High-frequency welding represents a significant leap in awning production, setting unparalleled standards for seam quality. This technology not only ensures durability but also enhances the visual appeal of awnings, which are essential for both residential and commercial applications. By delving into the mechanics of high-frequency welding, we'll uncover why it has become the preferred method for producing high-quality awnings.

Learn more about this technology at Miller Weldmaster's Radio Frequency Welding.

The Basics of High-Frequency Welding Technology

High-frequency welding, a form of electromagnetic welding, differs significantly from traditional welding techniques. It uses high-frequency electromagnetic waves to heat and bond materials. This process is particularly well-suited for synthetic fabrics commonly used in awnings, like PVC and vinyl. Unlike traditional sewing or adhesive methods, high-frequency welding creates a bond that is water-tight and visually seamless, crucial for outdoor applications where exposure to elements is a constant.

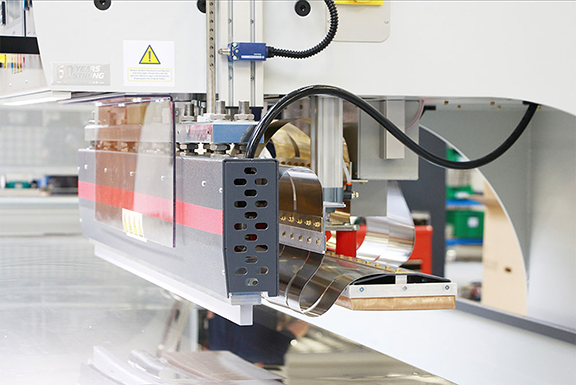

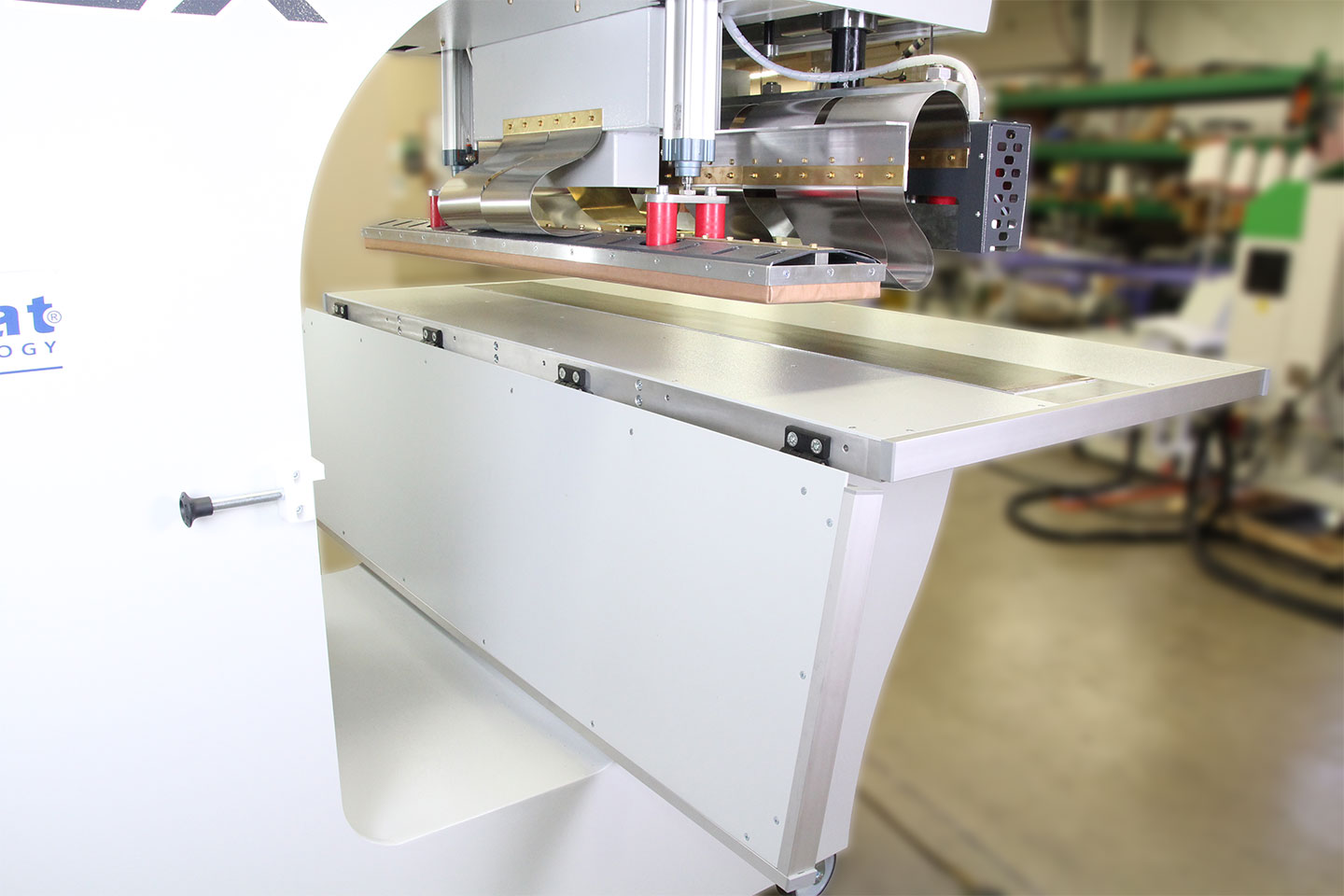

Key Components of High-Frequency Welding Machines

A high-frequency welding machine is an intricate system consisting of a high-frequency generator, a pneumatic press, and a specialized electrode or die. The generator produces electromagnetic waves. The pneumatic press applies pressure to the material, while the electrode directs the high-frequency waves to create a precise, localized bond. These components are engineered to work in harmony, ensuring that the seams are not only strong but also consistent in appearance, which is vital for high-quality awning production.

Why Perfect Seams Matter in Awning Manufacturing

The quality of seams in awnings is crucial. They must withstand wind, rain, and sun, all of which can quickly degrade poorly made seams. Moreover, the aesthetic appeal of awnings is paramount, especially in commercial applications where branding and visual presentation are key. High-frequency welding ensures that seams are not only functional but also contribute positively to the awning's overall appearance.

Challenges in Achieving Perfect Awning Seams

Creating the perfect seam in awning fabrication is a challenging task. Traditional methods can lead to inconsistencies, weak points, and susceptibility to environmental damage. High-frequency welding addresses these issues by providing a uniform bond that is strong and resilient, enhancing both the performance and longevity of the awning.

Transformations Achieved with High-Frequency Welding

The use of high-frequency welding in awning production has led to a notable improvement in product quality. The technology has made it possible to create awnings that are not only more durable and resistant to environmental factors but also more aesthetically appealing. The seamless finish achieved with high-frequency welding provides a sleek, modern look that is highly valued in today's market.

Advantages of High-Frequency Welding in Awning Production

High-frequency welding offers numerous advantages over traditional methods. These include enhanced seam strength, improved efficiency in production, and greater consistency in product quality. This technology allows for quicker production times and less material wastage, resulting in cost-effective manufacturing processes.

