This instruction manual is intended to be a guide when operating the Boxmat PRO. To ensure optimal performance from your welder, please follow the recommendations and specifications precisely.

Table of Contents

- Chapter 1: Introduction

- Chapter 2: Health and Safety Regulations

- Chapter 3: Technical Data

- Chapter 4: Technical Specifications

- Chapter 5: Installation

- Chapter 6: Machine Operation

- Chapter 7: Description of HMI Panel Screen

- Chapter 8: Maintenance

- Chapter 9: Occupational and Safety Rules

- Chapter 10: Electrical Documentation

- Chapter 11: Pneumatic Documentation

- Chapter 12: Utilization and Machine Breaking

- Chapter 13: Enclosures

For more technical information regarding this machine call our Resolution Center at 1-855-888-WELD or email service@weldmaster.com.

1.0 Introduction

Boxmat PRO is the most modern and most versatile machine on the market and revolutionizes the production of corrugated packaging. Thanks to the automatic and tool-free change of settings on the HMI touch panel which can be changed within a few seconds, any product size may be programmed in standard, FEFCO types. PRO is ideal for the production of short series as well as for large, mass production. Slot-cutting, the removal of excess material, scoring, the removal of tongues of adhesive, as well as cutting the format to size, is carried out in one cycle without the need for additional attachment.

In ‘one go’, boxes of 3/5 layers of corrugated cardboard can be made. More than one box can be made from a suitably large format in just a single cycle.

The positions of the longitudinal tools are set using servo drives depending on the required size and thickness of the cardboard. Formats are centrally positioned for automatically positioned bumpers. A set of non-slip rollers and input-output shafts ensures precise and stable carton guidance throughout the entire cycle.

The innovative system applied, using circular knives, allows excess, or waste cardboard to be cut off from the remainder of the sheet. This solution facilitates the bi-directional correction of the size of the sheets and enables the sheets currently in production, to be cut to different sizes simultaneously, without having to be cut on a separate, peripheral device.

FEATURES:

- Notching, bi-directional scoring and cutting off waste in one cycle

- One integrated module for cutting, scoring and cutting off, eliminates production errors in multi-module machines

- Quick change of machine settings, on the touch panel, thanks to servo drives

- Possibility of longitudinal scoring which is a scoring function, transverse scoring and cutting sheets into smaller pieces - a crevice tool

- 4 knives + 4 longitudinal scoring wheels adjustable on the panel - a standard option

- An integrated punching system for cutting holes

- Ecological power and drive system as well as low power consumption

- Selection of styles, sizes, functions and the depths of the scores, using the touch screen

- Cardboard feeder with a reliable pick-up system

- Vibro-insulating legs preventing transmission of vibrations

- Secure and fast remote machine calibration and updating, thanks to remote internet connection

- Easy exchange of scoring wheels and cutting blades

![]() ATTENTION: Any intention of using this machine for any purpose other than as described in this manual must always be discussed with the manufacturer.

ATTENTION: Any intention of using this machine for any purpose other than as described in this manual must always be discussed with the manufacturer.

![]() ATTENTION: For the safety of all operators and other personnel, it is important that this manual is read and understood by all personnel; all instructions should be followed.

ATTENTION: For the safety of all operators and other personnel, it is important that this manual is read and understood by all personnel; all instructions should be followed.

![]() ATTENTION: It is highly recommended that each operator, once trained to use this machine, should append their name and signature to the form in this manual.

ATTENTION: It is highly recommended that each operator, once trained to use this machine, should append their name and signature to the form in this manual.

![]() ATTENTION: This machine was designed for use by able-bodied operators. Please contact the manufacturer for help and advice if it needs to be adjusted or modified for others.

ATTENTION: This machine was designed for use by able-bodied operators. Please contact the manufacturer for help and advice if it needs to be adjusted or modified for others.

2.0 Health and Safety Regulations, Signs and Labels

The health and safety of operators and of other personnel within the vicinity of this machine, is of paramount importance.

In order to use this machine safely, it is very important that this manual is read thoroughly by all personnel who intent to work with, or near the machine. All safety instructions should be adhered to, including the warning labels in the manual, as well as those displayed on the machine.

It is imperative that the purchaser be obliged to work out their own WORKSTATION INSTRUCTIONS for their machine operators, using the instructions in this service manual and the knowledge derived from the manufacturer's own experience of the technology of the product.

The ultimate, legal and financial responsibilities for all the potential events that may occur, due either to ignorance of this service manual or ignorance of Occupational Health and Safety regulations, lies with the purchaser. It is, therefore, ESSENTIAL to read and follow the safety instructions.

Warning Signs

![]() ATTENTION: Each operator MUST read the text of this service manual before undertaking any work with the machine.

ATTENTION: Each operator MUST read the text of this service manual before undertaking any work with the machine.

![]() ATTENTION: The purchaser is strongly advised to draw up their own WORKSTATION INSTRUCTIONS for the machine operators, on the basis of the text included in this service manual and the knowledge derived from their own production technology.

ATTENTION: The purchaser is strongly advised to draw up their own WORKSTATION INSTRUCTIONS for the machine operators, on the basis of the text included in this service manual and the knowledge derived from their own production technology.

ATTENTION: UNDER NO CIRCUMSTANCES should the machine be operated by unqualified personnel. Machine operators must be familiar with Occupational Health and Safety regulations with special focus on the risks inherent in this machine. As a consequence of the aforesaid, documentation, approving completion of training and signed by the trained operator, should be issued.

ATTENTION: UNDER NO CIRCUMSTANCES should the machine be operated by unqualified personnel. Machine operators must be familiar with Occupational Health and Safety regulations with special focus on the risks inherent in this machine. As a consequence of the aforesaid, documentation, approving completion of training and signed by the trained operator, should be issued.

![]() ATTENTION: The machine was not designed to be operated by disabled operators. If the need arises - and after prior consultation with the Manufacturer- the machine can be appropriately adjusted for disabled operators.

ATTENTION: The machine was not designed to be operated by disabled operators. If the need arises - and after prior consultation with the Manufacturer- the machine can be appropriately adjusted for disabled operators.

![]() ATTENTION: According to the manufacturer's recommendations, the machine should be installed in an industrial environment only.

ATTENTION: According to the manufacturer's recommendations, the machine should be installed in an industrial environment only.

![]() ATTENTION: Careless handling of the machine, during transport and/or relocation, may lead to severe injury or accidents.

ATTENTION: Careless handling of the machine, during transport and/or relocation, may lead to severe injury or accidents.

![]() ATTENTION: Periodical, adequate preventive inspection of the fire protection system should be carried out, in and around the machine. The purchaser is fully responsible for arranging to conduct such inspections.

ATTENTION: Periodical, adequate preventive inspection of the fire protection system should be carried out, in and around the machine. The purchaser is fully responsible for arranging to conduct such inspections.

![]() ATTENTION: A life threatening, high-power network voltage of 3 x 480V; 50...60 Hz is supplied to the machine. As a result, all servicing should be undertaken by appropriately qualified personnel only, as required by law.

ATTENTION: A life threatening, high-power network voltage of 3 x 480V; 50...60 Hz is supplied to the machine. As a result, all servicing should be undertaken by appropriately qualified personnel only, as required by law.

ATTENTION: Work carried out in the feeding, cutting or bending zones within the systems, should be conducted by qualified personnel only, after taking all precautionary measures. In the above-mentioned zones, higher instances of potential body injury are possible.

ATTENTION: Work carried out in the feeding, cutting or bending zones within the systems, should be conducted by qualified personnel only, after taking all precautionary measures. In the above-mentioned zones, higher instances of potential body injury are possible.

ATTENTION: The EMERGENCY STOP button is designed to be pressed at any time but especially when an emergency shutdown is urgently needed.

ATTENTION: The EMERGENCY STOP button is designed to be pressed at any time but especially when an emergency shutdown is urgently needed.

![]() ATTENTION: The area surrounding the machine should not be blocked by any objects, as this may result in personnel stumbling, sliding and falling which may lead to severe injury.

ATTENTION: The area surrounding the machine should not be blocked by any objects, as this may result in personnel stumbling, sliding and falling which may lead to severe injury.

![]() ATTENTION: The operator should always ensure that all doors, lids, shields and other protective devices are securely in place before the machine is started.

ATTENTION: The operator should always ensure that all doors, lids, shields and other protective devices are securely in place before the machine is started.

![]() ATTENTION: An operator must never climb onto the machine when it is in operation.

ATTENTION: An operator must never climb onto the machine when it is in operation.

![]() ATTENTION: The through-route of the corrugated board must NEVER be blocked by personnel or by any obstacle.

ATTENTION: The through-route of the corrugated board must NEVER be blocked by personnel or by any obstacle.

Prohibitory and Mandatory Signs

UNDER NO CIRCUMSTANCES should the machine be operated by untrained personnel. The machine’s operators must be familiar with Occupational Health and Safety regulations with special focus on the risks inherent in this machine.

UNDER NO CIRCUMSTANCES should the machine be operated by untrained personnel. The machine’s operators must be familiar with Occupational Health and Safety regulations with special focus on the risks inherent in this machine.

ATTENTION: UNDER NO CIRCUMSTANCES should the machine be operated by unqualified personnel. Machine operators must be familiar with Occupational Health and Safety regulations.

ATTENTION: UNDER NO CIRCUMSTANCES should the machine be operated by unqualified personnel. Machine operators must be familiar with Occupational Health and Safety regulations.

UNDER NO CIRCUMSTANCES should the machine be assembled, dismantled or transported by untrained personnel, nor by those unfamiliar with the safety regulations included in this service manual, since such activities may lead to an accident or to financial loss.

UNDER NO CIRCUMSTANCES should the machine be assembled, dismantled or transported by untrained personnel, nor by those unfamiliar with the safety regulations included in this service manual, since such activities may lead to an accident or to financial loss.

UNDER NO CIRCUMSTANCES should servicing or maintenance be conducted, or preventive measures be taken, without fully disconnecting from the electrical supply.

UNDER NO CIRCUMSTANCES should servicing or maintenance be conducted, or preventive measures be taken, without fully disconnecting from the electrical supply.

UNDER NO CIRCUMSTANCES should any of the sub- assemblies, such as the guide rollers, the cutting or scoring tools, be touched.

UNDER NO CIRCUMSTANCES should any of the sub- assemblies, such as the guide rollers, the cutting or scoring tools, be touched.

UNDER NO CIRCUMSTANCES should any measures be undertaken which could lead to a reduction in the machine’s safety status; this includes such measures as blocking master switches, removing guards or disconnecting sensors, etc.

UNDER NO CIRCUMSTANCES should any measures be undertaken which could lead to a reduction in the machine’s safety status; this includes such measures as blocking master switches, removing guards or disconnecting sensors, etc.

UNDER NO CIRCUMSTANCES should an operator climb onto the machine during the loading procedure or during its regular work cycle.

UNDER NO CIRCUMSTANCES should an operator climb onto the machine during the loading procedure or during its regular work cycle.

UNDER NO CIRCUMSTANCES should any potential fire, near the machine, be extinguished with water. Use only licensed, sophisticated, firefighting agents and fire-hazard protection products.

UNDER NO CIRCUMSTANCES should any potential fire, near the machine, be extinguished with water. Use only licensed, sophisticated, firefighting agents and fire-hazard protection products.

UNDER NO CIRCUMSTANCES should the guards be removed during the machine’s work cycle.

UNDER NO CIRCUMSTANCES should the guards be removed during the machine’s work cycle.

UNDER NO CIRCUMSTANCES should the machine be sprayed with water during its regular work cycle or when it is idle.

UNDER NO CIRCUMSTANCES should the machine be sprayed with water during its regular work cycle or when it is idle.

UNDER NO CIRCUMSTANCES should any maintenance tasks be conducted while the machine is in operation.

UNDER NO CIRCUMSTANCES should any maintenance tasks be conducted while the machine is in operation.

UNDER NO CIRCUMSTANCES should any oil, solvent or any other caustic or toxic substances be poured out, either in or near the machine.

UNDER NO CIRCUMSTANCES should any oil, solvent or any other caustic or toxic substances be poured out, either in or near the machine.

UNDER NO CIRCUMSTANCES should mobile phones be used in the immediate vicinity of the machine.

UNDER NO CIRCUMSTANCES should mobile phones be used in the immediate vicinity of the machine.

UNDER NO CIRCUMSTANCES should any naked flame be used in the immediate vicinity of the machine.

UNDER NO CIRCUMSTANCES should any naked flame be used in the immediate vicinity of the machine.

UNDER NO CIRCUMSTANCES should cigarettes be smoked in the immediate vicinity of the machine.

UNDER NO CIRCUMSTANCES should cigarettes be smoked in the immediate vicinity of the machine.

UNDER NO CIRCUMSTANCES should alcohol be drunk in the immediate vicinity of the machine, nor should personnel, under the influence of alcohol, operate the machine.

UNDER NO CIRCUMSTANCES should alcohol be drunk in the immediate vicinity of the machine, nor should personnel, under the influence of alcohol, operate the machine.

UNDER NO CIRCUMSTANCES should personnel eat in the immediate vicinity of the machine.

UNDER NO CIRCUMSTANCES should personnel eat in the immediate vicinity of the machine.

