Selecting the right welding machine is crucial for any business involved in fabrication or manufacturing. The efficiency, quality, and cost-effectiveness of your welding operations depend significantly on the type of machine you choose. This guide will explore various types of welding machines, key factors to consider, and provide insights to help you make an informed decision. Discover the perfect welding equipment for your business needs by exploring different machine options and ensuring you choose the most suitable one for your projects.

Understanding the Different Types of Welding Machines

Choosing the right welding machine for your business involves understanding the array of available technologies and their specific applications. At Miller Weldmaster, we specialize in Hot Air, Hot Wedge, Radio Frequency (RF), and Impulse welding machines, each designed for particular tasks and materials. Selecting the appropriate type is critical for maximizing efficiency, quality, and cost-effectiveness in your welding operations.

Overview of Welding Machine Types

Here's a detailed look at the distinct welding technologies offered by Miller Weldmaster:

- Hot Air Machines: Employ heated air to melt materials at the weld point.

- Hot Wedge Machines: Use a heated metal wedge for consistent thermal application.

- Radio Frequency Machines: Harness high-frequency electromagnetic waves for heating and sealing.

- Impulse Machines: Generate quick bursts of heat through electrical impulses for precise welding.

Each type is tailored to meet the needs of different industries, from automotive to textiles, ensuring durable and high-quality welds.

Hot Air Welding Machines

Hot air welding machines are highly adaptable tools that direct a jet of hot air to melt the plastic material at the joint, allowing it to merge and solidify into a strong bond. This method is not only effective for various thicknesses and types of materials but also allows for adjustments in temperature and airflow to suit specific project needs. It's especially beneficial for products such as industrial curtains, automotive interiors, and advertising banners, where flexibility and strength are paramount. The hot air technique is renowned for its reliability and ease of use, making it a popular choice among professionals who require a versatile welding solution.

