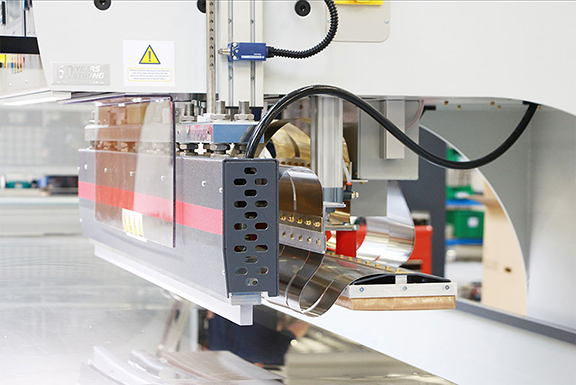

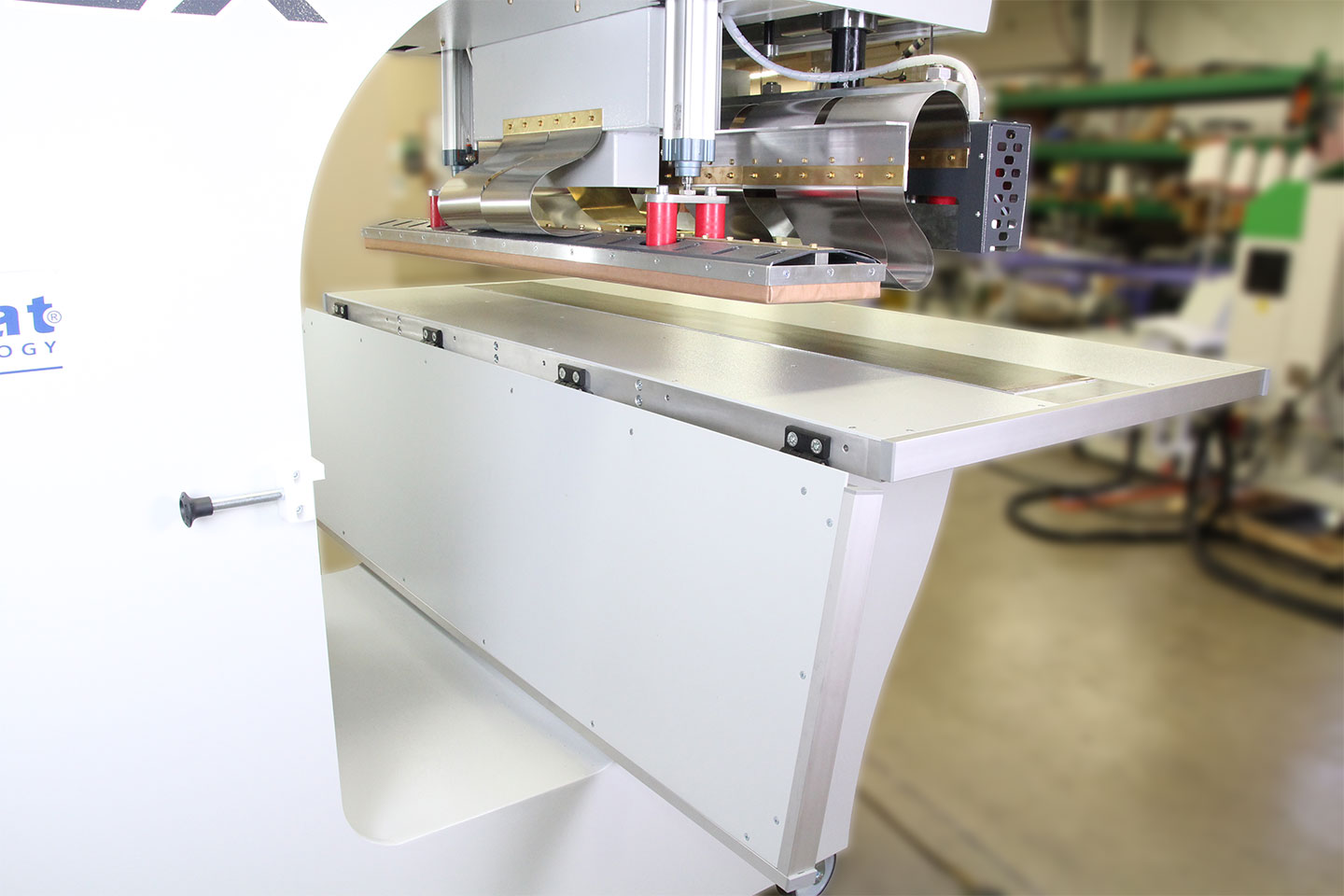

Radio frequency (RF) welding, also known as high-frequency welding machines, is a fabric welding technology that uses electromagnetic energy to fuse materials together. Commonly referred to as RF welding, this technology can accommodate a variety of custom projects and create secure seams. For a deeper dive into how this technology works, explore our comprehensive overview on Radio Frequency welding.

Radio frequency is the latest to join the Miller Weldmaster family of industrial fabric welding technologies. If you’re interested in radio frequency technology but aren’t sure if it’s the right solution for you, we’re here to help. To help guide your investment decision, we’ve rounded up the top perks of investing in radio frequency welding technology below.

1. Radio Frequency Welding Can Handle Various Materials

Unlike other industrial fabric welding technologies, radio frequency welding heats materials from the inside out. This is beneficial because it allows operators to work with a variety of thicknesses and materials. High-frequency machines can weld together multiple layers at one time, whereas other technologies can only weld two layers at once.

2. Radio Frequency Welding Protects Fabrics

With radio frequency welding technology, operators can weld over seam lines multiple times. This gives operators the ability to create ultra-secure seams and easily fix seam errors—something that traditional sewing methods cannot do.

3. Radio Frequency Welding Is an Energy Efficient Solution

Operators using radio frequency welding machines have the ability to easily control operations with the simple flip of a switch. In seconds, the welding machine can cool down or heat up, using less energy than other technologies. If safety is a concern, it's essential to follow a Radio Frequency Welding Safety Guide to ensure secure operations.

4. Radio Frequency Is Versatile

Radio frequency welding is a versatile fabric welding technology because it allows operators to use specialized dies and performs well with a wide variety of materials. This technology is capable of welding fabrics with a variety of thicknesses, colors, chemical makeup, and even coated and non-coated materials. For those seeking a deeper understanding of its nuances, our article on Understanding High-Frequency Welding provides a detailed analysis. This makes radio frequency welding ideal for custom projects that require unique shapes and seals.

Interested in Learning More About Radio Frequency Welding?

While there are various welding technology suppliers available, each has its own unique benefits. To learn more about our welding machines on the market, check out our other free resources.

.png)