Today’s e-commerce landscape is growing faster than ever, but so are its packaging challenges. One major concern is the widespread use of oversized packaging, which leads to wasted shipping space, high dimensional weight fees, and increased environmental impact. As online retailers seek more sustainable and cost-efficient operations, on-demand box making machines are becoming a game-changing solution.

These automated box manufacturing systems help businesses create right-sized box packaging for every order, slashing shipping costs and packaging waste. If you want to streamline operations, reduce costs, and meet growing consumer expectations for eco-friendly packaging solutions, this guide will help you understand the power of on-demand box making.

Explore more about Miller Weldmaster’s line of automated box makers here!

What are On-Demand Box Making Machines?

On-demand box-making machines are automated systems that create custom corrugated boxes in real time. Unlike traditional pre-made box inventories, these machines eliminate the need to stock dozens of sizes that may not fit products efficiently. Instead, operators input product dimensions—or scanners automatically capture them—and the machine cuts, creases, folds, and glues a perfectly sized box on the spot.

Core Components Include:

- Cutters and Scorers – precisely cut corrugated sheets and create fold lines

- Material Feeders – typically fanfold corrugated stock for continuous operation

- Dimension Scanners – capture product size data manually or automatically

- Die-Cutting Units – create hand holes, tear strips, or specialty features

These machines most often use corrugated fanfold stock and can produce anywhere from 10–35 boxes per minute, depending on machine size and manufacturer.

Why Oversized Boxes Are Costly and Inefficient

- Shipping Costs: Carriers calculate dimensional (DIM) weight, and oversized boxes can drive rates up by 30–50%.

- Material Waste: Extra corrugated board is used unnecessarily, adding up across thousands of shipments.

- Void Filler Costs: More bubble wrap, paper, or air pillows are required to secure items.

- Customer Experience: Oversized boxes feel wasteful and may lead to product shifting or damage during transit.

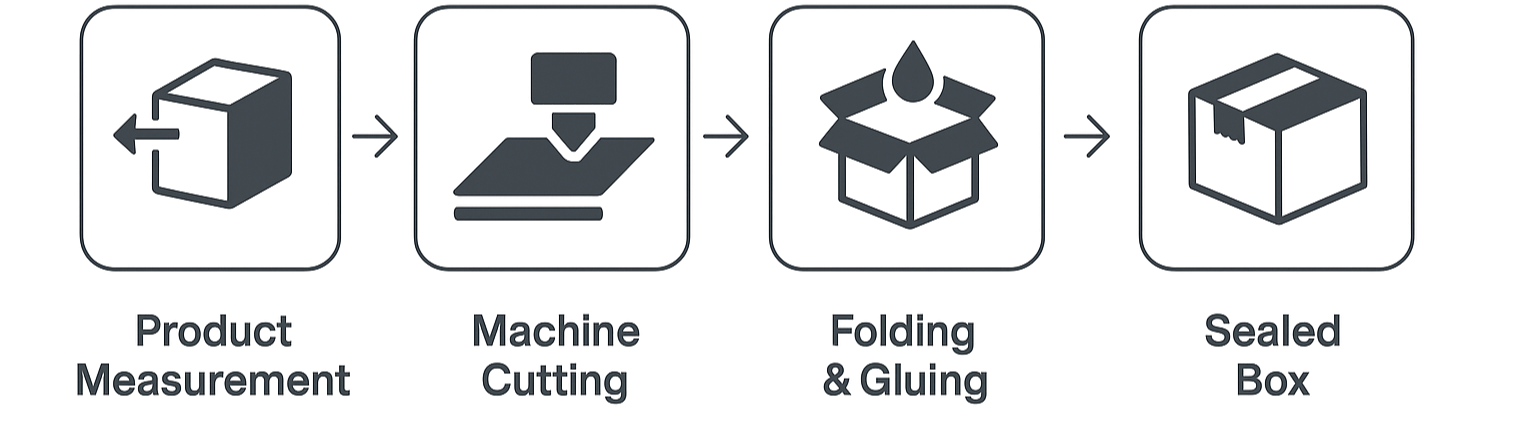

How On-Demand Box Machines Work

- Product Dimension Input – via manual entry or automated scanning.

- Algorithmic Calculation – software determines the optimal box layout.

- Cutting & Creasing – corrugated fanfold is cut and scored.

- Folding & Gluing – panels fold into shape, adhesive is applied.

- Sealed Box Output – ready for immediate packing and shipping.

Benefits of Right-Sized Packaging (Cost, Efficiency, Sustainability)

- Cost Savings:

- Reduce shipping costs by 28–50%

- Lower corrugated material use by 20–30%

- Operational Efficiency:

- Throughput improvements of 2–3×

- Automated operation reduces labour costs

- Vertical sizing eliminates costly machine changeovers

- Sustainability:

- Void fill waste reduced by 20–90%

- Greater use of recycled corrugated materials

- Smaller packaging footprint reduces emissions in transport

| Benefit Area | Traditional Packaging | On-Demand Right-Sized |

| Shipping Costs | Higher DIM charges | 28–50% lower |

| Material Use | Excess corrugated | 20–30% reduction |

| Labor | Frequent changeovers | Automated, 2–3× faster |

| Sustainability | High void fill | 20–90% less waste |

Which Businesses Need On-Demand Box-Making Machines?

