Common Welding Mistakes and How to Avoid Them

A crucial method utilized in a variety of industries, from packaging to the manufacture of parts of automobiles, is thermoplastic welding. Despite being widely used, can produce low-quality results or even dangerous outcomes if carried out incorrectly. Even if you've been welding for a long time or are brand new to the field, there's always potential for skill improvement. Here are some typical welding errors today and discuss how to avoid them.

Insufficient Material Preparation

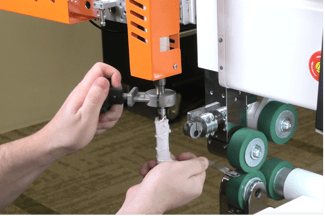

One of the most frequent mistakes is neglecting to prepare the material properly. Dirty weld rollers, wedge or nozzle, and wrinkled material can all interfere with the welding process, leading to a poor quality weld.

Solution: Always ensure your materials are clean before welding. Use appropriate cleaning agents for the weld rollers and wedge, nozzle, or die prior to using. Also, be sure to have enough space to properly feed your material through the machine. Preventing wrinkles and incomplete welds.

Incorrect Heat Control

Too much heat can cause the materials you're welding to wrinkle or deform, whereas insufficient heat will result in weak bonds. Knowing the correct temperature for your specific material is vital.

Solution: Familiarize yourself with the properties of the thermoplastic you're working with. Each type has its own optimal temperature range for welding. Even the application will impact the heat needed to create a secure weld. If possible, perform a few practice welds on scrap pieces to dial in your heat settings.

TIP: Miller Weldmaster's T300 has the ability to test your weld for you! The T300 comes equipped with a Weld Test feature that allows you to set the speed and temperature at various rates and run your material through. The machine will automatically adjust so you can get a quick glimpse as to how those affect your weld.

Faulty Equipment

If your equipment is in poor condition or is not suitable for the task at hand, it can negatively impact the quality of your welds and potentially lead to safety hazards.

Solution: Regularly inspect and maintain your equipment. Replace worn-out parts and ensure that you're using the correct tools and accessories for the material and type of weld you're performing. Miller Weldmaster's Resolution Center is available to help you stay up and running!

Inadequate Design

If the parts to be welded are not designed to allow efficient heat and pressure, the weld may be weak or inconsistent. This can be due to insufficient contact area, or incorrect alignment.

Solution: Invest time in planning the design. Consider the best design depending on the application to allow for the material to receive the appropriate amount of heat and pressure.

Inconsistent Pressure

Consistent pressure during the welding process is critical to ensure a good bond between the parts. Variations in pressure can lead to weak spots or uneven bonds.

Solution: Practice your welding technique to improve your ability to apply even pressure. Also, having clean and complete weld rollers will allow you to provide consistent and correct pressure throughout the welding process.

How can Miller Weldmaster Help?

Remember, every welding project is unique and comes with its own set of challenges. These common mistakes are not exhaustive, but they offer a solid starting point to ensure your welding processes are as accurate and efficient as possible. By being aware of these potential pitfalls, you can actively work to avoid them and continually improve your welding skills. Miller Weldmaster's Service Team is here to help you with making sure you are getting the best welds out of your machine! Or, if you want help with designing your product we do that too! Our team of experts is here to help with designing and sampling your material to ensure your product can be made on our machine! Talk to our team of experts today to learn how we can help you!