Impulse welding efficiency is key to achieving high-quality, durable seams while maintaining safe and energy-efficient operations. As one of several welding processes available for joining thermoplastics, impulse welding offers specific advantages such as precise temperature control and minimal material degradation. Whether you’re working with thermoplastic films, coated textiles, or technical fabrics, the versatility of impulse welding makes it suitable for a wide range of industries, from packaging and automotive to medical and industrial manufacturing. Additionally, impulse welding is compatible with a wide range of thermoplastic materials including PVC, PU, and laminates. Optimizing your impulse welding process ensures clean, consistent results and a longer machine lifespan. This versatility allows impulse welding to adapt to different materials and applications, meeting diverse production requirements across various industries.

Learn more about the process itself on our Impulse Welding Technology page.

Why Impulse Welding Efficiency Matters

Impulse welding is a preferred method for joining thinner thermoplastic materials due to its precise control, clean seam quality, and low energy consumption. The advantages of impulse welding over other methods include improved process control, reduced thermal distortion, and enhanced seam integrity. Its ability to deliver consistent results and adapt to different material requirements makes it highly versatile. Impulse welding is highly effective for materials like polyethylene, polypropylene, and PVC due to their favorable thermal properties. Unlike continuous hot air systems, impulse welders heat only during the weld cycle, improving both safety and efficiency. This makes impulse welding suitable for a variety of applications and materials, offering operational flexibility across multiple industries.

Key Benefits of High Efficiency:

-

Reduced rework and scrap

-

Fast cycle times

-

Lower operating costs

-

Improved operator safety

By improving impulse welding efficiency, manufacturers can enhance overall productivity while maintaining consistent product quality. Impulse welding efficiency is determined by a combination of electrical efficiency and weld quality.

Optimizing Impulse Welding Parameters

To achieve clean and reliable welds, it’s important to fine-tune the three main parameters that define impulse welding performance. The welding cycle involves precise control of heating and cooling cycles to achieve optimal welding results and seam integrity. The current in impulse welding creates rapid heating in the heating strip, which then transfers heat to the materials being welded.

| Parameter | Description | Tip |

|---|---|---|

| Heat Pulse Duration | Determines the amount of heat applied | Shorter pulses for thin vinyls; longer for multi-layer films. Rapid heating and the control of electrical current and welding current are essential for working with thin materials and specialty materials. |

| Pressure | Ensures proper bonding between layers | Increase for thicker or reinforced materials |

| Cooling Time | Stabilizes the weld before release | Prevents stretching or seam distortion |

System and welding machine settings, such as pulse welding modes—including single pulse, one pulse, first pulse, and second pulse—high frequency, and energy efficiency, can be adjusted to optimize production time and precision for the best solution.

Start with small adjustments and test welds before full-scale production. Each thermoplastic reacts differently, so consistent optimization is essential for long-term efficiency. Controlling heat generated and cooling cycles is crucial to ensure the proper form and melt of the weld seam, especially for demanding applications and specialty materials.

Material Preparation for Consistent Results

Clean, aligned materials are the foundation of every successful weld. Even the smallest contaminant can compromise seam integrity. Proper preparation of the material surface is essential to ensure optimal welding results, as surface cleanliness and condition directly affect the quality and strength of the weld seam.

Common Mistakes to Avoid:

-

Welding over dust or loose debris

-

Misaligned fabrics or uneven tension

-

Overlapping material too tightly or loosely

For long seams, use clamps, guides, or tension systems to keep materials taut and uniform. Proper preparation ensures repeatable, high-quality welds.