Industries Benefiting Most:

- E-Commerce Fulfilment Centres – reduce shipping and labour costs

- Subscription Boxes – flexible production for varying product mixes

- Food & Beverage – protect products with custom fit packaging

- Logistics & Warehouses – streamline operations with fewer box SKUs

- SME Manufacturers – gain branding control and reduce small-run costs

How to Choose the Right On-Demand Machine for Your Operations

Checklist for Evaluation:

- What is your average packaging volume?

- How varied are your SKU dimensions?

- What production speed is required (10–35 boxes/minute)?

- Do you need integration with ERP/WMS?

- What is your available floor space for fanfold stock and machine footprint?

- What ROI timeline (12–24 months) is acceptable?

- Will you buy outright or consider subscription models like “Box-as-a-Service”?

Asking these questions helps narrow vendors and models to fit your specific business case.

Implementation Tips & Best Practices

Rolling out an on-demand box-making system takes planning:

- Facility Layout: Allocate space for fanfold stock and feeders.

- System Integration: Connect with dimension scanners and ERP/WMS systems.

- Training: Educate operators on daily use, maintenance, and troubleshooting.

- Maintenance: Keep spare parts on hand and schedule preventative service.

- Pilot Runs: Start with a subset of products to measure box weight, shipping cost, and labour savings before scaling up.

Conclusion: The Path to Smarter Packaging

On-demand box-making is transforming packaging by reducing costs, improving operational efficiency, and supporting sustainability goals. Whether you’re an e-commerce giant or a small manufacturer, the right system can deliver measurable ROI in as little as a year.

With decades of packaging automation expertise, Miller Weldmaster helps businesses evaluate, implement, and optimize box-making technology tailored to their needs. To explore solutions for your operation, connect with our team for a consultation.

How Miller Weldmaster Supports Your Packaging Innovations

At Miller Weldmaster, we help e-commerce brands and manufacturers adopt automated packaging solutions that deliver measurable improvements in cost savings, sustainability, and efficiency. As a leading company in the box-on-demand machinery industry, we offer a comprehensive range of services, including technical support, training, and after-sales assistance. We encourage you to request more information or a quote to discover how our solutions can benefit your business.

Packaging Expertise and Trusted Solutions

With decades of experience in packaging automation, Miller Weldmaster offers solutions for both custom box production and other flexible packaging needs.

Miller Weldmaster’s Commitment to Sustainability

We are committed to helping businesses reduce packaging waste and move toward more eco-friendly box solutions that benefit both the planet and the bottom line. We also prioritize quality in all our packaging solutions, ensuring reliable performance and customer satisfaction. Read more insights on our blog about the “Five Benefits of Custom Packaging Solutions for your Business.”

Frequently Asked Questions About On-Demand Box Making Machines

What is an on-demand box making machine?

An on-demand box making machine is a system that creates custom boxes in real-time, based on exact product dimensions, reducing waste and shipping costs.

How do on-demand box machines reduce shipping costs?

By producing right-sized packaging, these machines help businesses avoid dimensional weight fees and minimize unused box space. Demand packaging ensures each order receives a custom solution, further reducing costs.

Are on-demand box making machines suitable for small businesses?

Yes—smaller e-commerce businesses benefit from the flexibility and efficiency of producing boxes only when needed, without large upfront inventory costs. These machines are also ideal for short run box production, making them perfect for customized, low-volume needs.

What’s the average ROI on an on-demand box making machine?

Many companies see an ROI within 12 to 24 months, depending on packaging volume and shipping cost savings.

How much material can businesses save with on-demand box making machines?

Industry benchmarks suggest 20–30% material savings through optimized box sizing, especially when producing custom corrugated boxes.

Do these machines integrate easily with existing logistics systems?

Most modern systems can integrate with WMS, ERP, and OMS platforms, streamlining packaging workflows.

How long does it take to produce custom boxes on-demand?

Typically, custom boxes can be produced in seconds per box, far faster than ordering pre-made packaging. In fact, some machines can produce a custom box in less than one minute, thanks to automated, servo-controlled adjustments.

Can on-demand box machines handle different types of cardboard materials?

Yes—most machines work with a variety of corrugated board grades and flutes, providing flexibility for different product needs. A boxmaker machine is designed to handle a wide range of corrugated materials, ensuring efficient production for various applications.

Are on-demand box machines environmentally friendly?

Absolutely. They contribute to reduced packaging waste, fewer transportation emissions (thanks to smaller box sizes), and more sustainable operations overall.

---2.jpg)