What Is the Triad Extreme Universal Welding Machine?

Imagine a fabric welding machine that combines power, precision, and portability. The Triad Extreme Universal uses a hot wedge as its heat source, offering benefits suitable for welding thinner materials without distortion. It is a hot wedge welding machine tailored for materials such as PVC, polyurethane, acrylics, and a variety of industrial textiles. It is invaluable for industries like awning manufacturing, tarp production, tent making, and geosynthetic fabrications. The Triad's ability to provide consistent, strong seams makes it a preferred choice among professionals who demand quality and durability in their products.

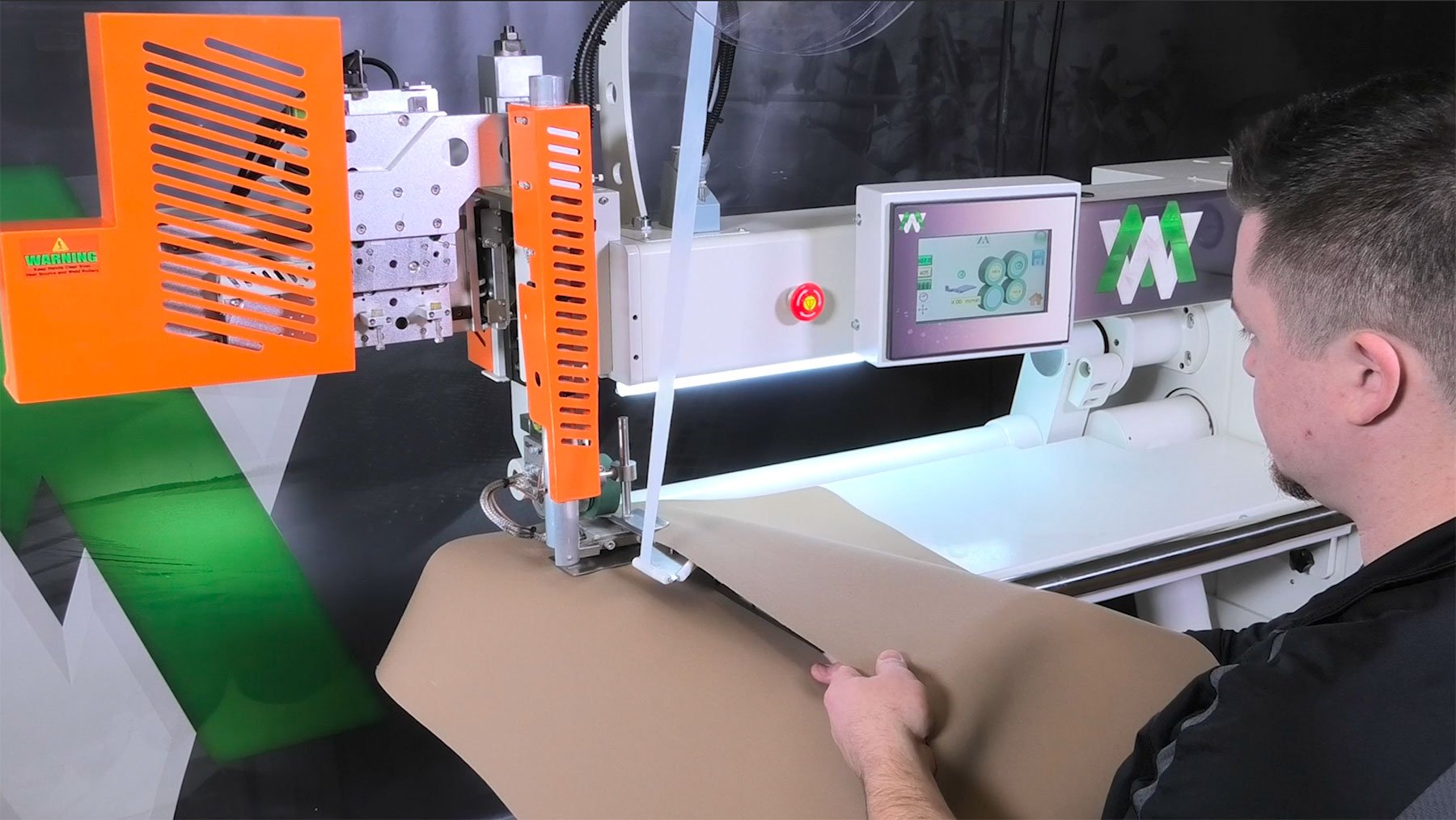

How Does the Triad Extreme Universal Welding Machine Work?

The essence of effective fabric welding lies in the perfect balance of heat, pressure, and speed. The Triad Extreme Universal utilizes state-of-the-art hot wedge technology to produce airtight seams that neither require adhesives nor additional stitching.

Understanding the Core Components

The Triad Extreme includes vital components like a heated wedge, precision rollers, and adjustable controls for speed and pressure. The temperature controller allows users to set the desired temperature for optimal performance. Each element is designed to contribute to a seamless welding process, ensuring each weld is strong and durable. Wedge adjustment is crucial for achieving optimal weld quality, requiring daily checks and fine-tuning to ensure consistent and efficient operation.

Stationary vs. Track Welding – Which Should You Use?

The machine offers flexibility with options for stationary or track-based operation. Stationary welding is suited for smaller, more detailed projects, while track welding is ideal for larger-scale, repetitive tasks. Understanding the benefits of each can significantly enhance workflow efficiency.

Key Features That Make the Triad Extreme Universal Stand Out

Portable Fabric Welding Machine for Any Industry

The portability of the Triad Extreme is a significant advantage in industries where production spaces vary and mobility can enhance productivity. The machine can come with various guides and a tape dispenser. Its design allows for easy movement between workstations or to different job sites.

Adjustable Seam Widths for Custom Applications

