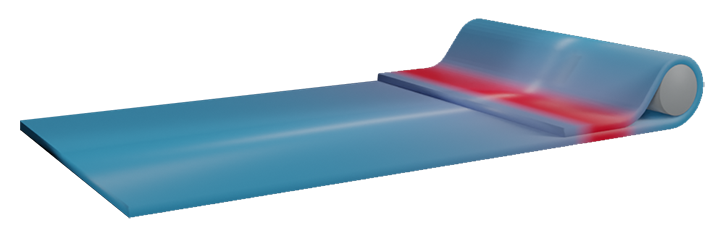

FREEWeld

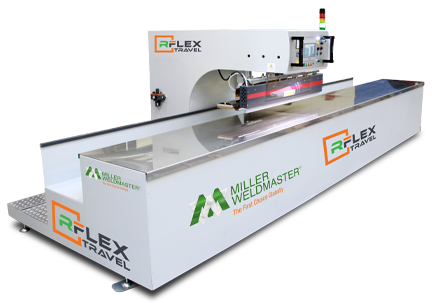

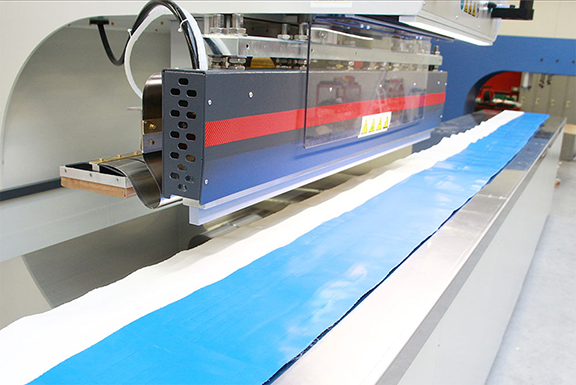

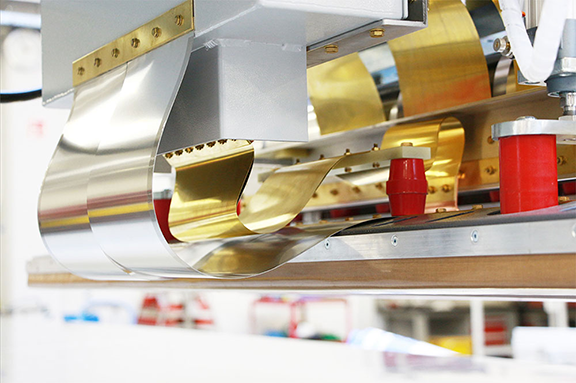

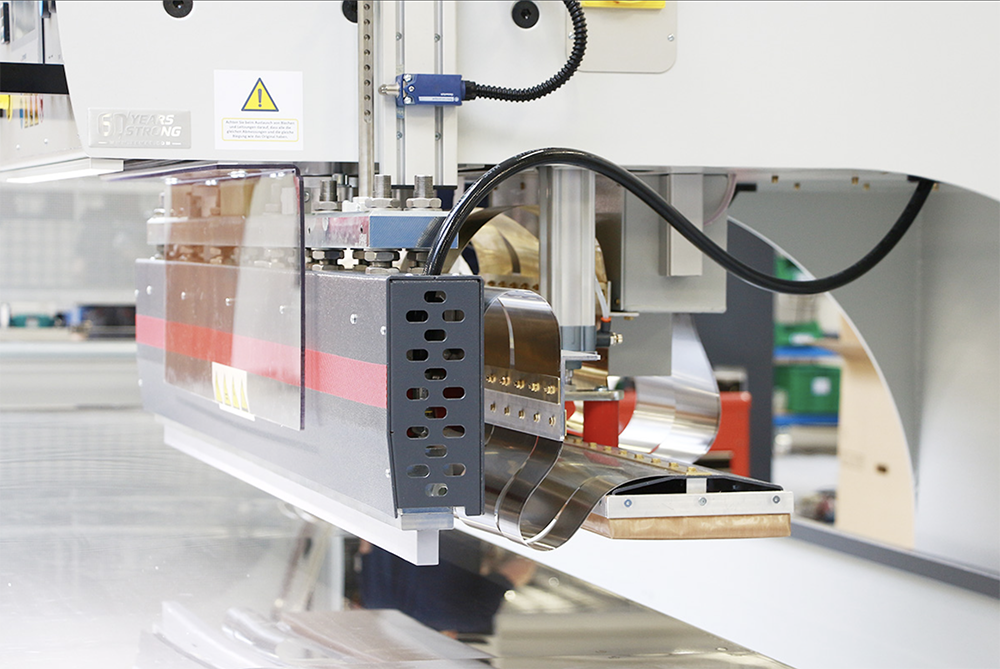

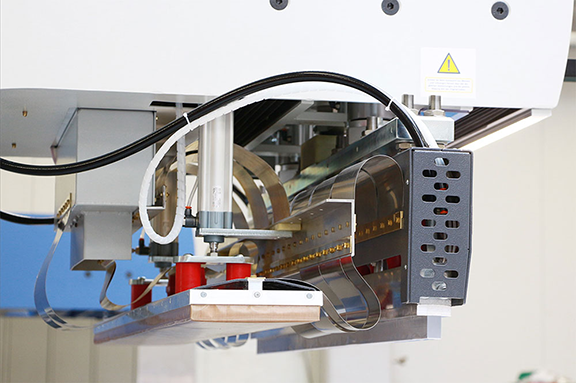

- FREEWeld is an optional solution that allows for grounding emissions without lowering a grounding foot.

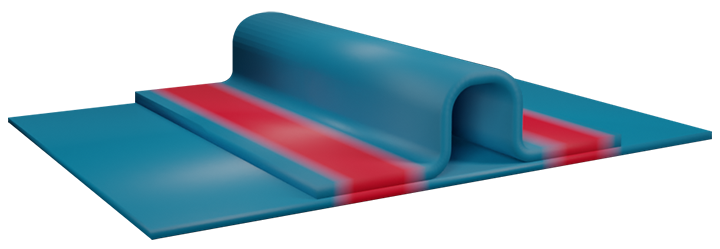

- The FREEweld option eliminates the grounding foot needing to be perfectly flat on the table. This enables the operator to make a wider range of products.

- Creates a stronger, more aesthetic, weld with two parallel weld lines.

