From banners and tarps to inflatables and technical films, hot air welding machines for vinyl materials and thermoplastics are essential for creating strong, consistent seams across many industries. Whether you’re operating a high-output banner shop or manufacturing protective covers, hot air welding offers speed, precision, and durability—without the need for adhesives or stitching.

Hot air technology provides numerous advantages for welding vinyl materials, including technical advantages such as versatility, efficiency, and the ability to create strong, high-quality bonds. These advantages make hot air welding machines a preferred choice for professionals seeking reliable and aesthetically pleasing results.

This complete guide is tailored to professionals who work specifically with vinyl and thermoplastic materials. It covers applications, machine types, process details, and temperature guidance. With over 50 years of expertise in heat sealing technology, Miller Weldmaster has the experience and insight to help you get the most from your hot air welding operations.

Explore our hot air welding technology overview

What Are Hot Air Welding Machines for Vinyl and Thermoplastics?

Hot air welding uses precisely controlled heated air to soften the edges of thermoplastic materials. Advanced machines allow for precise control of parameters, ensuring consistent results and repeatable weld quality. These edges are then pressed together under pressure to form a permanent bond. Unlike adhesives or stitching, the weld becomes part of the material itself—creating a stronger, cleaner seam.

Vinyl and thermoplastics are particularly well-suited for this process because of their thermally reactive nature. Materials like PVC, PE, and PU respond predictably to heat and can be bonded quickly without distortion or degradation. Hot air welding machines have the ability and versatility to create seamless joints and durable seams with excellent appearance, making them ideal for a wide range of applications.

Comparing Welding Methods

| Welding Method | Heat Source | Seam Strength | Best Suited For |

|---|---|---|---|

| Hot Air Welding | Heated air via nozzle | High | Vinyl, thermoplastics |

| RF Welding | Electromagnetic energy | Very high | Thick PVC, intricate seams |

| Sewing | Needle and thread | Medium | Woven fabrics, non-thermoplastics |

| Taping | Adhesive application | Low–Medium | Temporary signage, lightweight |

Note: Radio frequency welding is commonly used in automatic welders for high-volume production lines. These systems utilize programmable controls and sensor feedback to ensure consistent, high-quality welds, optimizing the entire assembly line for greater efficiency and output.

Why Hot Air Welding Is Ideal for Vinyl Applications

Banner Welding Machines for Vinyl Signs

Hot air welding is widely used in banner production, offering the speed and reliability needed for both short and long production runs. It produces smooth, uninterrupted seams that hold up under outdoor exposure and frequent handling.

Benefits of banner welding machines:

-

Seamless and clean edge finishes

-

Faster than taping or sewing

-

Stronger, longer-lasting seams

-

Excellent for double-sided graphics and pole pockets

Banner welding machines commonly come with a range of accessories and specialized tools that enhance their functionality and efficiency. There are several models available on the market to suit different production needs and applications.

Tarp Manufacturing and Vinyl Covers

When strength and weather resistance are critical, hot air welding outperforms stitching. Welded tarps and covers are more resilient to wind, rain, and sun—ensuring your product lasts longer in demanding environments.

Automated systems are often used to weld components of technical textiles like tarps, providing consistent quality and reliable seams for large-scale production.

Inflatable Vinyl Products

For tents, inflatable games, safety devices, and medical products, hot air welding ensures airtight seals that maintain structural integrity. Consistent, repeatable seams are key in high-volume production environments where safety cannot be compromised.

Hot wedge technology can also be used for inflatables, which can lead to faster production and reduced costs.

Hot Air Welding for Thermoplastics: What You Need to Know

The thermoplastic welding process involves heating the material until it becomes soft but not molten, then applying pressure to fuse the two surfaces together. Thermoplastics can be reshaped multiple times with heat, making them ideal for hot air welding.

For consistent, high-quality results in industrial applications, it is essential to use professional equipment and techniques. Regular maintenance of welding machines and tools is also crucial to ensure optimal performance and reliable outcomes.

Can Hot Air Weld Thermoplastic Films?

Yes. Hot air welding is suitable for many thin-gauge films, including:

-

Polyethylene (PE)

-

Polyurethane (PU)

-

Polyvinyl chloride (PVC)

These materials are common in packaging, medical devices, industrial liners, and signage applications.

