Large, fabric tents, structures and shelters require strong seams to increase longevity. Traditionally, these products were manufactured using manual sewing processes, leaving room for human error, increasing production times and decreasing product lifespan.

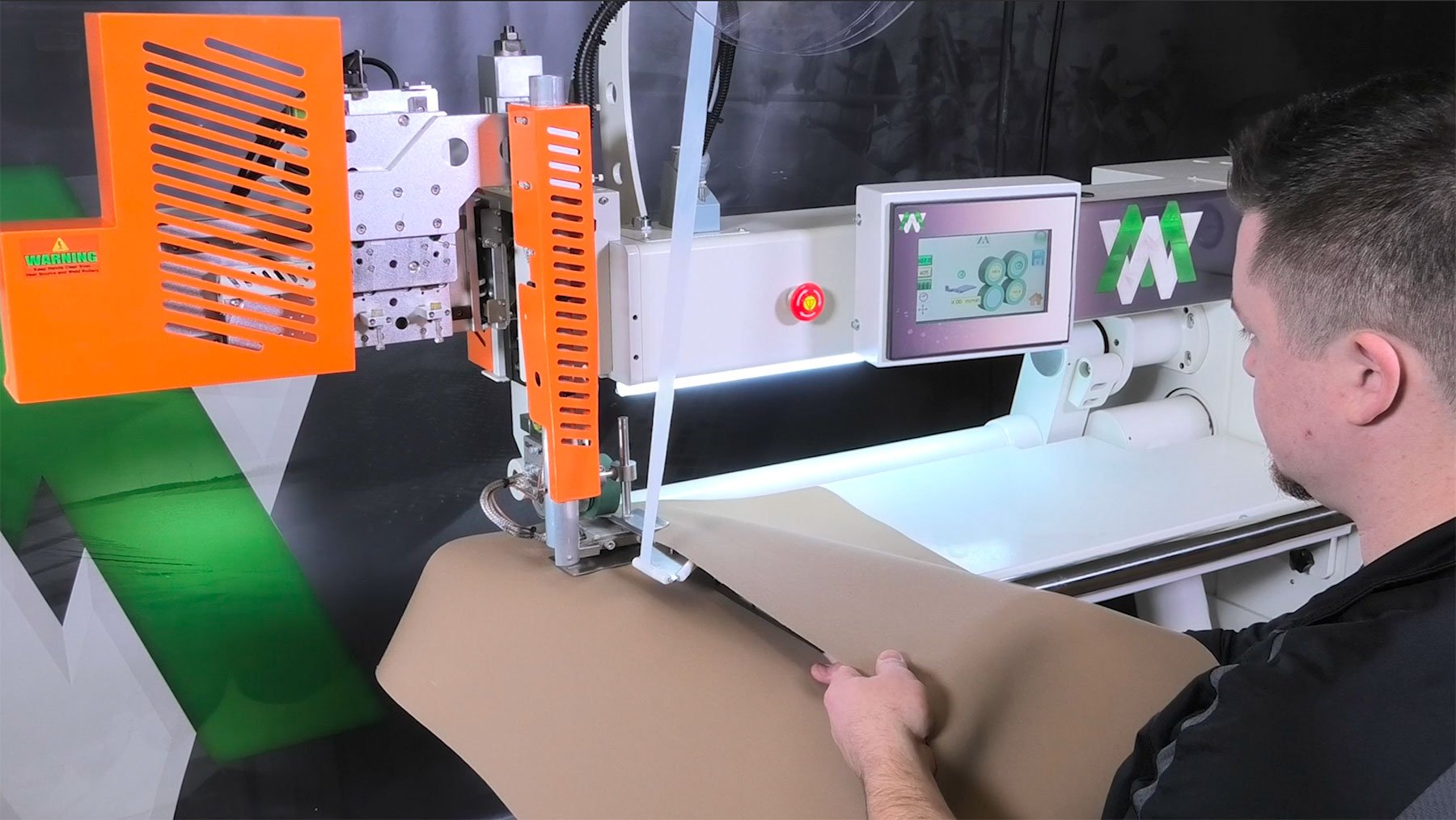

Industrial fabric welding equipment improves tent, structure and shelter seam quality and durability, creating products end-customers can rely on.

How else can tent, structure and shelter production improve with industrial fabric welding equipment? Below, we overview the key benefits.

Industrial Fabric Welding: The Key to High-Performance Tent, Structure and Shelter Seams

Tent, structure and shelter industry leaders rely on innovative, high-performance material welding machines to create extra-long, precise seams. With the proper heat-seaming equipment, manufacturers create watertight and airtight seams that eliminate the risk of leaks or other environmental weathering—giving you a competitive advantage.

Tent, structure and shelter manufacturers gain the following benefits from industrial fabric welding equipment:

- Increased seam and product longevity.

- Improved product quality and consistency.

- Streamlined tasks and reduced human error.

- Increased production speed, better meeting quantity and consumer demands.

- Creation of water-tight welds.

- Elimination of holes caused by needle and thread.

- No need to match exact thread thickness, color and quality.

What Type of Product Can I Manufacture Using Industrial Fabric Welding?

Due to the size and weight of materials used to create fabric tents, structures and shelters, it’s vital to invest in equipment that delivers. Industrial fabric welding equipment can handle a variety of thick materials that can easily flow through machinery to create stronger seams.

While industrial fabric welding systems can bond together many different materials, the majority of tent, structure and shelter manufacturers find the best success with thermoplastics. Thermoplastics are lightweight and strong, and offer more flexible, cost-effective end-products compared to metals. The most commonly used materials are laminate, PVC coated and polyethylene.

Furthermore, many tent manufacturers use industrial fabric welding technology for polyvinylchloride (PVC) products.

Specifically, industrial material welding improves quality, consistency and longevity on products like:

- Clearspan tent

- Frame tents

- Party / wedding canopies

- Pole tents

- Tension structures

- Temporary tents / structures

- Agricultural buildings

Tent, Structure and Shelter Manufacturers: Ready to Learn More About Industrial Fabric Welding?

Are you interested in learning more about industrial fabric welding equipment for your tents, structures and shelters? Connect with a Miller Weldmaster expert today.