IT IS STRONGLY ADVISED that each person, assigned to operate the machine, be fully trained. The scope of training should cover operation of the machine, as well as Occupational Health and Safety regulations, with special focus on the risks inherent in the machine.

IT IS STRONGLY ADVISED that each person, assigned to operate the machine, be fully trained. The scope of training should cover operation of the machine, as well as Occupational Health and Safety regulations, with special focus on the risks inherent in the machine.

IT IS HIGHLY RECOMMENDED that ALL covers and guards, designed for the machine, be used.

IT IS HIGHLY RECOMMENDED that ALL covers and guards, designed for the machine, be used.

IT IS ESSENTIAL that in the event of any accident involving the operator, or any machine failure, both should be reported to the management promptly.

IT IS ESSENTIAL that in the event of any accident involving the operator, or any machine failure, both should be reported to the management promptly.

IT IS ESSENTIAL to wear safe, close-fitting, workwear to reduce the possibility of being snagged or pulled into the machine.

IT IS ESSENTIAL to wear safe, close-fitting, workwear to reduce the possibility of being snagged or pulled into the machine.

IT IS ESSENTIAL to wear protective gloves while operating the machine.

IT IS ESSENTIAL to wear protective gloves while operating the machine.

IT IS ESSENTIAL to wear anti-slip working footwear.

IT IS ESSENTIAL to wear anti-slip working footwear.

Hearing protection must be worn in this area.

Hearing protection must be worn in this area.

IT IS ESSENTIAL that long hair be tied back in such a way as to reduce the risk of being snagged or pulled into the machine; operators must wear either appropriate hair covering or wear their hair tied up.

IT IS ESSENTIAL that long hair be tied back in such a way as to reduce the risk of being snagged or pulled into the machine; operators must wear either appropriate hair covering or wear their hair tied up.

IT IS ESSENTIAL to keep the floor around the machine clean and clear of any paper, board or other waste.

IT IS ESSENTIAL to keep the floor around the machine clean and clear of any paper, board or other waste.

IT IS REQUIRED that all machine operators are well-trained personnel, acquainted with Occupational Health and Safety regulations; they should also be familiar with all hazardous situations likely to occur in the operation of sophisticated machines of this complexity.

IT IS REQUIRED that all machine operators are well-trained personnel, acquainted with Occupational Health and Safety regulations; they should also be familiar with all hazardous situations likely to occur in the operation of sophisticated machines of this complexity.

IT IS ESSENTIAL to use the emergency stop switch button whenever the operator's life or health is at risk.

IT IS ESSENTIAL to use the emergency stop switch button whenever the operator's life or health is at risk.

IT IS ESSENTIAL to disconnect the machine from the power supply whenever servicing, maintenance or preventive activities are underway.

IT IS ESSENTIAL to disconnect the machine from the power supply whenever servicing, maintenance or preventive activities are underway.

During packing, unpacking and transportation, special measures should be taken, in order to prevent the machine from tipping over.

During packing, unpacking and transportation, special measures should be taken, in order to prevent the machine from tipping over.

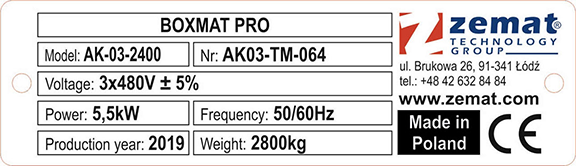

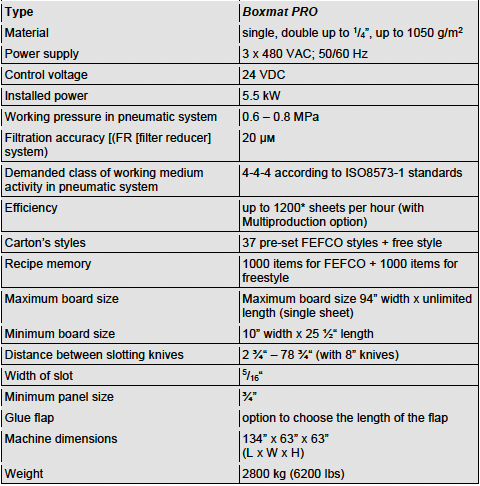

4.0 Technical Specifications

- The Boxmat Pro machine consists of the main body, containing all the electrical and mechanical components, and movable work table. The main body is based on a metal frame ensuring the adequate level of stability. The work table is designed to assist the operators feeding the corrugated material through the machine.

- The corrugated blanks are carried through the machine by a series of rollers and wheels driven by servo-drives. In a similar way the slotting beam is propelled by a servo drives.

- Behind the slotting/scoring beam is the innovative system of rotary tools that enable the operator to cut off excess board and eject them without any cuts or scores enabling them to be re-used for smaller boxes. This also allows oversized blanks to be trimmed to size as they pass through the machine instead of having to trim on another, separate machine.

- It also allows the production of two boxes at one time (with Multi-production option), if box size and sheet size are suitable by attaching a central knife.

- The slots are punched out by a system of blades attached to the scoring beam.

- The slotting blades are automatically moved to the correct positions by asynchronous motors driven by the inverter and encoder, once the dimensions is entered into the touch screen.

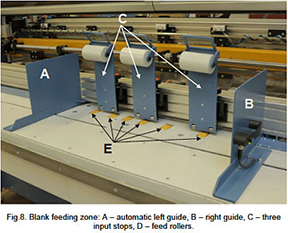

- The left hand guide is positioned automatically and, once a board blank is positioned against it, the right hand guide can be slid up to it to allow the blank to pass through the machine without any twisting.

- The machine is equipped with a full set of covers and guards to protect operators from the moving blades and knives. To comply with all European safety regulations, the machine will not operate if these are not all in place and an appropriate error message will be displayed on the screen.

The manufacturer will ensure that the machine is appropriately packaged for transport. The type and strength of packaging are adapted to the distance and means of transport used, as well with regard to the potential risks associated with the means of transport used. The Manufacturer suggests that Recipients use the Manufacturer's means of transport and service personnel.

Storage of an unused machine does not imply any requirements other than a suitable storage environment. Warehousing must provide sufficient protection against atmospheric agents and be dry, with an acceptable humidity level below 70%. The storage temperature should be between 5 ºC and 40 ºC.

Adequate anti-corrosion protection should be ensured, especially for metal parts which, for technical reasons, have not been painted or protected against corrosion.

If the machine is delivered in a crate and/or covered with film-wrap that creates an anti-corrosive atmosphere, the machine should remain in the same, throughout the entire storage period.

To protect against moisture, it is recommended that the machine is not stored on the floor of the warehouse but on pallets, in order to keep it lifted off the floor.

This box maker should be stored vertically in a dry and well ventilated room. The machine is sensitive to vibration, shock, violent jolts and long-lasting tilts. Even if it is dropped from a relatively insignificant height this may lead to its permanent and irreversible damage.

The above provisions are intended to make all persons and services, who have contact with this device, aware of its high sensitivity to any impactful stimuli and, at the same time, aware also, that no claims, arising from such permanent damage, as described above, will be considered as a valid complaint.

For further advice or information, please contact the manufacturer’s service technicians.

Transport

UNDER NO CIRCUMSTANCES should the machine be assembled, dismantled or transported in any way by unqualified personnel or those unfamiliar with the safety and care information included in this manual. Failure to comply with this basic rule may lead to accidental damage or injury not covered by the manufacturer’s warranty or liability.

UNDER NO CIRCUMSTANCES should the machine be assembled, dismantled or transported in any way by unqualified personnel or those unfamiliar with the safety and care information included in this manual. Failure to comply with this basic rule may lead to accidental damage or injury not covered by the manufacturer’s warranty or liability.

- The entity responsible for transporting and installing the machine at the Ordering Party's plant should be determined at the contract signing stage, however at the latest, after the technical acceptance of the machine at the Manufacturer's plant and before being issued to the Ordering Party.

- Due to the nature of the device, the Manufacturer suggests that the Recipients use the Manufacturer's means of transport and service personnel.

- The machine should be moved using lifting devices such as cranes, forklift trucks or pallet trucks, all of which should have sufficient lifting capacity for the purpose of safe transportation. The persons operating them should have the required permits and the training, as required by law.

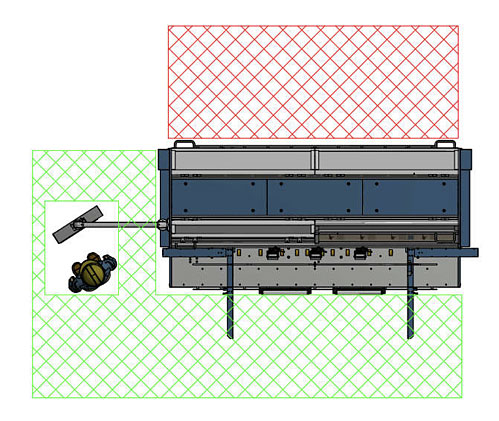

- The correct mode of transportation for BOXMAT PRO machines is presented below.

Fig. 2. The location for lifting the machine is indicated by the pictogram (Fig. 2 -1)

Fig. 3. The correct transportation of the machine using a forklift truck

It is forbidden to lift the BOXMAT PRO machine where so indicated by pictograms; the drawing below refers.

Fig. 4. It is forbidden to lift the BOXMAT PRO machine by its side walls, using a forklift truck.

![]() ATTENTION: Failure to comply with the above pictograms and methods of assembly, may result in damage to the machine's structure and components.

ATTENTION: Failure to comply with the above pictograms and methods of assembly, may result in damage to the machine's structure and components.

![]() ATTENTION: Machine must be transported vertically.

ATTENTION: Machine must be transported vertically.

It is essential that the machine, and all parts and accessories, must be packaged safely and securely. Suitable protective wrapping, pallets and/or crates should be supplied to ensure that the machine and all peripheral parts and accessories arrive for installation safely and undamaged. It is strongly advised to allow the manufacturer to undertake all these tasks to ensure a safe and efficient delivery and installation.

As far as transport procedure is concerned the machine's weight (c. 2800 kg - 6200 lb.) must be taken into account.

![]() ATTENTION: Careless handling of the machine during transport and/or relocation may lead to severe accidents or injuries.

ATTENTION: Careless handling of the machine during transport and/or relocation may lead to severe accidents or injuries.

Installation

Installation of the machine at the workplace, is effected by the Ordering Party's personnel, once the contents of these operating instructions and the Manufacturer's services have become familiar to- and have been agreed to- by the Ordering Party’s personnel. The correct setting of the printer is important as a precondition for its optimal functioning and for the comfort and safety of the operators.

Preparation of the location for the machine, the availability and parameters of electrical, pneumatic and ventilation connections, as well as the preparation of the specific design and acceptance requirements, needed to facilitate operation of the machine, is the responsibility of the Ordering Party.

The Manufacturer will provide the necessary guidance and information to assist the Ordering Party in this regard.

After delivering the machine to its designated location, it should be unpacked and leveled. Its technical condition should then be checked and any damage caused in transport, should be rectified.

![]() ATTENTION: The floor on which the machine is to be placed must have sufficient structural strength to support the weight of the machine and any vibration generated by the normal process of manufacturing boxes. It should also be noted that the majority of the weight of the machine is concentrated at the feet.

ATTENTION: The floor on which the machine is to be placed must have sufficient structural strength to support the weight of the machine and any vibration generated by the normal process of manufacturing boxes. It should also be noted that the majority of the weight of the machine is concentrated at the feet.

![]() ATTENTION: Once the machine is leveled it should not be moved without repeating the leveling process.

ATTENTION: Once the machine is leveled it should not be moved without repeating the leveling process.

The most optimal flooring is made of plain concrete of sufficient depth and coated with a thin layer of non-conducting material.

The foundation on which the machine is placed should be architecturally compliant with the building standards and safety rules fulfilling the requirements of depth, strength and level.

The Buyer is the only person responsible for preparation of base on which the machine is supposed to be installed.

![]() ATTENTION: If the assembly and set-up procedures are conducted individually by the purchaser, they should be performed due to the instructions included in this service manual and/or according to the instructions provided by the manufacturer during the technical acceptance procedure.

ATTENTION: If the assembly and set-up procedures are conducted individually by the purchaser, they should be performed due to the instructions included in this service manual and/or according to the instructions provided by the manufacturer during the technical acceptance procedure.

Use the screws in the machine feet to level the frame. (The sides of the machine's body are the reference plane for level).

![]() ATTENTION: After each change position the machine, check the gap between the upper and lower slotting knives. On the entire length of the upper slotting blades, from the front and back side, the gap should not be less than 0.004 inch.

ATTENTION: After each change position the machine, check the gap between the upper and lower slotting knives. On the entire length of the upper slotting blades, from the front and back side, the gap should not be less than 0.004 inch.

When the machine is leveled, then the work tables should be assembled and placed at the front and rear of the machine (tables are available on demand). Once both work tables are delivered, they should be leveled to the machine.

Work Conditions

GENERAL INFORMATION

![]() ATTENTION: It is the manufacturer’s recommendation, that the machine should be installed in an industrial environment only.

ATTENTION: It is the manufacturer’s recommendation, that the machine should be installed in an industrial environment only.

As written and described within this technical manual, this machine has been designed and manufactured to be used in an industrial environment for the conversion of corrugated fiberboard into a range of cartons and, as such, this machine must be operated within the health and safety regulations associated with the industrial box-making environment.