Maintaining Impulse Welding Equipment

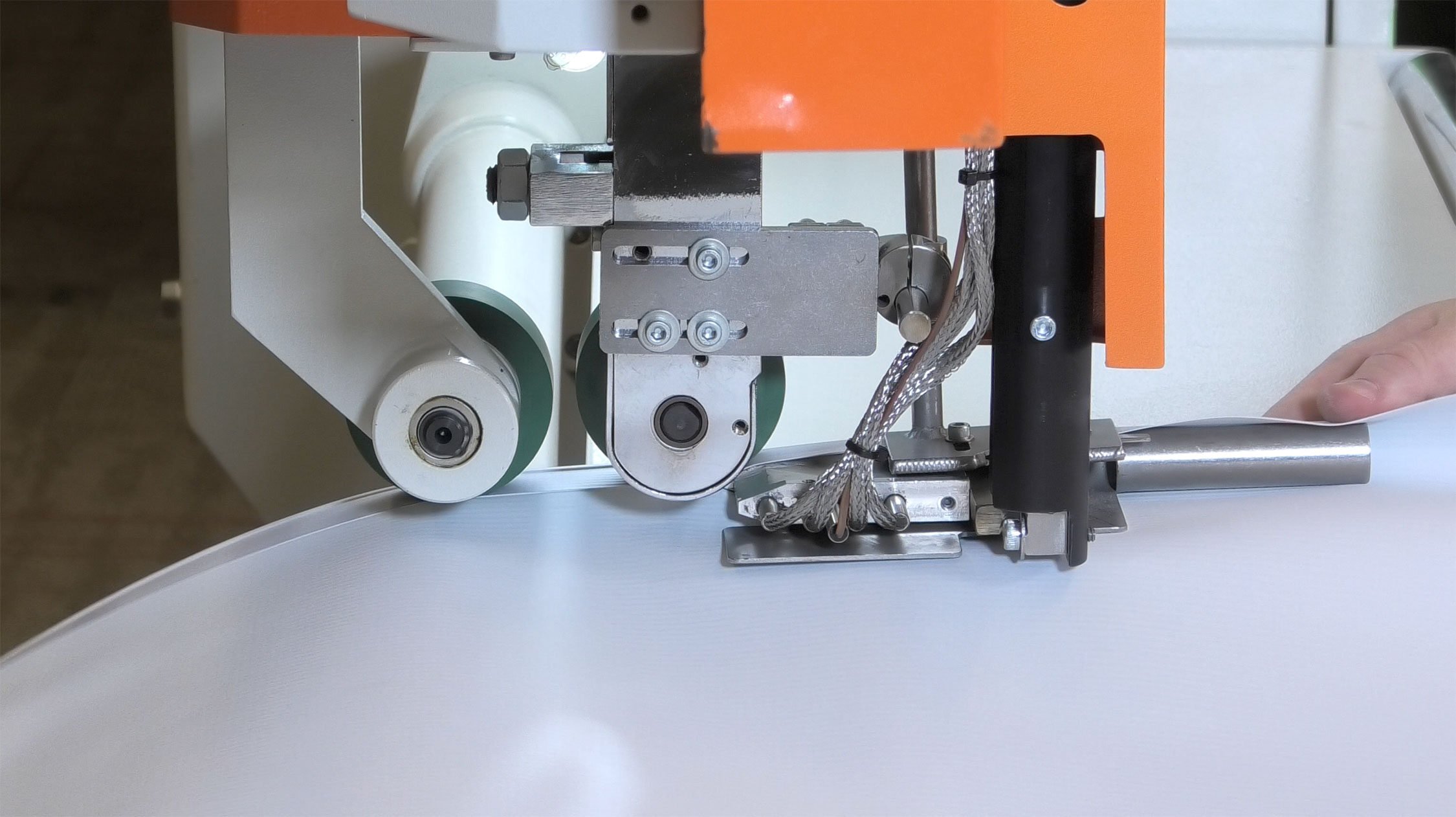

Regular maintenance keeps your impulse welder running at peak performance. Maintaining your impulse welding machine and its high resistance heating strip is essential for consistent, high-quality results. This includes proper care of impulse bands and PTFE tape—both crucial to even heating and seam consistency.

Weekly Maintenance Steps:

-

Inspect impulse bands for wear or hotspots.

-

Replace damaged or discolored PTFE covers.

-

Clean electrodes and alignment guides.

-

Check temperature sensors and connections.

