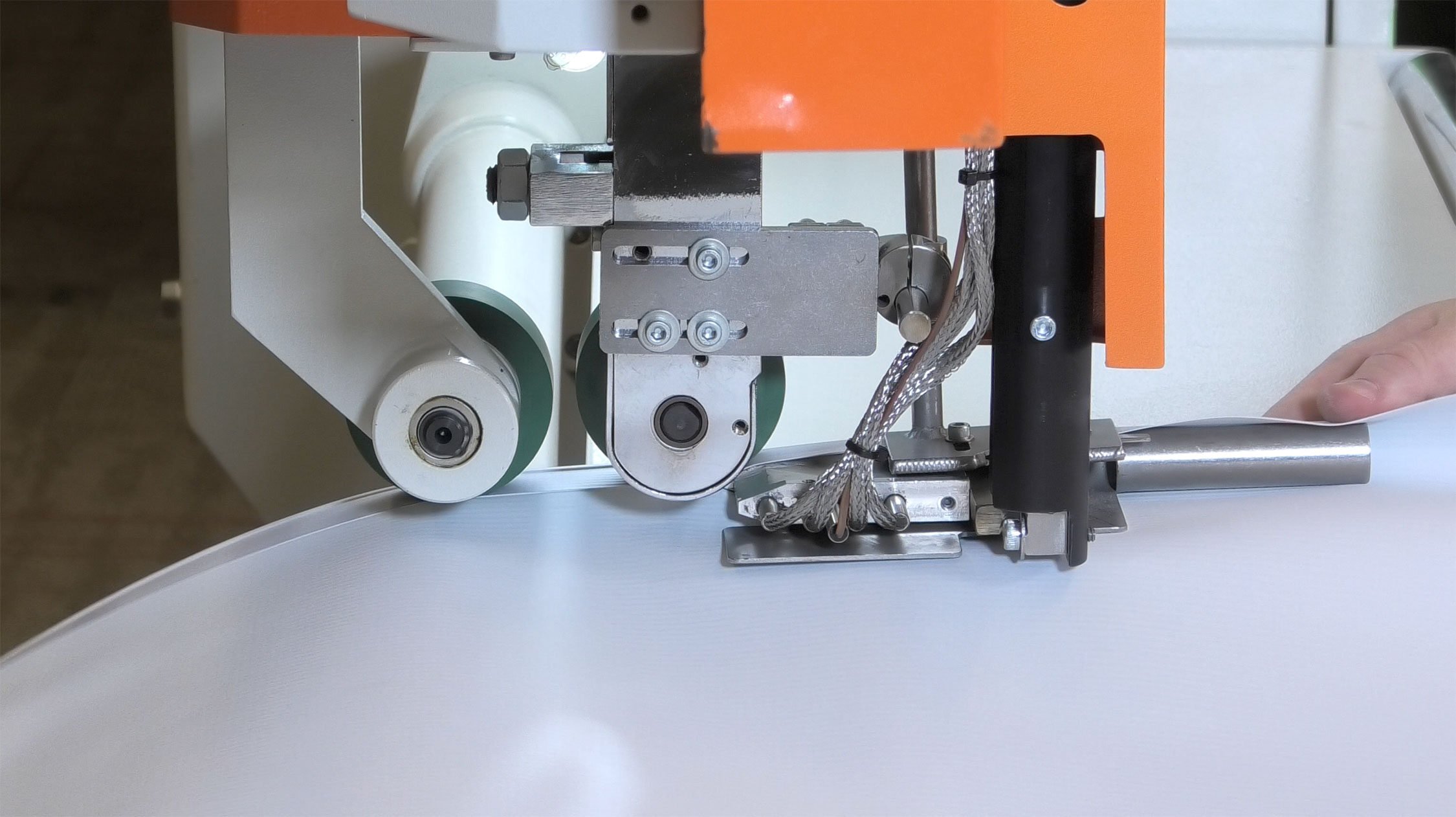

When it comes to joining thermoplastic materials, impulse welding excels as one of the most controlled, and energy-efficient methods available. An impulse welder is a specialized welding machine that delivers consistent results for demanding applications. Unlike continuous-heat systems, impulse welding uses electrically heated bars that pulse heat only during the weld cycle, then cool—producing consistent, airtight seams without warping or damaging materials. Impulse welding machines are engineered for precision and reliability. The process works by using controlled electrical pulses to heat a resistive wire for fabric bonding, ensuring precise and efficient results.