This machine must not be operated in a potentially explosive atmosphere, in an atmosphere with a high level of pollution, high humidity, high temperatures or in aggressive, or corrosive, fumes.

Due to the electronics and sensors within this machine, it should be used in temperatures from +15°C to +35°C and in a relative humidity ranging from 35% to 85%. Atmospheric humidity condensation, or any potentially aggressive agents, should be avoided.

Temperature changes within the operating environment should not exceed 10°C and the relative humidity should not vary by more than 10%.

![]() ATTENTION: If there are significant temperature and humidity differences between the delivery process and the installation site, the machine should be stored and acclimatized in the site where it is to be operated for 24 hours before starting up.

ATTENTION: If there are significant temperature and humidity differences between the delivery process and the installation site, the machine should be stored and acclimatized in the site where it is to be operated for 24 hours before starting up.

LIGHTING

The criterion for the minimum level of lighting indicates that the acceptable lighting on a horizontal working plane, in rooms where personnel attend for a long time, regardless of what visual tasks are performed, should be 300 lx.

Where, however, there is a degree of visual difficulty greater than average, resulting in difficulties in working, the requirement pertains to ensure higher viewing comfort; this also applies where employees are mostly people over 40 years of age. With this in mind, the level of intensity in the lighting should then be higher than the minimum permissible level of 500 lx.

5.4.3. NOISE

The device is the source of the noise intensity above 85dB requiring use of plant protection personnel.

Hearing protection must be worn in this area!

Hearing protection must be worn in this area!

We note that all environment have their own noise emissions, which can effectively influence the levels of noise issued by the machine during operation, especially in various technological systems.

Power Supply Parameters

ELECTRIC SUPPLY

The machine must be connected to a power supply of 3 x 480 VAC; 50/60 Hz; (3P+N+PE), equipped with overcurrent protection.

The Buyer's installation must provide shock protection in accordance with PN-EN 60204-1:2018-12.

COMPRESSED-AIR SYSTEM

The machine uses air pressure ranging from 6-8bar / 85-110 psi.

The filtered impurities are less than 20 µm, to comply with ISO8573-1 4-4-4 standards.

6.0 Machine Operation

Assuming that all conditions for the installation and activities described in the previous chapter have been met and successfully carried out, preparations can begin for the first start-up of the machine, in production conditions at the Contracting Party's plant.

Assuming that all conditions for the installation and activities described in the previous chapter have been met and successfully carried out, preparations can begin for the first start-up of the machine, in production conditions at the Contracting Party's plant.

![]() ATTENTION: Initially, the machine should be started up under the supervision of the manufacturer’s agents.

ATTENTION: Initially, the machine should be started up under the supervision of the manufacturer’s agents.

The Service Conditions must be read and understood before starting the machine.

SERVICE CONDITIONS – GENERAL GUIDELINES AND PROCEDURES

To ensure correct machine operation, all adjustments and settings must be carried out by the manufacturer's trained technicians, once the machine has been assembled and installed and the initial start-up procedures have been implemented. Corrugated material for testing the machine should be made available by the Buyer.

Before using the machine, that is, prior to its first start-up, the Contracting Party has the absolute obligation to train those employees who will be its future operators. Moreover, due to the different work cycles carried out by our machines, in various industrial environments, the Recipient has the absolute obligation to create a clear and transparent workplace instruction manual for the device, adapted to its own production cycles.

![]() UNDER NO CIRCUMSTANCES should the machine be operated by unqualified personnel. The machine operators must be familiar with the occupational health and safety rules, with the focus on giving special consideration to the risk created by using this machine.

UNDER NO CIRCUMSTANCES should the machine be operated by unqualified personnel. The machine operators must be familiar with the occupational health and safety rules, with the focus on giving special consideration to the risk created by using this machine.

ATTENTION: The Recipient, or a person authorized by him/her on the basis of these operating instructions and the characteristics of his/her own production technology, has the absolute obligation to compile a MACHINE-BASED INSTRUCTION MANUAL for the employees.

ATTENTION: The Recipient, or a person authorized by him/her on the basis of these operating instructions and the characteristics of his/her own production technology, has the absolute obligation to compile a MACHINE-BASED INSTRUCTION MANUAL for the employees.

IT IS STRONGLY RECOMMENDED to instruct each person assigned to work with, or near, this machine not only in the operating of the machine but also in the occupational health and safety rules associated with operating the machine.

IT IS STRONGLY RECOMMENDED to instruct each person assigned to work with, or near, this machine not only in the operating of the machine but also in the occupational health and safety rules associated with operating the machine.

The setting and checking procedure, implemented prior to using this machine, must only be performed by trained and authorized personnel.

The setting and checking procedure, implemented prior to using this machine, must only be performed by trained and authorized personnel.

BEFORE USING THE MACHINE IT IS STRONGLY RECOMMENDED TO CHECK THE FOLLOWING:

- the effectiveness of protection against electric shock;

- the supply voltage;

- value and phase compliance;

- the emergency buttons (safety switches - EMERGENCY STOP) if necessary, unlock by turning clockwise;

- the magnetic safety sensors of the covers and side windows;

- the security locks are, in fact, locked;

![]() ATTENTION: Any maintenance work or changing of tools etc., that requires the machine to be operated with covers open, must only be carried out by trained and competent personnel and must be completed as quickly as possible before the covers are closed and full safety status is restored.

ATTENTION: Any maintenance work or changing of tools etc., that requires the machine to be operated with covers open, must only be carried out by trained and competent personnel and must be completed as quickly as possible before the covers are closed and full safety status is restored.

![]() ATTENTION: All switch boxes, covers and guards must be closed before attempting to use the machine and must remain closed during use.

ATTENTION: All switch boxes, covers and guards must be closed before attempting to use the machine and must remain closed during use.

It is strictly forbidden to operate the machine with any safety switches or other safety devices defeated or altered in any way. All these devices are fitted to protect the safety of the operator and other personnel. It is recommended that all such devices are checked and tested regularly to confirm that they are all operating correctly.

Each machine operator should be familiarized with all the safety features and devices associated with this machine.

IT IS STRICTLY FORBIDDEN to remove any covers or guards while the machine is in operation.

IT IS STRICTLY FORBIDDEN to remove any covers or guards while the machine is in operation.

IT IS STRONGLY RECOMMENDED TO attach and close ALL covers and guards designed for the machine.

IT IS STRONGLY RECOMMENDED TO attach and close ALL covers and guards designed for the machine.

In the area around the machine, and up to 1.5m, all obstacles must be removed and the area must be clean and appropriately lit. Particular care should be taken when Fork Lift Trucks are fetching and removing materials and cartons.

The area in close vicinity to the machine should be clean and cleared of impurities such as oil, dust and dirt in order to reduce to the minimum the risk of a slip, trip or fall.

ATTENTION: When the machine is in operation the area surrounding the machine should not be blocked as it may cause a slip, trip or fall.

ATTENTION: When the machine is in operation the area surrounding the machine should not be blocked as it may cause a slip, trip or fall.

UNDER NO CIRCUMSTANCES should any oil, solvents or other caustic or toxic liquids be poured out in the close vicinity to the machine.

UNDER NO CIRCUMSTANCES should any oil, solvents or other caustic or toxic liquids be poured out in the close vicinity to the machine.

IT IS THEREFORE ORDERED to keep the floor around the machine clean and clear.

IT IS THEREFORE ORDERED to keep the floor around the machine clean and clear.

The machine controls, indicators, flexible conductors, pipes or shafts should not be used as handles. Any unintentional displacement of these machine parts may cause accidental and unintentional activation or changes to the machine working parameters and, in extreme situations, may lead to the machine failure or break- down.

IT IS ESSENTIAL that any accident involving the operator, or any machine failure, should be promptly reported to the management.

IT IS ESSENTIAL that any accident involving the operator, or any machine failure, should be promptly reported to the management.

The qualified machine operators should be equipped with the regular working clothing, protective gloves and anti-slip, safety footwear.

Since the basic risks to the machine operators are moving rollers, wheels and shafts, the machine should not be operated by personnel wearing loose clothing or long and loose hair.

IT IS ESSENTIAL to wear the suitable working clothing reducing to the minimum the possibility of being snagged or pulled into the machine.

IT IS ESSENTIAL to wear the suitable working clothing reducing to the minimum the possibility of being snagged or pulled into the machine.

IT IS ESSENTIAL to wear protective gloves while operating the machine and handling cardboard.

IT IS ESSENTIAL to wear protective gloves while operating the machine and handling cardboard.

IT IS ESSENTIAL to wear anti-slip working footwear.

IT IS ESSENTIAL to wear anti-slip working footwear.

Hearing protection must be worn in this area!

IT IS ESSENTIAL to secure the operator’s hair in such a way to reduce to the minimum the risk of being snagged or pulled into the machine.

IT IS ESSENTIAL to secure the operator’s hair in such a way to reduce to the minimum the risk of being snagged or pulled into the machine.

Controls and Indicators Available for Operator

In the machine presented, all handling elements are located directly on its construction body, or on the control panel. Before using the machine, all personnel operating the machine should familiarize themselves with the location of these elements and the functions they control.

The handling and control elements of the machine which are available to the operator include:

Fig.5. MAIN SWITCH Fig.6. CONTROL PANEL Fig. 7 COMPRESSED AIR TERMINAL

- MAIN SWITCH - the switch installed on the switch box doors (Fig.5), is designed to switch the electrical supply on and off. When it is turned to the 1 position it means that the machine is ON, when it is turned to the 0 position, it means that the machine is switched OFF.

- HMI panel – a touch-sensitive screen which can be found on the control panel (Fig.6), it is designed to programming and control the machine.

- START – This green button, when lit, indicates that the machine is ready for work (Fig.6)

- RESET – a blue button used to restart the control system and the machine’s safety system and alarms after an error (Fig.6).

- EMERGENCY STOP - a mushroom-headed button for the immediate shutdown of the entire machine, in the event of any failure or accident. Buttons are located on the operator's panel (Fig.6) and to the rear and side of the machine.

-

Compressed air terminal (Fig.7);

-

The manually operated compressed air shut-off valve (in order to open the valve - turn it to the left and set to ON position; a turn to the right - the OFF position - the valve is closed);

Positioning of Right Guide and Input Stops

ADJUSTING THE POSITION OF THE RIGHT LIMITER AND THE ENTRY BUMPERS

![]() ATTENTION! Regulation should be conducted after selection of style, entering the cardboard dimensions and automatic setting of left guide.

ATTENTION! Regulation should be conducted after selection of style, entering the cardboard dimensions and automatic setting of left guide.

- Place the blank on the table

- Undo handles of the input stops (Fig.9).

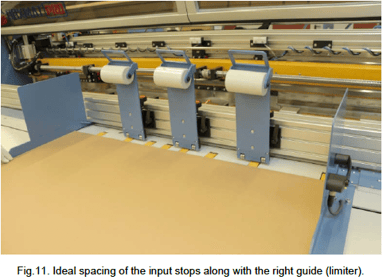

- Lift up the input stops gently and slide apart two of them towards the ends of board and the third one should be placed in the center and over the roller (Fig.11).

- Tighten up the orange handles of the input stops (Fig.9).

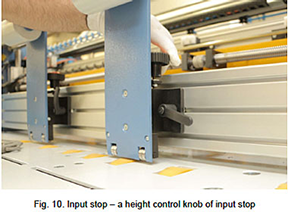

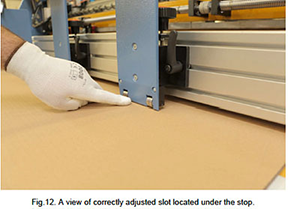

- Using the knob (Fig. 10) set the gap under each bumper so that it is possible to insert one carton into it; ensure, however, that it is not possible to insert two cartons (Fig.12).

- Set the right stop with the help of the hand grip (Fig.13) so that it almost sticks to the mat; leave 1/16” of slack so that the mats do not jam between the stops (Fig.14).

Connection to a Power Source

- Check the area around the machine. It is designed to work in a clean and neat environment without any waste or obstacles that could adversely influence on its regular working activity.

- Prepare the corrugated blanks, ready for production.

- If required by the production cycle provided by the user, place containers for waste and ready-printed cartons in a suitable place, near the machine.

- Check that all covers and guards are in place and that all doors are closed – it is strictly forbidden to perform work with open covers or missing guards as this will trigger the proximity sensors and prevent the machine from working.

- Check that the EMERGENCY STOP push-button on the control panel is in the correct position. In order to reset it turn the mushroom-headed push- button clockwise.

- Connect the electrical power supply to the machine (put the plug into the power supply socket and/or switch on) and the compressed air system by connecting the air hose to the terminal and switching on the compressor.

- Check that the pneumatic supply is between 85psi/6bar and 110psi/8bar.

- Turn the MAIN SWITCH installed in the machine side casing, to the 1 / ON position.

- Due to standard procedure when the machine is switched on, an error message such as ALARM: NOT READY; EMERGENCY STOP should be found on the HMI touch panel. In order to put the machine in motion press START button. As a result, the test of alarm systems and the drives shall be put into operation. When the START button flashes green, it means that the machine enters a stand-by mode and it is ready for work.

