Employee buy-in is an important first step when implementing a new process or piece of equipment. However, winning employee buy-in can be easier said than done.

Companies implementing change often experience hesitation from employees for a variety of reasons. Perhaps your team is comfortable with its current processes and sees no value in changing. Other times, employees may push back out of fear or resistance to change.

Regardless of the reason, employees on every level will want to know how the new solution will affect their day-to-day tasks. For some, it’s clear how quickly a new machine or process can dramatically expedite production, while others may need more time to adjust and embrace the change. That’s why employee buy-in is essential when adopting new equipment or technologies to enhance production—otherwise, you risk a failed investment.

To ensure a frictionless transition, we’ve broken down how to achieve employee buy-in for new fabric welding solutions into in three simple steps below.

1. Be Thorough and Proactive with All Communications

While every company’s manufacturing operations are different, thorough and proactive communication is key to successfully implement new equipment.

Even before selecting a fabric welding solution, consider what onboarding resources your equipment partner offers to support you in the communication stage. For instance, look for partnership features like:

- Onboarding materials, which could include training videos or online communities that offer equipment how-tos, answers to top user questions and more.

- Installation and training programs to ensure equipment is installed correctly and integrated with your current machines and processes. This will help reduce production downtime and delays, both after implementation and in the future.

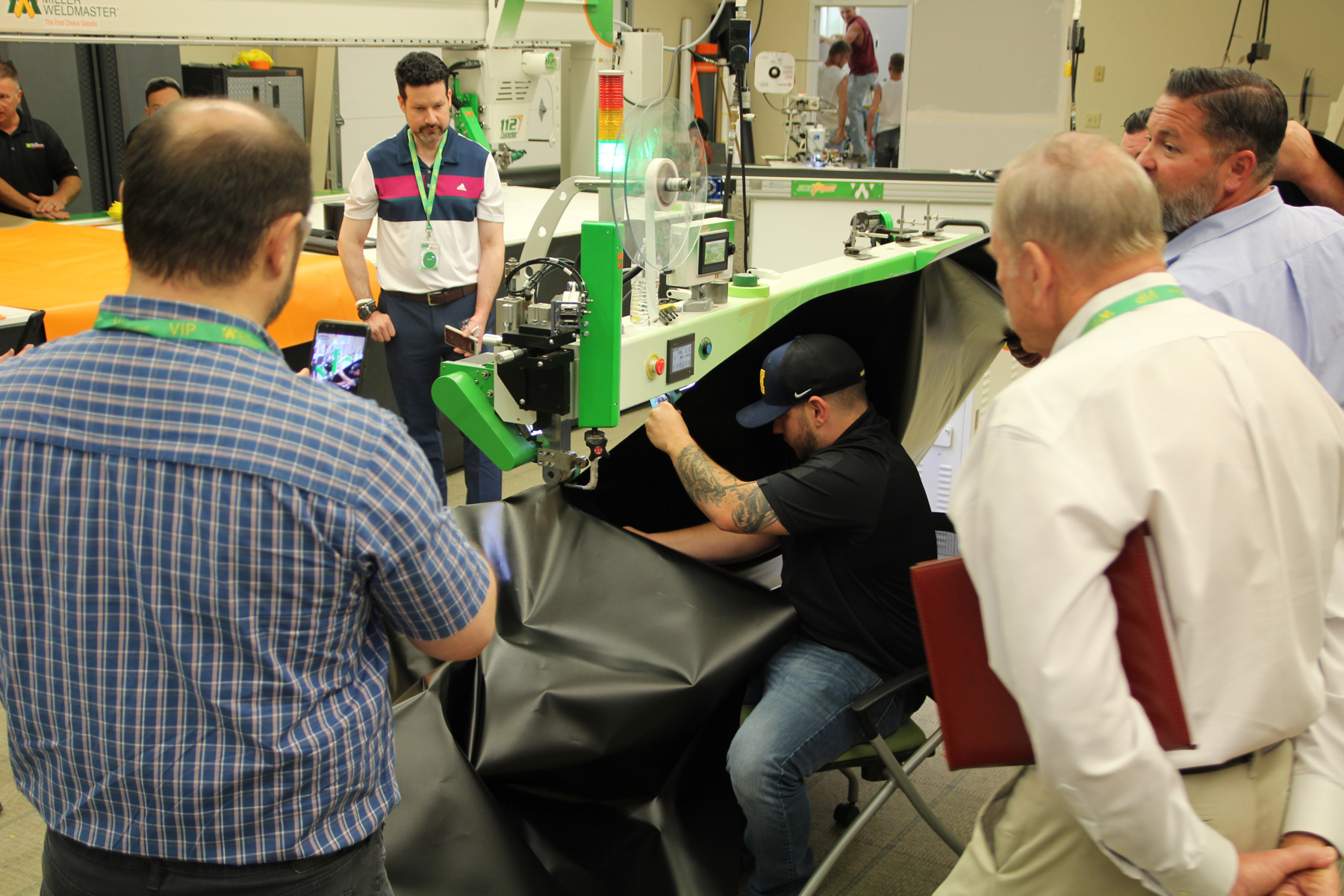

Armed with information from your equipment provider, consider holding department-wide meeting or town halls, either with your provider’s implementation specialists or the literature they’ve provided. This will give your team the opportunity to ask questions and have a sense of involvement, rather than being forced to adapt to the new process.

These meetings are your opportunity to secure employee buy-in. During these meetings, be transparent with employees about the long-term direction for the team. Here, you can also communicate to employees the specific benefits that the new fabric welding system will bring, such as:

