When it comes to building high-performance inflatable products like paddle boards, docks, and boats, the strength of the seams can make or break the final result. Enter drop stitch welding — a specialized bonding technique that creates airtight, durable seams essential for inflatables. If you’re in the business of manufacturing or designing inflatable gear, understanding this process is critical.

Many leading companies in the inflatable industry rely on drop stitch welding to ensure their products meet high standards for seam strength and durability.

In this blog, we’ll dive into what drop stitch welding is, how it works, why it matters, and how Miller Weldmaster supports top-tier production through innovative welding solutions.

What Is Drop Stitch Welding and Why Does It Matter?

Drop stitch welding is the process of sealing two fabric layers connected by thousands of internal threads. These threads maintain a fixed distance between the layers, allowing the inflated product to become rigid. Welding this material requires precision and care to preserve the threads and create a strong, airtight seal.

For inflatables like paddle boards, inflatable paddle board, inflatable boats, and air mattresses, maintaining air pressure and product rigidity is non-negotiable. A weak seam can lead to leaks, deformation, or even product failure. That’s where drop stitch welding stands apart from basic heat sealing or traditional sewn seams — it creates strong bonds without compromising the structural integrity of the drop stitch material. One key advantage of drop stitch welding is the increased stiffness it provides to inflatable paddle boards, making them feel more like traditional hard boards. The difference between welded and glued seams can significantly impact the performance and longevity of a paddle board.

Learn more about drop stitch fabric.

Understanding the Drop Stitch Welding Process

The drop stitch welding method consists of several meticulous steps. It begins with aligning the material layers carefully to ensure seam accuracy, which is vital to ensure consistency across a production run. Next, depending on the specific requirements of the product, some techniques may use adhesives as part of the bonding process, while others rely solely on thermoplastic layers activated using controlled heat and pressure. This step must be done with caution, ensuring the vertical threads inside the fabric remain intact and unharmed.

