Thermoplastic welding has become an essential manufacturing process for industries that demand durable, airtight, and watertight seams in flexible plastics. The ability of thermoplastics to be formed, reformed, and welded makes them highly versatile and suitable for a wide range of applications across industries such as aerospace, automotive, marine, and energy. Thermoplastic welding is widely used for the assembly of complex components, ensuring structural integrity and performance in sectors like aerospace, where lightweight and durable assemblies are critical. From industrial tarps and inflatables to medical packaging and roofing materials, the demand for strong thermoplastic seams continues to grow.

With over 50 years of innovation in fabric welding technology, Miller Weldmaster has supported engineers, fabricators, and manufacturers worldwide in mastering thermoplastic welding techniques. One key advantage of thermoplastic welding over other joining methods is its ability to produce clean, strong, and reliable seams with minimal distortion, making it preferable for many industrial applications. This guide will walk you through the fundamentals—ideal for anyone new to or expanding their capabilities in welding thermoplastic materials.

Learn more about thermoplastic welding here.

What Is Thermoplastic Welding and Why Does It Matter?

Thermoplastics are materials that become soft and moldable when heated and harden again upon cooling, making them ideal for permanent seam bonding.

Compared to metals, thermoplastics offer:

-

Lightweight performance

-

Resistance to corrosion

-

Flexibility and fatigue resistance

-

Lower production costs

- Excellent chemical resistance (notably in polypropylene (PP), making it ideal for applications in corrosive environments such as tanks and piping systems)

| Property | Thermoplastics | Metals |

|---|---|---|

| Corrosion Resistance | High | Low without coatings |

| Fatigue Resistance | High | Medium–High |

| Equipment Cost | Low | High |

| Weldability | High (with correct method) | High (requires skill) |

| Chemical Resistance | Excellent (especially PP for corrosive environments) | Variable |

Industries served: tents, tarps, inflatables, roofing, agriculture, medical packaging.

Benefits of Welding Thermoplastic Materials

-

Strong, airtight seams – ideal for outdoor or high-pressure applications.

- High quality welds – ensures precise heat application and consistent bonding for strong, durable joints.

-

Lower equipment costs compared to metal welding setups.

-

Energy-efficient bonding – requires less heat and power.

-

Lightweight but durable – maintains structural integrity without added weight.

Example: Hot air welding of truck tarps produces consistent seams that withstand years of highway exposure.

Key Thermoplastic Welding Techniques You Should Know

Several welding methods can be used depending on the thermoplastic material, thickness, and end application. Different types of thermoplastics require specific welding techniques because each type has unique material properties that influence the welding process and the final results.

