Why Polyurethane Welding is Essential in Modern Manufacturing

The integration of polyurethane welding caters to a growing demand across various industries for materials that combine flexibility with durability. This technology is essential for manufacturing products that must endure extreme usage or harsh environmental conditions while maintaining their integrity and functionality.

Benefits of Polyurethane Welding in Manufacturing

Enhanced Durability

Products manufactured with polyurethane welding benefit from exceptionally strong bonds that significantly increase their lifespan. These durable bonds are crucial for products used in demanding environments, ensuring they resist wear and tear far better than those created with traditional bonding techniques.

Flexibility in Design

Polyurethane welding allows for the creation of complex, intricate designs without sacrificing the material's strength or performance. This flexibility opens up new avenues for innovation in product design, enabling manufacturers to meet specific customer needs more effectively.

Cost-Effective Production

By reducing material wastage and optimizing production workflows, polyurethane welding offers a more economical manufacturing process. This efficiency is achieved through precise control over material handling and waste reduction, which in turn lowers overall production costs.

Applications of Polyurethane Welding Across Industries

Textile Industry

In textiles, polyurethane welding is pivotal for producing seamless waterproof garments and equipment, enhancing the functionality and durability of outdoor and protective fabrics. More insights into specific applications in textile manufacturing can be found on Miller Weldmaster’s website.

Construction and Infrastructure

The construction industry benefits from polyurethane welding by using it to join and seal materials that are exposed to environmental stressors, ensuring longevity and durability of structures and infrastructural components.

Key Techniques for Effective Polyurethane Welding

Different polyurethane welding techniques offer various advantages depending on the application. Understanding these techniques can greatly impact the efficiency and quality of the manufacturing process.

Heat Sealing in Polyurethane Welding

Process Overview

Heat sealing uses a combination of heat, speed, and pressure to create a bond between polyurethane materials. The process is renowned for its ability to produce strong, waterproof seals.

Best Practices

For best results in heat sealing, maintaining consistent temperature and pressure is crucial. Proper preparation of materials also plays a significant role in achieving optimal bonds. Detailed guidelines and best practices are available at Miller Weldmaster’s heat sealing page.

Hot Air Welding for Polyurethane Materials

Process Overview

Hot air welding involves blowing heated air to soften the materials before pressing them together to form a bond. This method combines flexibility with efficiency, making it suitable for both bespoke and large-scale productions.

Common Applications

This technique is commonly used for manufacturing large coverings, such as tarps and awnings, as well as various inflatable products. Each application benefits from the specific advantages of hot air welding, as detailed on Miller Weldmaster’s hot air welding page.

Radio Frequency (RF) Welding for Polyurethane

Process Overview

RF welding utilizes electromagnetic energy to bond polyurethane pieces together. This method is especially effective for delicate applications where precision is critical.

Advantages

One of the main benefits of RF welding is its consistency and ability to be replicated across high-volume productions, making it ideal for industries like healthcare where precision is paramount.

Best Practices for Integrating Polyurethane Welding into Your Manufacturing Process

Successfully integrating polyurethane welding into an existing manufacturing process requires careful planning and consideration of various factors.

Choosing the Right Polyurethane Welding Equipment

Assessing Production Needs

It’s crucial to choose equipment that not only meets the current production demands but also has the capability to scale as business needs grow. Factors to consider include production volume, material types, and the specific applications of the finished products.

Quality and Durability

Investing in high-quality, durable welding equipment is essential for ensuring consistent output and reducing downtime. High-performance machines from reputable manufacturers like Miller Weldmaster can significantly enhance production efficiency.

Training Your Team for Polyurethane Welding

Comprehensive Training Programs

To maximize the benefits of polyurethane welding, it is important to ensure that all operators are well-trained and fully understand the intricacies of the techniques they are using. Miller Weldmaster offers comprehensive training programs and resources to help teams achieve proficiency in polyurethane welding.

Ongoing Education

Continual learning and adaptation are key in keeping pace with advancements in welding technology. Encouraging ongoing education helps maintain high standards and fosters innovation within the team.

Streamlining Your Production Line for Polyurethane Welding

Workflow Optimization

Optimizing the workflow to incorporate polyurethane welding involves careful layout planning and workflow management to ensure that the new processes integrate smoothly without disrupting existing operations.

Monitoring and Quality Control

Setting up effective monitoring and quality control systems is essential to maintain the integrity of the welding process and ensure that all products meet the required standards. At Miller Weldmaster, we leverage state-of-the-art solutions like our SeamVision machine to provide unparalleled real-time monitoring and inspection capabilities. This technology enhances quality control by automatically detecting and reporting any inconsistencies in the weld seam during the production process, ensuring each product adheres to stringent quality criteria.

