Choosing the right fabric welding method can be the difference between high-performance results and premature seam failure. In this guide, we compare hot wedge welding vs hot air welding to help you understand when and why to use each. Whether you’re sealing geomembranes or finishing signs, the right method matters. Learn more about how hot wedge welding works here: Hot Wedge Welding Technology.

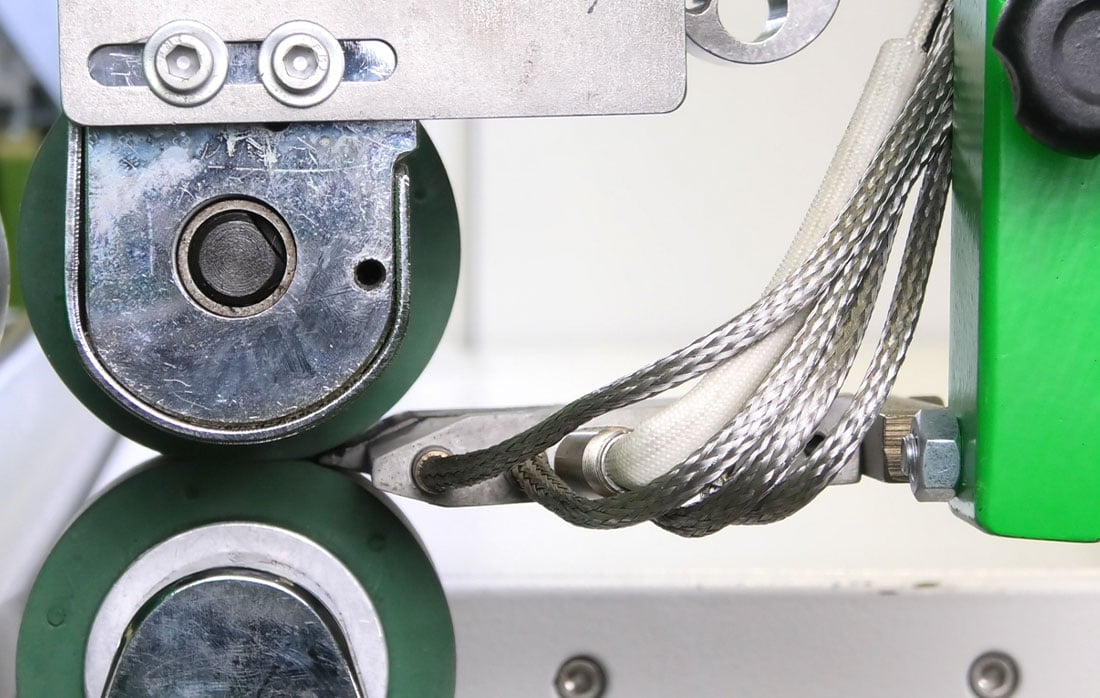

What Is Hot Wedge Welding? How It Works & Key BenefitsHot wedge welding is a precision seam-sealing method used in industrial fabric welding. A hot wedge welder is a specialized welding machine designed for thermoplastic geomembranes and other industrial applications. A heated metal wedge is inserted between overlapping layers of thermoplastic materials, such as PVC, PE, or HDPE. As the wedge moves, the heat softens the material, and pressure is applied via rollers to form a high-strength bond. Hot wedge welders use rubber wheels or steel wheels to create strong, welded seams, depending on the application and welding material thickness. The device's ability to adjust welding speed and temperature ensures high-quality welded seams across a range of thermoplastic geomembranes. Hot wedge welding can create durable, hermetic welds in automotive, civil engineering, and membrane welding applications. Membrane welding is commonly performed with hot wedge welders for geotextile and containment solutions.

Ideal Materials:

-

PVC

-

PE

-

HDPE

-

Other rigid or thick thermoplastics

Note: The properties of the material, such as thickness and melting point, are critical for successful welding.

Key Benefits:

-

High-speed production

-

Strong, uniform seams

-

Excellent for thick or rigid materials

-

Reliable in factory and field applications

-

High level of automation potential

- Precise control of temperature, welding speed, and power for optimal weld quality

What Is Hot Air Welding? How It Works & Key Benefits

Hot air welding uses a stream of heated air to soften the surface of thermoplastic materials before applying pressure to bond them together. This method is known for its flexibility across a wide range of materials and shapes.

