In the world of banner production, efficiency and strength are paramount. Enter the T300 Edge banner welding machine, a game-changer for businesses aiming to enhance both the quality and speed of their banner manufacturing processes. This machine is not just a tool; it's a revolutionary solution designed to overcome common challenges such as slow production speeds, weak seams, and labor-intensive processes. In this blog, we'll explore why the T300 Edge is an indispensable asset for anyone in the banner-making industry and how it can transform your production line from good to exceptional. To see the T300 Edge in action and learn more about its capabilities, visit our detailed page here.

The Importance of High-Quality Banner Welding for Longevity & Strength

Durability is crucial, whether banners are displayed indoors or braving the elements outdoors. The risks associated with poorly welded or stitched banners are significant—they can fray, tear, and show premature wear, all of which reflect poorly on a brand. Precision welding technology, like that found in the T300 Edge, ensures banners not only look professional but also last longer, no matter where they're displayed.

Common Banner Welding Mistakes That Hurt Production Quality

Weak seams are a frequent issue, often resulting from inconsistent manual processes or incorrect temperature settings during the welding phase. These can lead to banner failure under normal conditions, a scenario no business wants. The T300 Edge addresses these concerns by providing automated, temperature-controlled welding that ensures strong, uniform seams every time, significantly reducing the risk of human error.

How the T300 Edge Banner Welding Machine Speeds Up Production

The T300 Edge dramatically enhances production efficiency through its automation and precision welding capabilities. Unlike traditional methods, which might involve slow, manual stitching or unreliable tape, the T300 Edge uses hot air and wedge welding technologies to deliver clean, reliable, and fast results. This not only optimizes labor but also reduces material waste and minimizes downtime.

Comparing the T300 Edge to Traditional Sewing and Tape Methods

Stitching might be the old standard for banner joining, but it’s slower and less durable compared to modern welding methods. Tape, while quick, often fails under weather stress and can leave unsightly residues. In contrast, the welding techniques employed by the T300 Edge ensure that the finished banners are both aesthetically pleasing and ruggedly durable.

The T300 Edge’s Versatility: What Materials and Applications It Supports

This machine isn’t just for PVC or vinyl; it excels with a variety of coated fabrics, making it ideal for everything from outdoor banners to trade show displays and even heavy-duty tarps. The T300 Edge goes beyond simple seam welding by offering the capability to add webbing or extrusions to the edges of banners and fabrics. This additional feature significantly enhances the structural integrity and durability of the finished products.

Adding webbing or extrusions is particularly beneficial for items that will be subjected to high stress or need to withstand severe weather conditions. The reinforced edges prevent tearing and ensure that the banners and tarps can handle increased load and tension without compromising on their aesthetic appeal or functionality. The strength of the welded seams, combined with the reinforced edges, makes them exceptionally suitable for outdoor use where wind, rain, and other environmental factors are a concern.

By integrating webbing or extrusions, the T300 Edge allows manufacturers to produce not only more durable but also safer and more functional banners and tarps. This capability is essential for applications such as large outdoor advertising banners, industrial covers, and protective tarps, where edge strength is crucial for performance and longevity.

Why Welded Seams Are Superior to Other Banner Finishing Methods

Welded seams offer a clean, attractive finish without the stitch marks, glue residue, or peeling issues associated with other methods. Moreover, heat-sealed seams are waterproof and resistant to weather, which translates to longer-lasting banners and significant cost savings over time due to reduced need for replacements and repairs.

Real-World Benefits: How Businesses Improve Efficiency with the T300 Edge

Across the industry, from small print shops to large manufacturers, businesses are discovering the advantages of upgrading to the T300 Edge. Its precision welding capability supports high-volume, high-quality banner production, giving companies a crucial competitive edge in a crowded market.

Customer Success Stories: How the T300 Edge Transformed Their Production

Several clients have reported transformative results after integrating the T300 Edge into their production lines. A standout example is Lake Graphics Label and Sign Co. Inc., a company that has dramatically enhanced its operational capabilities with the help of both the T300 Edge and the Digitran systems from Miller Weldmaster. The combination of these machines has allowed Lake Graphics to not only improve the quality and durability of their banners but also significantly increase their production speed.