- When the TEST key is displayed on the touch-sensitive display panel, press it and as a result the rollers transporting cardboards will be put in rotation test along with a knife which is supposed to perform a down/up movement test (procedures last about 5 seconds).

- If all procedures end up successfully, the machine is ready for work – the main window should be displayed on the HMI panel.

![]() ATTENTION: Covers must always be closed or the machine will not work.

ATTENTION: Covers must always be closed or the machine will not work.

![]() ATTENTION: the EMERGENCY STOP button is designed to be pressed at any time especially when an emergency shut- down is promptly needed.

ATTENTION: the EMERGENCY STOP button is designed to be pressed at any time especially when an emergency shut- down is promptly needed.

![]() ATTENTION! In case the error message can still be seen on the display after pressing the START button, go to ALARMS, ERROR MESSAGES and FAILURES shown in the technical documentation.

ATTENTION! In case the error message can still be seen on the display after pressing the START button, go to ALARMS, ERROR MESSAGES and FAILURES shown in the technical documentation.

Disconnection

The following switch-off procedure should always be implemented when production is completed:

- Turn the MAIN SWITCH to the position 0-OFF – this means that the machine is switched off.

- Clear the working environment around the machine.

- If the machine is being shut down for a longer period – i.e. the weekend - The electrical power supply and the compressed air should be disconnected.

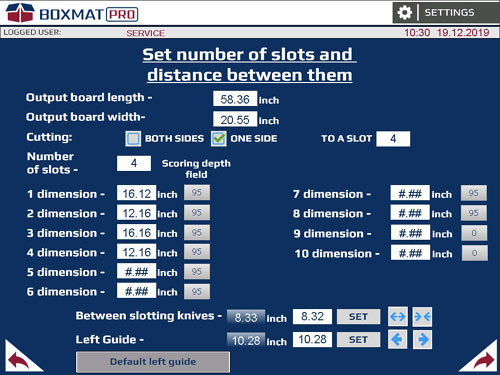

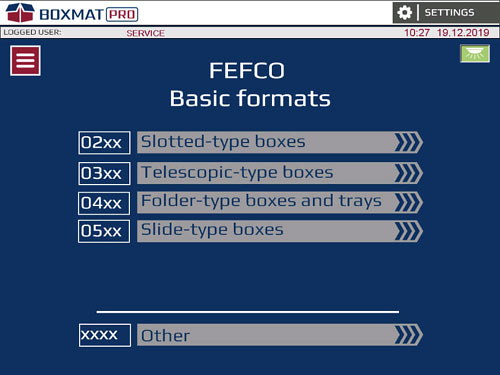

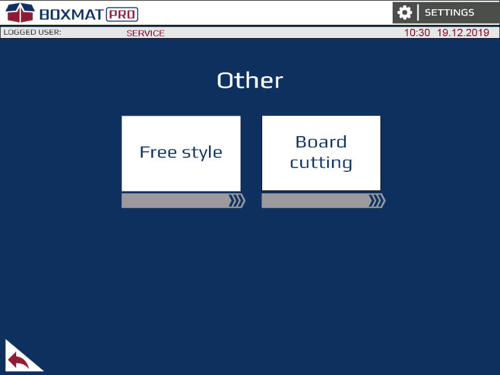

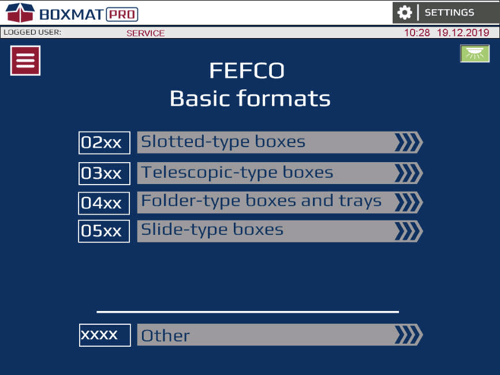

7.0 Description of HMI Panel Screen

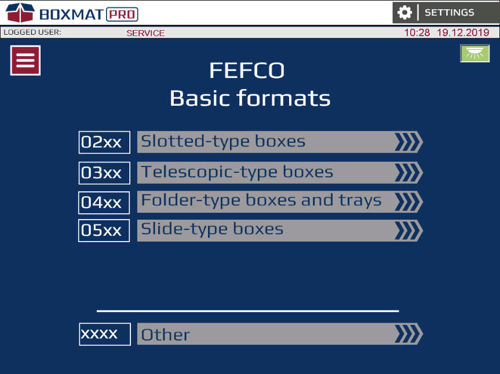

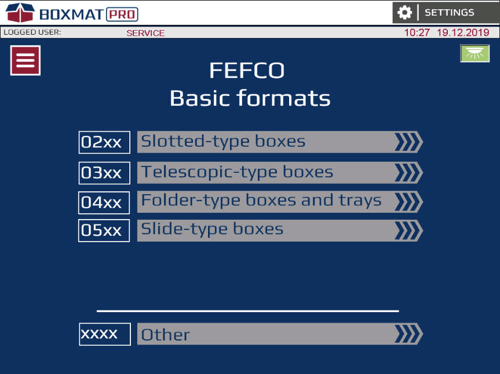

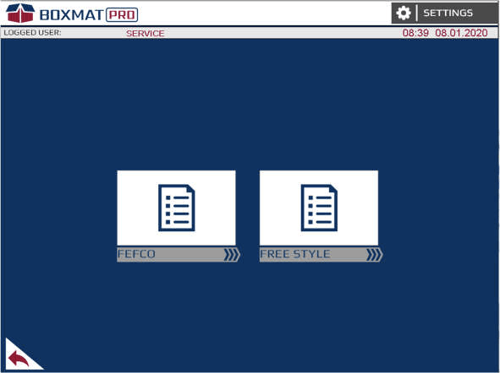

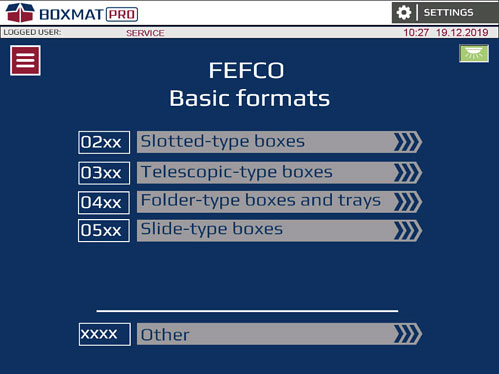

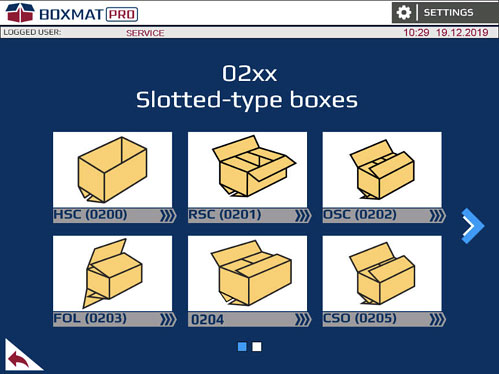

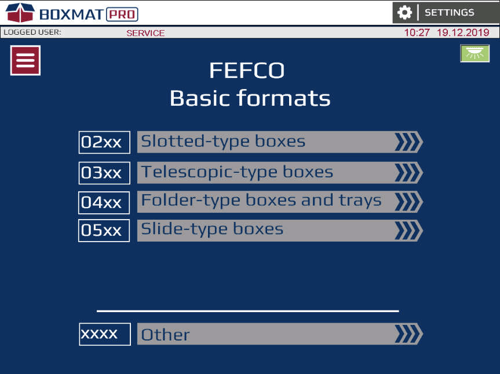

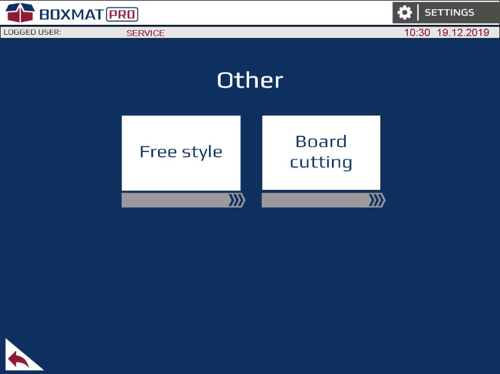

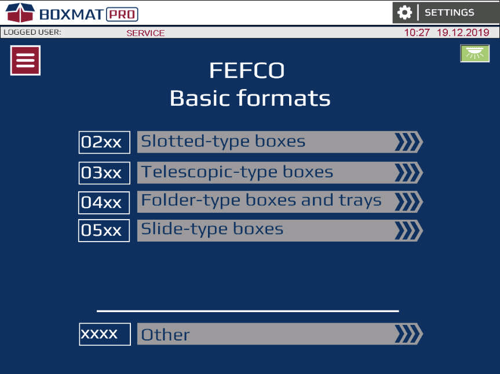

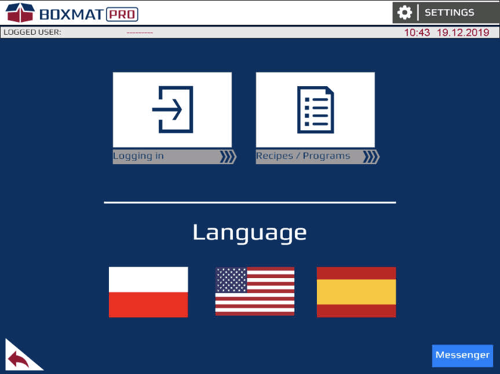

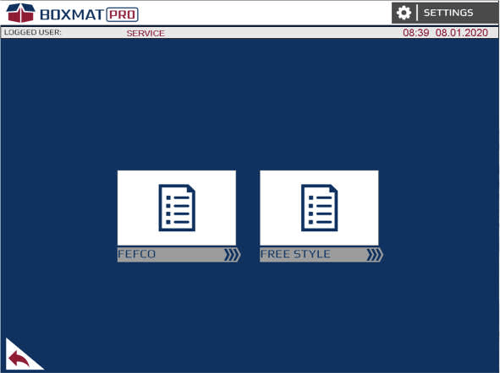

Home - Choice of Box Design

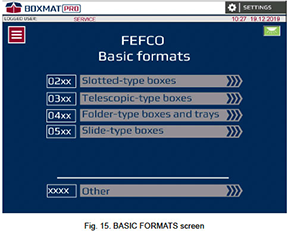

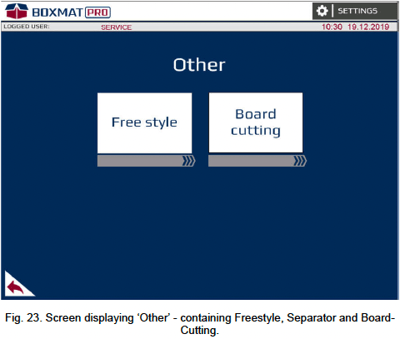

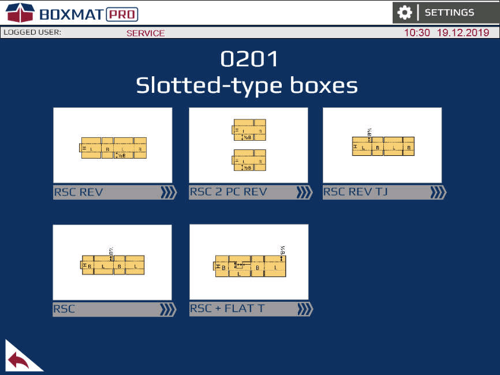

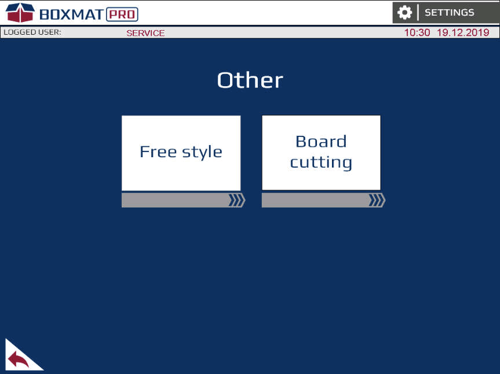

On the main screen, are the basic formats of the FEFCO styles available. First, select the style or select ‘Other’ if a Free Style box is to be designed.

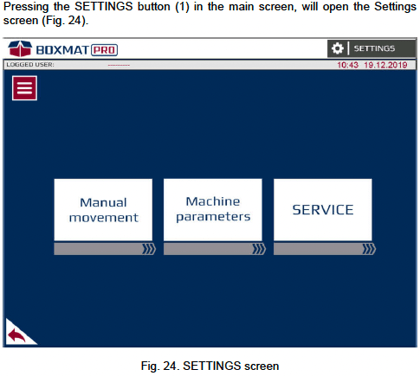

- SETTINGS - the button opens a SETTINGS screen (page 51). On this screen, three further screens can be selected:

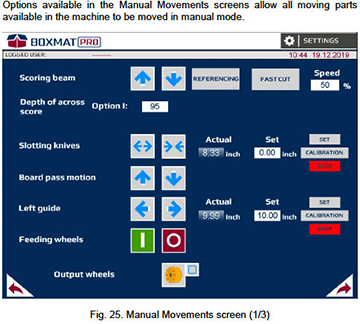

- Manual Movement - options available on the Manual Movements screens which allow all moving parts, available in the machine, to be moved manually.