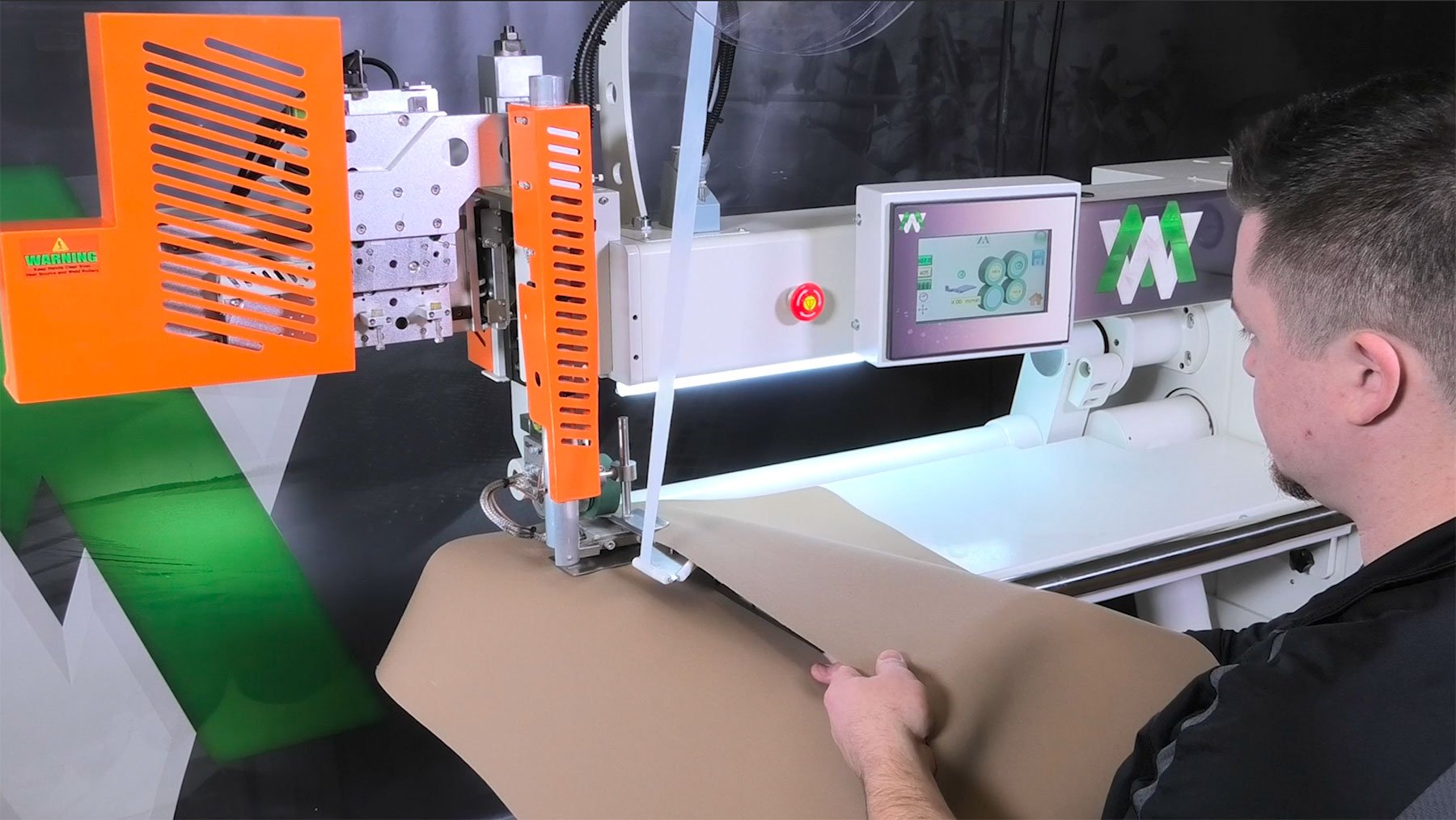

- Improving product and customer satisfaction. Fabric welders provide a clean seam and are a more durable solution than sewing, resulting in longer-lasting products and happy customers.

- Eliminating tedious task of working with thread. With fabric welding, operators no longer have to thread match or worry about thread rotting. Material welders provide a high-quality seam that is durable and thread-free.

- Reducing waste. Often, the amount of fabric used is reduced, allowing management to allocate budgets elsewhere.

No matter how much effort you put into communicating with your team, it won’t be effective unless you also listen to their concerns. Be prepared to address concerns such as:

- How will this affect my daily tasks?

- Who do I go to with questions specific to the new machine?

- What resources are there to help me get acquainted with this new technology?

- Will I be required to learn this new technology?

- How much downtime in production will we experience as we transition?

- Is this replacing or supplementing our current process?

Throughout initial installation and training, your service provider should coordinate with you to provide knowledge and resources for employees to help ease the transition.

Even after your team is familiar with the new technology, top fabric welding equipment providers will also offer support long after implementation, offering:

- A hands-on service team that you can turn to for technical help to keep your production running at optimal performance.

- Ongoing maintenance programs. Remember that a new equipment installation isn’t a fix-it-and-forget-it process. Regular, ongoing maintenance will increase the lifespan and longevity of your new fabric welding solution.

At Miller Weldmaster, our service team is available by phone or email to customers should team members run into any questions. We also offer a library of resources like operating training videos, how-to videos and easy scheduling for in-person training courses.

3. Set Actionable Next Steps for Team Members

As with any internal change, provide clear next steps for your team members. This is more than “reach out with any questions.” It’s part of the leadership’s responsibility to follow up to ensure team members are comfortable with process changes.

Once your team has had time to adapt, challenge your team to report on any improved metrics that are specific to their daily duties and related to the new material welding solutions. Ask the following questions to spark discussion:

- What was your efficiency rating prior to installation versus now?

- What is your new daily output?

- Have you noticed increased consistency while using the new equipment and/or process?

- Have customers commented on improved product quality or longevity?

It’s important to recognize that every organization is different, and these steps may need to be tailored to accommodate your team. With many options on the market, finding a partner who can not only provide you with the best technology, but also position your team for success with training and support, is key.

Get the Inside Scoop on All Things Fabric Welding

Stay up to date on all things regarding industrial fabric welding solutions by joining our online community, Insiders Welding Group. You’ll receive monthly communications about your fabric welder, product how-tos and tips, and specials and promotions.