Enhancing Production Efficiency with High-Frequency Welding

High-frequency welding significantly streamlines the production process. This method is faster than traditional sewing, resulting in increased throughput. Additionally, it reduces the need for post-production finishing, such as waterproofing, as the welding process inherently seals the seams against water ingress. This efficiency leads to a reduction in labor and material costs, providing a competitive edge in the awning market.

Material Compatibility and Flexibility in Design

One of the standout features of high-frequency welding is its compatibility with a wide range of materials, including various types of plastics and fabrics. This compatibility allows manufacturers to experiment with different materials and designs, offering more customized and innovative awning solutions to meet diverse customer needs.

Choosing the Right High-Frequency Welding Machine

Selecting the appropriate high-frequency welding machine is crucial. Factors to consider include the types of materials being welded, the size and complexity of the awnings, and the desired production volume. Machines vary in their capabilities, from smaller, manual machines to larger, fully automated systems. Understanding the specific needs of your awning production can guide you to the right equipment choice.

Features to Look for in High-Frequency Welding Equipment

When choosing a high-frequency welding machine, look for features like automation, precision control systems, energy efficiency, and safety features. Modern machines often come with advanced control systems that allow for precise adjustments, ensuring consistent quality across all products.

Maintenance Tips for High-Frequency Welding Machines

Proper maintenance is key to ensuring the longevity and performance of high-frequency welding equipment. Regular checks and servicing can prevent downtime and prolong the life of the machine. Following the manufacturer’s maintenance schedule and guidelines is essential for optimal operation.

The Future of Awning Fabrication with High-Frequency Welding

The future of high-frequency welding in awning fabrication looks promising, with ongoing advancements in technology paving the way for even more efficient and versatile production methods. These innovations are likely to further enhance the quality and durability of awnings, meeting the evolving demands of both commercial and residential markets.

Elevating Awning Quality with Advanced Welding Techniques

In conclusion, high-frequency welding has become an indispensable tool in awning manufacturing, delivering unmatched seam quality and efficiency. Its ability to produce strong, aesthetically pleasing, and durable seams makes it a cornerstone of modern awning production.

Enhance your awning products with advanced welding technology. Explore the range of high-frequency welding machines at Miller Weldmaster today and experience unmatched seam perfection.

For more insights into awning applications and state-of-the-art equipment, visit Miller Weldmaster's Awning Industries page, Machine Overview, and Contact Us for tailored solutions and expert advice.

.png)