- Service - options available in the Service screens contain statistical information on the machine’s operation and advanced parameters of the machine's operation.

-

MENU - the button opens a screen showing the following features: LOGGING IN, RECIPES, STATISTIC and LANGUAGE settings.

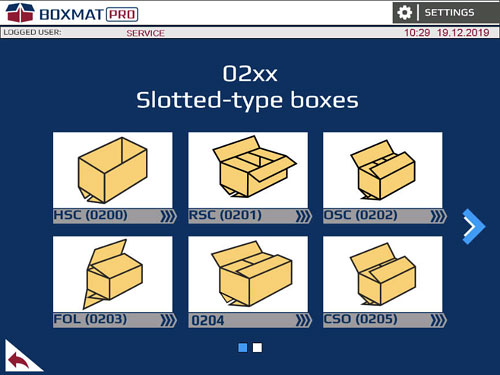

-

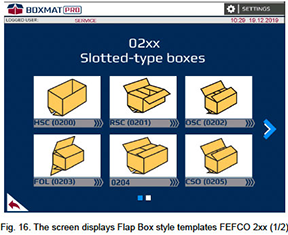

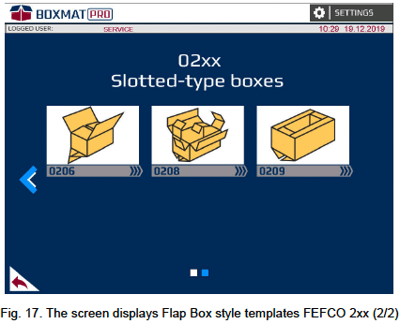

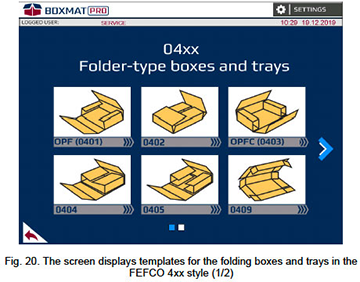

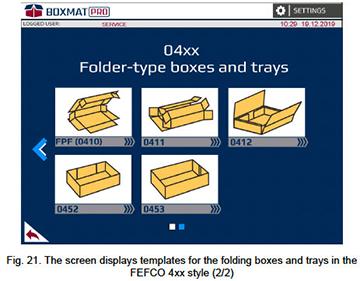

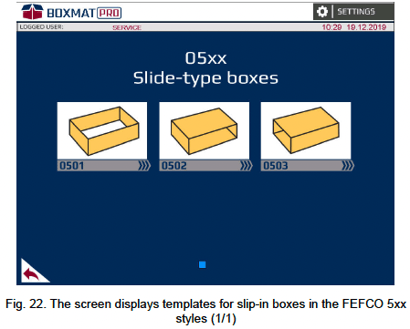

SLOTTED-TYPE BOXES (flap boxes) - the button opens a screen containing templates for flap boxes in FEFCO styles (Fig. 16, Fig. 17).

moves the scoring beam upwards

moves the scoring beam upwards moves the scoring beam downwards;

moves the scoring beam downwards;

When the Up Arrow button displays yellow, it indicates that the scoring/slotting beam is in the top position ready for starting.

When the Up Arrow button displays yellow, it indicates that the scoring/slotting beam is in the top position ready for starting.

14. REFERENCING - the button sets the scoring beam with slotting knives in the top position for starting.

15. FAST CUT - the button starts one full cycle of the scoring/slotting beam at setup speed- value 0% - without scoring between the slots;

- value 100% - max scoring depth between the slots;

17.  these buttons change the position of the slotting knives. Press and hold to move:

these buttons change the position of the slotting knives. Press and hold to move:

the slotting knives move apart slowly.

the slotting knives move apart slowly. the slotting knives move closer slowly.

the slotting knives move closer slowly.

The position of the slotting knives is measured as the distance fromthe point of the left knife to the point of the right knife. The knives move evenly toward or away from the center of the machine. Spacing of the blades can range from 2 1/2” to 78 1/2“.

When one of the buttons displays a yellow arrow, it indicates that the slotting knives have travelled as far as possible.

18. Actual - the field displays the current distance between the slotting knives.

19. Set field - enter the distance at which the slotting knives should be spaced.

20. Set button - starts the slotting knives' movement to a position as entered in the Set field (19).

21. Calibration button – opens a window to enter the actual measurement between the knives. This will update the ‘Actual’ field.

Opening of the calibration window is only possible after entering Password 7415

22. STOP – the button stops slotting knives movement

23. Board Pass Motion ![]() Press and hold to move the corrugated sheet in or out of the machine. Press

Press and hold to move the corrugated sheet in or out of the machine. Press ![]() for forward and

for forward and ![]() for reverse.

for reverse.

24. Board Guide ![]() Press and hold these buttons to change the position of the left, automatic, board guide.

Press and hold these buttons to change the position of the left, automatic, board guide.

The position of the left guide is measured as the distance from the inner wall of the guide to the center of the machine. It is possible to set the guide within the range 1 3/4” to 47”.

When one of the buttons displays a yellow arrow, it indicates that the left guide is in the extreme position.

25. Actual Position - the field displays the current position of the board guide.

26. Set - the field in which it is possible to enter the position at which the left board guide is to be set.

27. Set - this button moves the left guide to the position in the ‘Set’ field. (26).

28. Calibration button – opens a window to enter the actual distance from the center of the machine to the left guide. This will update the ‘Actual’ field (25).

Opening of the calibration window is only possible after entering Password 7415.

29. STOP – the button stops the left guide movement

30. Feeding Rolls: ![]() - these buttons are used to start or stop the feed rollers.

- these buttons are used to start or stop the feed rollers.

31. ![]() this button returns to the previous screen (Fig. 24).

this button returns to the previous screen (Fig. 24).

32. ![]() this button leads to the next screen (Fig.26).

this button leads to the next screen (Fig.26).

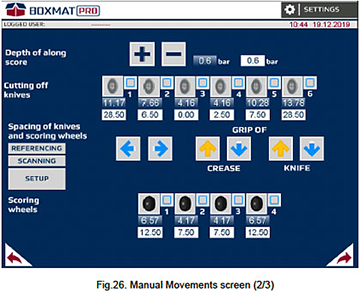

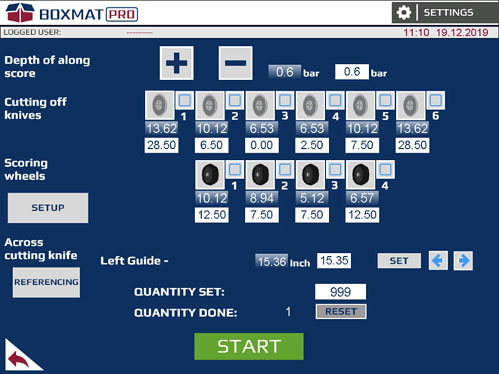

33. + - these buttons change the depth of the scores along the box by adjusting the pressure on the rolls. Pressing the button changes the pressure setting by 0.1 bar.:

- + increases the pressure;

- - reduces the pressure.

It is possible to set pressure within the range 0 to 3 bar.

The pressure can never reach a value greater than the supply pressure to the machine.

34. The field displaying the actual pressure applied to the scoring wheels.

35. The field displaying the set pressure applied to the scoring wheels. In this field, it is possible to enter the pressure value. By pressing the Enter button on the keyboard, the pressure will be updated.

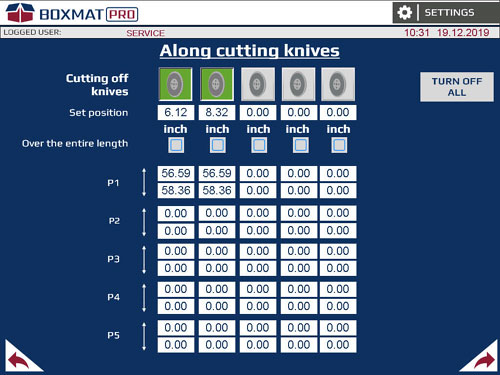

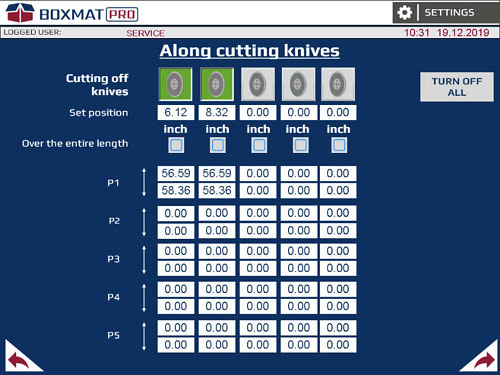

36. Along cutting off knives - These graphics show the active lengthwise cutting- off knives (trim-to-width). Pressing on the picture will lift or lower the corresponding knife. Lowering of the knife is indicated by a green "tick" ![]() .

.

The machine can accommodate 4, 6 or 8 knives. The maximum number of knives used depends on any additional options of the machine.

The machine can accommodate 4, 6 or 8 knives. The maximum number of knives used depends on any additional options of the machine.

37. The fields display the actual position of each rotary, lengthwise knife.

The position of each lengthwise cutting knife is measured as the distance from the blade to the center of the machine. It is possible to set the knives within the range 1 3/4” to 47”.

The position of each lengthwise cutting knife is measured as the distance from the blade to the center of the machine. It is possible to set the knives within the range 1 3/4” to 47”.

38. Fields displaying the pre-determined position of each lengthwise knife. In these fields, it is possible to enter the position at which each knife is to be set from the center.

The knives should be spaced in the same order as presented in the graphics, otherwise the message "NOT POSSIBLE TO SET UP ALONG KNIVES [KNIFE NUMBER ]” will be displayed.

The knives should be spaced in the same order as presented in the graphics, otherwise the message "NOT POSSIBLE TO SET UP ALONG KNIVES [KNIFE NUMBER ]” will be displayed.

Spacing of knives and scoring wheels ![]() these buttons change the position of the tool holder, that is, the scoring wheels and the longitudinal knives:

these buttons change the position of the tool holder, that is, the scoring wheels and the longitudinal knives:

moves the holder to the left;

moves the holder to the left; moves the gripper to the right.

moves the gripper to the right.

![]() these buttons lock or release the scoring wheels gripper pin:

these buttons lock or release the scoring wheels gripper pin:

unlocks the gripper pin;

unlocks the gripper pin; locks the gripper pin.

locks the gripper pin.

An arrow in yellow indicates the pin's position

An arrow in yellow indicates the pin's position ![]() pin locked,

pin locked, ![]() pin unlocked.

pin unlocked.

41. ![]() these buttons lock or release the longitudinal knives gripper pin:

these buttons lock or release the longitudinal knives gripper pin:

unlocks the gripper pin;

unlocks the gripper pin; locks the gripper pin.

locks the gripper pin.

42. REFERENCING - this button moves the tool holder to his initial position.

When REFERENCING procedure is active backlight of the push button is on.

When REFERENCING procedure is active backlight of the push button is on.

43. SCANNING - this button moves the scanner (tool holder) over the tools to define their actual positions and to check their quantities.

When SCANNING procedure is active backlight of the push button is on.

When SCANNING procedure is active backlight of the push button is on.

44. SETUP - this button moves the longitudinal cutting knives and scoring wheels to their pre-set positions as entered in the setup fields.

When SETUP procedure is active backlight of the push button is on.

When SETUP procedure is active backlight of the push button is on.

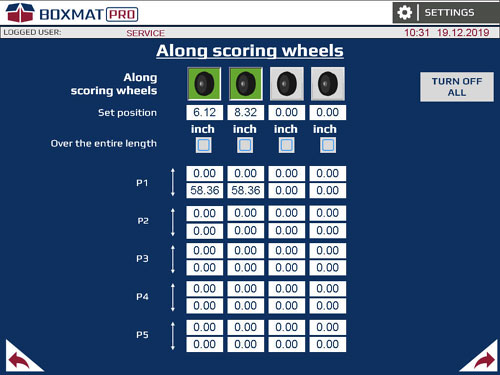

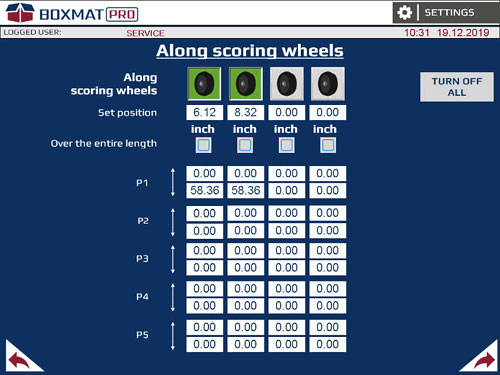

45. Graphic drawings representing active scoring wheels. Pressing on the graphic drawing lifts or lowers the corresponding scoring wheels. Lowering the roller is indicated by a green "tick" ![]()

The machine can accommodate 4, 6 or 8 scoring wheels.

The machine can accommodate 4, 6 or 8 scoring wheels.