Older machines are more prone to uneven heating, while modern impulse welders—like those from Miller Weldmaster—feature improved heat distribution and monitoring systems.

Find maintenance resources on our Service & Support page.

Safety Guidelines for Impulse Welding

Impulse welding is safe since the bars are not constantly hot. Still, following safety guidelines is critical for operators and equipment longevity. Proper safety procedures help reduce the risk of accidents, burns, and equipment damage during operation.

Safety Do’s and Don’ts:

-

Do allow full cooling before handling welded material.

-

Do follow lockout/tagout procedures before servicing.

-

Don’t bypass machine guards or sensors.

-

Don’t leave the machine unattended during operation.

Modern industrial impulse welders also feature built-in safety systems, such as emergency stops and shields, to further protect operators.

Boosting Efficiency and Energy Savings

Impulse welding is an energy-efficient welding method—heat is only generated during the weld cycle, resulting in lower energy use compared to hot air or RF systems. This high energy efficiency not only reduces operational costs but also shortens production time by enabling faster heating, cooling, and cycle completion. The electrical energy in impulse welding is only used during the welding process, making it cost-effective.

| Welding Method | Heating Type | Energy Use | Warm-Up Time |

|---|---|---|---|

| Impulse Welding | On-demand | Low | None |

| Hot Air Welding | Continuous | High | Short |

| RF Welding | Constant field | Moderate | Medium |

To boost throughput:

-

Use automation or programmable timers.

-

Optimize cycle times for material type.

-

Power down during idle periods—no preheat required.

Explore machine options designed for efficiency on our Machine Overview page.

Troubleshooting Impulse Welds

Impulse welding is the best solution for manufacturers seeking to maximize efficiency, minimize costs, and achieve optimal seam quality and durability. It is a fast process that allows heating, fusion, and cooling to occur in as little as 10 seconds.

Even optimized systems may encounter issues. Here’s how to diagnose and fix common problems quickly: Inspect the weld seam for signs of defects or inconsistencies, as issues in the weld seam can indicate problems with heating, melting, or solidification during the welding process.

Step-by-Step Diagnostic Checklist:

-

Weak Bond: Increase heat or pressure; check for contamination.

-

Scorch Marks: Reduce pulse time or temperature.

-

Uneven Welds: Verify alignment, pressure bar calibration, and PTFE condition.

-

Incomplete Seals: Extend dwell or cooling time slightly.

For more troubleshooting help, visit our Resolution Center.

Miller Weldmaster’s Expertise in Impulse Welding

With decades of experience in industrial impulse welders and impulse sealing as one of our core technologies, Miller Weldmaster offers complete solutions—from machine design to global service support. We have deep expertise in the manufacture of impulse welding machines, and our solutions demonstrate the versatility, speed, and precision that impulse welding offers across a wide range of industrial applications. Impulse welders are equipped with advanced control systems to ensure accurate and repeatable welding temperatures.

5 Ways to Maximize Impulse Welding Efficiency with Miller Weldmaster:

-

Proper parameter setup for each material

-

Consistent cleaning and maintenance schedules

-

Using quality PTFE and impulse components

-

Regular training for operators

-

Leveraging Miller’s global service and technical expertise

Explore our Standard Machines or contact our team to find the ideal solution for your production needs.

Frequently Asked Questions About Impulse Welding Efficiency

How can I improve impulse welding efficiency?

Regularly adjust parameters like pulse time, pressure, and cooling based on material type. Keep materials clean and maintain consistent alignment for best results.

What are common impulse welding maintenance steps?

Inspect the impulse band and PTFE tape weekly, clean the sealing area, and test sensors for even heat distribution.

How do I troubleshoot weak or uneven impulse welds?

Check for contamination, adjust pressure or pulse duration, and ensure the materials are properly aligned and tensioned.

Is impulse welding more energy-efficient than RF or hot air?

Yes. Impulse welders heat only during the weld cycle, resulting in significantly lower energy consumption and operating costs.

What safety precautions should operators follow?

Always follow lockout/tagout procedures, allow adequate cooling time, and never bypass built-in machine safety features.