High-Frequency (HF) welding is a method of joining thermoplastic materials using high-frequency electromagnetic waves. In this process, high frequency energy in the form of electromagnetic waves is used to generate heat within the materials. Known in the United States as Radio Frequency (RF) welding, this welding method is an efficient, and precise alternative to other welding techniques such as Hot Air and Hot Welding. As HF welding gains momentum in the United States, it is important to understand the benefits and how it may work for your business!

What Is High-Frequency?

High-Frequency Welding Explained

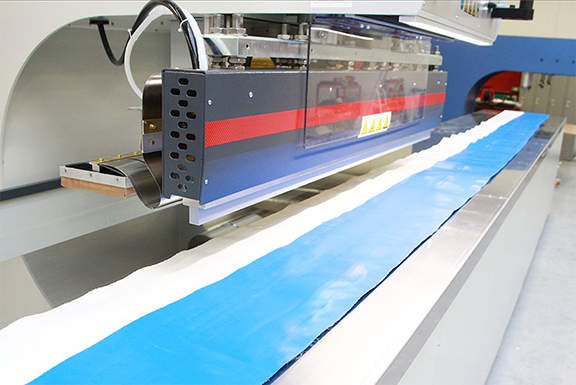

High-frequency (HF) welding—also called radio-frequency (RF) welding—is a process that uses electromagnetic energy to bond thermoplastic materials. Unlike traditional heat welding that uses external heat sources, HF welding heats the material from within using high-frequency electromagnetic fields. In this process, high frequency electromagnetic energy creates an electric field that causes dipole molecules in the material to undergo dipole polarization. Learn more in our glossary.

This molecular agitation leads to intermolecular friction resulting from the movement of dipole molecules under the electric field, which generates heat necessary for welding. The heating effect in HF welding is primarily due to molecular friction caused by dipole polarization within the thermoplastics.

How the HF Welding Process Works

-

Position Materials: Two layers of thermoplastic are placed between upper and lower electrodes in the defined welding area.

-

Apply Electromagnetic Field: A high-frequency field (typically 27.12 MHz) is applied across the electrodes in the welding area.

-

Molecular Agitation and Heating: Polar molecules within the materials vibrate, generating heat internally.

-

Apply Pressure: While heating, pressure is applied to ensure intimate contact between the material layers for effective welding.

-

Cool and Seal: The weld cools under pressure, and proper cooling time is essential to stabilize the weld and maintain its final properties, forming a strong, clean seal. HF welding ensures consistent results due to the control of pressure, welding time, and cooling time during the process.

Compatible Materials for HF Welding

Thermoplastics That Can Be Welded

| Material | Compatible with HF? | Notes |

| PVC | Yes | Most commonly used due to strong polarity. |

| PU (Polyurethane) | Yes | Ideal for inflatables and waterproof applications. |

| PET-G | Yes | Used in medical and clear packaging applications. |

| Polypropylene | No | Non-polar, incompatible with HF welding. |

| Polyethylene | No | Requires alternative welding methods. |

Only polar thermoplastics can be welded using HF because the process relies on molecular dipoles to generate heat. HF welding is particularly effective for joining polar thermoplastics like PVC and polyurethane.

Unsure if your material works? Contact us to test it.

Why Material Compatibility Matters

Choosing the right material ensures weld strength, durability, and regulatoompliance. Compatibility between two materials is crucial for achieving strong, reliable welds. In sectors like medical, outdoor gear, and industrial packaging, material compatibility can impact safety and performance. HF welds can be as strong as or stronger than the original materials.

Advantages of High-Frequency Welding

-

Strong seams: Produces airtight and watertight bonds suitable for heavy-duty use, and creates a strong bond between materials.

- High quality welds: HF welding delivers high quality welds by utilizing electromagnetic energy for strong, durable joints.

- Consistent results: The process ensures reliable, repeatable welds with consistent results across production runs.

-

Precise bonding: Clean edges and seam accuracy, even on complex shapes.

-

Fast production: Short cycle times ideal for high-volume manufacturing.

-

Minimal distortion: Localized heating avoids damage to surrounding materials.

