Delicate technical fabrics pose a unique challenge in the industrial welding space. From medical textiles to ultra-thin laminates, these materials often require bonding solutions that are both precise and gentle. But traditional hot air or wedge welding methods can scorch, warp, or even destroy fragile textiles, compromising product performance and safety. There are various welding processes and welding technologies available for fabric joining, each with its own advantages and limitations when working with delicate materials.

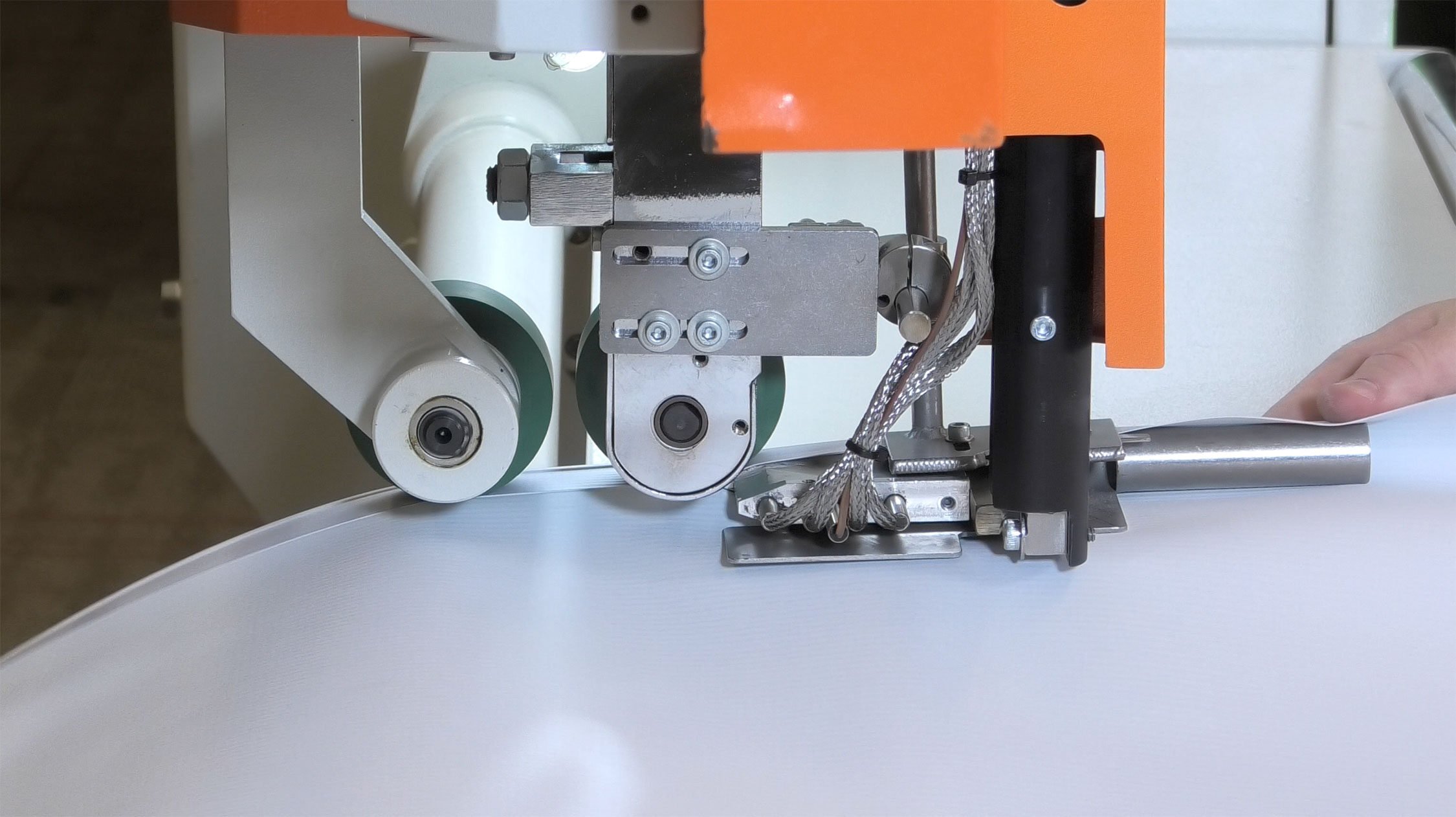

Impulse Welding—a method proven to deliver non-damaging, high-quality seals on heat-sensitive materials. With years of experience and innovation in this field, Miller Weldmaster has developed advanced impulse welding systems designed specifically for such applications. Learn more about how impulse welding works and why it’s the leading solution for fragile fabrics.