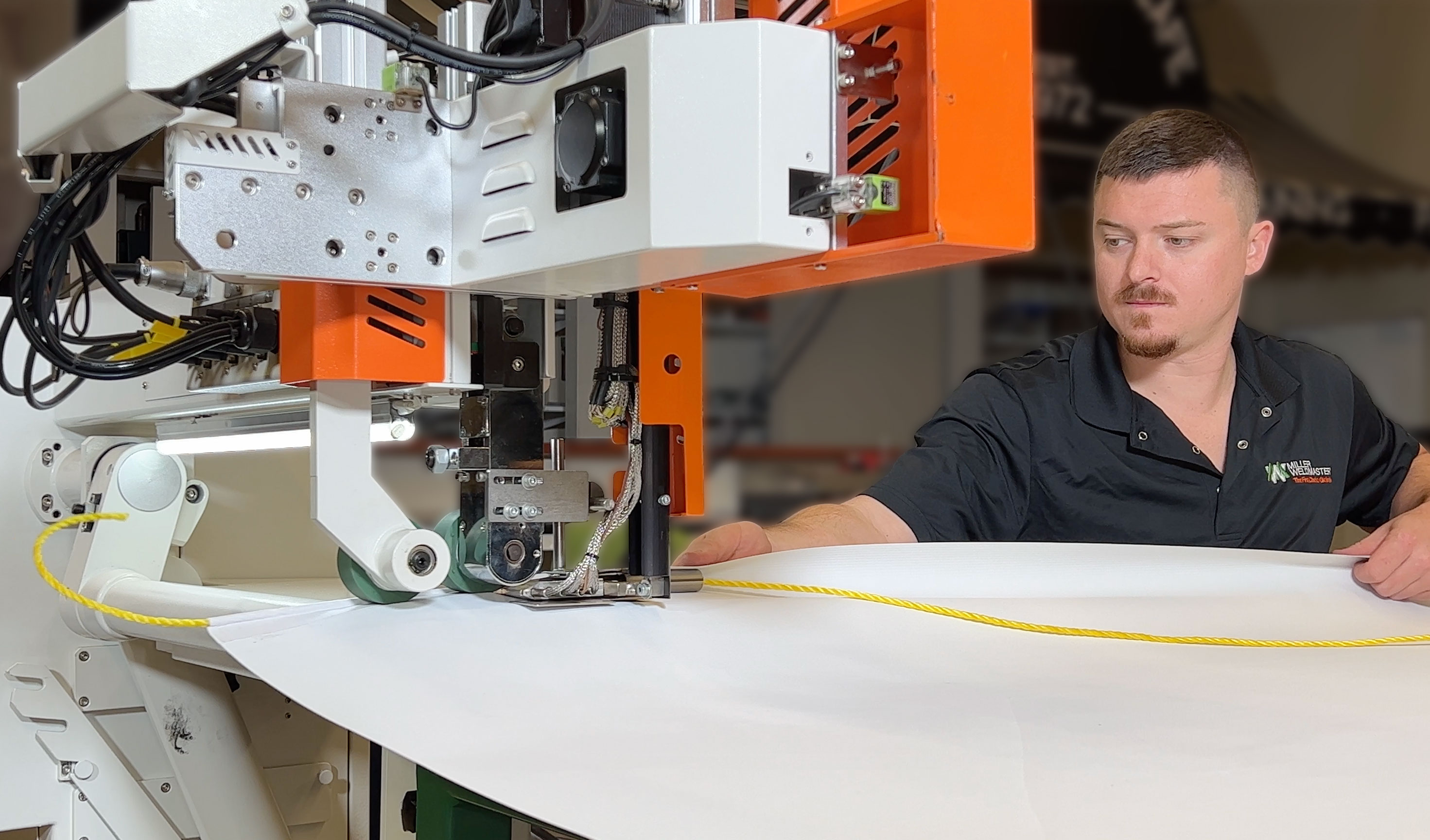

Lake Graphics Case Study: With the T300 Edge, Lake Graphics was able to expedite their workflow by automating the welding process, which in turn reduced their need for manual labor and decreased overall production time. This increase in efficiency is complemented by the Digitran machine, which provides precision and consistency in digital sewing. The synergy between the T300 Edge and Digitran has empowered Lake Graphics to produce high-quality products faster and more reliably than ever before, solidifying their reputation as a leader in the graphics industry.

This integration showcases how Miller Weldmaster's solutions can transform production processes, providing businesses with the tools to achieve higher throughput and superior product quality.

Why Miller Weldmaster Is a Trusted Name in Banner Welding Technology

With 50 years of experience and a focus on continuous innovation, Miller Weldmaster has become a leader in the industrial welding solutions market. Our machines, especially the T300 Edge, are designed with the end-user in mind, combining ease of use, reliability, and precision to ensure the best possible results for your business.

What Sets the T300 Edge Apart from Other Banner Welding Machines?

The T300 Edge stands out due to its intuitive controls that cater to all skill levels, reliability in high-volume production settings, and consistent delivery of high-strength seams. These features make it not just a piece of machinery but a pivotal part of modern banner production workflows.

Frequently Asked Questions About the T300 Edge Banner Welding Machine

What types of banners can the T300 Edge weld?

It is designed for PVC, vinyl, and various coated fabrics, making it incredibly versatile.

Is the T300 Edge suitable for small or large-scale production?

Absolutely, it’s perfect for any scale, adjusting easily to different production sizes.

How does hot air welding compare to sewing or adhesives?

Hot air welding offers a stronger, more durable bond that is both aesthetically pleasing and weather-resistant and water-proof when compared to sewing or adhesives.

Does the T300 Edge require specialized training?

While basic training is recommended to maximize machine performance, its intuitive design makes it accessible for users of all skill levels.

How long does it take to weld a banner with the T300 Edge?

The T300 Edge can significantly speed up production times, though exact times can vary based on material and size. The T300 Edge can weld all 4 sides in under a minute.

Can the T300 Edge be used for double-sided banners?

Yes, it can effectively weld double-sided banners with equal precision.

What maintenance does the T300 Edge require?

Routine maintenance is straightforward and ensures continuous, reliable operation. The T300 Edge also comes with a 1-year warranty.

Can the T300 Edge handle custom banner sizes and shapes?

Yes, it is highly adaptable to various sizes and shapes, making it ideal for custom orders.

The T300 Edge represents a significant leap forward in banner welding technology. By choosing the T300 Edge, businesses can not only increase their production efficiency but also produce stronger, more durable banners that stand out in the marketplace. Visit our website to learn more about the T300 Edge and start transforming your banner production today.