In today's fast-paced marketing world, the quality of signage can significantly impact brand visibility and perception. Banner welders are pivotal in crafting custom signage solutions that are not only visually appealing but also durable and efficient. These tools specialize in seamless banner welding and high-quality signage production, ensuring that every sign stands out as a professional piece of marketing. To learn more about the specific benefits, visit Miller Weldmaster sign finishing page.

Understanding Banner Welders

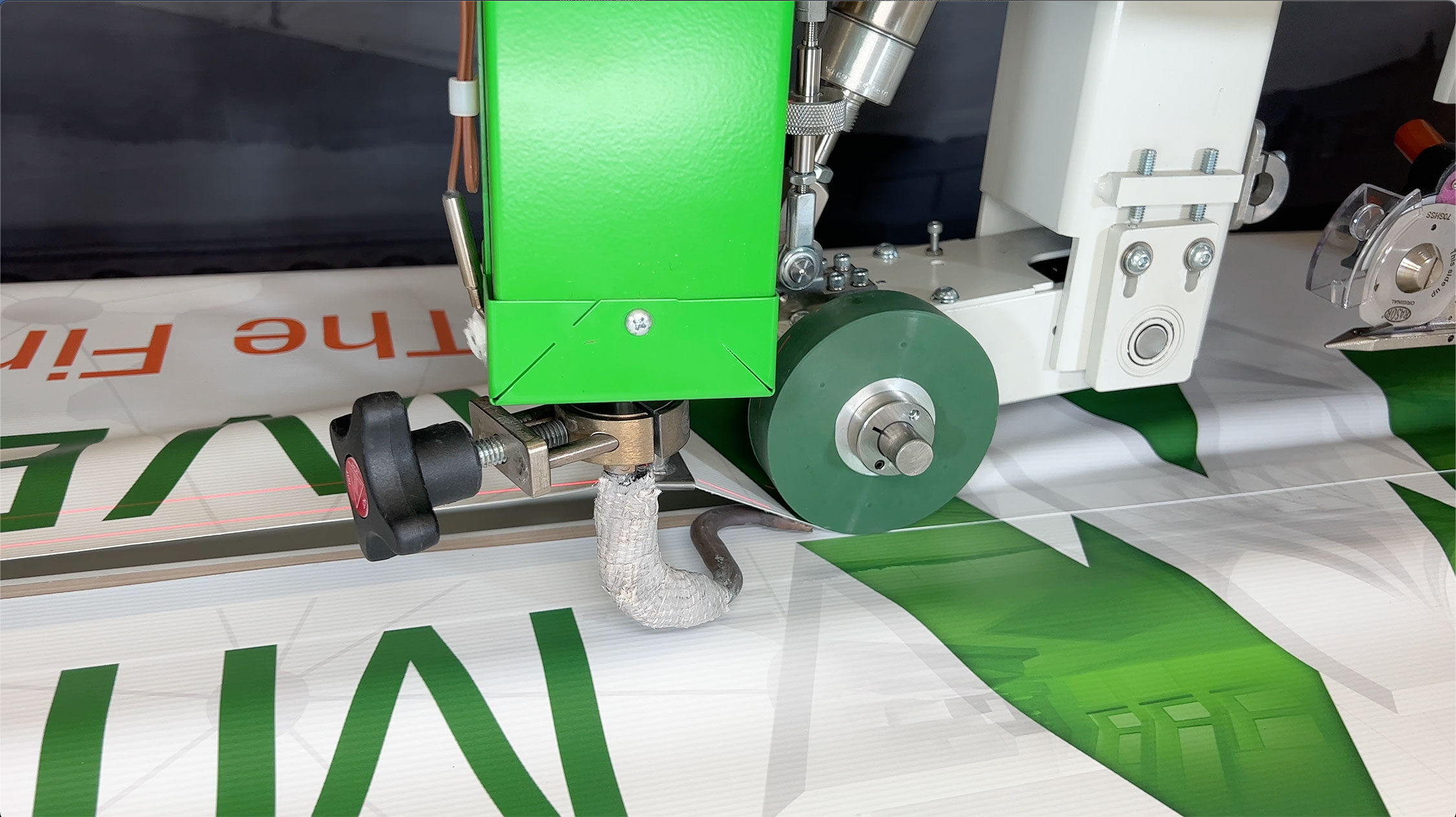

Banner welders are sophisticated pieces of industrial welding equipment for signs that use heat to join materials, creating durable banners that withstand environmental challenges. These signs production tools are essential for businesses seeking efficient banner fabrication and precision welding for banners.