46. The fields display the current position of each scoring wheel.

The position of the scoring wheel is measured as the distance from the apex of  the roller-or the middle of the roller when there are two pins - to the center of the machine. It is possible to set the rolls within the range 1” to 47”.

the roller-or the middle of the roller when there are two pins - to the center of the machine. It is possible to set the rolls within the range 1” to 47”.

47. These fields display the pre-determined position of each scoring wheel. In these fields, it is possible to enter the position at which each roller is to be set.

The rollers should be spaced in the same  order as presented in the graphics, otherwise the message "Incorrect data for the scores" will be displayed.

order as presented in the graphics, otherwise the message "Incorrect data for the scores" will be displayed.

48. ![]() - this button returns to the previous screen (Fig. 25).

- this button returns to the previous screen (Fig. 25).

49. ![]() - this button leads to the next screen (Fig.27).

- this button leads to the next screen (Fig.27).

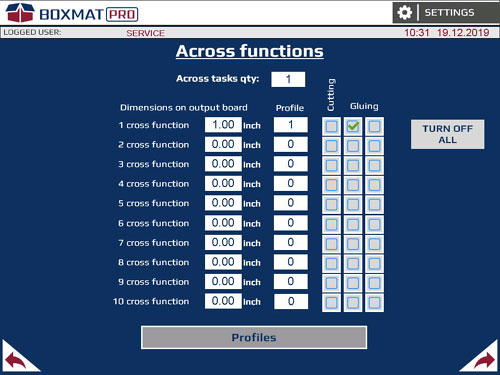

Fig.27. Manual Movements screen (3/3)

51. The graphic shows the transverse cutting knife. Pressing on the picture will lift or lower the knife. The lowering of the knife is indicated by a green "tick" ![]() .

.

52. REFERENCING - this button moves the across cutting knife to the home position.

When REFERENCING procedure is active backlight of the push button is on.

When REFERENCING procedure is active backlight of the push button is on.

53. Output Wheels - The graphic shows the non-crush roller. Pressing on the picture lifts or lowers all the exit rollers. Lowering the rollers is signaled by a green "tick" ![]() .

.

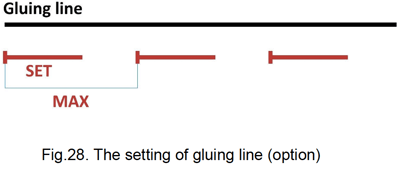

54. The graphic shows two the gluing head. Pressing on the picture will open the gluing head (option).

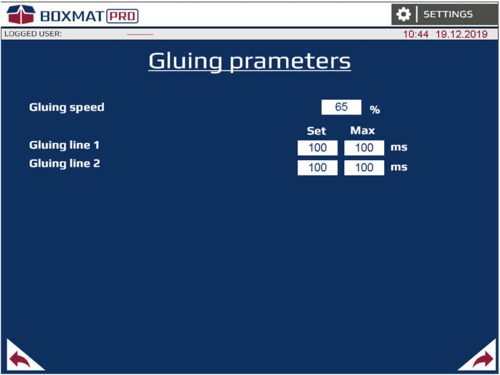

55. Gluing line 1 – Set – Opening time of the gluing head for the gluing line 1 (Fig.28) (option).

56. Gluing line 1 – MAX – Cycle time of the gluing head for the gluing line 1 (Fig.28) (option).

57. Gluing line 2 – Set - Opening time of the gluing head for the gluing line 2 (Fig.28) (option).

58. Gluing line 2 – MAX – Cycle time of the gluing head for the gluing line 2 (Fig.28) (option).

59. Move the printer module 1 (option):

lift up/down the printer module 1

lift up/down the printer module 1 or

or  indicates the position of printer module 1 Move the printer module 2 (option):

indicates the position of printer module 1 Move the printer module 2 (option):

Move the printer module 2 (option):

lift up/down the printer module 2

lift up/down the printer module 2 or

or  indicates the position of printer module 2

indicates the position of printer module 2  - this button returns to the previous screen (Fig.26).

- this button returns to the previous screen (Fig.26).

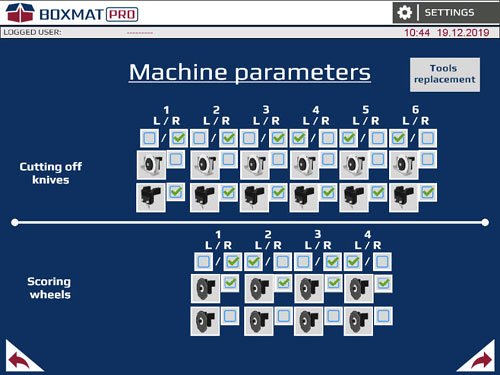

Machine Parameters Screens

The options available in the Machine Parameters screens are basic machine settings such as machine tool positions, velocity of individual sub-assemblies and so forth.

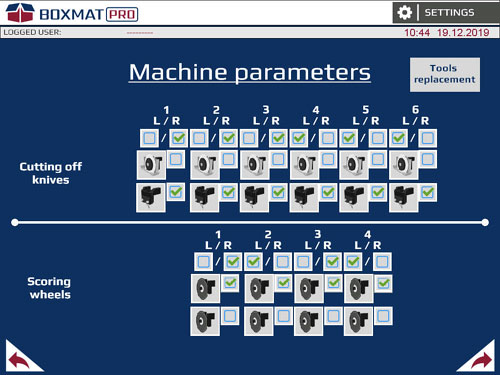

Fig. 29. The Machine Parameters’ screen (1/5)

62. Graphics showing active, along cutting knives. Pressing on the graphic element changes the orientation of the corresponding knife:

- a green "tick"

indicates that the knife's orientation is to the left or right of the fixing as viewed from the front of the machine (Fig. 30– A,B).

indicates that the knife's orientation is to the left or right of the fixing as viewed from the front of the machine (Fig. 30– A,B).

If the operator changes the position of a  tool, i.e. from the left side to the right, then this change MUST be entered into the machine parameters.

tool, i.e. from the left side to the right, then this change MUST be entered into the machine parameters.

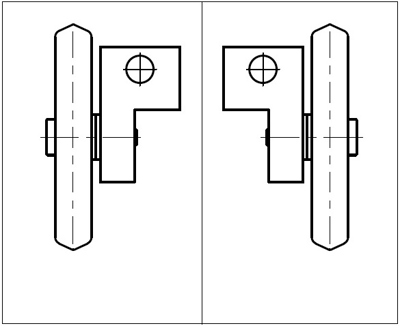

Fig. 30. An example of tool orientation on the basis of scoring wheels: A - to the left of the fixing as viewed from the front of the machine, B - to the right of the fixing as viewed from the front of the machine.

63. Rotary knives / razor blade knives - This parameter describes the type of knives mounted on the machine

The operator must always enter this  change into the parameter if the machine’s knives have been changed from one type to the other.

change into the parameter if the machine’s knives have been changed from one type to the other.

64. Graphics representing active scoring wheels. Pressing on the graphic image changes the orientation of the corresponding roll:

- a green "tick" indicates that the roller is to the left or right of the fixing when viewed from the front of the machine (Fig. 30 – A,B).

The operator must always enter this  change into the parameter if the machine’s scoring wheels have been changed from one side to the other.

change into the parameter if the machine’s scoring wheels have been changed from one side to the other.

65. Scoring wheels type 1 / type 2 - This parameter describes the type of scoring wheels mounted on the machine

The operator must always enter this  change into the parameter if the machine’s scoring wheels have been changed from one type to the other.

change into the parameter if the machine’s scoring wheels have been changed from one type to the other.

66. ![]() - this button returns to the previous (Fig. 24).

- this button returns to the previous (Fig. 24).

67. ![]() - this button leads to the next screen (Fig. 31).

- this button leads to the next screen (Fig. 31).

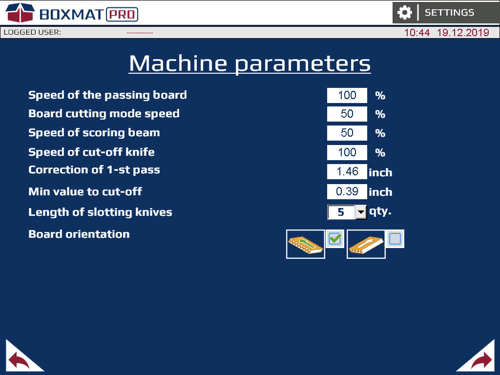

68. Speed of the passing board – speed of the board in the FEFCO or Free Style cycle.

69. Board cutting mode speed – speed of the board in board cutting mode

70. Speed of scoring beam – speed of the slotting/scoring beam in the cycle

71. Speed of cut-off knife – speed of the across cutting knife in the cycle

72. Correction of the 1st pass – this parameter will affect the length of the first panel of a box. If any maintenance has taken place, this parameter may need to be changed.

73. Min value to cut-off – set the min value to be cut-off by the length from oversized blank

74. Length of slotting knives – number of slotting knives mounted on the machine for every side

75. Board orientation – rapid or smooth board passing in cycle

76. ![]() - this button returns to the previous (Fig. 29).

- this button returns to the previous (Fig. 29).

77. ![]() - this button leads to the next screen (Fig. 32).

- this button leads to the next screen (Fig. 32).

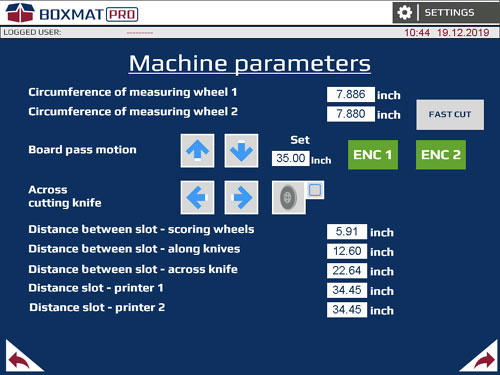

Fig. 32. The Machine Parameters’ screen (3/5)

78. Circumference of measuring wheel 1 and 2 - the exact circumference of the measuring wheels.

79. Board Pass Motion ![]() Press and hold to move the corrugated sheet in or out of the machine. Press

Press and hold to move the corrugated sheet in or out of the machine. Press ![]() for forward and

for forward and ![]() for reverse.

for reverse.

80. Set - the distance the board will travel after pressing the Encoder 1 or Encoder 2 buttons, measured by measuring wheel 1 or 2.

81. Encoder 1 - the button starts passage of the board for encoder 1.

The button should be enabled when the board is under encoder 1.

The button should be enabled when the board is under encoder 1.

82. Encoder 2 - the button starts passage of the board for encoder 2.

The button should be enabled when the board is under encoder 2.

The button should be enabled when the board is under encoder 2.

83. ![]() the buttons for the manual operation of the across knife:

the buttons for the manual operation of the across knife:

moves the knife to the left;

moves the knife to the left; moves the knife to the right.

moves the knife to the right.

84. The graphic shows the across cutting knife. Pressing on the picture will lift or lower the knife. The lowering of the knife is indicated by a green "tick" ![]() .

.

85. Distance slot-along scores – the distance from the center of the scoring beam to the center of the scoring wheels.

86. Distance between slot - along knives – the distance from the center of the scoring beam to the rotary knife.

87. The distance between slot - across knife – the distance from the center of the scoring beam to the across knife.

88. Distance slot – printer 1 – the distance from the center of the scoring beam to the printer module 1.

89. Distance slot – printer 2 – the distance from the center of the scoring beam to the printer module 2.

90. ![]() - this button returns to the previous screen (Fig. 31).

- this button returns to the previous screen (Fig. 31).

91. ![]() - this button leads to the next screen (Fig. 33).

- this button leads to the next screen (Fig. 33).

Fig. 33. The Machine Parameters’ screen (4/5) (option)

92. Gluing speed – Speed of the gluing head during glue mode (option).

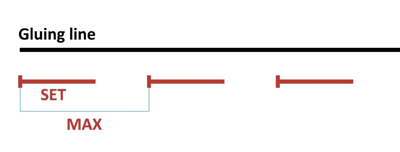

Fig.34. The setting of gluing line

93. Gluing line 1 – Set – Opening time of the gluing head for the gluing line 1 (Fig.34) (option).

94. Gluing line 1 – MAX – Cycle time of the gluing head for the gluing line 1 (Fig.34) (option).

95. Gluing line 2 – Set - Opening time of the gluing head for the gluing line 2 (Fig.34).

96. Gluing line 2 – MAX – Cycle time of the gluing head for the gluing line 2 (Fig.34) (option).

97. ![]() - this button returns to the previous screen (Fig. 32).

- this button returns to the previous screen (Fig. 32).

98. ![]() - this button leads to the next screen (Fig. 35).

- this button leads to the next screen (Fig. 35).

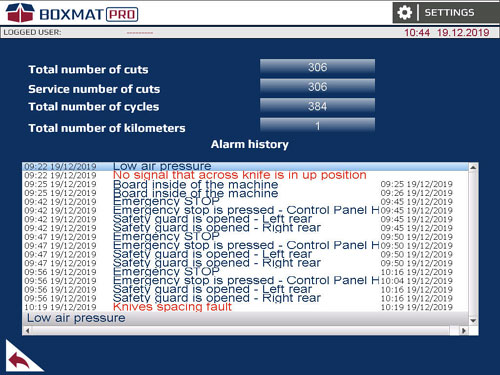

Fig. 35. The Machine Parameters’ screen (5/5)

99. Total number of cuts - the number of cuts made by the slotting beam since its inception.

100. Service number of cuts - the number of cuts made by the slotting beam since the last service.

101. Total number of cycles - the number of automatic work cycles since its inception.

102. Total number of kilometers - the number of kilometers of the boards measured by the encoders since its inception

103. Alarm history - the record of messages.

104. ![]() - this button returns to the previous screen (Fig. 33).