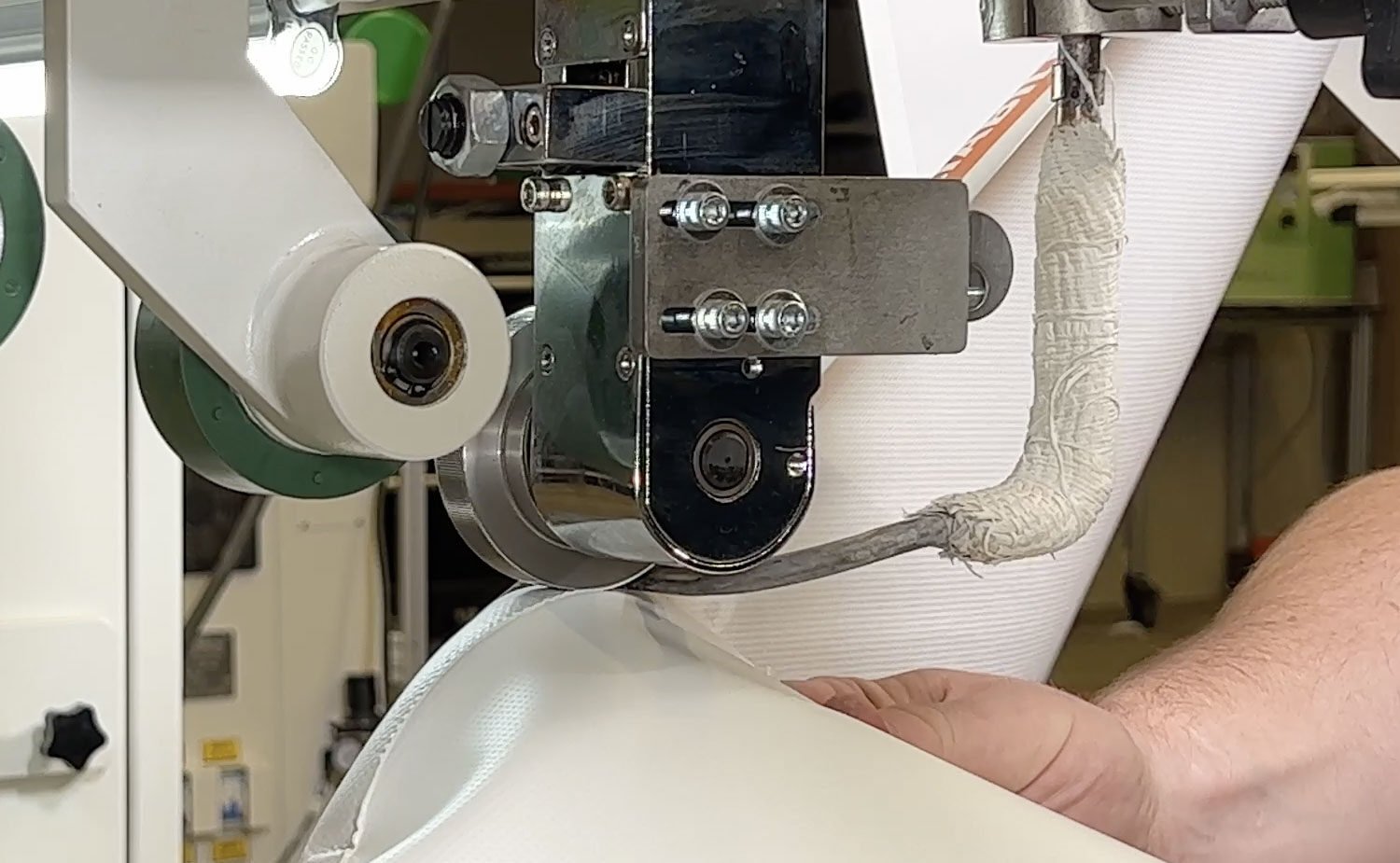

Once activated, the bonding layers are fused together using specialized machinery designed for drop stitch materials. These machines apply the precise amount of pressure and temperature to complete the seal. The final step involves allowing the seam to cool under compression, which locks the bond in place and ensures a long-lasting, airtight finish.

Tools often used in this process include welding machines that deliver consistent hot air or wedge welding, tension control systems to prevent fabric shifting, guides and jigs to keep seams uniform, and sensors that monitor temperature and pressure to prevent mistakes during welding. These techniques and methods are chosen based on their ability to produce strong, durable seams, and the overall structure of drop stitch fabric consists of multiple layers and threads that contribute to the product's rigidity and longevity.

The Role of Heat and Pressure in Creating Strong Seams

Heat and pressure are essential components of any welding process, and drop stitch welding is no exception. In this application, however, the margin for error is much smaller. Unlike traditional welding, the heat must be carefully managed to prevent internal damage to the vertical fibers that keep the fabric layers apart. The optimal thickness of the drop stitch fabric also influences how heat and pressure are applied, as different thicknesses require adjustments to ensure proper bonding without damaging the material.

The heat must be high enough to activate bonding agents on the fabric surface without compromising the integrity of the internal structure. Pressure must also be carefully moderated. Excessive pressure can compress or snap the vertical threads, weakening the structure and risking leaks.

By maintaining a delicate balance between heat and pressure, manufacturers can produce seams that are not only airtight but also strong enough to withstand repeated inflation and deflation, rugged use, and environmental stress. Maintaining the correct form of the inflatable product depends on precise control of these variables during welding.

What Is Drop Stitch Fabric Made Of?

Drop stitch fabric is a composite material typically made of two layers of PVC-coated polyester or nylon. The base material is critical for ensuring the durability and performance of the fabric. Drop stitch fabric, also known as double wall fabric, consists of two primary woven fabric layers connected by a dense network of vertical polyester threads. Advanced weaving techniques are used to create this network, providing the rigidity needed for high-performance inflatable products. This network ensures the layers remain a fixed distance apart, even when inflated to high pressures.