Banner welders are tools designed for the automated finishing of signs, streamlining the production process. They are crucial for ensuring professional sign making with a focus on durability and aesthetics.

Types of Banner Welders

- Hot Air Welders: These machines excel in versatility, allowing for custom banners and signs that require detailed graphics and multiple material types. Additionally, they are equipped with capabilities to precisely align images, ensuring your designs are seamless and professionally presented.

- Wedge Welders: Known for their speed and consistency, these welders are ideal for projects that require long, straight seams and are under tight deadlines.

These types differ primarily in their operational techniques but are united in their capability to produce robust and reliable results.

How Banner Welders work

Using advanced banner fabrication techniques, these machines ensure that each seam is flawless, enhancing both the structural integrity and visual quality of the sign. This reliable banner welding is key to extending the lifespan of outdoor and indoor signs alike.

Benefits of Using Banner Welders for Custom Signage

The integration of banner welders into the production process of custom signage offers substantial advantages, enhancing not only the quality and durability of the signs but also the efficiency and cost-effectiveness of their production. Below are detailed insights into these key benefits:

Enhanced Quality of Signage

Seamless Welding: Seamless welding enhances the visual appeal of signage by eliminating visible seams. This results in a smoother, more professional look, ideal for displaying detailed graphics and maintaining the integrity of complex designs.

Material Compatibility: Banner welders handle various materials effectively, allowing for diverse signage applications. This versatility ensures strong, consistent welds across different substrates, broadening the scope for creative and functional sign designs.

Durability and Longevity

Weather Resistance: Welded banners are highly resistant to harsh weather conditions. The seamless construction prevents water and wind penetration, safeguarding the banner’s integrity and appearance, making it ideal for prolonged outdoor use.

Structural Integrity: Welded seams offer superior strength and durability. This permanent bond ensures the signage can withstand physical stresses without unraveling, maintaining its structural integrity over time.

Efficiency and Cost-Effectiveness

Time-Saving: The use of banner welders significantly speeds up the production process. Unlike traditional methods that require time-consuming sewing or gluing, welding can rapidly join materials with a high degree of precision. This acceleration allows for quicker completion of projects, enabling businesses to meet tight deadlines and increase their output without sacrificing quality.

Reduced Waste: Precise welding techniques minimize material waste during production. Welders can accurately align and join materials, reducing the excess trim required and ensuring that each piece of material is utilized efficiently. This not only cuts down on the raw material costs but also supports environmentally friendly practices by decreasing the amount of waste generated.

Cost Savings: Durable welded banners offer long-term cost savings. Their enhanced resistance to wear and tear means that they do not need to be replaced as frequently as traditionally made banners. This durability reduces the ongoing costs associated with maintenance, repair, and replacement, providing a more economical solution over the banner's lifespan.

Applications of Banner Welders in Custom Signage

Banner welders play a crucial role in diverse custom signage projects across various industries. Their ability to produce durable, high-quality signs makes them indispensable in advertising, events, and retail environments.

Advertising Banners

Importance of High-Quality Banners: In advertising, the visual quality of banners directly impacts brand perception and customer engagement. High-quality banners capture attention and communicate messages effectively, making them vital for successful marketing campaigns.

Professional Look and Durability: Welded banners ensure a professional appearance with their smooth finish, free from any distracting stitches or joins. The durability afforded by welding means these banners can withstand environmental factors like wind and rain, maintaining their aesthetic appeal over time, which is crucial for long-term outdoor advertising campaigns.

