The Role of Industrial Sewing in Today’s Production Lines

Even with the rise of automated welding, industrial sewing remains a cornerstone in many manufacturing lines. Why? Because certain applications simply demand the unique strengths that only sewing provides.

Industries such as tarpaulins, banners, upholstery, and ducting still rely on sewing to join, reinforce, or finish materials that welding cannot easily handle. For products that need flexibility, breathability, or the ability to work with non-thermoplastic fabrics, sewing machines deliver unmatched versatility.

How Industrial Sewing Supports Flexible Production

Sewing shines when you need versatility across different fabrics or quick product changes. Unlike welding, which requires specific material properties, sewing adapts to a wide range of textiles. This flexibility makes it the go-to method for manufacturers producing diverse product lines or custom runs where speed and adaptability are crucial.

Industrial Sewing Stitch Types and Applications

Lockstitch for Heavy-Duty Seams

The lockstitch is one of the most common and durable stitches, created by interlocking two threads. It provides excellent seam strength and is widely used in bags, tents, and upholstery. Its main limitation is the potential for fabric puckering on lightweight materials.

Chain Stitch for Stretch and Elasticity

The chain stitch uses a looping method that allows for flexibility and stretch. This makes it ideal for knits, waistbands, and elastic seams where mobility and comfort matter. However, its drawback is that if one stitch breaks, the entire seam can unravel.

Zigzag and Cover Stitches for Specialty Needs

- Zigzag stitches reinforce fabric edges and prevent fraying, while also adding decorative appeal.

- Cover stitches create flat, flexible seams often found in athletic wear and banners, ensuring comfort and a clean look.

How to Choose the Right Industrial Stitch

Selecting the right stitch often comes down to the fabric:

- Canvas, tarps, heavy textiles → Lockstitch

- Knits, elastic fabrics → Chain stitch or cover stitch

- Edges, decorative applications → Zigzag

- Athletic wear, flat seams → Cover stitch

Industrial Sewing vs. Welding: Which is Right for You?

When Sewing Is the Better Choice

- Breathable fabrics

- Materials requiring elasticity

- Quick prototyping or small runs

When Welding Delivers Stronger Results

- Thermoplastic materials like PVC, TPU, and PE

- Products requiring airtight or watertight seams

Applications where eliminating consumables (thread, needles) reduces long-term costs

Sewing vs Welding Side-by-Side Comparison

| Factor | Sewing | Welding |

| Strength | Strong but thread-dependent | Extremely strong, material-bonded |

| Tightness | Breathable seams possible | Airtight/watertight seams achievable |

| Cost | Lower equipment cost, ongoing thread/needle expense | Higher upfront cost, minimal consumables |

| Speed | Fast for prototyping and small runs | Faster for continuous, automated production |

| Material Fit | Works with almost any fabric | Requires thermoplastics |

Cost Considerations of Sewing vs Welding

- Sewing: Lower machine cost, but requires consumables like thread and needles. Operator training is relatively quick.

- Welding: Higher equipment cost but eliminates consumables. Operators may need specialized training, but maintenance costs are typically lower long term.

Benefits and Drawbacks of Industrial Sewing

Key Benefits Manufacturers See

- Lower upfront equipment costs

- Wide compatibility with diverse materials

- High production speeds with skilled operators

- Flexibility for prototypes and short runs

Limitations to Be Aware Of

- Seams rely on thread, which can weaken or degrade over time

- Not suitable for airtight or watertight requirements

- Requires regular maintenance of consumables (needles, thread)

- Operator Dependency - results may vary

Best Practices to Improve Industrial Sewing Results

Choosing the Right Needles and Threads

Use this “cheat list” for reliable results:

- Canvas and heavy fabrics → Heavy-duty needle, polyester thread

- Knits and stretchy fabrics → Ballpoint needle, textured polyester thread

- Outdoor tarps → Large needle size, UV-resistant threat

- Upholstery → Leather needle, bonded nylon thread

Daily Maintenance That Extends Machine Life

- Clean lint and dust from moving parts

- Lubricate per manufacturer guidelines

- Check and adjust thread tension before each shift

Quality Checks Every Operator Should Perform

- Perform pull tests to confirm seam strength

- Visually inspect for skipped stitches or uneven tension

- Verify seam alignment and stitch density against standards

Industrial Sewing Applications Across Industries

Industrial Sewing for Tarps and Banners

Sewing allows manufacturers to add edge hems, reinforced corners, and webbing attachments, ensuring durability and strength for large outdoor applications.

Industrial Sewing for Ducting and Filtration

Specialized sewing enables spiral seams and ring pockets that maintain airflow and structural integrity in ducting and filtration systems.

Industrial Sewing for Upholstery and Soft Goods

From seating to cushions, sewing enhances comfort, aesthetics, and decorative stitching, balancing function with design appeal.

How Can Miller Weldmaster Help?

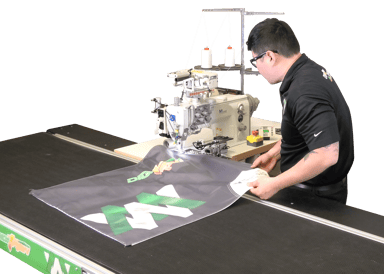

Miller Weldmaster is known for our Hot Air, Hot Wedge, and Radio Frequency welding technologies. The combining of two, thermoplastic materials together using heat, speed, and pressure. But, we also offer a variety of sewing solutions as well! Depending on the material, application, or both welding may not be the best way to produce your products.

Some of the most common sewing applications include filters, Cured In Place Pipeline (CIPP), as well as Signs and SEGs. Our industrial sewing machines vary from heavy-duty automatic sewing machines, where you can incorporate a sewing function into a large unit that welds, rewinds, unwinds, ext. Our standard solution for the sign industry is the Digitran. There are various applications that utilize sewing in their process, and Miller Weldmaster has the solutions and options available to meet those needs.

Industrial sewing is a fascinating combination of traditional craftsmanship and modern technology. It is an industry that weaves our world together, ensuring access to essential products, from clothing to furniture. As technology continues to evolve, the landscape of industrial sewing promises exciting innovation and development, ensuring it remains a crucial part of our industrial framework for years to come.

If you are interested in learning more about Industrial Sewing, check out our YouTube channel, or contact our team of experts today!

Frequently Asked Questions About Industrial Sewing

Is industrial sewing stronger than welding?

Not usually. Welding fuses materials together for maximum seam strength, while sewing strength depends on the thread and stitch type.

Can industrial sewing be waterproof?

Not fully. While coatings and seam tape can improve water resistance, sewn seams are never fully airtight or watertight.

What stitch works best for heavy fabrics?

The lockstitch is best suited for heavy-duty materials like canvas, tarps, and upholstery.

How fast are industrial sewing machines?

Most industrial machines operate at 3,000–5,000 stitches per minute, allowing for high-volume production.

When should I switch from sewing to welding?

Consider welding if you work with thermoplastics or need airtight, watertight, or thread-free seams for long-term durability.