Industry Applications of Thermoplastic Welding

-

Packaging: Sealing liners, bags, and flexible pouches

-

Automotive: Interior insulation, molded covers

-

Medical: Sterile packaging, compression wraps

-

Construction: Vapor barriers, geomembranes, welding thermoplastic membranes for roofs and roofing systems

-

Industrial: Flexible ducts, tubes, and tents

The reliability of hot air welded seams gives manufacturers confidence in demanding applications, such as roofing and waterproofing, where durable, watertight results are essential.

Temperatures and Settings: Best Practices for Vinyl & Thermoplastics

A common question: “What temperature should I use to hot-air weld vinyl or thermoplastic materials?” The answer depends on material type, thickness, and air speed.

Recommended Settings

| Material | Temperature Range | Air Speed | Pressure |

|---|---|---|---|

| PVC Vinyl | 350–600 °C | Medium | Moderate |

| Polyurethane Film | 300–450 °C | Medium | Moderate |

| Polyethylene | 250–400 °C | Low | Light |

These numbers are guidelines. Variables like seam width, welding speed, and nozzle type also affect results. Always test on sample material before full-scale runs.

Hot Air Seam Sealing: How It Works in Practice

Hot air seam sealing is a step-by-step process that ensures strong, consistent results when working with thermoplastics.

