With the proper welding equipment, sign and banner manufacturers can tremendously speed up production, increase output and reduce costs.

Whether you’re looking to improve productivity and product quality, or reduce overall time and labor costs, industrial fabric welding can do wonders for your operations.

From hot air welding to hot wedge and radio frequency, it can be difficult to decide which fabric welding solution is best for your operation’s size, budget and unique needs. We’ve rounded up the top five sign and banner welders to make your decision a little easier.

If you are finishing large signs and billboards or need to align images, the 112 Extreme is a no brainer. The 112 Extreme comes in any size you need. From 10 meters, to our largest machine yet, 133 meters long!

- Vacuum sealed track to keep your material lined up in place while the welding head moves and does the welding for you.

- Large table and trough for better material handling of large graphics

- Automatic cutter for precise cuts of your graphics

- Grommet machine that easily slides down the track to place grommets in your end product.

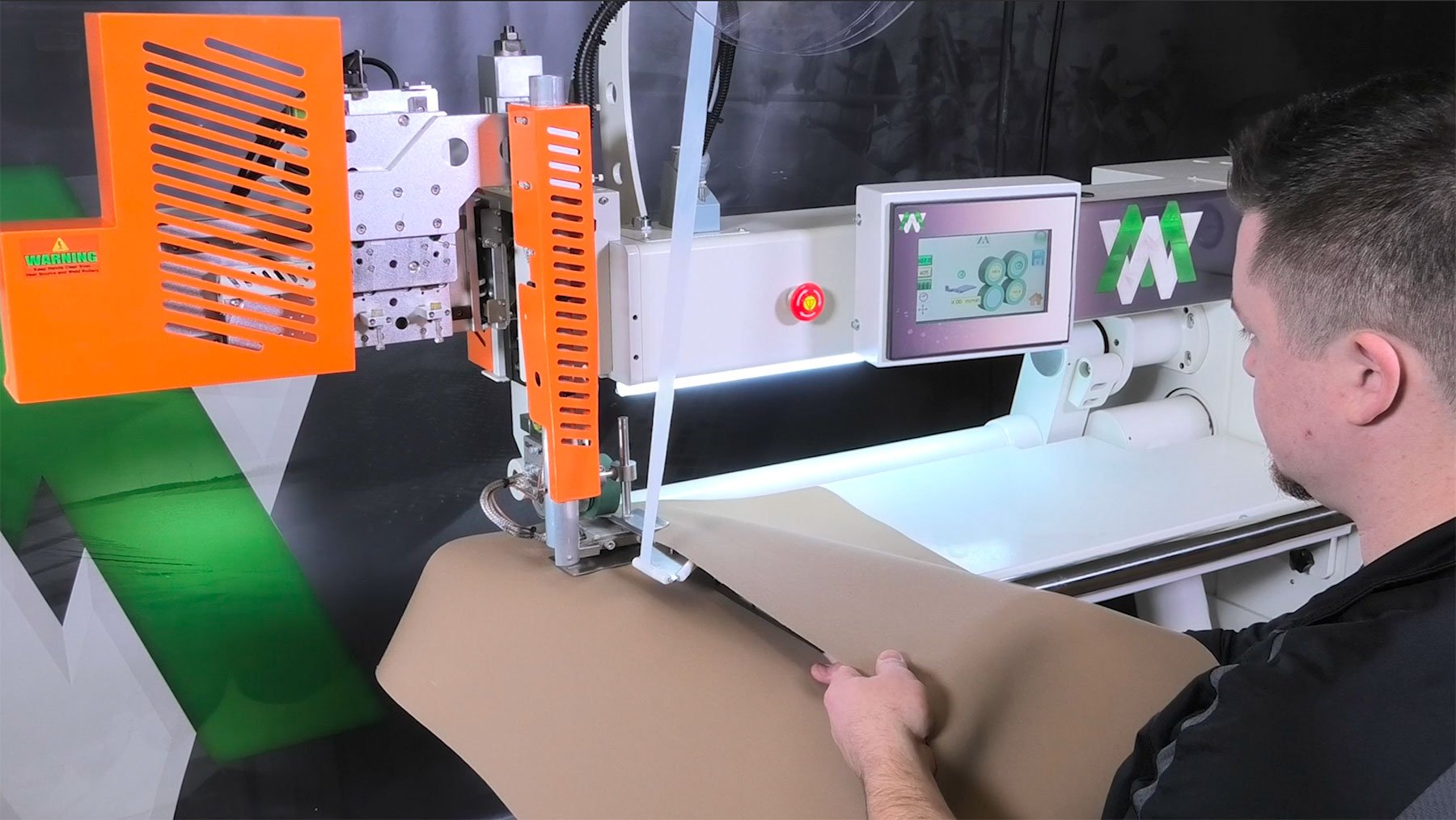

If speed and versatility are a priority for your operations, then the T300 Extreme Edge is for you. This machine is the fastest in our lineup of welders. In fact, the T300 Extreme Edge can weld a four-by-six banner in less than 60 seconds. The T300 Extreme Edge is available in hot air, hot wedge or both for ultimate product versatility.

Additional features include:

- Quick setting recall with touch screen and recipe storage of 25 memory settings.

- Dual arms to configure straight seams.

- Quick, repeatable, precision head adjustments.

If you prefer radio frequency (RF) welding technology, there’s an RF solution for sign and banners too. Our RFlex stationary welder is known for its incredible versatility—regarded as the most versatile option on the market. RFlex was designed for the production of a variety of products including awnings, banners, billboards, shades and signs.

Additional features include:

- A large, foldable worktable with deep trough to allow for easy material handling.

- New generation stable and efficient RF power generator.

- Fully automated weld cycles with 100 weld cycle recipe memory.

The T3 Extreme is a hot wedge welding machine that was specifically designed for smaller-sized operations. Despite its compact design, the T3 Extreme is still a powerful solution with its ability to reach welding temperatures up to 430 degrees Celsius and a solid steel frame for years of durability.

The T3 Extreme material welder is capable of producing all the seams required for the sign and banner maker.

Additional features include:

- User-friendly controls for easy operation.

- Simple weld adjustments for accurate material placement.

- Easy change guide for multiple seam configuration.

If you require a heavy-duty and consistent machine, the T2 Extreme is the fabric welder for you. The T2 Extreme is a table-mounted welder perfect for smaller banners and signs. This welder is easy to use and comes equipped with a single handle for operator use.

Additional features include:

- Speed control adjustable for welding speeds up to 45 feet per minute.

- Driven top and bottom weld rollers for consistent pressure and reduced wrinkles.

- Clamps for easy mounting.

Interested in Learning More About Your Welding Options?

To ensure the best results for your sign and banner production and discuss your options, talk to a Miller Weldmaster expert today.