The material’s construction is what allows it to perform so well in inflatable products that demand rigidity. The vertical threads keep the layers from bulging outward under pressure, enabling products like paddle boards or floating platforms to stay completely flat when inflated.

This fabric is both strong and lightweight, making it ideal for applications that require portability without compromising performance.

Key Benefits of Drop Stitch Fabric for Inflatables

One of the main advantages of drop stitch fabric is that it allows inflatables to become rigid, similar to solid structures. This rigidity is crucial for applications such as stand-up paddle boards or floating docks, where a flat, stable surface is necessary.

Another major benefit is the weight-to-strength ratio. Drop stitch products are significantly lighter than their solid counterparts while still offering impressive structural strength. The light construction of drop stitch fabric contributes to its portability and ease of use. The fabric is also capable of withstanding much higher internal pressures than traditional inflatable materials. This means manufacturers can design more durable and innovative products that stand up to heavy use and harsh conditions.

Additionally, the design flexibility of drop stitch fabric enables the creation of complex inflatable structures such as kayaks with multiple chambers or platforms with specific geometric features.

Paying attention to the details of fabric construction is essential for maximizing the benefits of drop stitch technology.

How Drop Stitch Welding Differs from Standard Fabric Welding

Unlike traditional fabric welding, drop stitch welding requires a more nuanced approach. Standard welding methods involve joining flat, flexible fabrics using hot air, hot wedge, or radio frequency energy. These processes are typically straightforward because there are no internal structures to consider.

With drop stitch material, however, internal threads must be preserved. Applying too much heat or pressure can melt or compress these threads, ruining the product’s functionality. Instead of simply focusing on melting the outer layer for bonding, drop stitch welding is about controlled activation of the bonding surface while maintaining the internal architecture.

Drop stitch welding produces superior seams compared to standard fabric welding, resulting in greater durability and performance.

Why Traditional Welding Tools May Not Work

Traditional fabric welding tools are often too aggressive for drop stitch applications. Machines not designed for drop stitch fabric may apply too much pressure or heat, leading to uneven welds, melted fibers, or even complete structural failure. Only machines engineered with precise control capabilities can handle the complexities of this material.

Best Practices for Welding Drop Stitch Material

Welding drop stitch fabric successfully requires a few key practices. First, precision alignment of fabric layers ensures that the seam is consistent across the length of the product. Any misalignment can lead to gaps, weak spots, or wasted material.

Next, maintaining the right temperature and pressure is vital. Machines used in this process should be equipped with sensors that automatically adjust these variables to ensure consistent weld quality. Using guides or jigs can further improve the accuracy of the seam.

Experienced technicians should also perform test welds and monitor results frequently during production. Seam failures are often due to minor inconsistencies that can be corrected with real-time feedback. Implementing these best practices can be time consuming, but is essential for ensuring consistent quality and durability.

How to Avoid Common Drop Stitch Welding Mistakes

There are several common pitfalls to avoid. Misaligned layers are a major cause of poor seams and can result from fabric shifting during welding. Overheating is another common issue that can damage internal threads, weakening the product. Uneven seals can occur if the welding heads are not properly aligned or if the machine settings are incorrect.

The key to overcoming these challenges lies in using the right equipment and monitoring each step of the process carefully. Regular maintenance of machinery and thorough training for operators can also help ensure consistently high-quality welds.

Ensuring Airtight Seams Every Time

To verify the integrity of the welds, manufacturers should conduct rigorous quality checks. These include visual inspections to detect surface flaws, pressure testing to identify potential leaks, and tensile testing to assess the strength of the seam. Industry standards such as ISO or ASTM guidelines may also be used to ensure performance consistency across production batches.