-

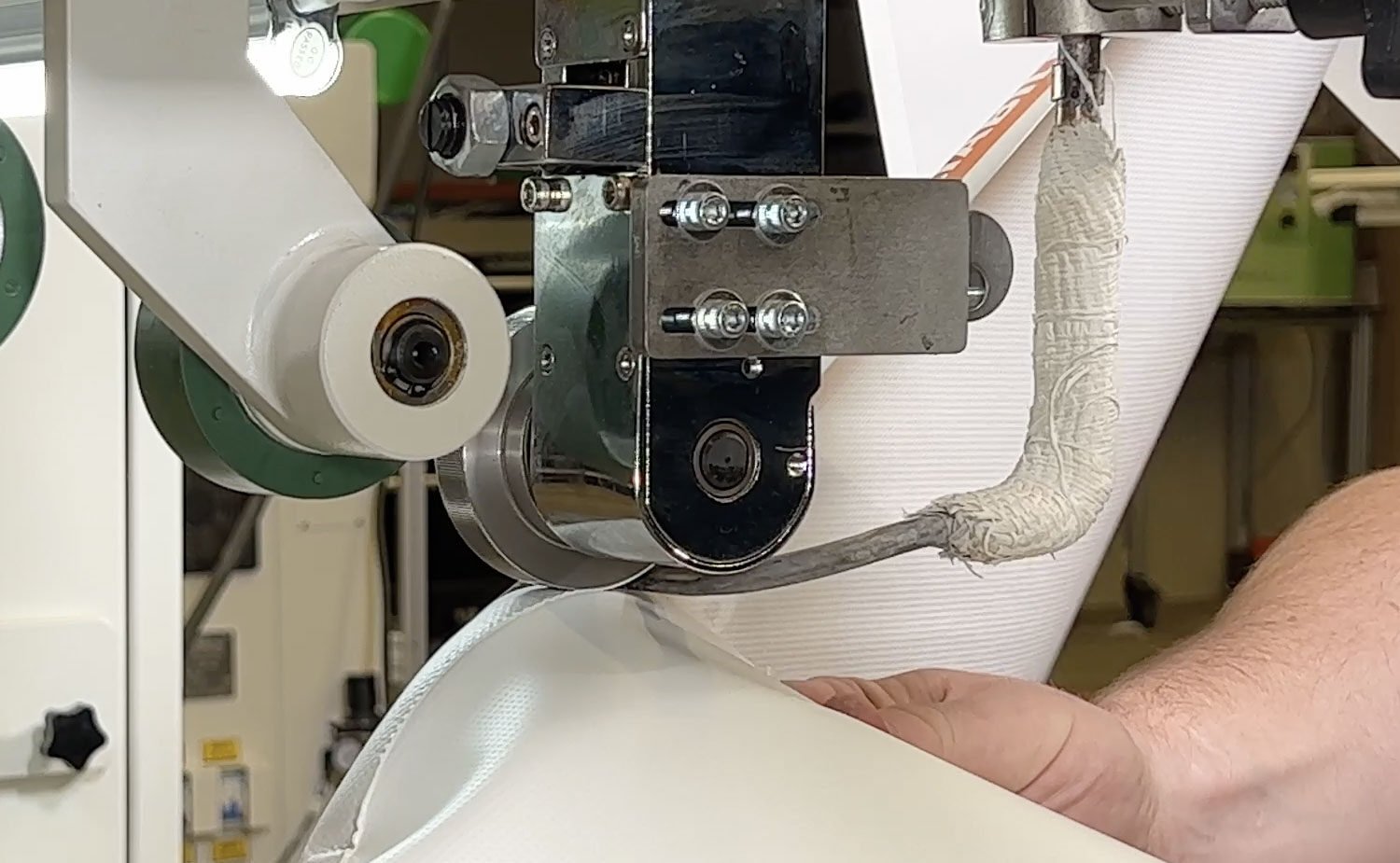

Heated air is precisely applied via a nozzle

-

Material edges soften to welding temperature

-

Pressure rollers press layers together

-

Seam cools and solidifies into a bond

This method is widely used in industries where seams must be waterproof, airtight, or able to withstand mechanical stress.

Choosing the Right Hot Air Welding Machine

Choosing the right machine depends on several factors:

-

Type of material being welded

-

Volume of production

-

Required seam strength

-

Desired level of automation

Before making a purchase, it is recommended to seek expert advice to ensure you select the best machine for your needs. Consulting the manufacturer can also provide valuable support, including troubleshooting, customer service, and warranty information.

See our guide: How to Choose a Hot Air Welder

Compare technologies: Hot Air vs RF Welding

Entry-Level vs Industrial-Grade Machines

-

Entry-Level: Best for small shops or prototyping. Lower output and fewer features.

-

Industrial-Grade: Engineered for long shifts, wide format materials, and high-speed production.

Features to Look for

-

Digital temperature control

-

Swappable nozzles for different seam widths

-

Laser guides or seam tracking

-

Integrated automation options

Miller Weldmaster Solutions for Vinyl and Thermoplastic Welding

At Miller Weldmaster, we’ve spent decades developing hot air welding machines that meet the needs of manufacturers working with vinyl and thermoplastics.

We take pride in delivering innovative, high-quality welding solutions that reflect our commitment to excellence and customer satisfaction.

Featured Equipment:

T300 Extreme Flex

Ideal for banners, tarps, inflatables, and more. Offers flexible seam width control, multiple welding heads, and touch screen operation.

We support customers in industries ranging from signage and agriculture to medical and aerospace, ensuring they get not just a machine, but a full solution.

Frequently Asked Questions About Hot Air Welding Machines for Vinyl and Thermoplastics

What temperature should I use to hot air weld vinyl?

Vinyl typically welds between 350–600 °C, depending on the material thickness, air speed, and seam configuration.

Can hot air weld thermoplastic films?

Yes. Common weldable thermoplastics include PVC, polyethylene, and polyurethane, which respond well to hot air sealing.

What is the difference between hot air welding and RF welding for vinyl?

Hot air welding uses heated air to melt surfaces externally. RF welding uses electromagnetic energy to heat materials internally. Hot air is more versatile for banners, tarps, and films; RF is ideal for thick PVC or medical-grade seams.

Is hot air welding stronger than stitching vinyl?

Yes. Welded seams are typically stronger, waterproof, and airtight, while stitched seams may leak or fray over time.

What machines are best for banner welding?

Look for machines with adjustable temperature and speed settings, a variety of nozzles, and semi-automated features. The T300 Extreme Flex is a top choice for this application.

Can I weld thermoplastics without special equipment?

No. Hot air welding requires purpose-built machines with consistent heat, airflow, and pressure control. Manual alternatives cannot replicate the bond strength or consistency.

Final Thoughts

Hot air welding machines for vinyl and thermoplastics provide efficient, high-strength solutions for a variety of manufacturing needs. Whether you’re sealing banners, tarps, films, or inflatable structures, hot air welding ensures quality, performance, and speed.

For more insights or to request a demo, visit weldmaster.com or speak with our team about your specific material and production goals.