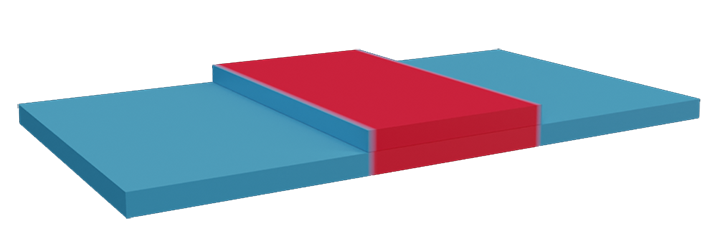

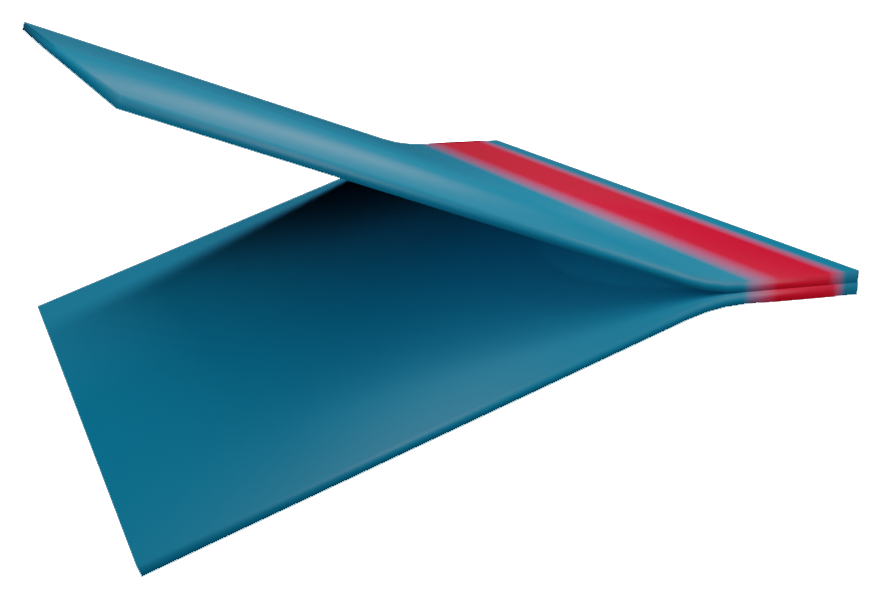

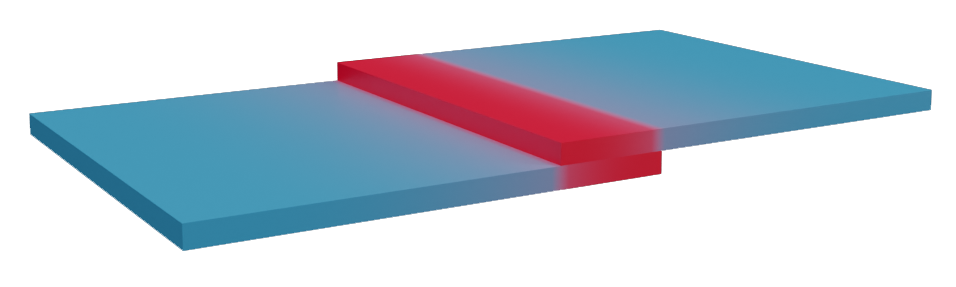

Butt Seam

Butt Seam  Channel Seam

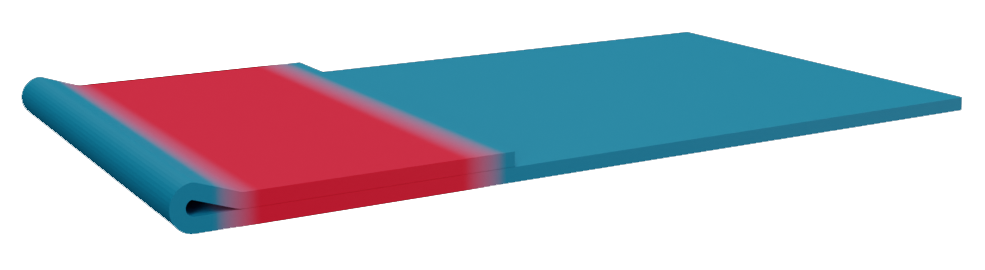

Channel Seam  Fin Prayer Seam

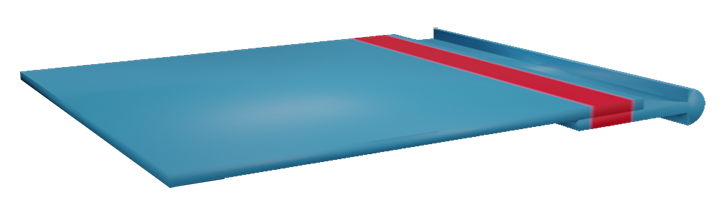