- this button returns to the previous screen (Fig. 33).

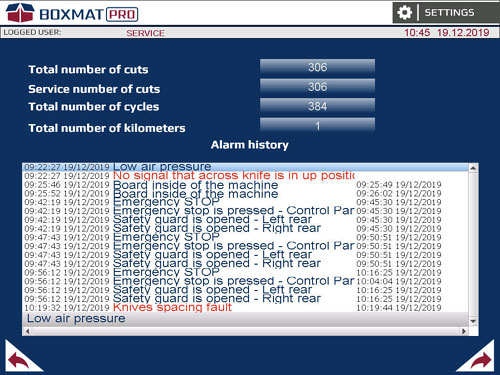

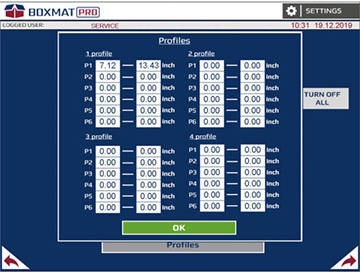

Service Screens

Service screens contain statistical information on the operation of the machine.

Fig. 36. Service Screen (1/3)

105. Total number of cuts - the number of cuts made by the slotting beam since its inception.

106. Service number of cuts - the number of cuts made by the slotting beam since the last service.

107. Total number of cycles - the number of automatic work cycles since its inception.

108. Total number of kilometers - the number of kilometers of the boards measured by the encoders since its inception

109. Alarm history - The record of emergency messages.

110. ![]() - this button returns to the previous screen (Fig. 24).

- this button returns to the previous screen (Fig. 24).

111. ![]() - this button leads to the next screen (Fig. 37).

- this button leads to the next screen (Fig. 37).

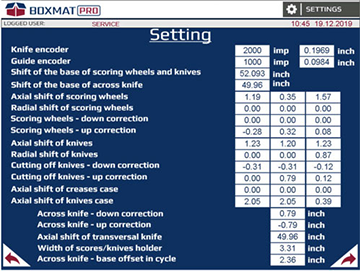

Fig. 37. Service screen (2/3)

For adjusting the ‘zero’ point for the tools and rolls

112. Knife encoder – sets the number of impulses per inch for the positioning of the slotting knives (i.e. 2000 = 0.1969”).

113. Left guide encoder – sets the number of impulses per inch for the left guide (i.e. 1000 = 0.0984”).

114. Shift of the base of the scores and knives – from the center of the machine to the “zero” position for scoring wheels and longitudinal knives.

115. Shift of the base of across knife – inactive

116. Axial shift of scores (3 sets) – the distance from the center of the scoring wheels to the point at which the gripper sensor detects it.

117. Radial shift of scores - correction for the rotary scoring point

118. Scoring wheels – down correction (3 sets) - offset for down action point on the board

119. Scoring wheels – up correction (3 sets) – offset for up action point on the board

120. Axial shift of knives (3 sets) - the distance from the center of the knives to the point at which the gripper sensor detects it.

121. Radial shift of knives (3 sets) - correction for the rotary blades cutting point

122. Cutting off knives - down correction (3 sets) – offset for down action point 0n the board

123. Cutting off knives - up correction (3 sets) – offset for up action point on the board

124. Axial shift of scores case (3 sets) – the distance from the edge of the case to the point at which the gripper sensor detects the tool

125. Axial shift of knives case (3 sets) - the distance from the edge of the case to the point at which the gripper sensor detects the tool

126. Across knife – down correction – offset for down action point on the board

127. Across knife – up correction – offset for up action point on the board

128. Axial shift of transversal knife – the distance from the center of the machine to the home position of across knife.

130. Across knife – base offset in cycle – offset for the first action point down on the board

131. ![]() - this button returns to the previous screen (Fig. 36).

- this button returns to the previous screen (Fig. 36).

132. ![]() - this button leads to the next screen (Fig. 38).

- this button leads to the next screen (Fig. 38).

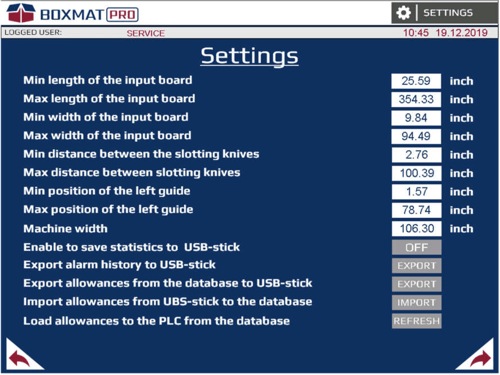

Fig. 38. Service screen (3/3)

133. JOG speed - slow pass of board - sets the speed of the boards in jog mode.

134. Pass speed – board exit - sets the speed of the boards when exiting the machine.

135. JOG speed - scoring beam - sets the speed of the scoring beam when controlled from the "Manual Movement" screen, by using the ‘Up’ and ‘Down’ arrows.

136. JOG speed - spacing of scores and knives - sets the speed of the scoring rolls and knives gripper when controlled from the "Manual Movements" screen.

137. Speed of the spacing scores and knives - sets the speed of the spacing of the scoring rolls and the knives after pressing the "Spacing - scoring and knives" button in the "Manual Movements" screen.

138. JOG speed - cut-off knife - sets the speed of the across knife when controlled from the "Manual Movements" screen.

139. Dry run (no board) - activation of the automatic cycle without a board.

140. Glue – enabling the glue mode allows the glue settings window to be unlocked

141. Printer qty - the number of print modules installed on the machine.

142. Number of knives - the machine can work using 4, 6 or 8 knives.

143. Number of scores - the machine can work using 4 or 6 scores.

144. Distance ENC1 – ENC2 – the distance from the measuring wheel 1 to the measuring wheel 2.

145. Reset service counter – enter the password and press the button RESET to clear service number of cuts.

146. ![]() - this button returns to the previous screen (Fig. 37).

- this button returns to the previous screen (Fig. 37).

147. System Menu – this button open system menu of touch panel

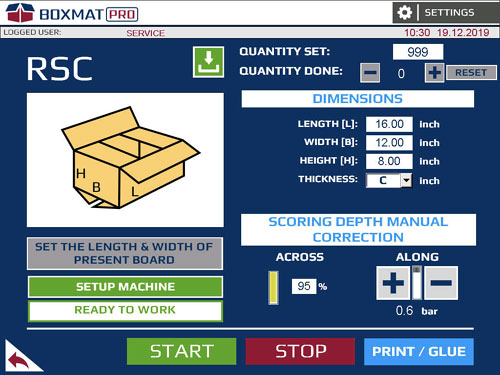

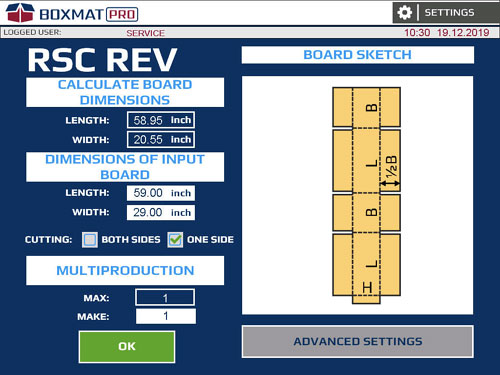

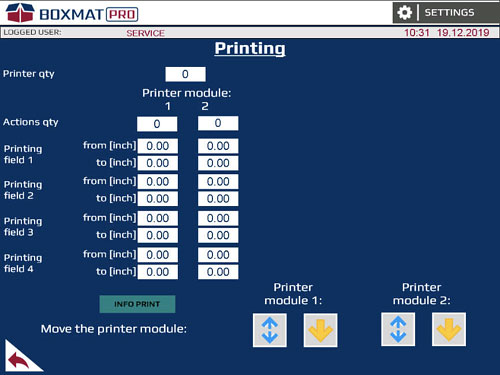

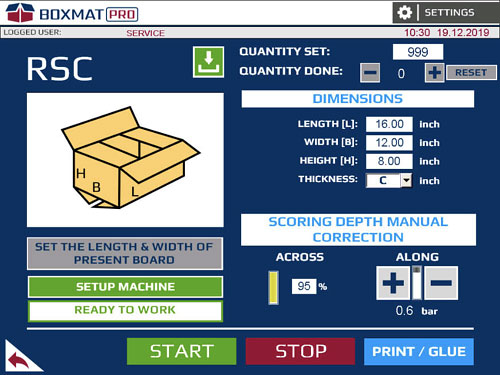

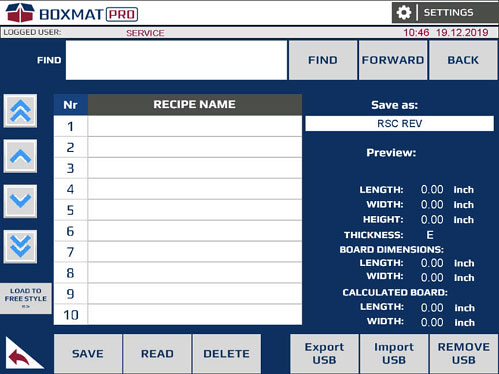

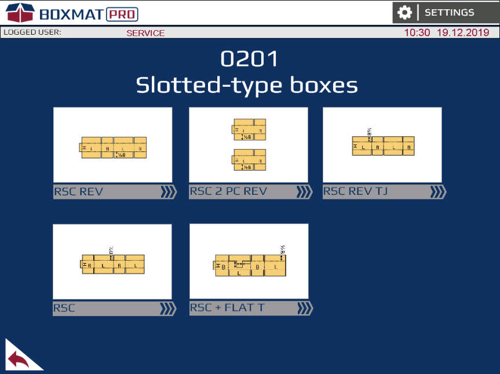

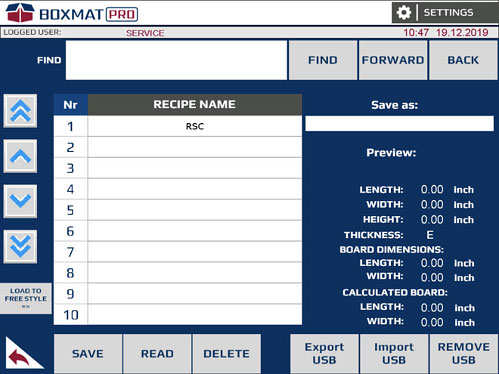

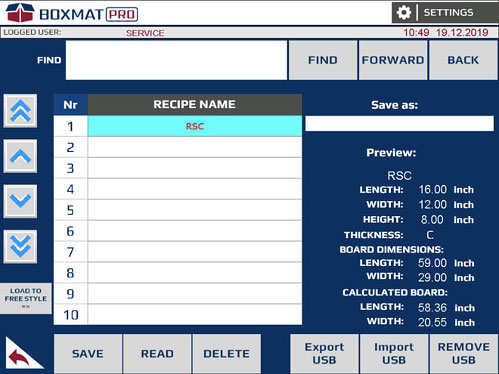

'FEFCO' Style Screens - Description on the Basis of RSC (Standard Style 201 REV)Following are the features available in the configuration screens for the RSC (FEFCO 0201 REV) standard style.

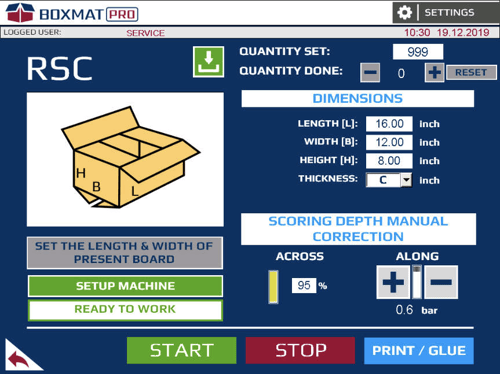

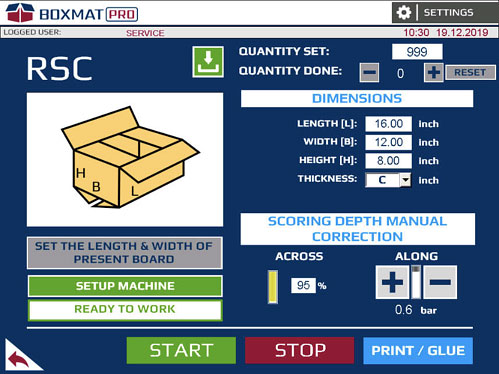

Fig. 39. Main the RSC style set-up screen

148. RSC - the FEFCO style selected.

149. ![]() - saves the current box into the machine's memory.

- saves the current box into the machine's memory.

150. QUANTITY SET - the number of boxes to be made.

151. QUANTITY DONE – the number of cartons already made. Next to it, there is a RESET button used to reset the count. To modify quantity done counter, use PLUS/MINUS buttons.