This precise control makes impulse welding a great solution for applications where aesthetics, seam integrity, and material protection are top priorities. The versatility of impulse welding and its ability to handle a wide range of materials and applications make it suitable for many industries. From awnings to medical textiles, this article explores the top five industries where impulse welding outperforms other thermoplastic welding methods.

Several factors contribute to impulse welding being the perfect solution for many industrial needs. One of its key advantages is its suitability for integration into automated production lines, which increases efficiency and reduces labor costs, making it a highly adaptable technology for modern manufacturing.

Learn more about impulse welding technology

Top 5 Applications:

-

Awnings & Shades

-

Banners & Signs

-

Lightweight Inflatables

-

Medical & Technical Textiles

-

Environmental Liners & Specialty Films

1. Awnings & Shades – Why Impulse Welding Excels for Heat-Sensitive Fabrics

Acrylic and layered awning fabrics can be difficult to join with hot air or wedge systems, which may cause scorching, discoloration, or wrinkling. Impulse welding eliminates these risks by applying controlled heat only where needed, ensuring smooth, wrinkle-free seams. Precise control of temperature and pressure is crucial for achieving uniform welds in heat-sensitive fabrics, resulting in strong, high-quality bonds without damaging delicate materials.

Why it’s preferred:

-

No needle holes or thread required

-

No risk of warping or discoloration

-

Cleaner appearance and enhanced durability

- Especially suitable for delicate and technical fabrics

For shade and awning manufacturers, impulse welding machines offer precision joining that maintains the visual quality customers expect.

2. Banners & Signs – Seam Strength Without Compromising Graphics

Keywords: banner welding equipment, clean seam welding technology

Visual presentation matters in signage. Impulse welding allows shops to create hems, pole pockets, and reinforcements with clean seams that preserve printed graphics. Adjusting machine settings and ensuring accuracy are essential for producing high quality welds in banners and signs, resulting in smooth weld lines without adhesive buildup or stitch marks—ideal for digitally printed or laminated films.

Compared to other methods:

| Method | Seam Appearance | Cost | Equipment Need | Output Consideration |

|---|---|---|---|---|

| Impulse | Smooth, clean, no holes | Low-Moderate | Compact & efficient | Appropriate output ensures consistent seam strength |

| RF | Excellent, but costly | High | Requires shielding | High output, suited for large-scale jobs |

| Sewing | Visible stitches | Low | Manual setup | Not applicable |

Benefits:

-

No punctures → better weather resistance

-

Clean finish → professional look

-

Lower investment → perfect for small to mid-size sign shops

Explore banner welding equipment options for signage production.

3. Lightweight Inflatables – Airtight Seams on Thin Films

Not all inflatables are made from heavy PVC. For thin polyurethane or PVC films used in toys, cushions, or consumer inflatables, impulse welding uses controlled electrical pulses to create a reliable seal in thin films, providing airtight, distortion-free seams without melting through the material. This technology is also a key enabler for manufacturing durable inflatable products, such as rafts and pools, ensuring long-lasting performance.

Key advantages:

-

Prevents material distortion and burn-through

-

Delivers airtight seals with minimal cycle time

-

Accessible and affordable for small or mid-scale production

- Maintaining machine components—such as electrodes, cables, and nozzles—helps prevent defects and ensures consistent, airtight seams

See how inflatable welding solutions can elevate your product quality.

4. Medical & Technical Textiles – Controlled Welding for Sensitive Applications

In medical and technical applications, seam consistency is critical. Impulse welding provides precise, repeatable results with no open flames or adhesives—making it ideal for sterile packaging, fluid containment bags, biosensors, or textile electronics. It is also utilized to weld clean, sealed edges for IV bags, PPE, and sterile packaging, ensuring the highest standards of hygiene and product integrity.

