The quality of the final product is paramount. Advanced hot air welding systems play a pivotal role in ensuring superior product quality, thanks to their precision, efficiency, and reliability. Companies like Miller Weldmaster stand at the forefront of this technology, continually innovating and improving their systems to meet diverse manufacturing needs.

Innovations in Hot Air Welding Technology

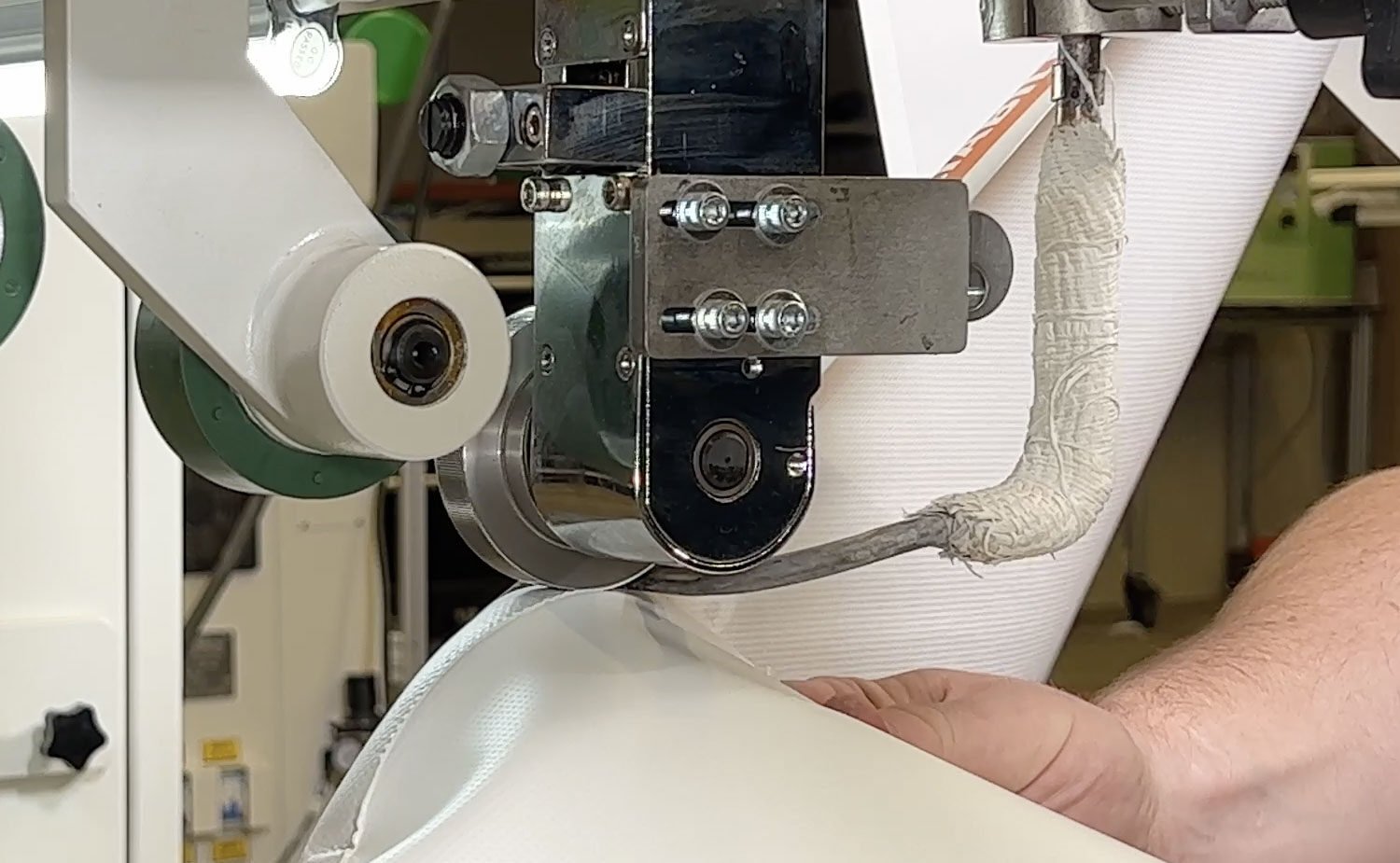

Recent advancements in hot air welding technology have significantly improved the precision and efficiency of welding processes. These innovations include enhanced temperature control, automated speed adjustments, and sophisticated nozzle designs, which collectively contribute to more consistent and high-quality welds. Miller Weldmaster's latest technologies embody these advancements, ensuring that their machines lead the industry in performance.