Hot Wedge Welding Machines

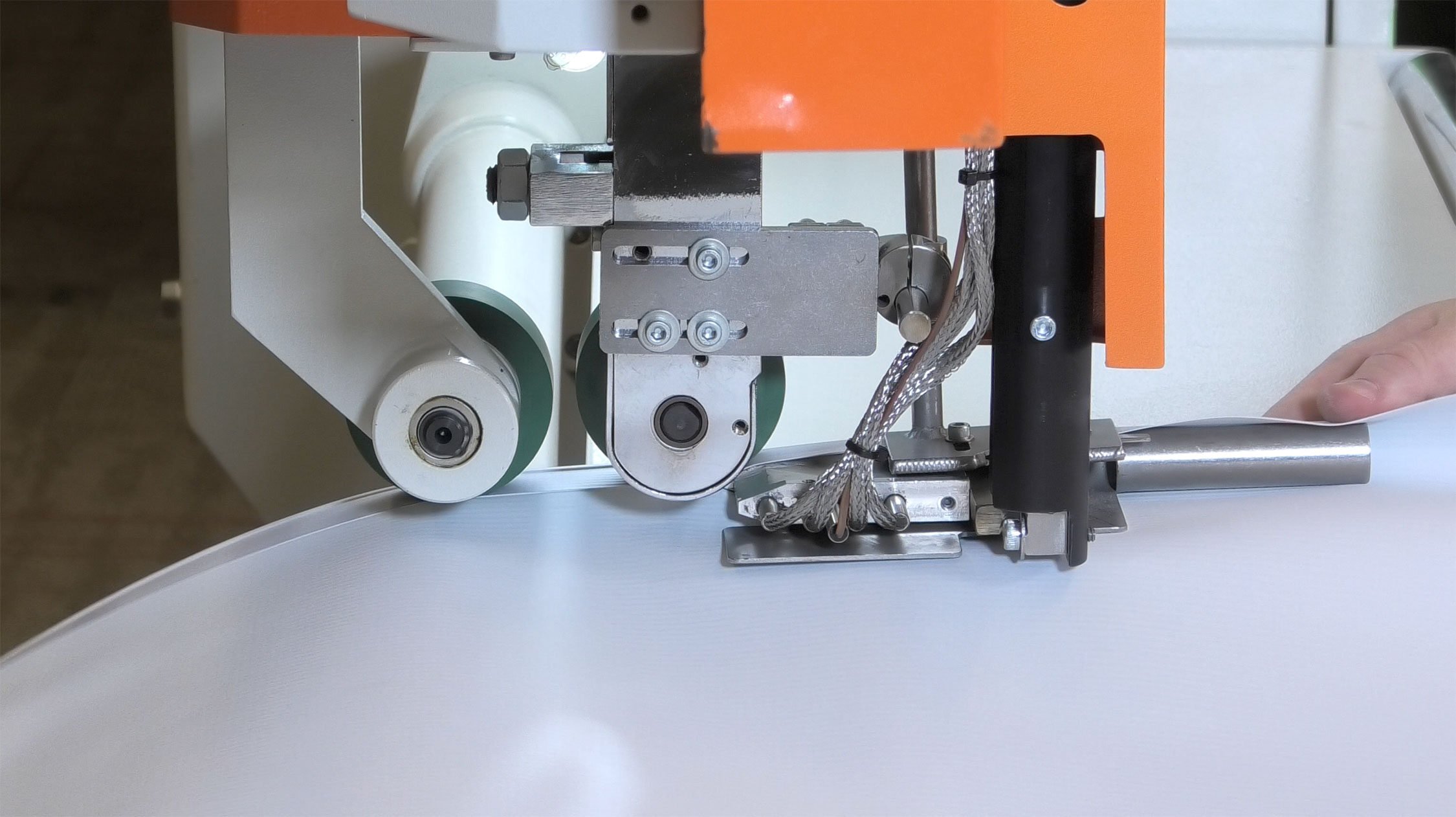

Hot wedge welding employs a heated metal wedge placed between two thermoplastic materials. As the materials pass over the wedge, they are heated and then fused together by pressure rollers behind the wedge. This method provides exceptional control over temperature and speed, making it ideal for high-volume applications requiring consistent, long, straight seams. Hot wedge welders are particularly effective in the production of geomembranes, agricultural covers, and other products requiring watertight seals. Their precision and efficiency make them indispensable in scenarios where product integrity and strength are critical.

Radio Frequency (RF) Welding Machines

Radio frequency welding, also known as dielectric sealing, utilizes high-frequency electromagnetic waves to create molecular agitation in the material, producing heat and melting the material without direct contact. This technology is particularly suited for materials like PVC, vinyl, and polyurethanes—common in the fabrication of products such as medical bags, stationery, and inflatable rafts. RF welding ensures deep penetration and uniform heating, which are crucial for achieving strong, uniform, and aesthetically pleasing seals. Its ability to weld complex shapes and maintain high production rates also makes RF welding a preferred choice for industrial applications requiring precision and scalability.

Impulse Welding Machines

Impulse welding machines operate by delivering short, controlled bursts of electrical energy to heat the welding element, which in turn heats the material only at the point of contact. This method is incredibly effective for delicate or thin materials, as it minimizes the heat exposure to the rest of the material, thus reducing the risk of warping or degradation. Impulse welders are commonly used in the packaging industry, for sealing bags and wrapping materials, and in applications where precise detail and minimal thermal impact are required. The key advantages of impulse welding include its energy efficiency, the precision of welds, and the ability to quickly adjust settings to accommodate different materials and thicknesses.

Each welding technology offered by Miller Weldmaster is designed to meet specific industry needs, providing businesses with the tools to achieve optimal results in their manufacturing and fabrication processes.

Key Factors to Consider When Choosing a Welding Machine

Selecting the right welding machine for your business involves a careful assessment of several crucial factors. Here’s a deeper dive into what you should consider to ensure you choose the most suitable welding machine for your specific needs.