Benefits:

-

Maintains sterility and product integrity

-

Compatible with delicate films and membranes

-

Prevents material degradation through localized heating

Process validation and inspection are essential for ensuring weld quality and consistency in medical and technical textiles. Understanding material properties and leveraging advanced equipment functionality are also essential for achieving optimal results in these sensitive applications.

By eliminating continuous heat exposure, impulse welding ensures safer, cleaner, and more consistent welds in sensitive manufacturing environments.

5. Environmental Liners & Specialty Films

Certain thermoplastics—like polyethylene (PE), EVA, or polyolefins—are non-polar and therefore difficult to weld using RF technology. Impulse welding excels here, creating clean, controlled welds for thin films, liners, or geomembrane repairs where other methods can be too aggressive. The technology can be applied to a wide range of thermoplastic materials, including polyethylene, polypropylene, PVC, and various multi-layer films. The use of high-quality welding bars, often made from aluminum for their durability and corrosion resistance, ensures precise and durable welds. The welded seams produced are smooth, uniform, and highly durable, contributing to the overall strength and safety of the finished product.

Advantages:

-

Welds non-polar materials that RF can’t

-

Produces precise, low-stress joints

-

Ideal for smaller, detailed fabrication or repair work

Learn more about polyethylene liner welding and compatible film solutions.

Why Impulse Welding Excels Over Other Methods

When choosing between welding processes, it is important to consider various factors such as material type, power output, maintenance needs, and the specific requirements of your application. Each welding process has its strengths—but impulse welding stands out for precision, cost-efficiency, and safety on delicate materials.

| Method | Ideal Materials | Seam Strength | Cost Efficiency | Finish Quality | Energy Use |

|---|---|---|---|---|---|

| Impulse | Thin films, PE, PU | High | High | Clean, invisible | Low |

| Hot Air/Wedge | Coated fabrics, PVC | High | Lower | Visible | Moderate |

| RF | PVC, PU | Excellent | Moderate | Very clean | Moderate |

| Sewing | Any fabric | Medium | Moderate | Visible | N/A |

Among these welding processes, impulse welding benefits from recent advancements that enhance efficiency, precision, and user experience. Its ability to use less power makes it an eco-friendly option. Proper maintenance is crucial to reduce wear and ensure optimal results, especially when working with heat-sensitive materials.

Rather than replacing other thermoplastic welding methods, impulse welding excels in specific scenarios where heat control and seam aesthetics matter most. Its versatility makes impulse welding a preferred choice for many applications.

Explore all the benefits of impulse welding technology.

Miller Weldmaster Impulse Welding Solutions for Your Industry

Miller Weldmaster offers a range of industrial impulse welders designed for awning, banner, inflatable, medical, and environmental applications. Their impulse welding solutions are engineered to deliver reliable performance across industries. The company also provides comprehensive support and guidance for proper handling and maintenance of their equipment.

Top 5 Applications Recap:

-

Awnings & Shades

-

Banners & Signs

-

Lightweight Inflatables

-

Medical & Technical Textiles

-

Environmental Liners

Looking for the right impulse welding system for your business? Explore our full machine lineup or contact our team today to discuss your production goals.

Frequently Asked Questions About Impulse Welding Applications

What is impulse welding used for?

Impulse welding joins thermoplastic materials using short, controlled bursts of heat. It’s commonly used for awnings, banners, inflatables, medical textiles, and liners—offering clean seams and energy-efficient operation.

How does impulse welding compare to RF welding?

RF welding is ideal for polar materials like PVC and PU, while impulse welding handles thinner, heat-sensitive materials at lower cost. The two methods complement each other depending on the material and application.

Which materials are best suited for impulse welding?

- Thin PVC and PU films

- Polyethylene (PE) and EVA

- Acrylic-coated fabrics

- Polyolefins

These are common in awnings, packaging, inflatables, and protective textiles.

Why do awning and banner companies choose impulse welding?

It delivers smooth, wrinkle-free seams that protect printed graphics and colors—an affordable, professional finish ideal for small and mid-sized manufacturers.

What industries benefit most from impulse welding technology?

- Outdoor textiles (awnings, shades)

- Signage and graphics

- Inflatables

- Medical and technical textiles

- Environmental liners

Miller Weldmaster’s experience across all five ensures the right welding solution for any application.