With seam width settings ranging from 10 to 50mm, the machine offers unparalleled flexibility in handling various types of projects. The machine also allows for repeatable head adjustments, ensuring precision and consistency in seam configurations. Whether you’re creating overlaps, hems, or pockets, these adjustable settings help ensure each weld is optimized for strength and appearance.

Hot Wedge Welding for Strong, Durable Seams

Hot wedge welding provides superior bonding strength over traditional methods like stitching. This method not only enhances the structural integrity of the seams but also ensures they are waterproof, weather-resistant, and airtight.

How to Set Up and Operate the Triad Extreme Universal Welding Machine

This section walks you through the initial setup, ensuring that you can start your welding projects with confidence.

Preparing Your Materials for Welding

Proper preparation of your materials is crucial. Having a flat and properly organized welding area is essential for optimal weld quality. This involves cleaning, precise cutting, and aligning your fabrics before welding. These preparatory steps significantly affect the quality of the final weld product.

Optimizing Speed, Temperature, and Pressure for Best Results

Adjustments to speed, temperature, and pressure can vary significantly between different materials. Understanding how to tailor these settings to specific fabrics can prevent common issues such as warping or inadequate seam strength.

Performing a Test Weld to Check Seam Quality

Before proceeding with full production, performing a test weld is essential. Precision welding is crucial in achieving high accuracy and strong seams, ensuring the reliability of the welding process. This allows you to adjust the machine settings based on the test results, ensuring every weld thereafter is perfect.

Common Mistakes and How to Avoid Them When Using the Triad Extreme Universal

Incorrect Temperature and Speed Settings

Recognizing and correcting temperature and speed settings can make a substantial difference in preventing material damage. This section provides tips on identifying and adjusting these settings effectively.

Misaligned Materials Leading to Weak Seams

Ensuring material alignment is key to strong, durable seams. Engaging the machine into the correct welding position is crucial for accurate alignment and quality welds. Tips and techniques for maintaining alignment will help avoid costly mistakes.