This blog will walk you through how to weld delicate fabric effectively using impulse welding, outline common challenges, provide a step-by-step guide, and show how different industries benefit from this technology.

Why Welding Delicate Fabric Is a Challenge

Delicate technical fabrics include materials like laminated films, medical textiles, lightweight TPU-coated fabrics, and thermoplastic membranes. These textiles are engineered for specific functions—sterilization, conductivity, impermeability—but their physical makeup makes them highly susceptible to heat damage and material damage if inappropriate welding methods are used.

Common welding issues include:

-

Scorching or burning: Overexposure to heat destroys the structural integrity of the fabric.

-

Warping or wrinkling: Uneven heating or pressure leads to deformities that weaken the final product.

-

Adhesion failure: Inconsistent sealing temperatures can result in bonds that fail under stress.

-

Material damage: Using unsuitable welding techniques on delicate fabrics can cause irreversible harm, compromising performance.

Real-world use cases that demand careful handling include:

-

Medical Devices: IV bags, fluid bladders, and sterile packaging

-

Electronic Textiles: Smart garments and sensors

-

Inflatables: Thin-film boats, paddle boards, and tents

These applications require a fabric welding solution that offers both accuracy and low thermal impact.

Impulse Welding: The Key to Precision and Protection

Impulse welding uses controlled electrical pulses to heat a resistive wire. The fabric layers are pressed between bars that briefly heat up to a specific temperature before rapidly cooling down. This unique cycle offers an incredibly accurate and repeatable welding process, especially for fragile or sensitive textiles.

Compared to hot air or hot wedge welding, impulse welding provides greater control for delicate materials. There are different welding technologies available, such as hot air welding, ultrasonic welding, and RF welding, each with their own advantages and limitations. Hot air welding is commonly used for vinyl and banners due to its precise temperature control, while ultrasonic welding is often chosen for thermoplastics and fabric finishing where strong, clean seams are required. However, some of these methods may not be suitable for the most delicate fabrics, making impulse welding a preferred choice in those cases.

Core Benefits of Impulse Welding

-

Controlled Heat Application: Short, targeted pulses reduce the risk of overheating.

-

Built-In Cooling Cycles: Immediately cools the bond area to set the weld without added heat exposure.

-

Minimized Heat Zones: Only the weld line is affected, leaving surrounding material untouched.

Impulse welding enables optimal results by producing uniform welds and consistent results, which is especially important for delicate technical fabrics.

Unlike hot air or hot wedge welding, impulse welding provides non-damaging fabric welding ideal for delicate, technical, or composite materials. It’s particularly advantageous in industries where consistency and clean edges are critical.

Step-by-Step Guide: How to Weld Delicate Fabric Without Damage

Step 1: Prepare the Fabric for Welding

-

Cleanliness is crucial. Remove dust, oils, or other contaminants.

-

Use alignment tools or jigs to hold fabric securely in place.

-

Inspect fabric properties, including coatings or laminated layers that might affect bond quality.

Step 2: Calibrate the Impulse Welding Machine

-

Set appropriate temperature thresholds based on the melting point of the fabric.

-

Adjust dwell time. This is how long pressure is maintained after heating; critical for proper sealing.

-

Set the correct pressure. Avoid crushing the material while still ensuring a full bond.

-

Fine-tune welding parameters. Carefully fine-tune welding parameters such as temperature, dwell time, and pressure to optimize results for each fabric type and ensure consistent, high-quality welds.

Step 3: Test Weld on Scrap Fabric First

-

Always perform a trial run.

-

Examine the sample for:

-

Burn marks

-

Edge integrity

-

Weld strength

-

Repeated testing and parameter adjustment help ensure you achieve consistent welds, which are essential for producing uniform, professional-quality finished fabrics.

-

Adjust parameters until the test meets your quality standards.

Step 4: Execute the Final Weld with Precision

-

Use controlled, short-duration heat pulses when applying heat. Applying heat in this way is key to preventing damage to delicate fabrics, as it allows the materials to soften and bond at a molecular level without overheating.

-

Ensure fabric remains aligned throughout the cycle.

-

Maintain consistent pressure to ensure even bonding.

Step 5: Post-Weld Inspection and Quality Control

-

Visually inspect for defects like burns, misalignments, or wrinkles.

-

Perform mechanical tests such as peel, tensile, or shear tests depending on application.

-

Ensure the finished product meets required standards for durability and appearance through thorough inspection.

