In the world of industrial manufacturing, quality control is not just a practice—it's a promise. At Miller Weldmaster, we're committed to upholding the highest standards of quality in every machine we make. This dedication ensures that our products are not only durable but also meet the exacting needs of our clients, fostering customer satisfaction and trust. Our systematic approach to quality control in industrial fabric welding machines is designed to detect and prevent defects from raw material selection to the finished product. By integrating innovative technologies and stringent standards, we lead the industry in delivering excellence. Discover more about our process by visiting Miller Weldmaster’s Material Handling Solutions

Overview of the Importance of Quality Control

Quality control in industrial fabric welding is crucial because the integrity of welded fabrics directly impacts product durability and, consequently, customer satisfaction. At Weldmaster, our unwavering commitment to quality ensures that every weld is not only robust but also precise. This adherence to excellence helps extend the lifecycle of the products and minimizes the need for repairs or replacements, providing long-term value to our customers.

Understanding Fabric Quality in Welding

Defining Quality Standards for Industrial Fabric

Industrial fabric welding requires compliance with rigorous quality standards to ensure that every product performs under the toughest conditions. At Miller Weldmaster, we not only meet these standards but often exceed them, ensuring that our products are a benchmark for quality in the industry.

Material Properties and Performance

The selection of materials plays a pivotal role in the quality of the final product. We suggest meticulously select materials that offer superior durability and adaptability to various environmental conditions. At Miller Weldmaster, we employee a dedicated employee whose job is to test material and final products. Ensuring our solutions can actually match what you are lookingfor! Our rigorous testing protocols, including tensile strength and abrasion resistance tests, help us understand how materials behave and how they will weld. This data is crucial for refining our production processes and ensuring that our products are the solution our customers need.

Quality Control Processes at Miller Weldmaster

Step-by-Step Quality Assurance Techniques

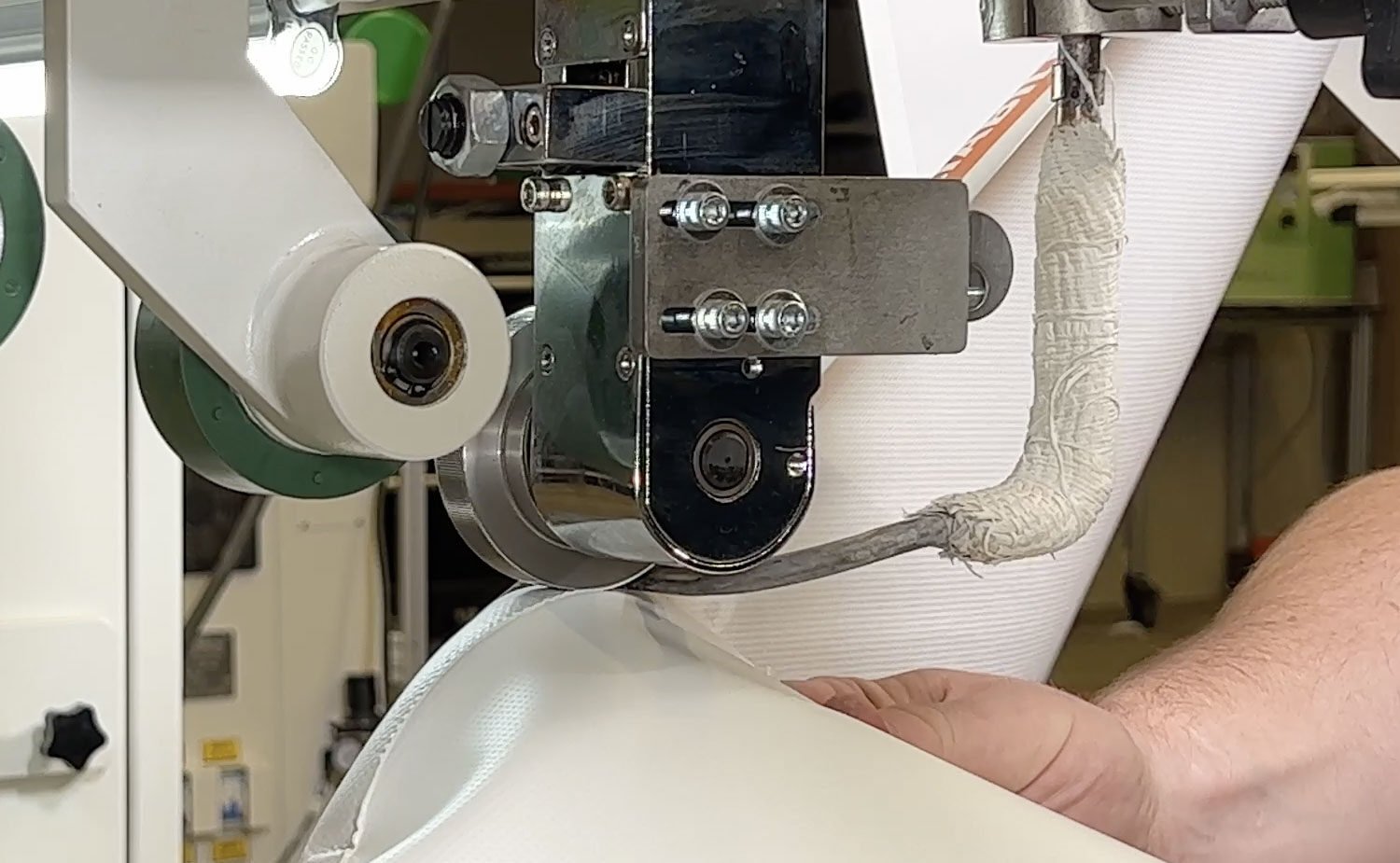

Our quality control process is comprehensive, covering every stage of production from raw material to the finished product. We use advanced machinery and technology to ensure precision in every weld. Our quality assurance tools, such as Seamvision, meticulously monitors each phase, employing both automated systems and manual inspections to guarantee that each product meets your high standards.

Role of Automation in Quality Control

Automation plays a critical role in enhancing the consistency and accuracy of our welding processes. By integrating automated systems we can achieve precise welds at high speeds, reducing the likelihood of human error. Lasers, seamvision, cameras, and edging guide, help operators to monitor welding process and quality while running a machine.

Compliance and Quality Certifications

Navigating Compliance in Fabric Welding

Adhering to regulatory requirements is essential in industrial fabric welding. These regulations ensure that products are safe and reliable. At Miller Weldmaster, we rigorously follow these guidelines and often engage in third-party audits to ensure our compliance.

Certification Processes and Their Importance

Our products are certified under various international standards which underscores their reliability and quality. These certifications are not just accolades; they signify our commitment to maintaining the highest standards and build trust with our clients, assuring them that our products are among the best in the market.

Continuous Improvement in Fabric Welding Quality

Innovations in Welding Technology

At Miller Weldmaster, we continuously seek out and incorporate the latest advancements in welding technology. This proactive approach allows us to improve the quality of our welds and introduce new solutions that meet the evolving needs of our industries.

Training and Development for Quality Assurance

We believe that the skill of our customers is as important as the technology we use. To this end, we provide ongoing training and development programs that ensure your team is proficient in the latest welding techniques and quality control processes. This commitment to training is reflected throughout Miller Weldmaster.

Get Involved with Miller Weldmaster's Quality Solutions

We invite you to connect with our team to learn more about our robust quality control processes and how our solutions can benefit your business. Explore our range of welding solutions and discover how our commitment to quality can enhance the reliability and durability of your products. At Miller Weldmaster, we are dedicated to ensuring excellence every step of the way.