- Decreased power loss: Optimized parameters can decrease power loss during welding, improving energy efficiency.

- Power loss control: Controlling power loss is important for weld quality and process efficiency.

-

Automation-ready: Easily integrated with digital and robotic systems. The precision and clean seams produced by HF welding make it the preferred choice for many manufacturers producing large volumes of plastic items.

Each benefit contributes to cost-effective, high-quality production across industries.

Common HF Welding Applications

Industries That Use HF Welding

-

Medical: Used for sealing and assembling medical items such as blood bags, blood pressure cuffs, disposable clothing, IV bags, fluid bladders, and surgical drapes where sterile, leak-proof seams are critical.

-

Inflatables: Ideal for rafts, bounce houses, and tents where airtightness and flexibility are essential.

-

Consumer Products and Industrial Applications: Perfect for pool liners, air mattresses, waterproof gear, and joining plastic parts in a variety of consumer and industrial products.

- Safety Equipment: Commonly used in the manufacturing of life jackets and other safety equipment that require strong, reliable seams in thermoplastic materials.

Why HF Welding Excels in These Areas

-

Clean sealing is crucial in the medical field to avoid contamination. HF welding is also highly effective for sealing thin sheets and films, which is important in medical and packaging applications.

-

High seam strength withstands stress and wear in transportation. The process can weld multiple layers simultaneously, enabling the creation of complex, layered products.

-

Fast production cycles make it ideal for mass-market consumer goods. HF welding is ideal for joining thin sheets of polar thermoplastics. HF welding can create complex shapes and is suitable for thin and thick plastic films.

HF Welding vs. Other Plastic Welding Methods

Comparison Table

| Feature | HF Welding | Hot Air Welding | Ultrasonic Welding |

| Heating Method | Electromagnetic | External Hot Air | High-Frequency Vibration |

| Material Compatibility | Polar Thermoplastics | Broader Range | Thin Plastics Only |

| Speed | Fast | Moderate | Very Fast |

| Seam Strength | High | Moderate to High | Moderate |

| Automation Integration | Excellent | Good | Good |

More info: Hot Air vs RF Welding Blog

When to Choose HF Welding

If you’re asking: “Is HF welding better than hot air welding for PVC tarps?” — the short answer is yes, especially when airtight seams, high strength, and clean aesthetics are required. HF welding is especially effective for materials like polyvinyl chloride (PVC) due to its polar molecular structure, which makes it ideal for this process. HF is the preferred choice for polar materials, high-volume runs, and industries with strict compliance needs.