-

Document the settings for future use and consistency.

Best Practices for Welding Heat-Sensitive Technical Fabrics

-

Use impulse welding systems with programmable controls for repeatability.

-

Regularly calibrate your equipment to ensure precision.

-

Operate in a clean environment to avoid contaminants.

-

Train operators in material-specific risks and handling.

-

Always use appropriate safety equipment when operating welding machines to protect against high temperatures, moving parts, and fumes.

-

Maintain detailed records for process validation and repeat production.

-

Ensure an efficient welding process by optimizing machine settings and workflow to maximize productivity and seam quality.

For additional materials guidance, explore what materials work best with impulse welding.

What Types of Materials Work Best with Impulse Welding?

Impulse welding excels with a wide range of fabric types, making it suitable for welding different materials such as PVC material, TPU, and other common materials used in technical applications. Its versatility allows for effective bonding of diverse materials, meeting various industry needs.

-

Laminated Films: For sterile packaging and moisture barriers

-

TPU-Coated Fabrics: Used in inflatables and protective gear

-

Thin Thermoplastics: Ideal for packaging or electronics

-

Medical-Grade Textiles: Must be biocompatible and cleanroom safe

-

E-Textiles/Conductive Fabrics: Require careful heat application to avoid damaging circuits

These materials benefit from precision temperature control and non-invasive bonding that impulse welding uniquely provides.

Industries That Benefit from Delicate Fabric Welding

Impulse welding is a must in sectors where both performance and material integrity are non-negotiable. Its versatility makes it ideal for a range of industrial applications, including the production of automotive interiors and inflatable products, where strong, reliable seams are essential.

Key Industries:

-

Medical Textiles: Weld clean, sealed edges for IV bags, PPE, and sterile packaging.

-

Electronics: Perfect for wearable sensors and conductive fabrics in smart textiles.

-

Inflatables: Create airtight seams without damaging lightweight PVC or TPU.

-

Protective Gear: Bonding of fire-resistant membranes and multilayer suits.

Impulse welding allows these industries to meet high-performance standards without compromising material properties.

How Miller Weldmaster Supports Precision Welding Applications

With decades of expertise in technical fabric bonding, Miller Weldmaster is a trusted leader in the impulse welding space. Our systems are designed to offer:

-

Tailored welding solutions for each fabric type, with a solution tailored to your specific production needs

-

Advanced welding machines and welding techniques engineered to deliver the perfect solution for delicate fabric welding

-

On-site and virtual training to get your team up to speed

-

Material testing labs for evaluating new applications

-

Ongoing support and maintenance programs

If you’re facing challenges with delicate fabric welding, talk to our experts to find the right impulse welding solution for your operation.

Explore our T3 Extreme for precision technical textile welding.

Whether you’re manufacturing medical products, inflatable structures, or sensitive electronics, impulse welding offers unmatched precision and protection. Trust Miller Weldmaster to provide the tools and support you need to master delicate fabric welding.

Frequently Asked Questions About Welding Delicate Technical Fabrics

What machine settings are best for impulse welding delicate fabrics?

Settings vary by material, but general recommendations include:

- Lower temperature thresholds

- Shorter dwell times

- Medium pressure

Adjusting welding parameters such as temperature, pressure, and dwell time is crucial for achieving consistent results, especially when welding delicate fabrics.

Always perform test welds and consult your machine supplier for precise specifications.

Can impulse welding be used in cleanroom environments like medical manufacturing?

Yes, impulse welding is ideal for cleanroom use:

- No fumes or particulates

- Precise and repeatable welds

- Compatible with sterilizable materials

-

Produces clean, sealed edges for a professional appearance, essential in medical and cleanroom applications

Miller Weldmaster offers cleanroom-compatible systems tailored for medical applications.

What industries require impulse welding for delicate materials?

- Medical and Healthcare

- Wearable Electronics and E-Textiles

- Defense and Aerospace

- Recreational Inflatables

Impulse welding is used across a vast range of industries due to its ability to bond diverse materials, making it highly versatile for different applications.

These sectors rely on precision bonding and material integrity that only impulse welding can provide.

Is impulse welding suitable for automated production lines?

Yes. Impulse welders can be integrated into automated and semi-automated lines, delivering:

- Faster throughput

- Higher consistency

- Fewer operator errors

Automation with impulse welding significantly reduces labor costs and increases cost effectiveness by streamlining production and minimizing manual intervention.

Miller Weldmaster provides systems designed for both manual and automated operations.