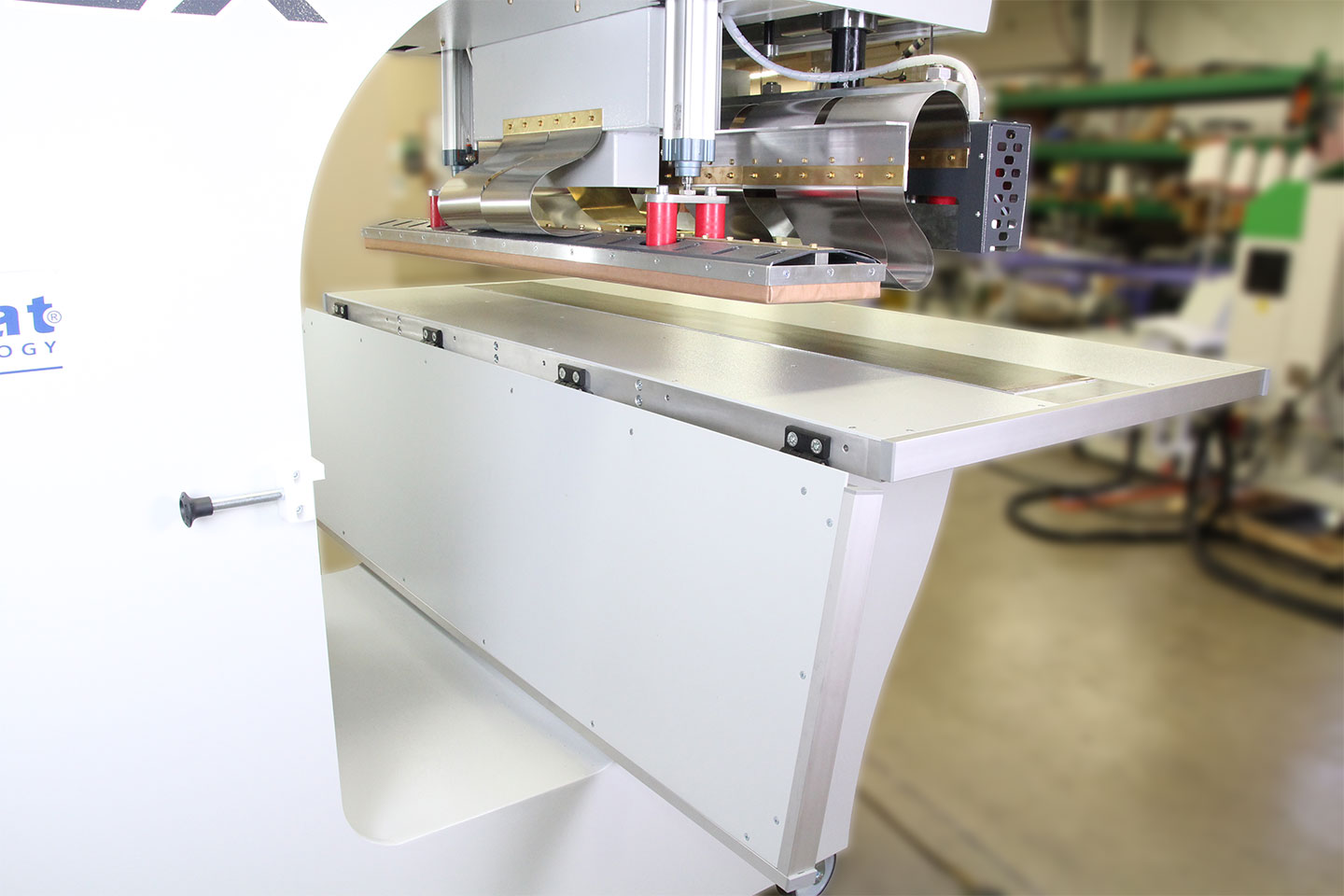

Additionally, our range of standard machines is equipped with advanced features designed to support rigorous quality control protocols. For example, machines like the T300 Extreme Flex and the Spec Extreme come with integrated systems that facilitate precise control and consistent output, crucial for maintaining high-quality production standards. These systems are tailor-made to handle various materials and applications, providing flexible yet robust solutions for any manufacturing setting.

Why Choose Miller Weldmaster for Your Polyurethane Needs?

Miller Weldmaster’s Expertise in Polyurethane Welding

Miller Weldmaster, with its long-standing industry presence and focus on innovative solutions, stands as a leader in polyurethane welding technology. Businesses looking to integrate efficient, reliable welding solutions into their production lines will find a robust array of options available through Miller Weldmaster.

Contact Miller Weldmaster for a Consultation

For businesses ready to enhance their manufacturing capabilities with polyurethane welding, Miller Weldmaster offers tailored solutions and expert consultation services. By exploring the specific needs and challenges of each manufacturer, Miller Weldmaster helps companies optimize their production processes and achieve higher quality outcomes.

To learn more about how Miller Weldmaster can assist with your polyurethane welding needs, visit our detailed product and service sections at www.weldmaster.com.

.png)