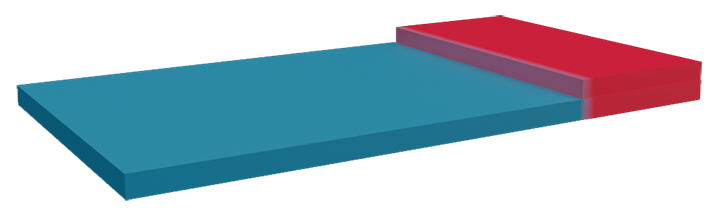

Butt Seam

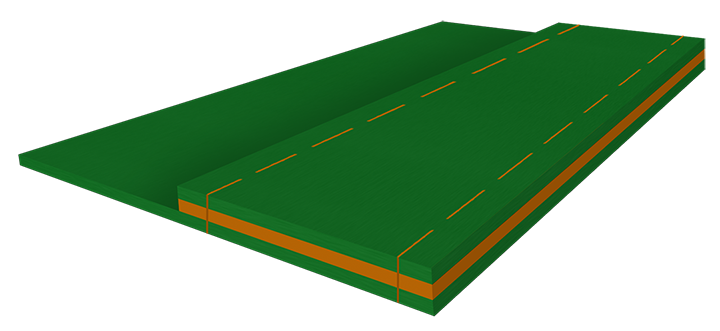

Butt Seam  Channel Seam

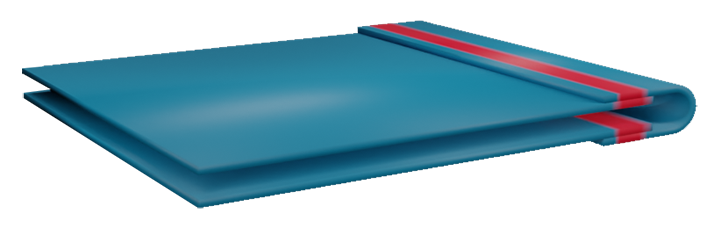

Channel Seam  Coverstrip

Coverstrip  Double Fold

Double Fold  Drop Stitch

Drop Stitch  Fin Prayer Seam

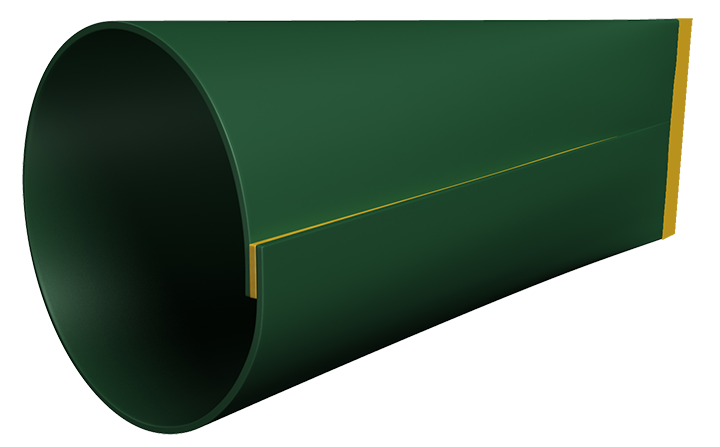

Fin Prayer Seam  Flat Seam Tube

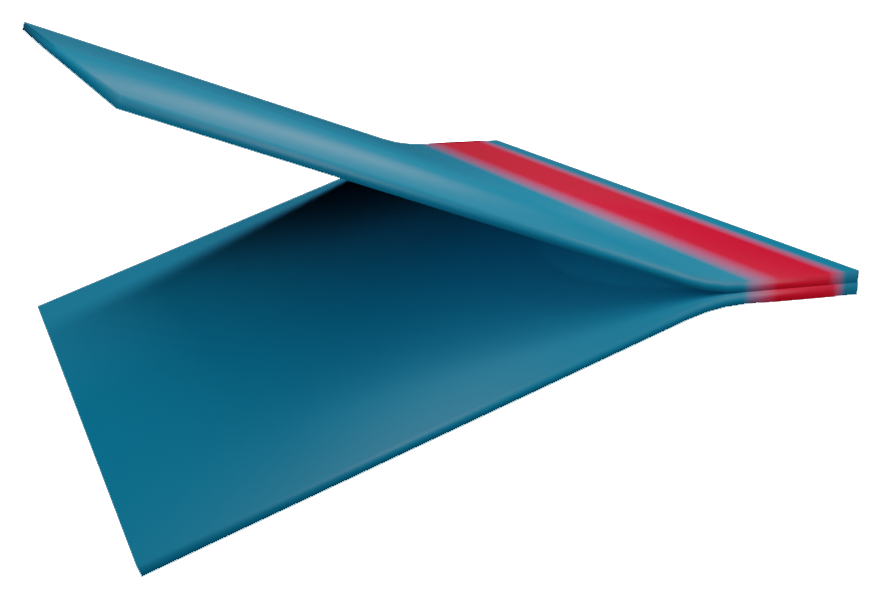

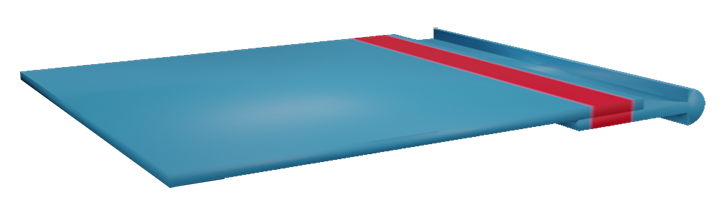