Applications of Drop Stitch Welding in Inflatable Products

Drop stitch welding is used in a wide variety of inflatable products. In the watersports industry, it’s commonly found in stand-up paddle boards, inflatable sups, and inflatable boards, where rigidity and performance are crucial. The rail of an inflatable board is often reinforced using tape and specific fold techniques to enhance durability and structural integrity. The way the board is rolled for storage can impact the longevity of the seams and rails. Drop stitch construction also helps the board maintain its intended shape even under high pressure. In the marine sector, inflatable docks, kayaks, and platforms rely on welded drop stitch fabric for durability and stability.

Outside of recreation, drop stitch is also used in air mats for medical use, temporary flooring systems, military applications, and even inflatable rescue equipment. Its ability to provide rigid, lightweight, and airtight performance makes it a go-to material across industries.

Why Drop Stitch Welding Is Revolutionizing Inflatable Design

Consumers and manufacturers alike are demanding more from inflatable products. They want items that are lightweight yet strong, portable yet rigid, and reliable in demanding environments. Drop stitch welding makes all this possible.

By enabling manufacturers to create high-pressure inflatables with solid-like surfaces, drop stitch technology is pushing the boundaries of what inflatable products can do. This has led to a surge in innovation across both consumer and commercial markets, redefining what's possible with air-filled products.

Miller Weldmaster Solutions for Drop Stitch Welding

Miller Weldmaster is a recognized leader in providing advanced welding solutions for drop stitch applications. Our team understands the unique challenges of working with drop stitch fabric and has developed machines specifically designed to address them. Miller Weldmaster machines incorporate the latest technologies to meet the needs of different manufacturers in the inflatable industry.

Our machines feature fine-tuned temperature and speed controls to ensure a perfect bond every time. They are built to handle thick, tensioned drop stitch materials with precision and repeatability. Whether you’re producing inflatable paddle boards, docks, or custom products, Miller Weldmaster has a solution to streamline your production.

Explore Drop Stitch-Capable Equipment Options

One of our premier machines for drop stitch welding is the T300 Extreme Curve. This machine is ideal for creating curved and complex seam patterns, making it perfect for paddle boards and other performance inflatables. With advanced settings, easy-to-use controls, and proven durability, it's a go-to choice for many leading manufacturers.

To learn more, visit our drop stitch solutions page.

Why Trust Miller Weldmaster for Drop Stitch Welding?

With over five decades of experience, Miller Weldmaster is one of the most trusted names in the fabric welding industry. Our expertise in engineering, combined with a deep understanding of material behavior, allows us to create solutions that meet the most rigorous demands.

Our global customer base spans industries from outdoor recreation to defense, and our machines are known for their reliability, ease of use, and consistent results. With dedicated R&D and technical support, we don’t just provide machines—we deliver manufacturing confidence.

Frequently Asked Questions About Drop Stitch Welding

What is drop stitch welding?

Drop stitch welding is a specialized process that bonds two fabric layers connected by internal threads, creating airtight, durable seams critical for inflatables.

What makes drop stitch fabric different?

Drop stitch fabric includes thousands of vertical threads that hold the two outer layers together. This creates a rigid surface when inflated, unlike standard flexible materials.

Can any welding machine be used for drop stitch fabric?

No. Drop stitch requires machines that control heat and pressure precisely to avoid damaging internal fibers. Specialized machines are necessary.

What are the advantages of drop stitch welding for inflatables?

Airtight seams, enhanced rigidity, durability, increased product lifespan, and design flexibility all contribute to improved performance and usability.

What industries use drop stitch welding?

Industries include watersports, marine, medical, military, and outdoor recreation, each benefiting from drop stitch’s strength, portability, and versatility.

How do you test the quality of a drop stitch weld?

Welds are tested using visual inspection, pressure tests, and tensile or peel testing. Following established quality standards ensures product reliability.

Is drop stitch welding suitable for DIY applications?

Due to the precision required, drop stitch welding is not typically suited for DIY use. Professional equipment and training are needed to ensure reliable results.

Ready to revolutionize your inflatable product line?

Contact Miller Weldmaster to discuss drop stitch welding solutions that fit your needs.