| Method | Ideal Materials | Thickness Range | Precision Level | Speed |

|---|---|---|---|---|

| Hot Air Welding | PVC, TPU, vinyl | Medium–Thick | High | High |

| Impulse Welding | PE, PP, thin films | Thin | Very High | Medium |

| Hot Wedge Welding | Geomembranes, roofing | Thick | High | Medium |

| RF Welding | PVC, TPU | Thin–Medium | High | Medium |

| Ultrasonic Welding | Small parts, films | Very Thin | Very High | Very High |

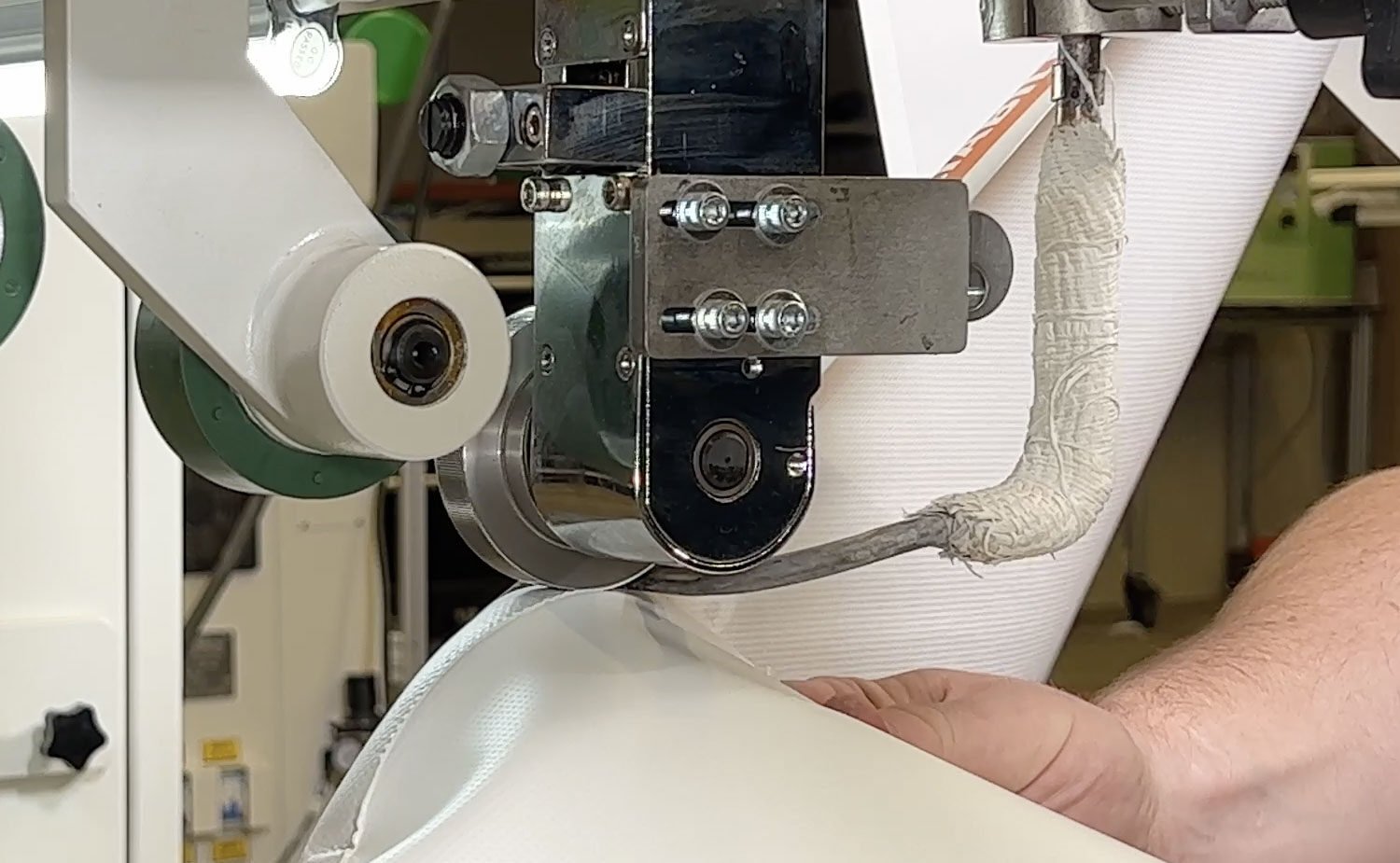

Hot Air Welding: The Industry Standard

Uses a controlled stream of heated air and pressure to fuse materials. Best for PVC and polyethylene welding and thicker fabrics (≥ 1/16”).

Learn about hot air welding.

Impulse Welding: Precision for Thin & Delicate Plastics

Uses resistance heating and clamp pressure to create precise welds, perfect for welding polypropylene fabric and medical-grade films.

Learn about impulse welding.

Other Welding Methods

-

Hot Wedge Welding – for heavy-duty, thick thermoplastics like geomembranes.

-

RF Welding – excellent for polar plastics like PVC.

-

Ultrasonic Welding – micro-bonding for electronics and specialty films.

- Hot Plate Welding – uses an electrically heated plate to melt the ends of parts, which are then pressed together to form a strong joint.

- Spin Welding – joins circular thermoplastic parts using rotational motion to generate heat and bond the materials.

- Friction Welding – offers speed and precision for joining delicate or heat-sensitive components, making it suitable for applications in medical devices and electronics.

- Linear Vibration – employs reciprocating motion to generate frictional heat, effectively joining parts through melting at the interface.

- Linear Vibration Welding – commonly used in automotive manufacturing to attach complex plastic components by generating friction and melting at the joint interface.

- Laser Welding – a non-contact, high-precision method for joining plastics, utilizing laser energy as a precise and controlled heat source for efficient, consistent, and high-quality bonding.

Choosing the Right Thermoplastic Material for Welding

| Material | Weldability Score | Best Method(s) | Common Uses |

|---|---|---|---|

| PVC | High | Hot Air, RF | Banners, tarps, inflatable boats |

| PE (Polyethylene: LDPE & HDPE) | Medium | Hot Air, Impulse (with primer) | Agricultural films, liners |

| PP | Medium–High | Impulse, Extrusion | Packaging, filtration products |

| TPU | High | Hot Air, RF | Inflatable products, footwear |

Note: When welding polyethylene (PE), it is important to distinguish between low density polyethylene (LDPE) and high density polyethylene (HDPE). These two types have different melting points and structural properties. For optimal weld strength, always match the density of the LDPE or HDPE components being joined. Attempting to weld incompatible densities can cause the weld to break or result in a broken joint, compromising the integrity of the assembly. Selecting the right material is crucial for ensuring compatibility and optimal performance of welded components, especially in industries like automotive, medical, and electronics.