Flat Seam Tube  Fold Overlap

Fold Overlap  Hem

Hem  Hem with Pocket

Hem with Pocket  Hem with Rope

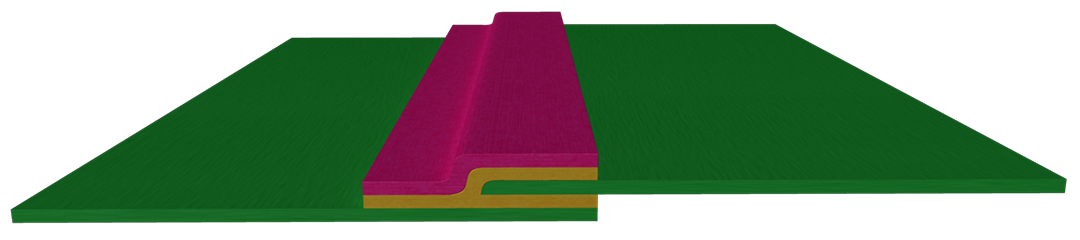

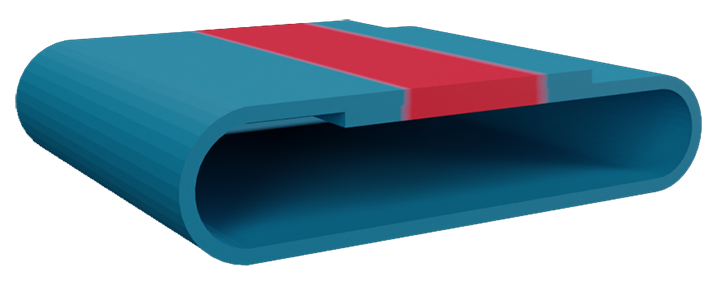

Hem with Rope  Keder

Keder  Multi Roll

Multi Roll  Overlap

Overlap  Sewn Seam

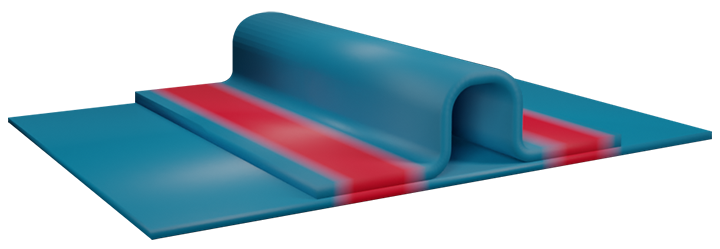

Sewn Seam  Tube

Tube  Extrusion Beading

Extrusion Beading  Velcro Webbing

Velcro Webbing  Webbing - SEG

Webbing - SEG