Neglecting Maintenance and Cleaning

Regular maintenance and cleaning are pivotal for prolonging the life of your welding machine and maintaining consistent weld quality. Installing smooth steel rollers during maintenance is crucial to ensure the proper function of the machine and achieve accurate welds. This section outlines essential maintenance practices that are often overlooked.

Best Practices for Industrial Fabric Welding with the Triad Extreme Universal

Choosing the Right Seam Configuration for Your Application

Different projects require different seam types. This part of the guide helps you choose the right seam configuration to match the specific needs of your project, enhancing both functionality and aesthetic appeal.

Tips for Improving Weld Consistency and Strength

Expert tips on maintaining consistent heat distribution and avoiding weak spots in your seams will ensure your projects are both visually pleasing and structurally sound. The quick setting recall feature enhances operational efficiency and product versatility by allowing easy operation through a touch screen and recipe storage.

Miller Weldmaster’s Expertise in Industrial Fabric Welding

Delve into the history and innovation that Miller Weldmaster brings to the fabric welding industry. This section highlights how real-world applications and feedback have driven the advancements in their machines.

Industries That Benefit from the Triad Extreme Universal Welding Machine

- Tarp and Awning Manufacturers

- Geosynthetic Production

- Tents and Shelter Manufacturing

Frequently Asked Questions About The Triad Extreme Universal Welding Machine

What materials can the Triad Extreme Universal weld?

Triad Extreme Universal is versatile and capable of welding a variety of materials including PVC, polyurethane, acrylics, and other industrial textiles. Its design allows it to handle both thin and thick fabrics, making it suitable for applications across various industries such as tarpaulin production, tent manufacturing, and awning creation.

How does hot wedge welding compare to hot air welding?

Hot wedge welding and hot air welding both serve the purpose of joining thermoplastic materials, but they differ in their mechanisms and ideal applications:

- Hot Wedge Welding: This method uses a heated metal wedge placed between two layers of material. The wedge heats the materials to their melting point and then they are pressed together to form a bond as they cool. This technique provides precise control over temperature and speed, leading to strong, consistent seams that are excellent for waterproof and airtight applications.

- Hot Air Welding: This method blows hot air between two layers of material, melting them so they can be pressed and bonded together. It's highly effective for detailed or intricate welding because it allows for more flexibility in moving the nozzle around different shapes. However, it might require more skill to maintain consistent seam quality compared to wedge welding.

How do I know if my seam is strong enough?

To assess the strength of a seam, consider performing a few tests:

- Peel Test: Try to peel the two welded fabrics apart with your hands. A strong seam won't come apart easily.

- Tensile Test: If possible, use a tensile testing machine to measure the force required to break the seam. This provides quantitative data on the seam's strength.

- Visual Inspection: Look for any irregularities or gaps in the seam. A uniform, consistent seam without any visual defects typically indicates good weld quality.

Can the Triad Extreme Universal be used manually and automatically?

Yes, the Triad Extreme Universal offers flexibility in operation modes. The easy operation touch screen simplifies user interaction, allowing for quick setting recall and recipe storage, which enhances product versatility and operational efficiency. It can be used manually for smaller, custom projects where direct control is beneficial. It also supports automatic operation for larger-scale productions where consistency and speed are crucial. This dual capability allows it to adapt to varying production needs and user skill levels.

How do I troubleshoot uneven seams?

Uneven seams can be caused by several issues. Here are steps to troubleshoot and correct them:

- Check Material Alignment: Ensure the materials are properly aligned before starting the weld. Misalignment can lead to uneven pressure and heat distribution.

- Adjust Pressure and Speed Settings: If the pressure is too low or the speed too high, it can result in inadequate bonding. Experiment with these settings to find the optimal balance for the materials you are working with.

- Inspect the Wedge and Rollers: Make sure the wedge is heated evenly and that the rollers are not worn out. Any inconsistency in the hardware can translate to the seam.

- Regular Maintenance: Perform routine maintenance checks to ensure all components are functioning correctly.