Precision Engineering

The accuracy of a weld can drastically affect the overall integrity and appearance of a product. Miller Weldmaster’s systems are designed with precision engineering at their core, utilizing advanced sensors and control algorithms to ensure exact heat distribution and seam alignment. This attention to detail guarantees that each weld is as strong and precise as possible.

Automation and Control

Automation in hot air welding systems has revolutionized the way products are manufactured. By implementing automated controls, machines can consistently reproduce high-quality welds with minimal human intervention. Miller Weldmaster's automated welding solutions are renowned for their reliability and ease of use, ensuring that every product meets stringent quality standards.

Enhancing Product Longevity with Hot Air Welding

Miller Weldmaster's hot air welding systems create products that withstand harsh chemicals, extreme temperatures, and more! Making them ideal for industries like construction and maritime, where durability is crucial.

Material Integrity

Maintaining the integrity of materials during the welding process is crucial. Miller Weldmaster’s advanced hot air welding systems are engineered to prevent material degradation, even under intense heat and pressure. This ensures that the materials retain their strength and aesthetic qualities after welding. Our systems are calibrated to manage thermal stress effectively, reducing the risk of warping or weakening materials, which is essential for producing products that are both durable and visually appealing.

Environmental Resistance

Products that are exposed to harsh environmental conditions require welds that can hold up against these stresses. Miller Weldmaster’s welding systems are capable of producing seals that are resistant to water, making them ideal for outdoor and industrial applications. Furthermore, these systems enhance the resistance of welds to extreme temperatures and abrasive environments, ensuring that the welded products can maintain their functionality and appearance in various challenging conditions, from icy cold to desert heat.

Custom Solutions for Unique Manufacturing Needs

At Miller Weldmaster, we understand that each manufacturing challenge is distinct, demanding tailor-made solutions that align with specific operational needs. Our expertise in designing hot air welding systems ensures that every client receives a solution perfectly suited to their requirements. We specialize in crafting systems that are not just solutions, but transformative tools that enhance the manufacturing process.

Flexible System Configurations

Flexibility is at the heart of our design philosophy. Miller Weldmaster offers highly adaptable welding systems that can be customized for various materials, sizes, and shapes, making them suitable for a wide range of manufacturing scenarios. Whether you need to handle delicate fabrics or robust industrial materials, our systems ensure precise, efficient, and reliable welds, providing effective solutions for any task at hand.

Collaboration and Development

True innovation in manufacturing comes from collaborative efforts. At Miller Weldmaster, we pride ourselves on the partnerships we build with our clients, working together to develop solutions that address unique challenges. Our approach involves direct engagement with your team, understanding your specific needs, and designing systems that enhance your production capabilities. This collaborative process is backed by our commitment to ongoing support and adaptation, ensuring that our solutions evolve with your business.

Future Trends in Hot Air Welding Technology

As the manufacturing industry evolves, so too does the technology that supports it. Miller Weldmaster stays ahead of the curve by embracing emerging trends such as the integration of smart manufacturing techniques and the pursuit of sustainability.

Integration with Smart Manufacturing

The future of hot air welding involves its integration with smart manufacturing processes. Miller Weldmaster’s systems offer enhanced monitoring, control, and adaptability, driving significant improvements in welding efficiency and product quality.

Experience the Miller Weldmaster Difference

Discover the unparalleled advantages of Miller Weldmaster's advanced hot air welding systems, designed to enhance the efficiency, quality, and durability of your manufacturing processes. Our cutting-edge technology stands out in the industry, offering tailored solutions that meet the specific needs of each client. We invite you to explore the full range of what Miller Weldmaster has to offer and see how our innovative approaches can transform your production line.

Explore Our Advanced Welding Solutions

Dive into the world of exceptional welding with our advanced solutions by visiting our technology page. Here, you'll find details on the unique features and benefits of our systems, such as increased automation, superior precision, and enhanced durability. Discover how our commitment to innovation leads to more efficient and reliable hot air welds. Don’t miss out on special offers and the opportunity to request a demonstration to see our machines in action.

Contact Our Experts

If you're looking for personalized advice and solutions tailored to your specific manufacturing challenges, our experts are here to help. At Miller Weldmaster, we pride ourselves on exceptional customer support and deep industry knowledge. Reach out to us through our contact page to discuss your needs and how our advanced hot air welding systems can make a significant difference in your production capabilities. Let us assist you in achieving the highest standards of quality and efficiency.