There are many different types of inflatable fabric that are used for inflatable structures. But a sound structure begins even before these steps with the fabric, or material, selection. Materials play a crucial role in a structure’s performance, especially in air-supported structures, such as inflatables. Given that they do not have much of a frame, the fabric must carry the load of the overall structure.

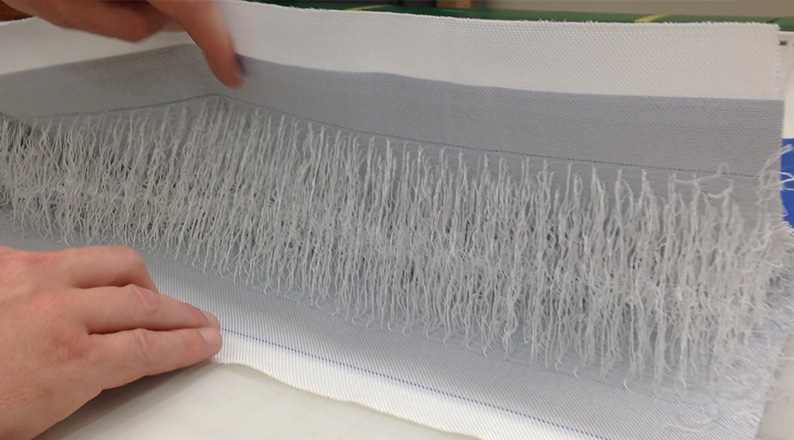

Inflatable fabrics are typically coated or laminated with synthetic materials to increase their strength and environmental resistance. Among the most widely used materials are polyvinyl chloride (PVC) coated vinyl or nylon, and oxford woven cloth. PVC coated materials are more durable and more expensive.

Determining which type of inflatable fabric to use depends on many factors. One of the most important factors that inflatable manufacturers must take into account is whether or not the inflatable structure will have what are commonly referred to as “impact areas.” Impact areas, like slides or bounce surfaces must have extra durability. Can you identify the impact areas on the inflatables below?

Miller Weldmaster manufactures a variety of inflatable fabric welding machine equipment for the production of durable and reliable inflatable products. Contact us today for more information.