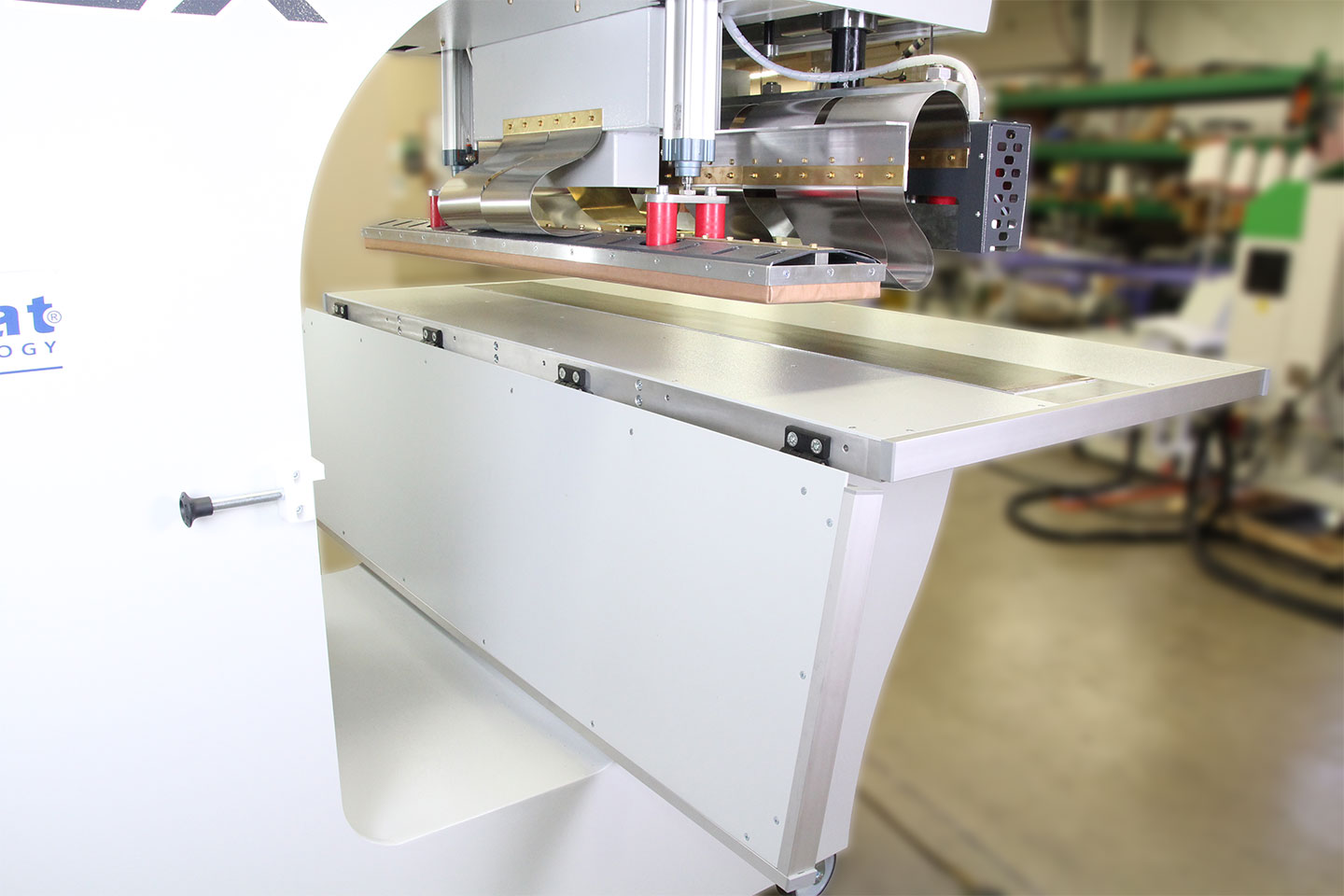

Innovations & Automation in HF Welding

Smarter Equipment and Seam Control

Modern HF welders offer:

-

Digital controls for repeatable settings

-

Real-time diagnostics to ensure seam integrity

-

IoT integration for predictive maintenance and quality control

These innovations help reduce errors and improve throughput.

Sustainability and Material Efficiency

High-frequency welding supports greener manufacturing by:

-

Minimizing scrap waste through precise welding

-

Using clean electricity instead of fossil-fuel heating

-

Supporting recyclable materials like PVC and PU

- Reducing the need for adhesives or solvents, making it a more environmentally friendly option

Final Thoughts and Next Steps

High-frequency welding is a reliable, scalable solution for manufacturers working with polar thermoplastics. Its strength, speed, and compatibility with automation make it ideal for modern production environments.

Explore further:

Frequently Asked Questions About High-Frequency Welding

What frequency does HF welding use?

Most HF welding machines operate at 27.12 MHz, a frequency reserved internationally for industrial heating applications.

Is HF welding safe for medical-grade plastics?

Yes, HF welding is widely used for medical devices and packaging due to its clean, sealed seams and compatibility with sterilization.

Can I weld different plastics together?

Not typically. HF welding is most effective when both materials are polar and chemically compatible, such as PVC to PVC.

What are the cycle times like?

HF welding offers rapid cycle times, often under 5 seconds per weld, depending on material and thickness. The welding time, which refers to the duration high-frequency energy is applied during the process, must be carefully controlled based on material properties and desired weld quality to achieve optimal results.

How does HF compare to ultrasonic?

HF is better for thicker, larger weld areas and polar plastics. HF welding relies on controlled current flow and electrical current to generate heat within the material, while ultrasonic welding uses mechanical vibrations. Ultrasonic is ideal for small, thin components and fast micro-welding.

.png)