Event Signage

Role of Banner Welders: For events ranging from trade shows to concerts, durable and visually appealing signage is essential. Banner welders facilitate the creation of such signage, which not only needs to look good but also withstand the bustling activity typical of event settings.

Specific Use Cases: At trade shows, banners serve as the backdrop to exhibitions, needing to stand out while enduring constant exposure. Concerts and sports events often require large, eye-catching banners that can be seen from a distance and resist various weather conditions throughout the event.

Retail Signage

Enhanced Visual Appeal: In retail, the attractiveness of signage can significantly influence consumer behavior. Welded banners offer a high-end look that can elevate the overall aesthetic of a retail space, making it more inviting and engaging for customers.

Benefits of Durable Signage: The durability of welded banners means they can withstand the frequent changes in retail displays and the general wear and tear of high-traffic environments. This longevity helps retailers maintain a consistent and professional appearance without frequent replacements, thus saving costs and enhancing the shopping experience.

Choosing the Right Banner Welder for Your Project

Selecting the appropriate banner welder is crucial to ensure the success of your projects. Understanding the specific needs of your project, from the materials and size to the budget and production demands, is essential in choosing a welder that will deliver optimal results.

Factors to Consider

Material Compatibility: The type of material you plan to use for your banners plays a pivotal role in selecting the right welder. Different materials require different welding technologies; for example, thick, rigid materials may need more robust welding capabilities than lightweight or delicate fabrics. Ensuring the welder is compatible with your material choice will lead to better quality and durability of the signage.

Project Size and Scope: The overall size and scope of your project will also influence the choice of banner welder. Larger projects or those requiring a high volume of signs might benefit from welders that can operate at higher speeds and include automated features to streamline production. Smaller, more detailed projects may need welders that offer greater precision.

Budget and Resources: Balancing cost and quality is crucial. While higher-end welders may offer more features and better durability, they also come with a higher price tag. Consider the long-term benefits of investing in a high-quality welder against the initial cost, especially if you anticipate frequent signage projects.

Miller Weldmaster’s Solutions

Miller Weldmaster offers a comprehensive range of banner welders that cater to various needs within the signage industry. Here are some highlights:

Specific Products Suitable for Various Projects: From compact, versatile models ideal for small businesses to large-scale, industrial automated machines designed for high-volume production, Miller Weldmaster has options to suit any project scale.

Unique Features and Benefits: Miller Weldmaster's welders are renowned for their versatility, durability, efficiency, and precision. Features such as automated material handling, customizable welding settings, and high-speed capabilities make these machines highly effective for a wide range of signage applications.

Customer Testimonials and Case Studies: Success stories from customers who have utilized Miller Weldmaster’s welders demonstrate their effectiveness. For instance, a large advertising company reported significantly reduced production times and lower material costs after switching to a Miller Weldmaster welder, highlighting the machine's impact on both productivity and profitability.

By carefully considering these factors and exploring Miller Weldmaster’s diverse range of products, you can choose the right banner welder that meets the specific needs of your signage projects, ensuring quality, efficiency, and cost-effectiveness in your sign-making endeavors.

Discover the Miller Weldmaster Advantage for Custom Signage

In the world of custom signage, the precision, durability, and aesthetic appeal of your banners can significantly impact brand perception and marketing success. Miller Weldmaster’s banner welders offer a competitive edge in the industry, providing solutions that ensure high-quality, efficient, and cost-effective production.

Explore Our Banner Welding Solutions

Miller Weldmaster’s range of banner welders is designed to meet various production needs, from small custom projects to large-scale industrial operations. These machines are built with cutting-edge technology to deliver seamless, durable, and visually appealing banners. Explore the full capabilities and find the perfect welding solution for your projects by visiting Miller Weldmaster’s Product Page.

Get in Touch with Miller Weldmaster Experts

Miller Weldmaster prides itself on not just its products but also its exceptional customer support and expertise. Our team is ready to assist you with personalized advice and practical solutions tailored to your specific signage needs.

By choosing Miller Weldmaster, you’re not just buying a machine; you’re gaining a partner dedicated to improving your signage quality and production efficiency. Let us help you achieve the best possible results for your signage projects.