Ideal Materials:

-

Vinyl

-

Lightweight coated fabrics

-

Flexible thermoplastics

Pros:

-

Great for field repairs

-

Effective for curved or irregular seams

-

More portable and lightweight equipment

Cons:

-

Not ideal for thick or rigid materials

Hot Wedge Welding vs Hot Air Welding: A Side-by-Side Comparison

| Feature | Hot Wedge Welding | Hot Air Welding |

|---|---|---|

| Best for Material Thickness | Medium to Thick | Thin to Medium |

| Seam Strength | High | Medium |

| Portability | Moderate | High |

| Automation Compatibility | Excellent | Good |

| Energy Usage | Moderate | Slightly Higher |

| Initial Equipment Cost | Higher | Lower |

Related terms: wedge welders for PVC, thermoplastic seam sealing, hot air welding vs hot wedge.

When comparing these methods, choosing the right welding machine and properly adjusting welding speed and welding material thickness are essential for achieving optimal weld quality.

Choosing the Right Method: Best Applications for Each Welding Type

Choose Hot Wedge Welding for:

-

Thick thermoplastic fabrics

-

Industrial tarps

-

Geomembranes (Learn more)

-

Roofing membranes

-

Overlap seam welding

-

Landfills and other environmental containment solutions

-

Civil engineering projects requiring durable geomembrane seams

-

Automotive components such as car covers and weatherproofing applications

-

Welding on uneven surfaces where precise seam quality is required

Choose Hot Air Welding for:

-

Field repairs

-

Curved seams in tents or inflatables

-

Lightweight signage and banners

-

Portable operations

A helpful rule of thumb: If you’re welding thick thermoplastics or need automation, go hot wedge. If flexibility or portability is key, go hot air. Hot wedge welding also offers tailored solutions for challenging industrial and environmental applications.

Tips for Ensuring Seam Quality and Performance

Whether you’re using hot wedge or hot air welding, these best practices help avoid seam failure:

Checklist for Quality Welding:

-

Ensure proper overlap (typically 1")

-

Calibrate heat and speed settings for material

-

Clean and prep materials thoroughly

-

Maintain consistent travel speed

-

Conduct peel and visual inspections regularly

-

Use a copper test channel to verify the integrity of welded seams during quality inspections

Miller Weldmaster’s decades of experience ensure top-tier welds every time, ensuring all seams are properly welded for maximum durability.

Why Seam Quality Matters in Industrial Fabric Welding

Poor seams can lead to leaks, structural failure, or product recalls. In industries like geomembranes and containment, seam integrity can impact safety, compliance, and operational costs. Welded thermoplastic geomembranes are critical for preventing leaks in landfills and other containment applications, ensuring reliable, watertight barriers.

Quality Seams Improve:

-

Durability in field conditions

-

Waterproof performance

-

Regulatory compliance

-

Total cost of ownership

How Miller Weldmaster Supports Seam Perfection

At Miller Weldmaster, we offer a full range of hot wedge welding machines, hot air welders, and specialized device solutions, along with expert consulting and custom engineering support. Our goal is to help you choose the right equipment and achieve dependable, high-quality welds across all applications.

For tailored welding solutions or to request a device demonstration, contact our team today.

Explore our versatile T300 Extreme Flex for both hot air and hot wedge configurations.

Ready to upgrade your welding process? Contact Miller Weldmaster today for expert advice and customized solutions tailored to your materials and workflow.

Frequently Asked Questions About Hot Wedge Welding vs Hot Air Welding

What materials are best for hot wedge welding?

- PVC

- PE

- HDPE

- Thick tarps and membranes

- Industrial thermoplastics

Can you use hot air welding for thick materials?

Hot air welding is generally not ideal for thick materials. Hot wedge welding is better suited due to its ability to apply concentrated heat and pressure simultaneously.

What’s the difference between hot wedge and impulse welding?

Impulse welding uses electrical resistance to heat sealing bars that apply pressure and heat simultaneously. It’s slower and more suitable for small, delicate materials compared to hot wedge or hot air.

When should I use hot air welding instead of hot wedge?

- Field repairs on lightweight materials

- Curved seams in tents or domes

- Small shops with portable needs

- Light signage or banners

How do I prevent seam failure in thermoplastic welding?

- Use clean, dry materials

- Maintain proper overlap

- Calibrate machine settings

- Perform routine quality tests

Are hot wedge welding machines hard to operate?

No. Most machines feature intuitive interfaces, adjustable settings, and automation options. Training and support are readily available.

How long do hot wedge welds typically last?

Depending on materials and usage, hot wedge welds can last 5–20 years or more with proper technique and maintenance.

What type of seam is best for waterproofing applications?

Overlap seams produced via hot wedge welding offer the best waterproofing performance due to strong bond and material fusion.

How do I choose the right welding machine for my application?

Assess:

- Material type and thickness

- Production speed needs

- Field vs factory use

Consult with a welding expert to select the best fit.