If your material handling is’t efficient then it can cost you. The goal of the manufacturing industry is to create products efficiently. Many of the innovations that have gone into modern manufacturing came about as a way to make products quicker.

One of the most important steps in creating a lean manufacturing environment is reducing material handling.

How is material handling wasteful?

Material handling makes your operation suffer in many ways:

Production Bottlenecks

Production bottlenecks are processes that have lower capacity. For example, if you are manufacturing an inflatable product, a bottleneck might occur when the product is being sewn together, if your sewing machines are human-operated and move slower than the rest of your production.

A production bottleneck will cause delayed final products and can be frustrating to employees and customers, as they increase lead times. A severe bottleneck also pauses the rest of the production from moving forward, ultimately costing you more money in the end.

Damaged Material

If your manufacturing system is not optimized to minimize material handling, you run the increased risk of material being damaged. The more your staff or machines handle any given material, the bigger the risk of damage, which equates to waste.

Excess inventory

Bad material handling isn’t only applicable when it results in fewer finished products. Creating too many of a product is also poor material management. Creating excess product takes up space in your building, and in many cases, can end with wasted products if demand doesn’t match the excess supply.

Ineffective use of staff

When your production is not efficient and streamlined, your staff likely will not be used to the best of their abilities. If you have a bottleneck in the middle of your production, the end-line staff will be unable to move forward with their tasks. If you’re creating too much inventory, your staff’s will be spending time storing or retrieving stockpiled products. And although there will probably always be work to be done, any length of time in which your employees have to pause and wait for the production to catch up will be frustrating to them. It’s better to keep your production flow as continuous as possible.

Increased maintenance requirements

Having an operation setup in which your machines run inefficiently will result in increased maintenance needs over time. Whether you’re running a machine too quickly to catch up after a bottleneck, or are seeing some of your machines resting idle too frequently, you’ll see an increase in wear and tear, and will have to have your machine serviced often.

How can I reduce material handling?

Arrange your manufacturing floor in a way that reduces backtracking

Analyze the way that your production is run, and the organization of your machines. Is there any instance in which you have to move materials back in the production line? If so, consider rearranging your machines into as much of a straight line as possible to reduce any extra backtracking and material handling.

Analyze the technology you use and determine if there are more efficient alternatives

No matter what your production line creates, it is likely that there are automated machines made to assist in trimming the production into as lean a process as possible. Automated machines can take care of some of the legwork in a production, meaning your employees will be able to pour more time and energy into customer service and innovation.

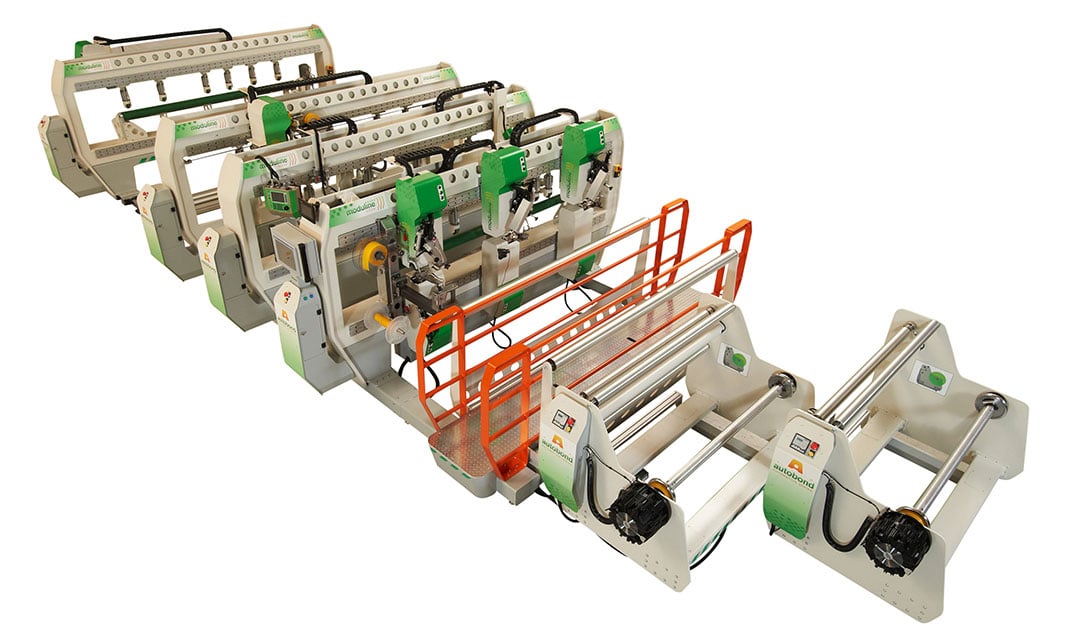

For example, when manufacturers partner with us for their automation solutions, we look at their entire product flow to find the pain points – bottlenecks, backtracking, unproductive output – and create a solution that will make production better and operators’ lives easier. Oftentimes adding even a few automated steps will ease any production difficulties and help you delivers a great product every time.

Need some automation inspiration?

Implementing automated machinery is going to be a big assist in getting your operation as efficient as possible. We’ve been working on automated machinery for our customers, and have developed machines that streamline production and are customized to many different industrial requirements. Check out some of our automated systems here, or talk with us about how automated manufacturing can minimize your material handling.