Material Type and Thickness

Understanding the materials you'll be working with and their thickness is essential. Delicate materials like thin plastics or fabrics often require precise, low-heat welding methods such as impulse or hot air welding to ensure a secure seal without causing damage. Conversely, thicker materials like heavy plastics or geomembranes might need more robust methods such as hot wedge or RF welding, which are capable of managing the material's weight and stress effectively.

Welding Environment

The environment where the welding will take place significantly influences the choice of machine. Indoor environments usually offer more controlled conditions, ideal for machines that might be sensitive to environmental variables. However, space constraints and ventilation need to be considered. Outdoor welding demands machines that can withstand variable weather conditions like wind and moisture. Machines used in confined spaces should be portable and compact, featuring safety measures to prevent overheating and allow safe operation.

Power Supply Requirements

The welding machine you choose must be compatible with your available power supply in terms of voltage and phase requirements. This is especially crucial for industrial machines that may require setups not available in smaller workshops. Additionally, energy efficiency plays a significant role; more efficient machines can help reduce operational costs, which is particularly important in businesses where welding is a frequent activity.

Evaluating Welding Machine Features

When choosing a welding machine, evaluating its features is essential for ensuring not only the quality and efficiency of your welding tasks but also the safety of the operators. Here’s a closer look at the critical features to consider:

Advanced Controls and Settings

Modern welding machines come equipped with advanced control settings that can significantly enhance the precision and efficiency of the welding process. Adjustable amperage controls allow for fine-tuning the heat output, which is essential for working with different materials and thicknesses. Pulse welding, another advanced feature, helps control the heat input in welding, reducing the chances of material warpage and burn-through, especially in thinner materials. These controls help operators maintain a consistent weld quality throughout the project.

Safety Features

Safety features in welding machines are vital for protecting operators from common hazards associated with welding. Thermal overload protection helps prevent the machine from overheating, which can lead to equipment failure and safety risks. Auto-shutoff capabilities ensure the machine turns off automatically if it detects a safety threat or operational anomaly. Other safety features to look for include voltage reduction devices, which help minimize the voltage at the welding circuit when not active, reducing the risk of electric shock.

Comparing Industrial and Commercial Welding Machines

Choosing the right type of welding machine—whether industrial or commercial—depends largely on the scale of your projects, the frequency of use, and specific performance requirements. Understanding the differences between these two categories can help you make an informed decision tailored to your business needs.

Industrial Welding Machines

Industrial welding machines are built for durability and performance, ideal for large-scale and continuous operations. They are robust, handle various materials and thicknesses, and are designed to meet the demanding needs of industries like automotive and construction. With higher power outputs and advanced cooling systems, these machines can operate under intense conditions without frequent downtime, making them essential for high-output environments.

Commercial Welding Machines

Commercial welding machines, on the other hand, are more suited for smaller businesses or occasional use. These machines are cost-effective, easier to handle, and versatile enough to perform a variety of lighter tasks such as repairs and small-scale fabrications. They're perfect for businesses that require reliable welding capabilities but not the intense, continuous operation that industrial machines provide.

Contact Miller Weldmaster for Expert Assistance

For personalized advice and a deeper understanding of how our welding solutions can meet your needs, contact Miller Weldmaster. Our experts are ready to help you select the perfect welding machine, tailored to your specific requirements.

Personalized Welding Machine Recommendations

Reach out to our team for bespoke guidance on selecting the right welding equipment, ensuring you get the best return on your investment.

Exploring Miller Weldmaster’s Product Range

Discover our wide range of high-performance and automated welding machines, each designed with quality and innovation in mind.

Request a Consultation or Demonstration

Experience our welding machines firsthand by scheduling a consultation or live demonstration. This opportunity allows you to see our machines in action, helping you make an informed purchase decision.