After completing the required number of cardboard boxes, the machine will stop. To  continue production, the RESET button should be pressed, otherwise it will not be possible to start a new cycle

continue production, the RESET button should be pressed, otherwise it will not be possible to start a new cycle

152. LENGTH - the internal length of the box required.

153. WIDTH - the internal width of the box required.

154. HEIGHT - the internal height of the box required.

155. THICKNESS - a field where the thickness of the cardboard from which the board is made, should be entered.

156. SCORING DEPTH MANUAL CORRECTION - beam scoring depth in %: The setting for the depth of the across score should be in range 0% to 100%

- value 0% - without scoring between the slots;

- value 100% - max scoring depth between the slots;

157. SCORING DEPTH MANUAL CORRECTION - + and - buttons for adjusting the depth of along scores on the board:

The setting for the depth of the scores should be selected according to preference.

The setting for the depth of the scores should be selected according to preference.

158. SET THE LENGTH AND WIDTH OF PRESENT BOARD - this button opens a screen (Fig. 37) to add the input sheet size.

159. SETUP MACHINE – when all dimensions have been added also the sheet size this button moves all cutting/scoring tools to their correct positions.

160. MACHINE IS NOT SET – this indicates that not all information has been entered or machine is not setup. It will change to READY TO WORK when all is set.

161. START - starts the automatic box production in the current style.

162. STOP - stops the machine AFTER the whole board has passed through.

163. PRINT/GLUE (or PRINTING) – this button opens a screen to set parameters of printing (Fig. 40) (option).

164. ![]() - this button returns to the previous screen.

- this button returns to the previous screen.

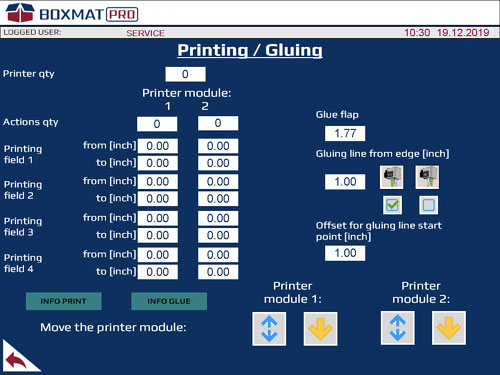

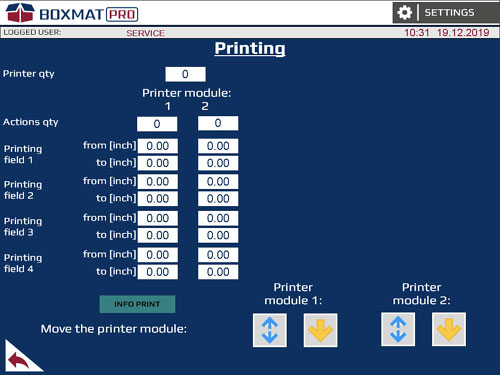

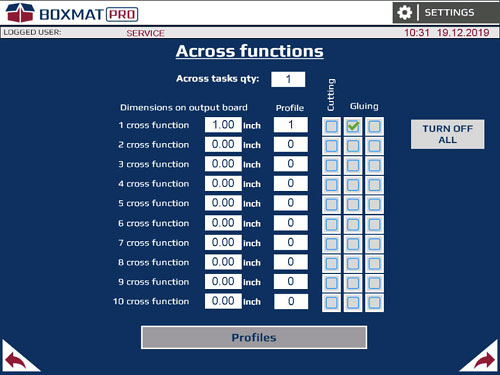

Fig. 40. Printing settings (option).

165. Printer qty - number of printers installed on the machine (option).

The machine can accommodate 1 or printers.

The machine can accommodate 1 or printers.

166. Action qty – a field with option of setting print fields on cardboard

The maximum number of prints is 4.

The maximum number of prints is 4.

167. Printing field [1…4] - from – determines the position on the board where the printing head lift up (option).

168. Printing field [1…4] - to - determines the position on the board where the printing head move down (option).

169. Printer module 1 / 2 – checkboxes of the printer module (1 or 2) (option).

170. Move the printer module 1 (option):

lift up/down the printer module

lift up/down the printer module or

or  indicates the position of printer module

indicates the position of printer module

171. Move the printer module 2 (option):

lift up/down the printer module

lift up/down the printer module or

or indicates the position of printer module

indicates the position of printer module

172. ![]() - this button returns to the previous screen.

- this button returns to the previous screen.

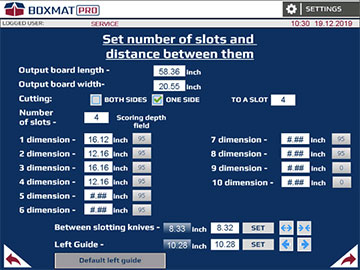

Fig. 41. The RSC style set-up screen – board dimensions.

173. Graphic showing the finished board in the selected FEFCO style.

174. LENGTH - the length of board required.

175. WIDTH - the width of board required.

176. LENGTH – enter the length of the input sheet.

177. WIDTH – enter the width of the input sheet.

178. CUTTING – cutting off scrap form:

- BOTH SIDES

- ONE SIDE

179. MAX – shows the number of current boxes that can be produced from the length of the current sheet.

180. MAKE - enter the number of boxes required from the sheet. The value may be lower or equal to the MAX value.

181. OK - accept all values entered into the screen and return to the previous screen (Fig. 39).

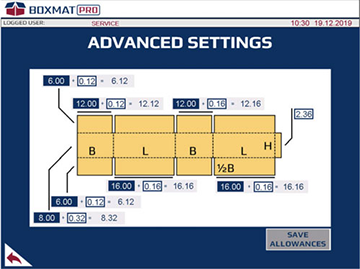

182. ADVANCED SETTINGS - the button opens a screen displaying the advanced settings for the current box (Fig. 42).

Fig. 42. RSC style setup screen - advanced settings

183. Blue field - current value of the carton panel length without allowances (Fig. 42 - 1)

184. White field - allowance value (Fig. 42 - 2)

185. Grey field - total value of carton panel length (Fig. 42 - 1) SAVE ALLOWANCES button - pressing the button saves the oversize into the oversize database. The changes made to the allowances will be restored to their previous values after exiting the style. In order to save the allowances permanently, press the SAVE ALLOWANCES button for about 1 second, the saved allowances will be confirmed by the message (Fig. 43).

Fig. 43. Confirmation window of saved allowances

The button is active after logging into the operator’s account.

The button is active after logging into the operator’s account.

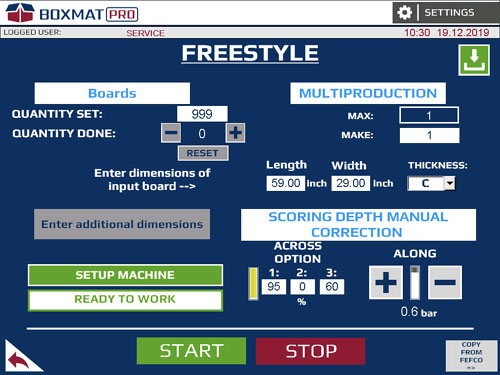

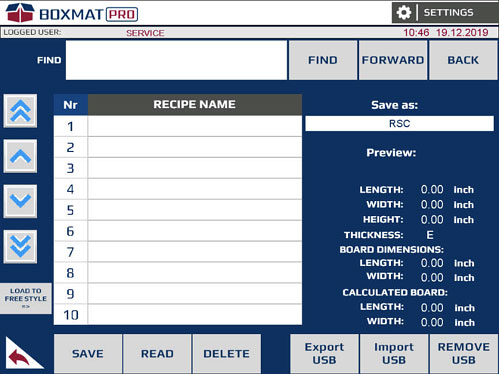

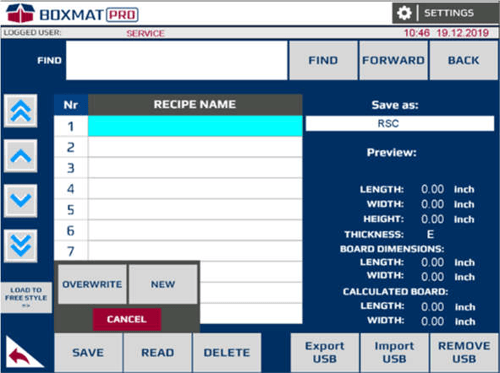

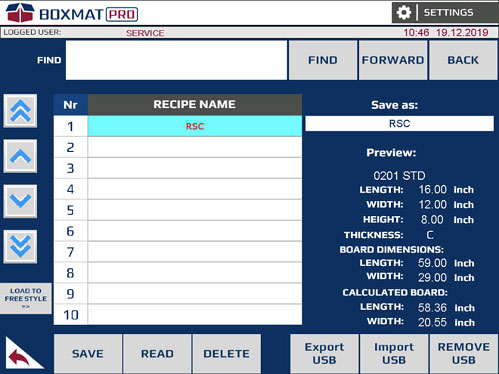

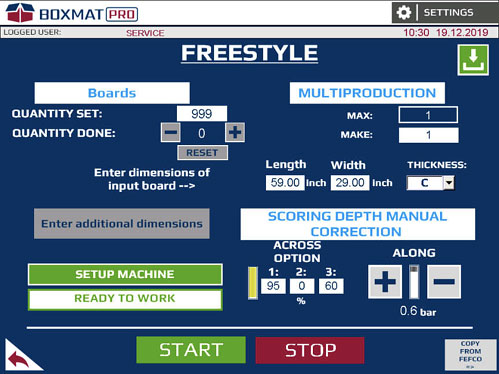

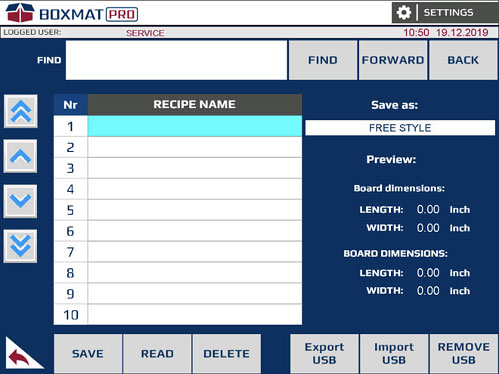

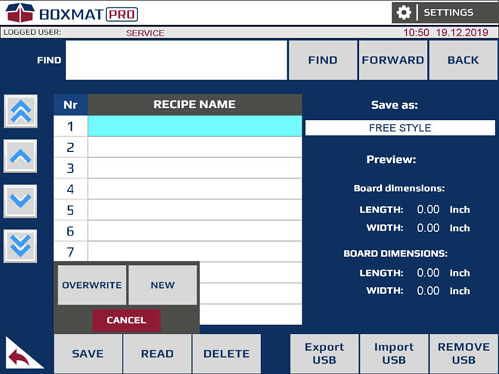

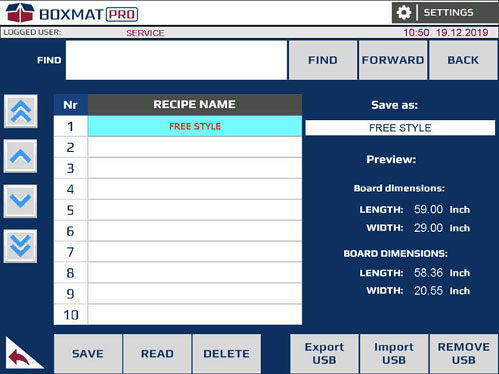

Freestyle Screens

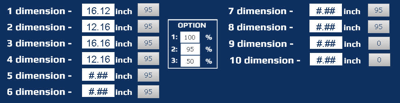

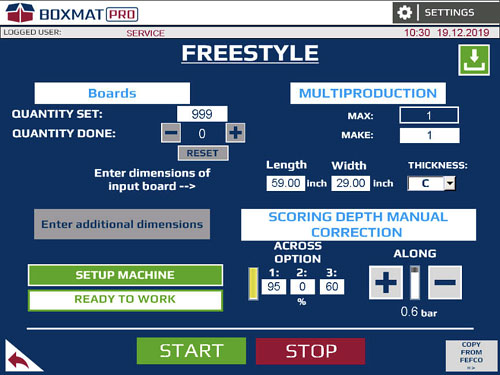

Fig. 44. The main, Freestyle configuration screen

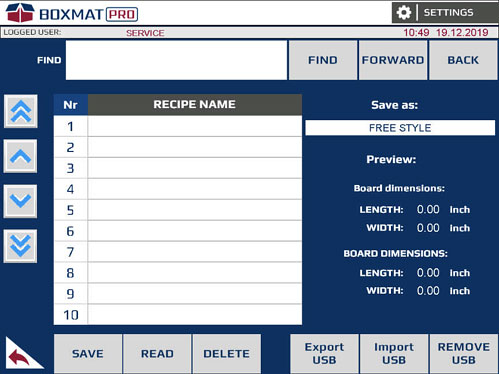

186. Save the recipe - this button saves the currently configured parameters of the box to the machine's memory.

187. QUANTITY SET - a field where the specified number of boxes to be made in automatic mode can be entered; this is activated by pressing START

188. QUANTITY DONE - a field displaying the current number of cartons made in the automatic cycle. Next to it is a RESET button used to reset the count of the cardboard boxes made.

After completing the set number of cardboard boxes, the machine will stop. To  continue production, the RESET button should be pressed, otherwise it will not be possible to start a new cycle.