Fin Prayer Seam  Hem

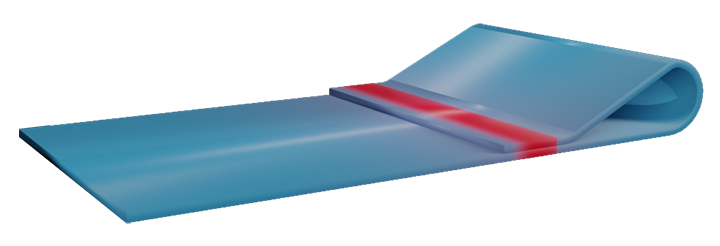

Hem  Hem with Pocket

Hem with Pocket  Hem with Rope

Hem with Rope  Keder

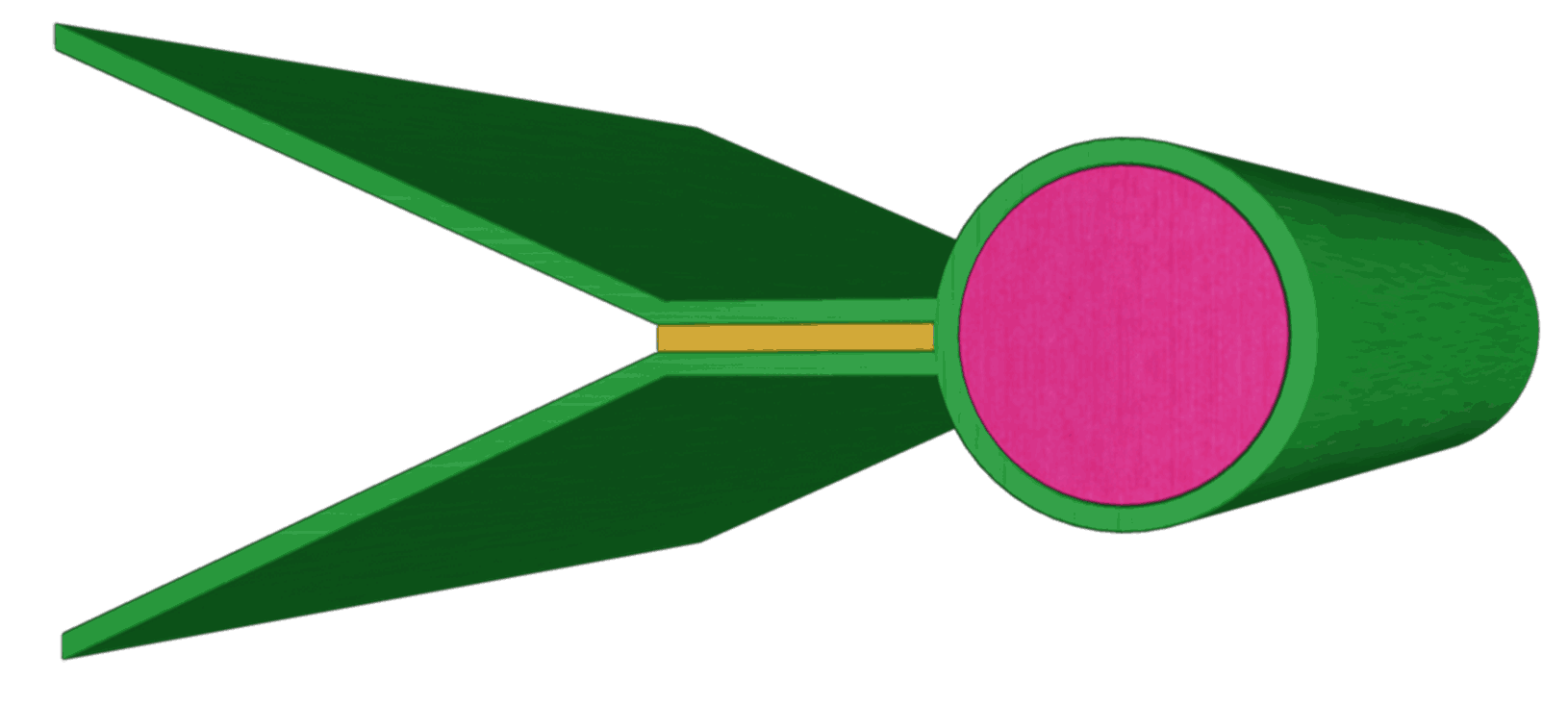

Keder  Overlap

Overlap  Extrusion Beading

Extrusion Beading