Welding PVC, Polyethylene (PE), and Polypropylene (PP)

-

PVC: Easy to weld, bonds well with hot air or RF due to polar molecular structure. The strength of the weld depends on proper preparation of the joint and joint area, ensuring good heat transfer and bond integrity. At the joint line, energy is applied to fuse the materials, causing them to melt and flow together. The joint interface and weld interface are critical zones where a strong, consistent bond is formed. Preparing the substrate and matching it with the correct welding rod is essential for optimal results, as the welding rod must melt and fuse with the substrate. The ability of polymer chains in PVC to re-bond when melted is fundamental to achieving a durable weld.

-

PE: Requires higher temperature or chemical priming for optimal adhesion. Proper preparation of the joint area and substrate, along with selecting the right welding rod, ensures a strong weld at the joint interface. During welding, the materials melt at the joint line, allowing the polymer chains to re-bond and create a seamless weld.

-

PP: More rigid, best with impulse or extrusion welding. Achieving a strong weld requires careful alignment of the substrate and attention to the joint area. The joint interface and weld interface must be heated sufficiently to melt the materials, enabling the polymer chains to re-bond and form a robust joint. Matching the welding rod to the base material is also important for weld quality.

Best Practices for Strong, Lasting Thermoplastic Welds

Checklist:

-

Clean surfaces thoroughly and ensure proper surface preparation to optimize bonding.

- Avoid contamination by maintaining a clean work environment, especially in sensitive applications.

-

Match temperature to material (typically 250–500°C).

- Monitor and control welding parameters such as temperature, pressure, and dwell time for consistent results.

-

Apply proper pressure and dwell time.

-

Use compatible materials and fillers.

-

Test weld samples before full production.

- Ensure operators are properly trained and certified, as skilled operators are critical for achieving high-quality, consistent welds.

- Recognize that certain parameters are critical to weld quality and must be carefully controlled.

Common Mistakes to Avoid: overheating, under-pressurizing, welding dirty surfaces, neglecting surface preparation, and failing to control welding parameters.

Heat Sealing vs Welding: What’s the Difference?

| Feature | Heat Sealing | Welding |

|---|---|---|

| Energy Source | Heat only | Heat + pressure/mechanical; can generate heat using electrical energy (e.g., impulse or ultrasonic welding) |

| Best For | Packaging films | Structural seams |

| Bond Strength | Medium | High |

| Scalability | High for short runs | High for continuous runs |

How Miller Weldmaster Supports Thermoplastic Welding Success

For over five decades, Miller Weldmaster has provided industrial plastic welding tips, equipment, and service for a range of applications. Our equipment is widely used for the repair and maintenance of large-scale industrial infrastructure, ensuring durable and long-lasting welds. From heat sealing thermoplastics to large-scale production automation, our machines are designed for durability, consistency, and flexibility, with the possibility of scaling up and automating thermoplastic welding processes to meet growing industry demands.

Frequently Asked Questions About Thermoplastic Welding

What is thermoplastic welding used for?

Bonding components in plastics for industrial, medical, and consumer goods where strength and durability are key. Thermoplastic welding is commonly used for joining components in these sectors to ensure optimal joint strength and compatibility.

Which thermoplastics are easiest to weld?

PVC and TPU are generally easiest due to their polar molecular structure.

What’s the difference between hot air and impulse welding?

Hot air uses continuous heated airflow; impulse uses timed electrical heating with pressure.

Can polyethylene (PE) be welded?

Yes, but requires higher temperatures or primers for a strong bond.

What temperature is needed for thermoplastic welding?

Typically between 250°C–500°C, depending on material type.

How do you ensure a strong thermoplastic weld?

Clean surfaces, match temperature to material, and apply correct pressure and dwell time.

Is thermoplastic welding stronger than adhesive bonding?

In most structural applications, yes—welds provide molecular-level bonds.

Can I weld PVC and polypropylene together?

Not directly; they have different melting points and polarity, making them incompatible without adhesives.

What’s the best method for welding medical-grade plastic film?

Impulse welding for precision and minimal heat distortion.

How long does a thermoplastic weld last in outdoor conditions?

With proper technique and UV-stable materials, 10–20 years or more.